Table of Contents

Market Insight: Insulated Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Insulated copper strip remains a critical material for specific high-performance transformer applications despite aluminum’s prevalence in distribution networks. Its demand is driven by sectors requiring superior electrical conductivity and thermal stability under high current density. Key growth areas include traction transformers for high-speed rail and electric vehicle (EV) fast-charging infrastructure, where compact designs necessitate copper’s 60% higher conductivity versus aluminum. Renewable energy integration also fuels demand; solar and wind inverters increasingly use copper strip in high-frequency transformers to minimize resistive losses. Global grid modernization programs further accelerate adoption, as utilities prioritize reliability in critical substations. While aluminum dominates cost-sensitive distribution transformers, copper maintains a 15-20% market share in premium segments where space constraints and efficiency mandates outweigh material cost considerations.

Quality integrity in insulated copper strip directly determines transformer longevity and grid safety. Substandard materials introduce catastrophic failure risks. Electrical conductivity must consistently exceed 100% IACS (International Annealed Copper Standard); deviations above ±1.5% increase I²R losses, accelerating thermal aging. The insulation system—typically polyamide-imide or polyester-imide coatings—requires precise dielectric strength (≥30 kV/mm per IEC 60450) and thermal endurance (Class 180°C+). Microscopic pinholes or coating thickness variations below 50 µm can initiate partial discharges, degrading insulation over time. Dimensional tolerances are equally critical; strip width deviations exceeding ±0.05 mm disrupt winding precision, causing interlayer short circuits. Surface defects like scratches or oxide inclusions act as stress concentrators, promoting corona discharge at operating voltages.

The consequences of quality lapses extend beyond component failure. A single transformer explosion in a data center or metro substation can incur multi-million-dollar downtime costs and grid instability. Industry data indicates 32% of premature transformer failures correlate with subpar conductor or insulation quality. Rigorous material certification—including batch-specific conductivity tests, insulation adhesion validation (per ASTM D2303), and surface profilometry—is non-negotiable. Luoyang Xinzhaohe Aluminum Co., Ltd. leverages 20+ years of metallurgical expertise to enforce multi-stage quality gates, from oxygen-free copper (OFC) sourcing to automated optical inspection of insulation integrity. This ensures compliance with IEEE C57.12.00 and IEC 60076 standards, mitigating lifecycle risks for mission-critical power infrastructure.

Transformer manufacturers must prioritize suppliers with verifiable process controls, as material quality directly impacts their reputation for reliability in an era of increasingly stringent grid codes and sustainability mandates.

Technical Specs: Insulated Copper Strip

Technical Specifications for Insulated Copper Strip

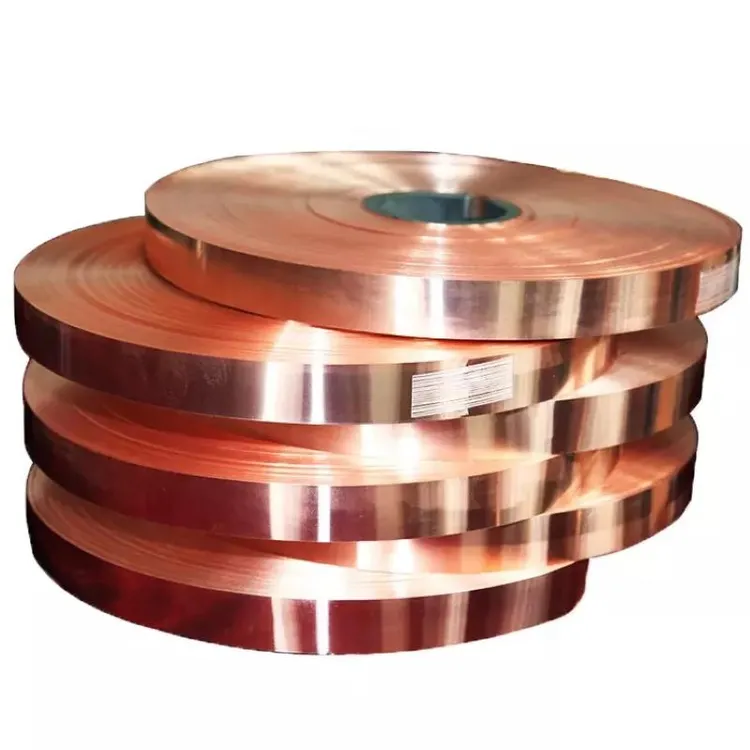

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision insulated copper strip for critical applications in power transformers, electrical switchgear, and high-efficiency motor windings. With over two decades of metallurgical and slitting process expertise, our insulated copper strip is engineered to meet stringent industry standards for electrical performance, dimensional accuracy, and mechanical integrity. The core material is high-purity electrolytic tough pitch (ETP) copper (Cu-ETP1, ASTM B187), ensuring optimal conductivity and formability. Each strip undergoes a multi-stage process including cold rolling, precision slitting, edge conditioning, and insulation coating, resulting in a product designed for reliable performance under high thermal and electrical loads.

Dimensional precision is paramount in transformer and winding applications where tight coil tolerances are required. Our slitting technology achieves a width tolerance of ±0.002 mm, ensuring uniform layer stacking and minimizing air gaps in wound components. This level of accuracy is maintained through servo-controlled tension systems and laser-guided edge tracking during the slitting process. The thickness range spans from 0.10 mm to 3.00 mm, with standard thickness tolerances held within ±0.005 mm for strips below 1.0 mm and ±0.01 mm for thicker gauges. Lengths are customizable between 350 mm and 500 mm per segment, with continuous coil options also available for automated winding lines.

Edge quality is critical to prevent insulation damage during coiling. All strips are processed to achieve burr-free edges through precision shear slitting followed by edge deburring and polishing. Surface roughness (Ra) is maintained below 0.8 µm to minimize stress concentration and ensure compatibility with thin insulation layers. The copper substrate is cleaned and passivated prior to insulation application to enhance coating adhesion and long-term reliability.

Electrical conductivity is tested per ASTM B3 and consistently exceeds 98% IACS at 20°C, confirming minimal impurity content and optimal crystalline structure. The insulation layer—typically polyurethane (PU), polyesterimide (PEI), or polyamide-imide (PAI)—is applied via continuous enameled coating and cured under controlled thermal profiles. Dielectric strength is rated at a minimum of 3 kV (AC) per layer, with thermal classes ranging from 130°C (Class B) to 220°C (Class H), depending on coating type.

The following table summarizes key technical parameters for our insulated copper strip product line.

| Parameter | Specification |

|---|---|

| Base Material | Cu-ETP1 (ASTM B187) |

| Conductivity | ≥98% IACS at 20°C |

| Thickness Range | 0.10 mm – 3.00 mm |

| Thickness Tolerance | ±0.005 mm (<1.0 mm), ±0.01 mm (≥1.0 mm) |

| Width Range | 3.0 mm – 100.0 mm |

| Width Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, Ra ≤ 0.8 µm |

| Insulation Types | PU, PEI, PAI |

| Dielectric Strength | ≥3 kV AC per layer |

| Thermal Class | 130°C (B) to 220°C (H) |

| Standard Length | 350 mm – 500 mm (cut-to-length); coil options available |

| Packaging | Anti-tarnish paper, sealed in moisture-resistant cartons |

Factory Tour: Manufacturing

Manufacturing Process for Insulated Copper Strip

The production of insulated copper strip begins with cold rolling of high-purity electrolytic copper ingots, typically conforming to ASTM B370 Grade C11000. Initial hot rolling reduces ingot thickness to approximately 10–15 mm, followed by cold rolling to achieve precise final gauges ranging from 0.05 mm to 3.0 mm. This stage employs multi-stand rolling mills with computer-controlled tension and roll gap adjustments, ensuring dimensional tolerances within ±0.005 mm. Critical to maintaining mechanical properties, intermediate annealing in inert atmosphere furnaces (750–800°C) relieves work hardening between rolling passes. Real-time monitoring via X-ray fluorescence (XRF) and eddy current testing verifies elemental purity (>99.99% Cu) and detects surface defects. Final cold rolling achieves the target tensile strength (200–350 MPa) and elongation (3–10%), with continuous thickness measurement using beta gauges logging data at 100 Hz intervals.

Precision slitting transforms wide master rolls into narrow strips per customer specifications, typically 5–100 mm in width. This phase utilizes tension-leveling slitters with servo-driven knife arbors and laser-guided edge tracking systems. Slitting occurs under controlled tension (15–25 MPa) to prevent edge waviness or camber deviation exceeding 0.5 mm per meter. Critical parameters include knife clearance (set at 5–8% of material thickness) and rotational speed synchronization to minimize burr formation. In-process quality control employs high-resolution line-scan cameras inspecting slit edges at 2 m/s, rejecting strips with burrs exceeding 5 μm or edge irregularities beyond ±0.02 mm. Tension uniformity is validated via load cells, with automatic correction for coil set or residual stress.

Edge conditioning follows slitting to eliminate micro-burrs and ensure compatibility with downstream insulation application. Strips undergo mechanical brushing using precision-calibrated nylon-abrasive brushes or electrochemical deburring in neutral electrolyte baths. Brushing parameters—pressure (20–50 N), rotational speed (1,500–3,000 RPM), and dwell time (0.5–2 s)—are optimized for gauge and alloy. Electrochemical methods apply controlled DC current (5–20 A/dm²) to dissolve burrs without altering strip geometry. Post-conditioning, edge radius is verified via profilometry to 2–10 μm Ra, and surface cleanliness is confirmed through particle counting (ISO 14644 Class 8 compliance).

Quality assurance is embedded throughout the process. Final inspection includes 100% visual examination under 500 lx lighting, electrical resistivity testing (≤1.724 μΩ·cm), and edge defect scanning per IPC-TM-650 standards. Dimensional reports detail width, thickness, camber, and edge profile against purchase order requirements. All data is traceable to melt batch numbers via integrated MES systems, with certificates of conformance documenting adherence to IEC 60140 and customer-specific protocols. This integrated approach ensures strips meet the stringent flatness and edge integrity demands of transformer winding applications, where insulation adhesion and electrical performance are non-negotiable.

| Process Stage | Key Parameters | Tolerance/Control Limit | Primary QC Method |

|---|---|---|---|

| Cold Rolling | Thickness, Tensile Strength | ±0.005 mm / ±10 MPa | Beta Gauge, Tensile Tester |

| Precision Slitting | Width, Burr Height, Camber | ±0.02 mm / ≤5 μm / ≤0.5 mm/m | Laser Scanner, Microscopy |

| Edge Conditioning | Edge Radius, Surface Cleanliness | 2–10 μm Ra / ≤50 particles/m² | Profilometer, Particle Counter |

Packaging & Logistics

Export Packaging for Insulated Copper Strip: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and export of transformer-grade aluminum and copper strips, we recognize that packaging is not merely a logistical necessity but a critical component of product integrity. For insulated copper strip shipments destined for international markets, our export packaging system is engineered to withstand the rigors of sea freight while preserving the electrical and mechanical properties of the material.

All insulated copper strip exports are secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to support coil weights ranging from 500 kg to over 3,000 kg, ensuring structural stability during multi-modal transport. The use of treated timber prevents biological infestation and complies with global phytosanitary regulations, minimizing customs delays at destination ports.

Each coil is individually wrapped with multi-layer moisture-proof composite film, featuring a core barrier of aluminum foil laminated between polyethylene layers. This configuration provides a vapor transmission rate of less than 0.1 g/m²·day, effectively shielding the insulated strip from humidity, salt spray, and condensation—common hazards during prolonged maritime transit. The film is hermetically sealed using heat-welded seams and reinforced at the coil’s outer and inner diameters to prevent capillary ingress.

To further enhance protection, desiccant packs are placed within the sealed enclosure at calculated densities based on shipment duration and expected climatic exposure. An integrated hygrometer strip is affixed inside the packaging to allow non-invasive monitoring of internal humidity levels upon receipt.

The palletized load is then strapped laterally and diagonally with galvanized steel or high-tensile PET bands, anchored to the pallet base to prevent coil shift during vessel movement or crane handling. Edge protectors made from corrugated fiberboard or steel are applied at critical contact points to mitigate mechanical damage.

For containerized shipping, we adhere to ISO 1496 standards for freight container loading. Coils are arranged to optimize weight distribution and minimize lateral forces, with voids filled using dunnage to prevent in-transit movement. All packages are labeled with standardized maritime hazard and handling indicators, including “This Way Up,” “Protect from Moisture,” and “Heavy Coil,” in compliance with IMDG and IATA cargo protocols.

Our packaging methodology has been validated across shipments to Southeast Asia, the Middle East, Europe, and South America, consistently delivering material with zero corrosion or insulation compromise. By integrating material science with freight logistics, Luoyang Xinzhaohe ensures that every meter of insulated copper strip arrives in the same condition as it left our facility.

This systematic approach underscores our commitment to quality assurance and customer reliability in the global transformer and electrical equipment supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Insulated Copper Strip Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized expertise in conductor material engineering to deliver mission-critical insulated copper strip for transformer and inductor manufacturing. Our vertically integrated facility in Henan Province operates under stringent ISO 9001 and IATF 16949 quality management systems, ensuring traceability from raw material sourcing to finished product. Unlike commodity suppliers, we focus exclusively on high-performance electrical conductors, combining metallurgical precision with advanced insulation processing to meet the exacting demands of power electronics.

Our technical capabilities center on tight-tolerance copper strip production with proprietary insulation coating. We process high-conductivity electrolytic tough pitch (ETP) copper (C11000) to thicknesses ranging from 0.05 mm to 3.0 mm and widths up to 800 mm, maintaining dimensional tolerances within ±0.005 mm. The insulation system employs thermoset polyamide-imide (PAI) or polyester-imide (PEI) enamels applied via precision die-coating, achieving uniform film thickness control of ±2 µm. Each batch undergoes rigorous validation per IEC 60317 standards, including:

Thermal endurance testing (Class 180 to Class 220)

Dielectric strength verification (≥8 kV/mm)

Adhesion assessment per EN 13523-8

Solvent resistance and flexibility validation

This disciplined process ensures consistent performance under high thermal cycling and electrical stress. Our 24/7 production lines feature in-line laser micrometry and automated optical inspection, eliminating manual handling errors and enabling real-time correction of coating defects. Material certifications include full mill test reports with OES chemical analysis and ASTM B244 conductivity verification (≥100% IACS).

Supply chain resilience is engineered into our operations. We maintain strategic copper cathode inventory through direct LME-linked contracts with primary smelters, mitigating market volatility. Dual sourcing for insulation resins and redundant coating lines guarantee 99.2% on-time delivery performance, even during global disruptions. Our logistics hub near Zhengzhou offers multimodal shipping (rail, road, sea) with optimized container loading for reduced transit damage. For urgent requirements, we provide expedited processing within 72 hours of order confirmation.

As a technical partner, we go beyond transactional supply. Our metallurgical team collaborates on material selection, offering finite element analysis (FEA) support for thermal management optimization and custom insulation formulations for extreme environments. Recent innovations include nano-ceramic reinforced coatings for >220°C continuous operation and low-loss strip profiles minimizing eddy currents in high-frequency applications.

Transform your sourcing strategy with a manufacturer committed to engineering excellence. Contact Cathy Zhang, International Sales Manager, at cathy@transformerstrip.com to request material specifications, production capacity schedules, or arrange a virtual factory audit. Specify your required copper grade, insulation class, and dimensional parameters for a tailored technical proposal within 24 business hours. Luoyang Xinzhaohe delivers not just components, but validated performance for the world’s most demanding power systems.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing insulated copper strip directly from China.