Table of Contents

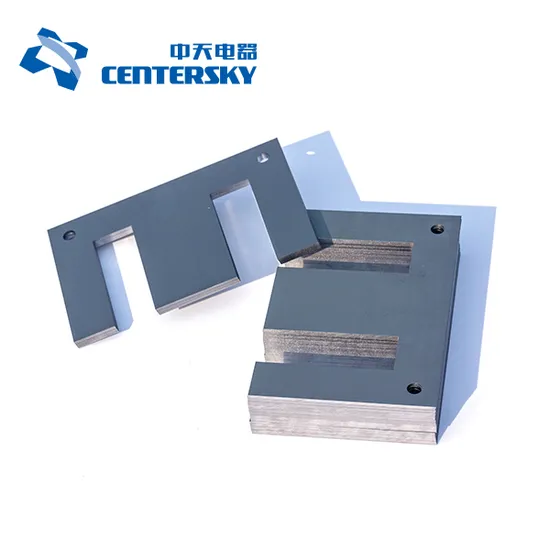

Market Insight: Ei Transformer Laminations

Market Analysis: Silicon Steel Demand for EI Transformer Laminations

Global demand for high-grade silicon steel in EI transformer laminations is driven by escalating energy infrastructure investments and stringent efficiency regulations. As grids modernize to accommodate renewable integration and rising industrial loads, transformers must minimize core losses to meet IE4 and IE5 efficiency standards mandated across the EU, North America, and Asia-Pacific. This regulatory pressure directly increases demand for non-oriented electrical steel (NOES) with precise magnetic properties, particularly in distribution transformers where EI laminations dominate due to their cost-effective manufacturability and reliable performance in <3 MVA applications. Annual consumption of silicon steel for transformer cores exceeds 15 million metric tons globally, with Asia-Pacific accounting for 60% of this volume, fueled by China’s and India’s aggressive grid expansion programs.

Quality in silicon steel is non-negotiable for EI lamination performance, directly impacting transformer operational economics and longevity. Core loss (W/kg), measured at 1.5 T and 50/60 Hz via Epstein frame testing per IEC 60404-2, dictates no-load energy waste. A 0.1 W/kg increase in core loss across a 500 kVA transformer translates to 430 kWh/year of excess energy consumption, costing utilities over $50 annually per unit at industrial rates. Substandard steel with inconsistent grain orientation or excessive carbon content elevates hysteresis and eddy current losses, accelerating thermal aging of insulation systems and potentially reducing transformer lifespan by 15–20 years.

Mechanical precision equally governs lamination integrity. Burr height exceeding 5% of material thickness during stamping degrades stacking factor by 2–3%, increasing magnetic path reluctance and localized heating. Xinzhaohe’s production process controls burr height to <3% through hardened progressive dies and tension-leveling, ensuring stacking factors >96%. Additionally, magnetostriction—a material’s dimensional change under magnetic flux—must be minimized to <10 ppm. High magnetostriction induces audible noise (exceeding 45 dB limits) and mechanical stress, risking core degradation under cyclic loading. Premium grain-oriented steel (GOES) with laser-scribed domains reduces magnetostriction by 30% versus conventional grades, critical for urban substations.

Supply chain volatility further elevates quality assurance. Fluctuations in raw material purity (e.g., sulfur >0.005% inhibits grain growth) or annealing atmosphere control during decarburization cause batch-to-batch property drift. Xinzhaohe mitigates this via in-line OES monitoring and hydrogen-nitrogen annealing furnaces, maintaining core loss variance below ±3% across coils. For buyers, specifying certified material with traceable test reports isn’t merely compliance—it prevents field failures where a single defective lamination stack can trigger cascading grid instability. In transformer manufacturing, 70% of premature failures originate from core defects; thus, partnering with suppliers possessing metallurgical expertise and process rigor is fundamental to lifecycle cost reduction.

Ultimately, the EI lamination market prioritizes silicon steel that balances magnetic efficiency, dimensional stability, and supply chain resilience. As global energy demands intensify, the premium for certified, high-consistency electrical steel will continue rising, making technical due diligence on material quality a strategic procurement imperative.

Technical Specs: Ei Transformer Laminations

Technical Specifications for EI Transformer Laminations

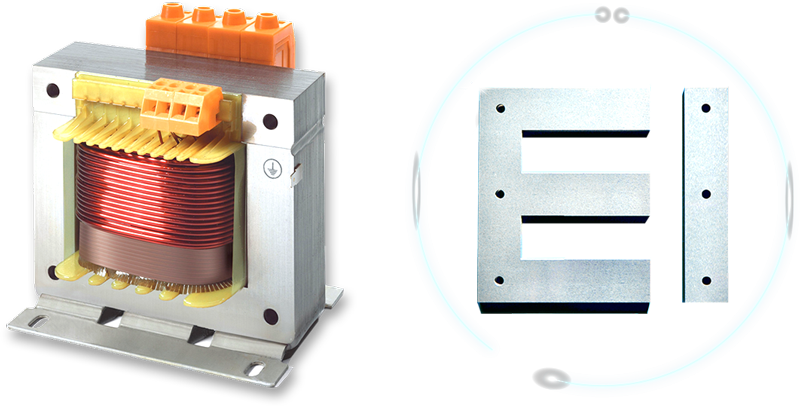

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-performance silicon steel laminations tailored for EI transformer core applications. With over two decades of metallurgical and manufacturing expertise, our products are engineered to meet stringent international standards while ensuring optimal magnetic performance, dimensional consistency, and long-term reliability. The technical specifications below define the critical parameters governing the performance of EI transformer laminations, with emphasis on core loss, magnetic flux density, and flatness—three key indicators of material quality and efficiency.

Core loss, also known as iron loss, is a fundamental performance metric representing the energy dissipated in the core material under alternating magnetic fields. It directly impacts the efficiency and thermal behavior of transformers. Our cold-rolled grain-oriented (CRGO) silicon steel laminations achieve ultra-low core loss values, measured at standard test conditions of 1.7 Tesla and 50 Hz. These losses are minimized through precise control of grain orientation, silicon content (typically 2.9%–3.3%), and insulating coating application, which reduces eddy current losses. Low core loss translates into reduced operating temperatures and higher energy efficiency, particularly in distribution and power transformers operating under continuous load cycles.

Magnetic flux density, expressed in Tesla (T), determines the magnetic loading capacity of the core. Higher flux density allows for smaller core sizes and reduced material usage without compromising performance. Our premium-grade CRGO laminations exhibit a guaranteed minimum magnetic flux density of 1.90 T at 800 A/m, with typical values reaching up to 1.95 T. This high permeability is achieved through optimized annealing processes and sharp Goss texture development (110)[001] orientation, ensuring minimal magnetizing power requirements and excellent performance at rated voltage conditions.

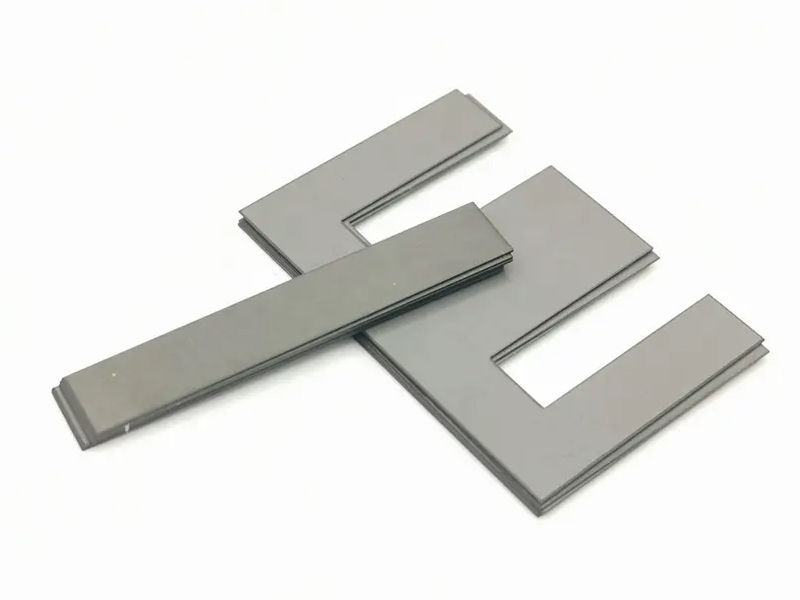

Flatness is a critical dimensional attribute that influences core stacking factor, air gap minimization, and overall magnetic circuit integrity. Poor flatness leads to increased noise, vibration, and localized flux crowding. Our production process incorporates tension leveling and precision rolling techniques to ensure flatness deviation of less than 2 mm over a 1-meter length. This high degree of flatness ensures uniform lamination stacking, tight joint fitment in EI configurations, and reduced no-load losses due to minimized magnetic leakage.

All laminations are coated with a semi-organic insulating layer that provides interlaminar resistance, enhances mechanical durability, and contributes to long-term corrosion resistance. The coating is fully compatible with standard varnishing and annealing cycles used in transformer manufacturing.

The following table summarizes the key technical parameters for our standard EI transformer lamination grades:

| Parameter | Symbol | Test Condition | Typical Value | Standard Compliance |

|---|---|---|---|---|

| Core Loss (Iron Loss) | Pv | 1.7 T, 50 Hz | ≤ 1.00 W/kg | IEC 60404-2, GB/T 2521 |

| Magnetic Flux Density | B800 | 800 A/m | ≥ 1.90 T (min) | ASTM A876/A876M |

| Specific Total Loss (P15/50) | P15/50 | 1.5 T, 50 Hz | ≤ 3.0 W/kg | IEC 60404-3 |

| Flatness Deviation | – | Over 1 m length | ≤ 2.0 mm | Internal QC Specification |

| Thickness Tolerance | – | 0.23 mm, 0.27 mm, 0.30 mm | ±0.004 mm | ISO 9001:2015 |

| Insulating Coating Resistance | – | Interlaminar | 2–5 Ω·cm² (avg) | JIS C 2521 |

These specifications reflect our commitment to delivering silicon steel laminations that meet the evolving demands of modern transformer design—emphasizing energy efficiency, compactness, and operational reliability.

Factory Tour: Manufacturing

Manufacturing Process for EI Transformer Laminations

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized expertise in electrical steel processing to deliver high-performance EI transformer laminations. Our rigorously controlled manufacturing sequence ensures optimal magnetic properties and dimensional precision critical for efficient transformer operation. The process initiates with precision slitting of grain-oriented silicon steel (GOES) coils, typically grades M4 to M0H per IEC 60404-2. Utilizing tension-controlled slitting lines with hardened tooling, we achieve narrow width tolerances of ±0.05 mm and edge quality essential for subsequent stacking. Strict monitoring of coil tension and blade clearance prevents edge burring and minimizes residual stresses induced during slitting, preserving the steel’s inherent magnetic characteristics.

Following slitting, the strips undergo a critical continuous annealing process in a protective nitrogen-hydrogen atmosphere furnace. This step is paramount for stress relief and recrystallization, directly influencing core loss (W/kg) and permeability. Our precisely calibrated thermal profile, reaching peak temperatures of 800-850°C with controlled heating and cooling rates, eliminates mechanical stresses from prior processing while optimizing the Goss texture. In-process verification using在线 core loss testers ensures the annealed material consistently meets stringent Epstein frame test requirements per IEC 60404-2, typically achieving P1.7/50 values below 1.00 W/kg for premium grades.

Application of a uniform insulation coating follows annealing. We employ a hybrid organic-inorganic coating system applied via roll-coater, providing essential interlaminar resistance and corrosion protection. Coating weight is meticulously controlled within 1.5-2.5 g/m² per side, verified through gravimetric analysis. This dielectric layer minimizes eddy current losses during transformer operation and withstands standard varnishing processes. Critical quality checks include surface resistivity measurement (target > 100 Ω·cm²) using a Gauss meter and adhesion testing per ASTM D3359 to guarantee coating integrity during cutting and stacking.

The final stage is high-speed precision punching using progressive dies in mechanical presses. Our tooling, manufactured to micron-level tolerances, produces standard EI shapes (e.g., E20, E30, E40) with strict adherence to dimensional specifications per IEC 60404-1. Key parameters include lamination thickness tolerance (±0.01 mm), critical feature alignment (±0.02 mm), and controlled burr height (< 5% of material thickness, typically < 3 µm). Each lamination undergoes 100% automated optical inspection for dimensional accuracy, burr presence, and coating defects before stacking. Final stacked cores are subjected to rigorous magnetic testing under simulated operating conditions.

Critical Quality Control Parameters Summary

| Parameter | Test Method | Target Specification | Frequency |

|---|---|---|---|

| Core Loss (P1.7/50) | Epstein Frame IEC 60404-2 | ≤ 1.00 W/kg (M0H) | Batch (25 tons) |

| Coating Weight | Gravimetric Analysis | 1.5 – 2.5 g/m² per side | Continuous |

| Interlaminar Resistance | Gauss Meter | > 100 Ω·cm² | Hourly |

| Burr Height | Optical Profilometer | < 3 µm | Per Tool Change |

| Dimensional Tolerance | CMM / Optical Comparator | ±0.02 mm (critical features) | 100% Inspection |

Packaging & Logistics

Export Packaging for Silicon Steel in EI Transformer Laminations

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and export of high-grade silicon steel materials, we maintain rigorous standards in packaging to ensure the integrity of electrical steel products during international transit. Our packaging methodology is specifically engineered to meet the demands of sea freight, the most common mode of transport for bulk shipments of EI transformer laminations. Given the hygroscopic nature of electrical steel and its susceptibility to mechanical damage and corrosion, our export packaging system is designed to provide structural stability, moisture resistance, and long-term protection.

All silicon steel coils and cut-to-length laminations destined for export are securely mounted on custom-engineered wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are built to international ISPM 15 standards, ensuring compliance with global phytosanitary regulations for wooden packaging materials. Each pallet is designed to support the full weight of the steel load while maintaining dimensional stability under variable climatic and handling conditions. The use of robust wooden bases prevents deformation during stacking and facilitates secure forklift handling at ports and warehouses.

Immediately after palletization, the entire load is wrapped in multiple layers of industrial-grade moisture-proof film. This film features a multi-laminate structure incorporating aluminum foil and polyethylene barriers, providing an effective vapor transmission rate of less than 0.1 g/m²·day. This level of protection is critical in preventing moisture ingress during prolonged sea voyages, particularly in tropical and high-humidity regions where condensation within shipping containers poses a significant risk. The film is heat-sealed at all seams and extends fully to the base of the pallet to create a hermetic enclosure.

Additional protective measures include corner boards made from reinforced cardboard or plastic to guard against edge damage, and steel strapping applied at multiple points to prevent lateral shifting. Each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch numbers, weight, and handling instructions, ensuring full traceability and compliance with logistics protocols.

Our packaging system has been validated through extensive real-world shipping trials across major trade routes, including trans-Pacific and trans-Indian Ocean container services. It consistently demonstrates effectiveness in preserving the surface quality, dimensional accuracy, and electromagnetic performance of silicon steel laminations upon arrival. By integrating material science, structural engineering, and international logistics expertise, Luoyang Xinzhaohe ensures that every shipment meets the exacting standards required by transformer manufacturers worldwide. This commitment to packaging excellence reinforces our reputation as a reliable supplier of electrical steel in the global energy infrastructure sector.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision EI Transformer Laminations

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in electrical steel processing to deliver superior EI transformer laminations meeting the most stringent global performance and reliability standards. Our integrated manufacturing ecosystem, centered on advanced silicon steel (non-oriented and grain-oriented), provides transformer manufacturers with a critical competitive advantage through unparalleled material consistency and dimensional precision.

Our core strength resides in deep metallurgical control over the silicon steel substrate. We utilize high-purity, low-carbon base steel with precisely controlled silicon content (2.9-3.3% for GOES), ensuring optimal magnetic properties. Critical annealing processes, including decarburization and high-temperature purification, are meticulously managed to develop the essential Goss texture (110)[001] in grain-oriented material. This results in exceptionally low core loss (achieving as low as 0.65 W/kg at 1.7T, 50Hz per IEC 60404-2) and high magnetic permeability, directly translating to higher transformer efficiency and reduced operational costs for end-users. Rigorous in-line monitoring of magnetic properties throughout production guarantees batch-to-batch uniformity essential for predictable transformer performance.

Precision slitting for EI laminations is executed on state-of-the-art tension-leveling lines equipped with laser-guided edge control systems. We maintain industry-leading dimensional tolerances critical for minimizing air gaps and vibration in stacked cores. Our standard slit width tolerance is ±0.05 mm, with tighter tolerances of ±0.02 mm achievable for critical applications. Burr height is consistently held below 3% of material thickness (typically ≤ 2µm on 0.23mm-0.35mm gauges), significantly reducing interlaminar eddy currents and associated losses. Surface cleanliness is strictly controlled to ISO 14644 Class 8 standards, preventing insulation degradation during varnishing or bonding.

Vertical integration within our facility ensures seamless material flow from coil processing to finished slit strip. We operate dedicated annealing lines specifically configured for electrical steel, eliminating cross-contamination risks inherent in multi-product facilities. Our robust supply chain management system, backed by a 50,000-ton annual processing capacity, guarantees on-time delivery performance exceeding 98%. We maintain strategic inventory buffers of key grades (M4, M5, M6, 27P105, 35P210, etc.) to accommodate urgent project demands without compromising quality protocols. Stringent ISO 9001 and IATF 16949 certified quality management systems govern every process step, from raw coil inspection to final packaging.

Engage our engineering team to co-develop lamination solutions optimized for your specific transformer design, efficiency targets, and production workflow. We provide comprehensive technical documentation, including full material test reports (MTRs) covering chemical composition, magnetic properties, and mechanical characteristics. Partner with Luoyang Xinzhaohe to secure a reliable source of high-performance EI laminations that enhance your transformer’s energy efficiency and market competitiveness.

Contact Cathy directly at cathy@transformerstrip.com to discuss your technical requirements and initiate a precision supply partnership.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing ei transformer laminations directly from China.