Table of Contents

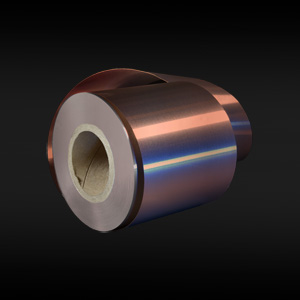

Market Insight: Copper Material

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for copper material in transformer applications remains robust, driven by the continuous expansion of power transmission and distribution networks, rising electrification rates, and the integration of renewable energy systems. Copper is extensively used in transformer windings due to its superior electrical conductivity, thermal performance, and mechanical reliability. Despite the increasing adoption of aluminum as a cost-effective alternative in certain applications, copper maintains a dominant position in high-efficiency, high-reliability transformers, particularly in distribution and power transformers deployed in urban infrastructure, industrial facilities, and critical grid systems.

Industrial demand for copper transformer strip and foil is closely tied to performance requirements in modern electrical systems. Copper’s conductivity—approximately 100% IACS (International Annealed Copper Standard)—enables reduced resistive losses, contributing directly to higher transformer efficiency. This is increasingly important as regulatory standards such as the DOE 2016 efficiency mandates in the U.S. and the EU Ecodesign Directive push manufacturers to minimize energy losses over equipment lifecycles. In applications where space, weight, and long-term operational costs are critical, copper’s higher current-carrying capacity per unit cross-sectional area provides a decisive technical advantage.

Quality of copper strip and foil is paramount in ensuring transformer integrity and longevity. Impurities, inconsistent thickness tolerances, surface defects, or inadequate mechanical properties can lead to localized heating, insulation breakdown, or premature failure under electromagnetic and thermal stress. High-purity electrolytic tough pitch (ETP) copper, typically ASTM B187 compliant, is the baseline standard, but advanced applications may require oxygen-free high-conductivity (OFHC) copper to minimize porosity and enhance weldability and fatigue resistance. Moreover, precise control over temper (e.g., H01, H02, or annealed conditions) ensures compatibility with winding processes and dimensional stability during operation.

Supply chain reliability and material traceability are growing concerns in the transformer industry. End users and OEMs increasingly demand certified material test reports (MTRs), full lot traceability, and adherence to international quality management systems such as ISO 9001 and IATF 16949. At Luoyang Xinzhaohe Aluminum Co., Ltd, our two decades of experience in non-ferrous strip production have enabled the development of stringent process controls, advanced rolling technologies, and comprehensive quality assurance protocols. While our core expertise includes high-precision aluminum transformer foil, we provide technical consultation and sourcing support for copper-based solutions, ensuring clients receive materials that meet exacting performance and compliance standards.

In summary, copper remains a critical material in the transformer sector due to its unmatched electrical and thermal properties. As energy efficiency and system reliability become non-negotiable parameters in power infrastructure, the demand for high-quality, consistently manufactured copper strip and foil will continue to grow, reinforcing the importance of technical precision and supply chain integrity in material sourcing.

Technical Specs: Copper Material

Technical Specifications for Copper Transformer Strip/Foil

Transformer efficiency and longevity are critically dependent on the metallurgical and dimensional precision of conductor materials. For copper transformer strip and foil applications Luoyang Xinzhaohe Aluminum CO. Ltd enforces stringent specifications aligned with ASTM B152 and IEC 60138 standards. These parameters ensure optimal electromagnetic performance reduced eddy current losses and seamless integration into high-speed winding processes.

Dimensional accuracy is non-negotiable with thickness tolerances held to ±0.002 mm across the full width. This precision slitting capability eliminates coil buckling during winding and maintains consistent interlayer insulation integrity. Width tolerances are equally rigorous at ±0.05 mm to prevent edge misalignment in stacked cores. Such tolerances require state-of-the-art tension leveling and laser-guided slitting systems with real-time closed-loop feedback to counteract material springback inherent in high-conductivity copper alloys.

Edge quality directly impacts dielectric reliability. Burr formation exceeding 2 µm can initiate partial discharges in high-voltage transformers. Our process employs hardened tungsten carbide rotary knives with sub-micron concentricity control and optimized blade clearance (0.5-1.0% of material thickness) to guarantee burr-free edges. All coils undergo 100% edge inspection via optical profilometry with reject thresholds set at 1.5 µm Ra surface roughness.

Electrical conductivity must achieve a minimum of 100% IACS (International Annealed Copper Standard) measured at 20°C per ASTM E1004. This ensures resistivity remains below 1.724 µΩ·cm critical for minimizing I²R losses in high-current windings. Oxygen-free electronic (OFE) copper C10100 is standard for voltages >35 kV due to its superior purity (>99.99% Cu) and absence of hydrogen embrittlement risk. For distribution transformers electrolytic tough pitch (ETP) copper C11000 with 101% IACS conductivity is supplied where cost efficiency is prioritized without compromising performance.

Mechanical properties balance formability and structural stability. Typical tensile strength ranges from 200–250 MPa with elongation of 5–8% in H02 temper. This prevents cracking during tight-radius bending while maintaining core rigidity under electromagnetic forces. All lots undergo batch traceability with certified mill test reports including chemical composition grain structure analysis and eddy current testing for subsurface defects.

Critical Copper Strip/Foil Parameters

| Parameter | Requirement | Test Standard |

|---|---|---|

| Thickness Range | 0.10–3.00 mm | ASTM E29 |

| Thickness Tolerance | ±0.002 mm | ASTM B9 |

| Width Tolerance | ±0.05 mm | ASTM B9 |

| Edge Burr Height | ≤1.5 µm | ISO 8501-1 |

| Conductivity (IACS) | ≥100% (min) | ASTM E8 |

| Tensile Strength | 200–250 MPa | ASTM E8 |

| Elongation | 5–8% | ASTM E8 |

| Surface Roughness (Ra) | ≤0.8 µm | ISO 4287 |

Sourcing copper strip with these exacting specifications mitigates field failures by ensuring dimensional repeatability thermal stability and maximum current-carrying capacity. Luoyang Xinzhaohe’s 20-year focus on transformer materials guarantees compliance through integrated metallurgical process control from melt casting to final slitting. Partnering with a supplier possessing vertical process oversight is essential to avoid the performance degradation associated with inconsistent conductivity or edge defects in mission-critical power infrastructure.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil: Copper and Aluminum

The production of high-performance transformer strip and foil, whether in copper or aluminum, follows a tightly controlled manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and electrical conductivity. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical expertise, this process is executed with precision engineering and rigorous quality oversight. The core manufacturing stages include cold rolling, precision slitting, and edge conditioning, each contributing to the final product’s suitability for demanding electrical applications.

Cold rolling serves as the foundational step in achieving the desired thickness and mechanical properties. Incoming hot-rolled coils are first cleaned and descaled to remove surface oxides. These coils are then fed into a multi-stand cold rolling mill where they undergo progressive reductions in thickness under high pressure. The process is conducted at ambient temperature, which enhances the material’s strength through strain hardening while improving surface finish. Throughout cold rolling, precise tension control and roll gap calibration are maintained to ensure uniform thickness across the strip, typically within tolerances of ±0.005 mm. For copper materials, intermediate annealing may be applied to restore ductility, particularly when achieving foil gauges below 0.1 mm.

Following cold rolling, the coil undergoes precision slitting to meet specific width requirements dictated by transformer design. Utilizing high-tolerance rotary slitters, the master coil is longitudinally cut into narrower strips with tight width tolerances, typically ±0.1 mm. This stage requires exact alignment and blade sharpness to prevent edge burrs or deformation. The slit lines are monitored in real time using laser measurement systems to ensure consistency. Slitting is performed under controlled tension to avoid edge waviness or camber, which could compromise winding performance in transformer cores.

Edge conditioning is the final mechanical treatment, critical for preventing insulation damage during coil winding. The slit edges are processed through a brushing or roller-based edge rounding system to remove micro-burrs and achieve a smooth, radius-formed edge. For copper transformer strip, this step is particularly vital due to the material’s higher hardness compared to aluminum, which increases the risk of insulation abrasion. Edge quality is verified using optical profilometry and tactile measurement to confirm radius consistency, typically in the range of 0.03–0.08 mm.

Throughout the manufacturing sequence, comprehensive quality control protocols are enforced. In-process inspections include surface defect scanning via high-resolution cameras, thickness monitoring with beta gauges, and mechanical property testing via tensile and hardness evaluation. Final product inspection includes eddy current testing for subsurface flaws and precise dimensional validation using coordinate measuring machines. All data is documented to ensure full traceability from raw material to finished strip.

This integrated manufacturing approach enables Luoyang Xinzhaohe Aluminum Co., Ltd. to deliver transformer strip and foil with exceptional consistency, supporting reliability in high-efficiency electrical systems.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard copper and aluminum transformer strip and foil during extended international sea freight transit. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging is a primary cause of material degradation and financial loss, particularly for hygroscopic metals like copper. Sea freight exposes consignments to extreme humidity cycles, salt-laden atmospheres, temperature fluctuations, and significant mechanical stress. Our system addresses these risks comprehensively through standardized, multi-barrier protection.

All copper and aluminum transformer strip and foil coils are secured onto robust, ISPM 15 compliant wooden pallets. These pallets utilize kiln-dried, heat-treated softwood meeting international phytosanitary standards, eliminating pest transmission risks. Standard pallet dimensions are 1100mm x 1100mm x 150mm, constructed with double stringers and sufficient deck boards to support coil weights up to 2500 kg without deflection. Coils are firmly strapped to the pallet base using galvanized steel or polyester tension straps rated for marine environments, preventing lateral shift or toppling during vessel motion. Edge protectors are applied to coil rims to prevent mechanical damage during handling.

The critical moisture barrier system employs a multi-layer approach. Primary wrapping consists of high-density polyethylene film (minimum 125µm thickness) with integrated Vapor Corrosion Inhibitor (VCI) technology. This film actively suppresses electrochemical corrosion on copper surfaces by releasing volatile inhibitors that form a protective molecular layer. The VCI film is meticulously sealed using heat welding, creating a hermetic enclosure. Over this, a secondary layer of metallized moisture-barrier film (MVTR < 0.5 g/m²/24h) is applied, providing exceptional resistance to salt spray and high ambient humidity. Desiccant units (minimum 100g per m³ internal volume) are strategically placed within the sealed envelope to absorb residual moisture and buffer against condensation during temperature swings. The entire assembly is then encased in a durable, UV-stabilized polyethylene outer cover, securely taped to prevent ingress.

This integrated packaging system achieves a verified internal relative humidity of < 40% for durations exceeding 90 days, effectively preventing copper oxidation, pitting corrosion, and the galvanic degradation risks inherent in sea transport. Palletized units are unitized with corner boards and stretch-wrapped for container stability, minimizing intra-container movement. Each shipment undergoes pre-shipment verification: humidity indicators are checked, seal integrity is confirmed, and pallet load distribution is validated against ISO container lashing requirements. Documentation includes a packing list detailing film specifications, desiccant quantity, and humidity control measures. This methodology, refined over decades of global shipments, ensures transformer materials arrive at destination facilities in optimal condition, preserving critical surface properties and dimensional tolerances essential for downstream processing. Safe sea freight is not an assumption but an engineered outcome of our metallurgical understanding and supply chain precision.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for High-Performance Copper and Aluminum Transformer Strip Solutions

With over two decades of specialized expertise in non-ferrous metal processing, Luoyang Xinzhaohe Aluminum Co., Ltd. stands as a trusted manufacturer of precision transformer strip and foil, serving global clients in power transmission, electronics, and industrial equipment sectors. While our name reflects our foundational strength in aluminum, our advanced production capabilities extend comprehensively into high-purity copper materials, engineered to meet the stringent demands of modern transformer and inductor applications.

Our manufacturing facility integrates vertical process control from raw material sourcing through final inspection, ensuring consistency, traceability, and compliance with international standards such as GB/T, ASTM, and IEC. We operate fully automated rolling lines equipped with laser thickness gauging, tension leveling systems, and controlled atmosphere annealing furnaces, enabling us to produce copper strip and foil with precise dimensional tolerances down to ±0.005 mm and exceptional surface finish. This level of precision is critical in minimizing eddy current losses and enhancing the efficiency of high-frequency transformers and power electronics.

We specialize in oxygen-free copper (C10100, C10200) and electrolytic tough pitch (ETP) copper (C11000), available in tempers ranging from soft (O) to hard (H), with widths from 10 mm to 800 mm and thicknesses spanning 0.05 mm to 3.0 mm. Custom slit widths, edge conditioning, and coiled or cut-to-length formats are available to meet specific customer integration requirements. All copper products undergo rigorous in-process and final quality verification, including conductivity testing (≥100% IACS), microstructure analysis, and bend testing to ensure superior formability and electrical performance.

In addition to copper, our dual-material capability in aluminum and copper transformer strip allows for optimized material selection based on application requirements, cost efficiency, and thermal management needs. This flexibility supports clients in hybrid designs and next-generation energy systems where weight reduction, conductivity, and reliability are balanced.

Our facility is ISO 9001:2015 certified, with an integrated supply chain management system that ensures on-time delivery and responsive technical support. We maintain strategic raw material inventory and operate lean production scheduling to accommodate both high-volume contracts and low-volume, high-mix engineering orders.

Partnering with Luoyang Xinzhaohe means accessing a stable source of technically validated copper materials backed by deep metallurgical expertise and responsive engineering collaboration. Our technical team works directly with clients to review specifications, support material qualification, and optimize product performance in end-use environments.

For reliable supply, precision manufacturing, and long-term partnership in transformer strip and foil, contact us today.

Cathy Zhang

Export Manager

Luoyang Xinzhaohe Aluminum Co., Ltd.

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper material directly from China.