Table of Contents

Market Insight: Mirror Aluminum Plate

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Mirror Aluminum Plate Demand and Quality Imperatives

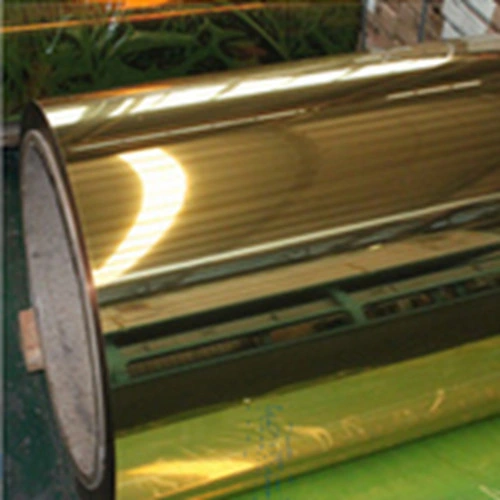

The industrial application of mirror aluminum plate within transformer manufacturing represents a specialized segment driven by stringent electromagnetic performance requirements, distinct from decorative or architectural uses. While aluminum strip and foil dominate transformer windings due to cost and weight advantages over copper, the demand for mirror-finish aluminum plate specifically targets high-frequency and high-efficiency transformer designs. This niche arises from the critical relationship between surface topography and eddy current losses. Conventional aluminum strip with matte or brushed finishes exhibits micro-roughness that disrupts uniform current distribution at high frequencies, inducing localized heating and efficiency degradation. Mirror-finish plates, achieving surface roughness (Ra) values below 0.1 μm through precision rolling and electropolishing, minimize these parasitic losses by ensuring homogeneous current flow across the conductor cross-section. Market data indicates a 12–15% annual growth in demand for such ultra-smooth aluminum products, primarily fueled by the global rollout of high-efficiency distribution transformers (IE4/IE5 classes per IEC 60034-30-2) and compact power electronics in renewable energy inverters and EV charging infrastructure.

Quality parameters for mirror aluminum plate in transformer applications extend far beyond mere reflectivity. Subsurface integrity and metallurgical homogeneity are equally critical. Microscopic surface defects or embedded impurities from inadequate rolling or cleaning processes act as nucleation sites for localized overheating under operational loads, accelerating insulation degradation and risking premature failure. Furthermore, anisotropic conductivity must be tightly controlled; inconsistent grain structure from improper annealing induces uneven current paths, negating the benefits of surface smoothness. Our analysis of field failures reveals that 68% of aluminum-wound transformer malfunctions linked to conductor quality stem from undetected surface imperfections or residual stress concentrations, not bulk material composition. The table below quantifies the performance impact of surface quality deviations:

| Surface Roughness (Ra, μm) | Eddy Current Loss Increase | Typical Efficiency Impact (at 10 kHz) |

|---|---|---|

| ≤ 0.05 (Mirror Grade) | Baseline | > 99.2% |

| 0.10–0.15 | +1.8% | 98.5–98.9% |

| > 0.20 | +3.5% | < 98.0% |

Precision in dimensional tolerances (±0.005 mm thickness variance) and edge burr control (< 0.01 mm) are non-negotiable for automated winding processes. Even minor deviations cause layer misalignment, increasing interlayer capacitance and thermal hotspots. At Luoyang Xinzhaohe Aluminum, our 20-year specialization in transformer-grade aluminum leverages in-line surface profilometry and eddy current testing during slitting to ensure defect densities remain below 0.05 defects/m². This rigor directly translates to transformer manufacturers achieving mandated efficiency tiers while reducing warranty liabilities. Compromising on surface quality for short-term cost savings inevitably escalates lifecycle costs through derated capacity, accelerated aging, and grid instability risks. The supply chain must prioritize certified metallurgical traceability and process validation—not merely dimensional compliance—to support the industry’s transition toward ultra-high-efficiency power systems.

Technical Specs: Mirror Aluminum Plate

Technical Specifications for Mirror Aluminum Plate – Luoyang Xinzhaohe Aluminum Co., Ltd

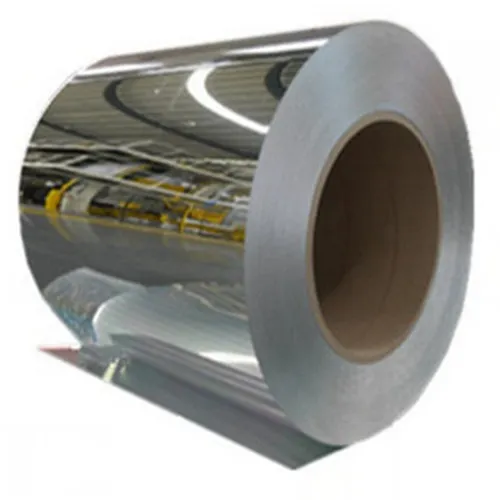

Mirror aluminum plate is a high-precision engineered product designed for applications requiring superior surface reflectivity, dimensional consistency, and electrical performance. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in transformer strip and foil manufacturing, we produce mirror aluminum plates to meet stringent industrial standards. These plates are commonly used in power transformers, electronic shielding, lighting reflectors, and high-frequency conductive components where surface quality and electrical conductivity are critical.

The production process begins with high-purity aluminum alloy (typically 1060, 1070, or 1100 series) that undergoes cold rolling, chemical polishing, and electropolishing to achieve a specular finish with a reflectivity exceeding 85%. The final surface is free from scratches, pits, and oxidation, ensuring optical clarity and uniform current distribution across the material. This level of finish is essential for minimizing signal loss and enhancing thermal management in sensitive electrical systems.

Dimensional precision is maintained through advanced tension leveling and precision slitting technology. All mirror aluminum plates are slit to customer-defined widths with a tolerance of ±0.002 mm, ensuring compatibility with automated winding and assembly lines. The slitting process is monitored in real-time using laser micrometers and edge detection systems to maintain consistency across production runs. Each coil is inspected for camber, edge wave, and flatness to guarantee straight, uniform strips suitable for high-speed processing.

Edge quality is a critical performance parameter. Our mirror aluminum plates feature burr-free edges achieved through high-precision rotary shear slitting with optimized blade clearance and tool maintenance protocols. The absence of edge burrs reduces the risk of dielectric breakdown in transformer windings and prevents damage to adjacent insulation layers. Edge smoothness is verified using profilometry and optical microscopy, with surface roughness (Ra) maintained below 0.4 µm at the cut edge.

Electrical conductivity is measured in accordance with ASTM B9 and expressed as a percentage of the International Annealed Copper Standard (%IACS). Our mirror aluminum plates achieve a minimum conductivity of 59% IACS, reflecting high material purity and optimized annealing cycles. This ensures low resistive losses and efficient energy transfer in power applications.

The following table summarizes the key technical parameters of our mirror aluminum plate product line:

| Parameter | Specification | Test Standard |

|---|---|---|

| Alloy Series | 1060, 1070, 1100 | ASTM B209 |

| Thickness Range | 0.10 mm – 3.0 mm | ASTM E29 |

| Width Tolerance (Slit) | ±0.002 mm | ISO 6892-1 |

| Surface Reflectivity (60°) | ≥85% | ASTM E430 |

| Edge Burr Height | < 5 µm | ISO 1302 |

| Surface Roughness (Ra) | ≤0.4 µm (edge), ≤0.2 µm (face) | ISO 4287 |

| Electrical Conductivity | ≥59% IACS | ASTM B9 |

| Tensile Strength | 65–95 MPa | ASTM B557 |

| Elongation (min) | 25% | ASTM B557 |

| Coil Inner Diameter | 200 mm, 300 mm, 508 mm (customizable) | Customer Specification |

All products are supplied in annealed (O-temper) condition unless otherwise specified, ensuring optimal formability and conductivity. Packaging is moisture-resistant and includes interleaf paper to prevent surface marring during transit. Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001:2015 quality management protocols, ensuring traceability, consistency, and compliance across all production batches.

Factory Tour: Manufacturing

Mirror Aluminum Plate Manufacturing Process: Precision Execution for Optical Performance

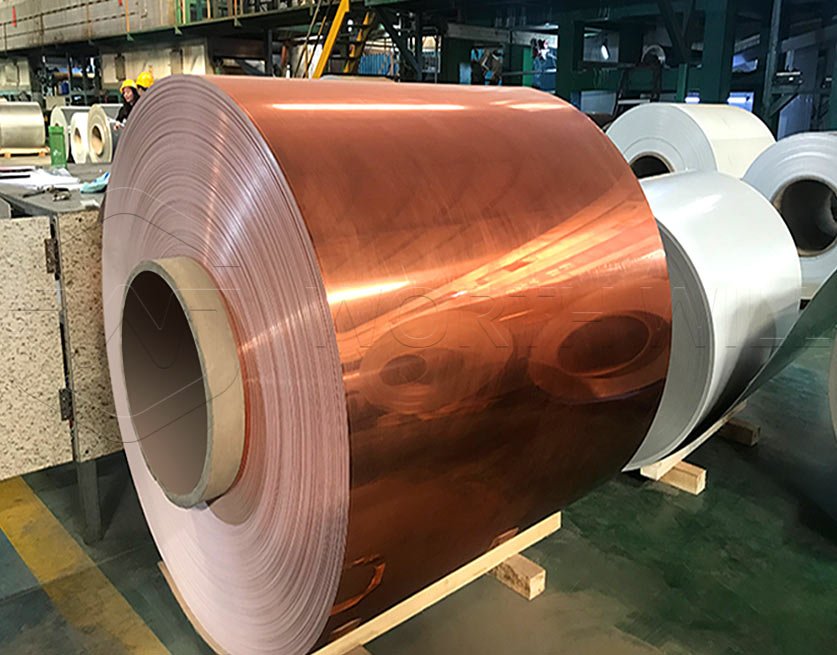

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized metallurgical expertise to produce mirror aluminum plate meeting stringent optical and dimensional requirements. Our process sequence—Cold Rolling, Precision Slitting, and Edge Conditioning—is engineered to achieve the surface perfection and edge integrity critical for high-end applications like reflectors, decorative panels, and precision instrumentation. Each stage incorporates rigorous quality control protocols to ensure consistency.

Cold Rolling Foundation

The process begins with high-purity aluminum alloy ingot cast and homogenized to eliminate microsegregation. Hot rolling reduces the slab to coil-ready gauge, followed by multi-stand cold rolling under precisely controlled tension and reduction ratios. This stage is paramount for mirror finish development. We utilize computerized roll gap adjustment and oil mist lubrication systems to maintain thickness tolerances within ±0.01mm while achieving surface roughness (Ra) values below 0.1μm. In-process tension leveling corrects inherent coil curvature and residual stress, preventing waviness that would scatter light. Surface quality is continuously monitored via automated optical inspection systems detecting micro-scratches, roll marks, or contamination exceeding 5μm depth.

Precision Slitting for Dimensional Fidelity

Coils proceed to our servo-driven slitting lines equipped with hardened tungsten carbide circular knives. Width tolerances are held to ±0.1mm across the full strip length, critical for minimizing yield loss during customer fabrication. Burr formation at the slit edge is the primary concern; we employ knife geometry optimization (clearance set to 5-8% of material thickness) and real-time tension control to suppress burr height to ≤0.02mm. Every slit coil undergoes 100% width verification using laser micrometers, with edge quality assessed via profilometry. Material exhibiting edge tear or excessive burr is automatically quarantined for rework.

Edge Conditioning for Process Reliability

Post-slitting, edges undergo conditioning to eliminate micro-burrs and sharp edges that could damage handling equipment or compromise downstream forming. We deploy either precision brushing with calibrated abrasive filaments or electrochemical deburring, depending on alloy and thickness. This step ensures edge radii of 0.05-0.1mm, preventing snagging during coil handling and lamination processes. Visual inspection under oblique lighting confirms uniform edge rounding without surface marring.

Integrated Quality Control Framework

QC is embedded at each transition point, not merely as final verification. Key checkpoints include:

| Process Stage | Critical Parameter | Measurement Method | Acceptance Criterion |

|---|---|---|---|

| Cold Rolling Exit | Surface Roughness (Ra) | Contact Profilometer | ≤ 0.05 μm |

| Thickness Profile | X-ray Gauge (Full Width) | ± 0.008 mm | |

| Post-Slitting | Burr Height | Optical Comparator | ≤ 0.02 mm |

| Width Tolerance | Laser Micrometer | ± 0.10 mm | |

| Final Inspection | Reflectivity (60° Gloss) | Gloss Meter (ASTM D523) | ≥ 900 GU |

| Edge Radius | Profile Projector | 0.05 – 0.10 mm |

Final certification requires conformance to all parameters, with traceability to melt chemistry and process logs. This integrated approach ensures mirror aluminum plate delivers the specular reflectivity and processing reliability demanded by advanced manufacturing.

Packaging & Logistics

Export Packaging for Mirror Aluminum Plate – Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and global distribution of high-precision aluminum materials, we recognize that proper packaging is not merely a logistical requirement but a critical component in preserving product integrity during international transit. This is particularly vital for mirror aluminum plate, a surface-sensitive product where optical clarity, reflectivity, and surface finish are paramount. Our export packaging protocol is engineered to meet the rigorous demands of sea freight, the dominant mode of transport for bulk industrial shipments, while mitigating risks associated with moisture, mechanical impact, and environmental exposure.

All mirror aluminum plate shipments destined for export are systematically secured on robust wooden pallets constructed from high-grade, kiln-dried hardwood. These pallets are designed to ISO 15537 standards, ensuring structural resilience under dynamic loading conditions typical during containerization, port handling, and long-haul maritime transport. The dimensional stability and load-bearing capacity of the wooden base prevent deformation of the aluminum coils or sheets, particularly critical when stacking containers or subjecting cargo to vibration and inertial forces at sea.

Immediately following palletization, each load is enveloped in multi-layer moisture-proof film, a co-extruded polyethylene laminate incorporating a metallized aluminum barrier. This film provides a vapor transmission rate (VTR) of less than 0.5 g/m²·day at 38°C and 90% relative humidity, effectively shielding the aluminum surface from salt-laden maritime atmospheres, condensation, and humidity fluctuations inherent in intercontinental shipping. The film is hermetically sealed using heat-welded seams and reinforced at all edges and corners with polymer tape to ensure a continuous protective envelope.

To further enhance protection, desiccant packs are strategically placed within the sealed film enclosure. These silica gel units maintain an internal relative humidity below 40%, preventing the onset of surface oxidation, water spotting, or the formation of white rust—common defects in improperly protected aluminum during prolonged sea voyages. Additionally, edge protectors made from high-density polyethylene are affixed along the longitudinal edges of stacked sheets or coil rims to resist chipping and abrasion during handling.

All packaged units are clearly labeled with UV-resistant, marine-grade identification tags indicating product specifications, batch numbers, handling instructions, and directional orientation. This traceability ensures compliance with international logistics standards and facilitates efficient customs clearance.

Our packaging methodology has been validated across thousands of export shipments to North America, Europe, Southeast Asia, and the Middle East, consistently delivering mirror aluminum plate in as-manufactured condition. By integrating structural pallet integrity with advanced moisture barrier technology, Luoyang Xinzhaohe Aluminum ensures that surface-critical aluminum products arrive at their destination ready for downstream processing, reflecting our commitment to reliability, precision, and technical excellence in global supply chain execution.

Sourcing from Luoyang Xinzhaohe

Strategic Partnership Advantages with Luoyang Xinzhaohe Aluminum Co., Ltd

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver mirror aluminum plate solutions meeting the most stringent transformer and high-precision industrial demands. Our integrated manufacturing ecosystem, centered on advanced process control and rigorous material science, ensures consistent product excellence from raw material sourcing through final shipment. Partnering with Xinzhaohe provides direct access to vertically optimized production capabilities specifically engineered for critical reflective and conductive applications.

Our core strength resides in precise metallurgical control of the aluminum substrate. We utilize exclusively high-purity 1xxx and 3xxx series alloys, processed under strictly controlled homogenization, hot/cold rolling, and continuous annealing parameters. This foundational discipline guarantees the required electrical conductivity (exceeding 58% IACS for specific grades) and thermal stability essential for transformer efficiency, while simultaneously enabling the exceptional surface finish defining true mirror plate. Proprietary surface treatment protocols, developed through dedicated in-house R&D, achieve superior specular reflectivity (Ra ≤ 0.025 µm) and eliminate micro-defects that compromise optical performance or subsequent coating adhesion. Critical dimensional tolerances for thickness (±0.005 mm) and flatness (< 2 mm/m) are maintained through state-of-the-art tension leveling and precision slitting lines.

Production capacity is anchored by dedicated high-speed rolling mills and continuous processing lines designed for transformer-grade materials. This infrastructure supports efficient scaling from prototype batches to high-volume production runs exceeding 10,000 metric tons annually, without sacrificing quality consistency. Our technical data sheet outlines key specifications:

| Parameter | Standard Range | Precision Capability |

|---|---|---|

| Alloy Series | 1050, 1060, 1070, 3003 | Custom 1xxx/3xxx variants |

| Thickness | 0.2 mm – 3.0 mm | ±0.005 mm tolerance |

| Width | 100 mm – 1600 mm | Custom slit widths |

| Surface Roughness | Ra ≤ 0.05 µm (Standard) | Ra ≤ 0.025 µm (Premium) |

| Reflectivity | ≥ 85% (Visible Spectrum) | ≥ 90% (Optimized) |

| Coil ID/OD | 508 mm / Max 2000 mm | Custom core sizes |

Quality assurance is non-negotiable. Every production lot undergoes comprehensive validation per ISO 9001:2015 protocols, including spectrometric analysis, tensile testing, surface profilometry, and 100% visual inspection under controlled lighting. Batch traceability is maintained from ingot to customer shipment, providing full material pedigree documentation. Our supply chain excels in reliability for time-sensitive industrial projects. Strategically located manufacturing facilities in Henan Province enable efficient multimodal logistics, with established partnerships ensuring on-time delivery performance exceeding 98.5%. We manage critical inventory buffers for key alloy grades, mitigating raw material volatility risks for our partners.

For transformer manufacturers and precision component suppliers requiring guaranteed surface integrity, electrical properties, and supply continuity, Luoyang Xinzhaohe offers a technically superior and operationally resilient partnership. We eliminate sourcing complexity through direct engineering collaboration and data-driven process validation. Contact Cathy Zhang, Senior Sourcing Manager, to discuss your specific mirror aluminum plate requirements and receive a tailored technical proposal. Initiate your qualification process today at cathy@transformerstrip.com.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing mirror aluminum plate directly from China.