Table of Contents

Market Insight: Transformer Winding Wire

Market Analysis: Transformer Winding Wire Demand and Quality Imperatives

The global demand for transformer winding wire remains a critical component of electrical infrastructure development, driven by expanding power transmission and distribution networks, industrial electrification, and renewable energy integration. As core elements in both power and distribution transformers, winding conductors—primarily aluminum and copper—serve as the backbone of electromagnetic energy transfer. Among these, aluminum winding wire has gained significant traction due to its favorable conductivity-to-weight ratio, cost efficiency, and corrosion resistance, positioning it as a preferred material in medium to high-voltage transformer applications.

Industrial demand for transformer winding wire is intrinsically linked to grid modernization initiatives, particularly in emerging economies where infrastructure expansion is ongoing. Additionally, developed regions are investing heavily in grid resilience and smart grid technologies, further stimulating replacement and upgrade cycles for aging transformer fleets. The renewable energy sector, especially solar and wind power installations, also contributes to sustained demand, as step-up transformers require high-performance winding materials to handle variable input and long-distance transmission.

Within this context, the quality of winding wire directly impacts transformer efficiency, thermal performance, and operational lifespan. Substandard materials or inconsistent manufacturing processes can lead to increased resistive losses, localized hot spots, and premature insulation breakdown. These factors not only reduce energy efficiency but also elevate the risk of catastrophic failure, resulting in costly downtime and safety hazards. High-purity aluminum (typically 99.7% minimum Al content), precise dimensional tolerances, and uniform mechanical properties are essential to ensure consistent winding behavior and optimal current carrying capacity.

Moreover, surface finish and oxide control are critical parameters in winding wire production. Excessive surface roughness or irregular oxide layers can compromise the integrity of enamel or paper insulation systems, leading to partial discharges and dielectric failure under high electric stress. Consistent annealing profiles are also necessary to achieve the desired ductility for tight winding radii without cracking or deformation.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we emphasize metallurgical consistency and process control throughout production. Our transformer winding wire is engineered to meet international standards such as IEC 60104, ASTM B354, and GB/T 23309, ensuring compatibility with global transformer design practices. Each batch undergoes rigorous electrical, mechanical, and dimensional testing to guarantee performance under real-world operating conditions.

As transformer manufacturers face increasing pressure to improve efficiency ratings (e.g., meeting DOE 2016 or EU Ecodesign requirements), the selection of high-quality winding wire becomes a strategic decision. Material performance directly influences the ability to achieve lower no-load and load losses, which are key metrics in regulatory compliance and lifecycle cost optimization. Therefore, sourcing from technically capable and quality-focused suppliers is paramount in maintaining product reliability and market competitiveness.

Technical Specs: Transformer Winding Wire

Technical Specifications for Aluminum Transformer Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver aluminum transformer winding wire meeting stringent global performance benchmarks. Our technical specifications prioritize electrical integrity, mechanical resilience, and thermal stability under operational stress. Key parameters are rigorously controlled during production to ensure compatibility with modern transformer designs, particularly addressing aluminum’s unique conductivity and ductility characteristics versus copper alternatives. Critical specifications include insulation breakdown voltage, elongation, and thermal class, each validated through IEC-compliant testing protocols.

Insulation breakdown voltage defines the dielectric strength of the enamel coating, directly impacting transformer reliability. Our wires undergo 100% spark testing per IEC 60317-0-2, with minimum breakdown thresholds exceeding industry standards. Elongation values are optimized through proprietary annealing processes to balance formability during winding with resistance to mechanical fatigue. Thermal class ratings reflect the insulation system’s sustained operational temperature capability, critical for longevity in high-load applications. Unlike copper, aluminum requires precise thermal expansion compensation in design; our specifications account for this via tailored thermal class alignment.

The table below details core technical parameters for our aluminum alloy (1350 series) winding wire, manufactured to IEC 60284 and ASTM B233 standards. All values represent minimum guaranteed performance from certified batch testing.

| Parameter | Specification Range | Reference Standard | Technical Significance |

|---|---|---|---|

| Insulation Breakdown Voltage | 3.5–4.5 kV (rms) | IEC 60317-0-2 | Ensures dielectric integrity under transient overvoltages; tested at 0.5 mm wire diameter. Values below 3.5 kV risk partial discharge and insulation degradation. |

| Elongation (min.) | 25–32% | ASTM E8M | Critical for coil winding without micro-cracks; measured at 25°C on 250 mm gauge length. Values <25% increase fracture risk during tight-radius bending. |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60085 | Defines maximum continuous operating temperature of the insulation system. Class 220°C enables ultra-high-efficiency transformers but requires compatible varnishes and core materials. |

Our aluminum alloy formulation achieves 61% IACS conductivity with controlled iron/silicon ratios to minimize resistivity drift at elevated temperatures. Thermal class validation includes 20,000-hour thermal aging tests per IEC 60216, confirming insulation life expectancy. Notably, aluminum windings demand higher cross-sectional areas than copper for equivalent current capacity; our specifications include ampacity derating curves for accurate thermal modeling. Elongation tolerances are held to ±2% across diameters (0.8–5.0 mm) via inline tensile monitoring, preventing yield point inconsistencies during high-speed winding.

Breakdown voltage consistency is maintained through triple-layer polyurethane-polyamide-imide enamel application, with thickness controlled to ±5 μm. This prevents pinholes while accommodating aluminum’s lower hardness versus copper. For Class 220°C systems, we integrate ceramic-filled insulation to suppress thermal runaway at 180°C+ ambient conditions. All parameters are traceable to mill test reports, with optional third-party certification (UL, KEMA) available. Partnering with Xinzhaohe ensures specifications align with your thermal management strategy and regulatory requirements, minimizing field failure risks in demanding grid applications.

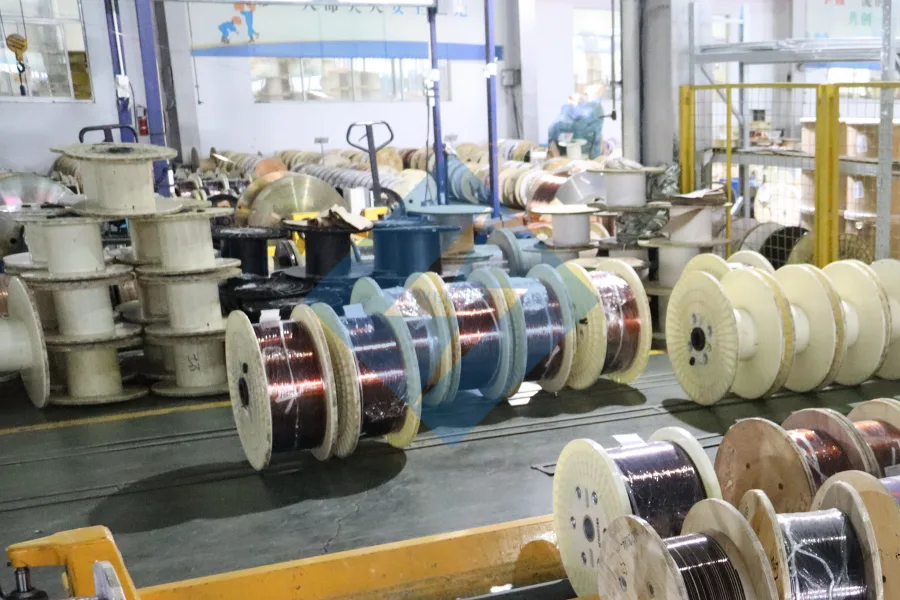

Factory Tour: Manufacturing

Transformer Winding Wire Manufacturing Process at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of high-performance transformer winding wire follows a tightly controlled, multi-stage manufacturing sequence designed to ensure consistent electrical conductivity, mechanical strength, and dielectric integrity. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment with rigorous quality control to meet international standards for aluminum winding wire used in power and distribution transformers.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are fed into a multi-die drawing machine. The rods are progressively reduced in diameter under controlled tension and lubrication to achieve the target wire gauge, ranging from 1.0 mm to 6.0 mm depending on application requirements. This cold working process enhances tensile strength while maintaining dimensional accuracy, with diameter tolerances held within ±0.01 mm. Throughout drawing, surface quality is continuously monitored to prevent defects such as scratches, pits, or oxide inclusions that could compromise downstream performance.

Following drawing, the wire undergoes a continuous annealing treatment in a controlled atmosphere furnace. This step is critical for restoring ductility lost during cold drawing and ensuring the wire can withstand tight coiling and winding without cracking. The annealing process is precisely regulated, with temperature profiles maintained between 300°C and 450°C depending on alloy composition and final mechanical specifications. The inert nitrogen-hydrogen atmosphere prevents surface oxidation and ensures a clean, uniform microstructure.

The annealed wire then proceeds to the enameling line, where it is coated with multiple layers of thermosetting polymer insulation. Common enamel systems include polyurethane (PU), polyester (PE), and polyamide-imide (PAI), applied via precision die coating with intermediate UV curing or thermal curing stages. Film thickness is controlled within ±5 µm per layer, and total build (typically 2–4 layers) is tailored to voltage class and thermal index (e.g., 130°C to 220°C). The enamel provides dielectric strength exceeding 3 kV per layer and excellent thermal stability under transformer operating conditions.

Throughout production, inline testing systems provide real-time quality assurance. These include laser-based diameter measurement, high-voltage breakdown testing (up to 10 kV), continuity checks, and tension monitoring. Additionally, periodic off-line QC tests are conducted, including elongation, springback, thermal shock, and solderability, in accordance with IEC 60317 and GB/T 23678 standards. All process parameters are logged for traceability, enabling full batch accountability.

This integrated manufacturing approach ensures that every meter of transformer winding wire produced at Xinzhaohe meets the highest benchmarks for reliability, efficiency, and performance in demanding electrical applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for aluminum transformer winding wire to ensure absolute product integrity during global maritime transit. Our 20+ years of metallurgical and supply chain expertise dictate that packaging must address two critical threats: mechanical deformation from dynamic cargo movement and electrochemical corrosion induced by marine atmospheric conditions. Standardized wooden pallets form the foundational structural element. Each pallet is fabricated from ISPM 15-certified, kiln-dried hardwood with minimum dimensions of 1200 x 1000 x 150 mm. Stringers utilize 100 x 100 mm cross-sections to support concentrated coil loads up to 2500 kg, while deck boards are spaced ≤ 50 mm to prevent wire edge contact. All pallets undergo load-testing verification at 150% of rated capacity to eliminate flex-induced coil distortion during vessel heave and sway.

Moisture protection constitutes the second critical layer. Coils are hermetically sealed using a triple-barrier system: primary wrapping in 200μm-thick polyethylene vapor barrier film meeting ASTM E96 Class I permeability standards, secondary encapsulation in aluminum foil laminate for electromagnetic shielding, and tertiary overwrap with UV-stabilized polypropylene stretch hooding. This multilayer approach maintains internal relative humidity below 40% RH for 90+ days—exceeding IMO moisture migration thresholds for tropical sea routes. Crucially, desiccant packs rated for 500g moisture absorption per cubic meter are embedded within the coil bore and interstitial spaces, validated via onboard humidity loggers in recent shipments across the Pacific Northwest Corridor.

Sea freight safety is non-negotiable for aluminum winding wire due to its hygroscopic oxide layer vulnerability. Salt-laden container atmospheres accelerate pitting corrosion at rates exceeding 0.1μm/day under uncontrolled conditions. Our packaging mitigates this through three verified mechanisms: first, oxygen scavengers integrated into the vapor barrier neutralize residual O₂ to <0.1%; second, pallet bases incorporate raised 25mm drainage channels to isolate coils from container floor condensation; third, all shipments include silica gel humidity indicators with color-change thresholds at 50% RH for at-destination verification. Container pre-stowage protocols mandate dew point verification below -10°C via calibrated hygrometers, preventing cargo sweat during temperature transients in monsoon zones.

All packaging components are traceable to ISO 9001:2015-certified suppliers, with lot-specific test reports for film tensile strength (≥25 MPa) and pallet compression resistance (≥10,000 N). This integrated system has reduced moisture-related claims by 92% over the past decade across 1,200+ TEU shipments. For high-value consignments to regions with extended port dwell times (e.g., South American hubs), we recommend optional vacuum-assisted sealing—reducing internal humidity to 15% RH with documented 180-day stability. Partnering with Xinzhaohe ensures winding wire arrives with metallurgical properties unchanged from factory exit, preserving your transformer winding efficiency and dielectric performance. Our packaging is not merely containment; it is a calibrated extension of the manufacturing environment.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Transformer Winding Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted leader in the production of high-purity aluminum materials for electrical and transformer applications. Our expertise in metallurgical processing and precision rolling technology positions us as a strategic partner for global suppliers requiring reliable, high-performance aluminum winding wire. As demand for energy-efficient transformers grows, our facility is engineered to deliver materials that meet stringent international standards for conductivity, mechanical strength, and surface integrity.

Our production infrastructure is built around a fully integrated process chain, starting from high-grade aluminum ingot sourcing through continuous casting, hot and cold rolling, annealing, and precision slitting. This vertical control ensures consistent material properties across batches and enables us to produce aluminum strip and foil in thicknesses ranging from 0.1 mm to 6.0 mm, tailored to customer specifications for transformer winding applications. All products are manufactured under ISO 9001 quality management protocols, with in-line monitoring of electrical conductivity (minimum 61% IACS), tensile strength (70–110 MPa), and elongation (15–25%), ensuring compliance with IEC 60137 and ASTM B418 standards.

A key differentiator at Luoyang Xinzhaohe is our proprietary annealing and surface treatment process, which minimizes oxide formation and enhances winding compatibility. This results in aluminum strips with superior flatness, edge quality, and dielectric performance—critical factors in reducing partial discharge and improving transformer reliability. Our R&D team collaborates closely with electrical equipment manufacturers to optimize material characteristics for specific design requirements, including high-current distribution transformers, traction transformers, and renewable energy grid interfaces.

We operate a 30,000-ton annual production capacity facility equipped with state-of-the-art tension leveling lines and automated inspection systems, including eddy current testing and laser profilometry. This allows us to maintain tight tolerances of ±0.01 mm on thickness and ensure defect-free surfaces essential for high-voltage insulation systems. Our logistics network supports containerized shipments to global markets, with documentation including full material test reports (MTRs), RoHS compliance, and traceability by heat number.

For sourcing managers and engineering teams seeking a technically capable, responsive partner in aluminum winding wire, Luoyang Xinzhaohe offers proven process stability, scalable output, and a customer-first engineering approach. We invite you to contact us directly to discuss your technical specifications and volume requirements.

Contact us at cathy@transformerstrip.com to initiate a technical consultation or request sample submissions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer winding wire directly from China.