Table of Contents

Market Insight: Wire Wound Transformer

Market Analysis: Winding Wire for Wire Wound Transformers

Industrial demand for wire wound transformers remains robust and structurally growing, driven by fundamental requirements across power infrastructure, industrial automation, and renewable energy integration. These transformers are indispensable components for voltage transformation, isolation, and impedance matching within electrical systems. Key growth vectors include global grid modernization initiatives necessitating higher efficiency distribution transformers, the expansion of renewable energy generation (solar PV inverters, wind turbine converters) requiring robust power conversion, and the proliferation of industrial machinery and data centers demanding reliable power conditioning. Within this segment, aluminum winding wire has gained significant traction, particularly in distribution transformers above 50 kVA, due to its favorable cost-to-conductivity ratio and lighter weight compared to copper, offering substantial material savings in large-scale deployments without compromising core functionality when engineered correctly.

The criticality of winding wire quality in wire wound transformers cannot be overstated, as it directly dictates the transformer’s operational reliability, efficiency, lifespan, and safety. Aluminum wire, specifically electrolytic tough pitch (ETP) grade meeting stringent ASTM B233 or IEC 60122-1 standards, must exhibit exceptional electrical conductivity (typically 59-61% IACS minimum) to minimize resistive (I²R) losses, a primary contributor to heat generation and energy waste over the transformer’s 25-40 year operational life. Impurities, inconsistent grain structure, or inadequate annealing significantly degrade conductivity and increase operating temperature, accelerating insulation degradation. Mechanical properties are equally vital; precise tensile strength and elongation control are essential for consistent, damage-free winding during manufacturing. Wire that is too hard fractures under tension, while overly soft wire deforms, leading to poor layer packing, increased voids, and potential turn-to-turn shorts under electromagnetic forces during service. Surface quality is paramount; excessive oxide layers, scratches, or lubricant residues act as insulators between turns, creating localized hotspots and initiating partial discharge, the precursor to catastrophic insulation failure.

Substandard aluminum winding wire introduces systemic risks that manifest as premature field failures, unplanned downtime, and significant financial liabilities. Inconsistent dimensional tolerances disrupt automated winding processes, increasing scrap rates and production costs for transformer manufacturers. Variability in resistivity directly impacts the transformer’s ability to meet mandated efficiency standards (e.g., DOE 2016, EU Ecodesign), potentially leading to non-compliance penalties and market access restrictions. Crucially, latent defects in the wire often remain undetected during routine factory testing but precipitate failures under real-world load cycles or fault conditions, incurring exorbitant replacement costs, reputational damage, and safety hazards. For reliability-critical applications like utility substations or industrial process lines, the initial cost savings from inferior wire are vastly outweighed by the lifecycle cost of failure. Stringent process control from molten metal purification through continuous casting, rod rolling, and precision wire drawing is non-negotiable to ensure the metallurgical homogeneity, surface integrity, and consistent electro-mechanical properties demanded by modern wire wound transformer design. Quality is not a cost center but the foundational investment securing transformer performance and grid stability.

Technical Specs: Wire Wound Transformer

Technical Specifications for Aluminum Winding Wire in Wire Wound Transformers

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-purity aluminum winding wire engineered for reliable performance in wire wound transformers. With over two decades of metallurgical and manufacturing expertise, our products meet stringent international standards for electrical conductivity, mechanical integrity, and thermal endurance. The performance of a wire wound transformer is critically dependent on the quality of the conductor and its insulation system. Key technical parameters such as insulation breakdown voltage, elongation, and thermal class directly influence operational safety, efficiency, and service life.

Insulation breakdown voltage is a fundamental indicator of dielectric strength and determines the wire’s ability to withstand electrical stress without failure. For aluminum winding wire used in medium to high-voltage transformers, a minimum breakdown voltage of 3,000 VAC is recommended under standard test conditions (ASTM D2307). Our enamel-coated aluminum wires consistently achieve breakdown voltages in the range of 4,000–6,000 VAC, depending on insulation thickness and grade. This ensures robust protection against short circuits and transient overvoltages, particularly in demanding grid environments.

Elongation, measured as a percentage during tensile testing, reflects the ductility of the aluminum conductor. High elongation values are essential to accommodate winding stresses during coil fabrication without cracking or necking. Our aluminum wire, produced from high-conductivity EC-grade aluminum (≥99.7% purity), exhibits elongation values between 18% and 25% in the soft annealed state (O-temper). This ductility enables tight winding radii and uniform layering, critical for minimizing inter-turn stresses and achieving consistent electromagnetic performance.

Thermal class defines the maximum continuous operating temperature the insulation system can withstand without significant degradation. For wire wound transformers, thermal classes ranging from 130°C to 220°C are common, depending on application requirements. Our product portfolio includes polyurethane (PU), polyester (PE), and polyamide-imide (PAI) insulated aluminum wires rated for thermal classes 130, 155, 180, 200, and 220. These insulation systems are designed to maintain dielectric integrity and mechanical adhesion under thermal cycling, preventing premature aging and insulation delamination.

The following table outlines the key technical parameters of our aluminum winding wire series suitable for wire wound transformers:

| Parameter | Standard Value / Range | Test Method | Notes |

|---|---|---|---|

| Conductor Material | High-purity Aluminum (≥99.7%) | IEC 60122 | EC-grade, soft annealed (O-temper) |

| Electrical Conductivity | ≥61% IACS | ASTM E1004 | Ensures low resistive losses |

| Insulation Breakdown Voltage | 4,000 – 6,000 VAC | ASTM D2307 | Measured at 1.5x nominal thickness |

| Elongation | 18% – 25% | ASTM E8 / ISO 6892-1 | Tensile test, soft temper condition |

| Thermal Class | 130°C to 220°C | IEC 60317 / NEMA MW 1000 | PAI insulation up to Class 220 |

| Temperature Index (TI) | Up to 220°C | UL 1446 | For polyamide-imide systems |

| Adhesion Resistance | Class A (Excellent) | IEC 60317-0-7 | No flaking or peeling after winding |

These specifications are validated through in-house and third-party testing to ensure compliance with global transformer manufacturing standards. Luoyang Xinzhaohe Aluminum Co., Ltd. supports OEMs with customized wire diameters, insulation types, and spool configurations to meet specific design requirements.

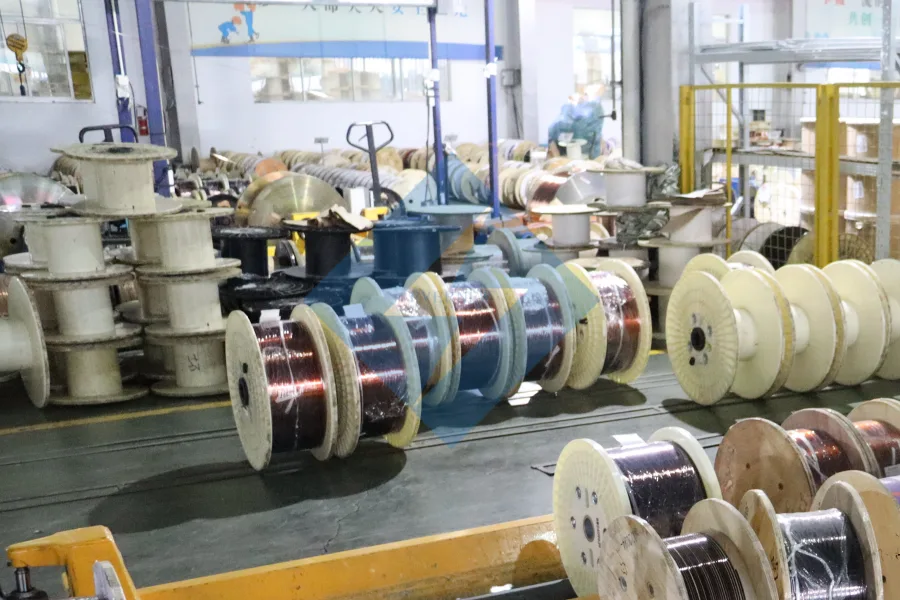

Factory Tour: Manufacturing

Manufacturing Process for Precision Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to produce high-purity aluminum winding wire meeting stringent wire wound transformer specifications. Our vertically integrated process ensures dimensional stability, electrical consistency, and dielectric reliability through four critical phases.

Rod drawing initiates production using 99.7% pure aluminum rod (IEC 60284 compliant) from continuous casting. Rods undergo multi-pass cold drawing through precision tungsten carbide dies under controlled tension, reducing diameter from 9.5mm to final gauges (0.10–3.00mm). Laser micrometers monitor diameter in real time, maintaining tolerances within ±0.005mm. This phase optimizes tensile strength (130–160 MPa) while minimizing surface defects through automated lubricant filtration and die calibration protocols.

Annealing follows immediately via continuous in-line furnaces with nitrogen-hydrogen atmosphere (O₂ < 0.01%). Wires pass through precisely regulated temperature zones (550–600°C) for 30–120 seconds, restoring ductility and electrical conductivity to 61% IACS minimum. Oxygen exclusion prevents oxide inclusion, critical for subsequent enamel adhesion. Post-annealing, wires undergo quenching with deionized water to stabilize microstructure, verified hourly via conductivity meters and tensile testing.

Enameling applies triple-layer insulation using solvent-free polyurethane-imide resin. Wires traverse precision applicators at 8–15 m/min, with each coat baked at 380–420°C in oxygen-controlled ovens. Total insulation thickness ranges 30–120μm (per IEC 60317), with automated thickness gauges ensuring ±2μm uniformity. UV-curing completes the process, achieving dielectric strength >1,200 V/μm. Resin viscosity and cure kinetics are monitored every 30 minutes to prevent pinholes or delamination.

Inline testing validates performance at three critical control points. First, 100% hi-pot testing applies 3 kV AC for 1 second to detect insulation breaches. Second, diameter and ovality are scanned via non-contact laser systems at 50m intervals. Third, continuous tensile and elongation checks occur per ASTM B557M. Final QC includes batch-level verification:

| Parameter | Standard | Test Frequency | Method |

|---|---|---|---|

| Conductivity | ≥61% IACS | Hourly | ASTM E1004 |

| Adhesion | Class 1B | Per batch | IEC 60851-5 |

| Thermal Shock | Pass 200°C | Weekly | IEC 60851-6 |

| Elongation | ≥2.0% | Per batch | ASTM B557M |

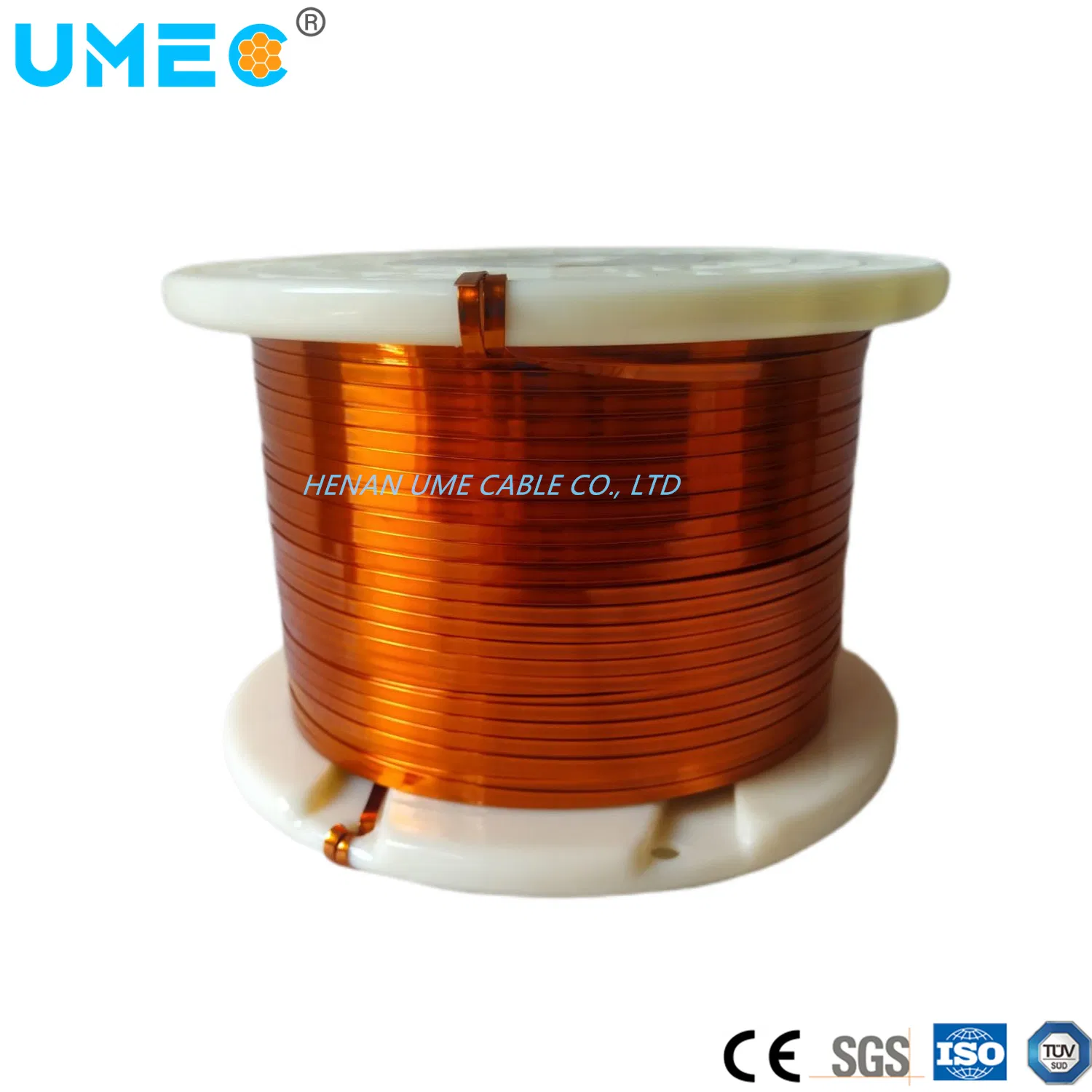

All wire undergoes final visual inspection for surface defects and is spooled under tension-controlled winding to prevent layer distortion. Certificates of Conformance detail lot-specific conductivity, dimensions, and insulation properties, ensuring traceability from raw material to finished coil. This end-to-end control guarantees wire capable of withstanding transformer winding stresses and long-term thermal cycling.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in manufacturing high-purity aluminum winding wire for wire wound transformers, we recognize that performance consistency begins not only in production but also in logistics. Export packaging is a critical phase in the supply chain, particularly for sensitive materials such as aluminum conductor wire, where exposure to environmental stressors can compromise electrical and mechanical properties. Our export packaging system is engineered to ensure product integrity during extended sea freight operations, which remain the most common and cost-effective mode of international transport for bulk industrial materials.

All aluminum winding wire reels are secured on custom-fabricated wooden pallets constructed from high-strength, kiln-dried hardwood. These pallets are designed to support the full weight of wound coils, which can range from several hundred kilograms to multiple metric tons depending on diameter and length. The structural rigidity of the pallet prevents deformation during lifting, stacking, and transit. Each pallet is treated to ISPM 15 standards, ensuring compliance with international phytosanitary regulations for wood packaging material. This certification is essential for seamless customs clearance across global markets, including the EU, North America, and Southeast Asia.

Immediately after palletizing, the wound reels are wrapped in multiple layers of industrial-grade moisture-proof film. This polyethylene-based laminate includes a metallized barrier layer that provides a high level of resistance to water vapor transmission. Given that aluminum is susceptible to surface oxidation when exposed to humidity—particularly in tropical maritime environments—this vapor barrier is crucial for maintaining the wire’s surface cleanliness and conductivity. The film is applied using automated stretch wrapping equipment to ensure uniform tension and full coverage, including the flanges and axial ends of the reel, which are most vulnerable to lateral moisture ingress.

In addition to moisture protection, the packaging system includes corner boards and edge protectors made from laminated corrugated board or reinforced plastic. These components shield the reel edges from impact damage during container handling and prevent abrasion when units are stored in proximity. For shipments to regions with extreme climatic conditions or extended transit times, optional desiccant packs are sealed within the wrapped layer to actively control internal humidity.

Each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch number, net weight, and handling instructions. Barcodes and QR codes enable full traceability throughout the logistics chain. Our packaging protocols are validated through internal drop, tilt, and vibration testing to simulate real-world sea freight conditions.

By integrating robust wooden pallets with advanced moisture-resistant wrapping, Luoyang Xinzhaohe ensures that every coil of aluminum winding wire arrives at its destination in the same condition as when it left our facility. This commitment to packaging excellence supports the reliability of wire wound transformers in end-use applications and reinforces our position as a trusted partner in global power infrastructure supply chains.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and integrated supply chain management to deliver aluminum winding wire meeting the exacting demands of high-performance wire wound transformer manufacturing. Our vertically aligned production ecosystem, from refined aluminum ingot sourcing through precision rolling and annealing, ensures unparalleled consistency and traceability critical for transformer reliability and efficiency. We understand that dimensional stability, electrical conductivity, and surface integrity are non-negotiable parameters; our processes are engineered to exceed industry benchmarks consistently.

Our core strength resides in advanced metallurgical process control. Utilizing state-of-the-art continuous casting and rolling lines coupled with precisely calibrated annealing furnaces, we achieve exceptional homogeneity in microstructure and mechanical properties across every production run. This rigorous control directly translates to superior wire drawability, minimized breakage during high-speed winding, and optimal core loss performance in the final transformer assembly. We maintain stringent oversight of critical parameters including aluminum purity (min 99.70% Al), grain size distribution, and residual stress levels, ensuring the wire performs predictably under demanding electromagnetic and thermal cycling conditions. Our quality management system is certified to ISO 9001:2015, with dedicated in-line and final product testing adhering to IEC 60138 and ASTM B354 standards.

Production capability is matched by robust technical support. Our facility operates multiple high-precision rolling mills capable of producing aluminum strip in thicknesses ranging from 0.15mm to 3.00mm and widths up to 800mm, with tolerances held to ±0.02mm for critical dimensions. Surface finish is meticulously controlled to Ra < 0.4µm, eliminating defects that could compromise insulation integrity. Key material properties are consistently maintained within the following specifications:

| Parameter | Specification Range | Test Standard |

|---|---|---|

| Thickness Tolerance | ±0.02 mm | ASTM E29 |

| Width Tolerance | ±0.10 mm | ASTM E29 |

| Conductivity | 61.0 – 63.0 % IACS | ASTM E1004 |

| Tensile Strength | 40 – 65 MPa | ASTM E8 |

| Elongation | ≥ 25% | ASTM E8 |

| Surface Roughness | Ra ≤ 0.4 µm | ISO 4287 |

Supply chain resilience is fundamental to our partnership model. We operate strategic raw material inventory buffers and maintain flexible production scheduling to accommodate urgent OEM requirements without compromising quality. Our logistics network, optimized for global shipment of sensitive coil goods, ensures on-time delivery performance exceeding 98.5% while minimizing transit-related damage risks. Dedicated technical account managers provide seamless coordination from initial specification review through to just-in-time delivery, offering proactive insights on material selection and process optimization.

For transformer manufacturers seeking a reliable, technically proficient winding wire partner committed to enhancing product performance and manufacturing yield, Luoyang Xinzhaohe delivers proven solutions. Contact Cathy Zhang directly to discuss your specific requirements and receive a tailored technical quotation. Reach out at cathy@transformerstrip.com to initiate a collaboration focused on quality, precision, and supply chain certainty.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing wire wound transformer directly from China.