Table of Contents

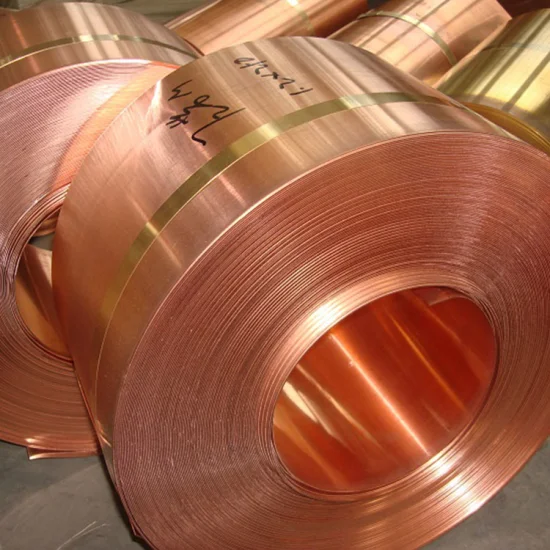

Market Insight: 3Mm Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

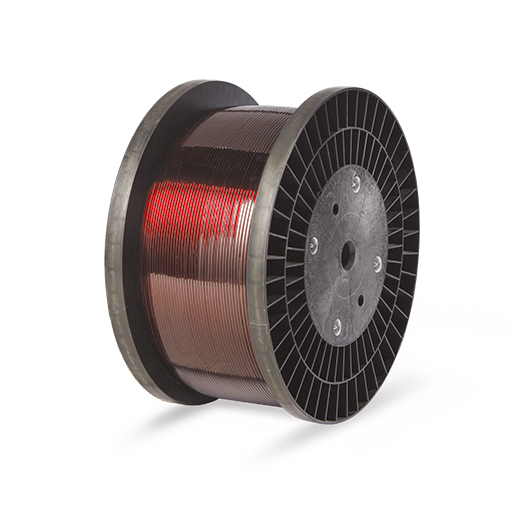

The global transformer industry continues to drive consistent demand for high-performance conductive materials, with copper strip—particularly in the 3mm thickness range—playing a critical role in the manufacture of both distribution and power transformers. As electrical infrastructure expands and modernizes, especially in emerging economies and renewable energy integration projects, the need for reliable, high-conductivity copper strip remains robust. The 3mm dimension is strategically selected for applications requiring a balance between mechanical stability and efficient current carrying capacity, particularly in low- to medium-voltage transformer windings and busbar interconnects.

Copper’s inherent advantages—high electrical conductivity (exceeding 100% IACS for ETP copper), superior thermal dissipation, and excellent formability—make it the material of choice where efficiency and reliability are paramount. In transformer design, the use of 3mm copper strip enables precise winding geometries, reduces resistive losses, and supports compact core-coil configurations. This is especially important in urban substations and industrial facilities where space constraints and energy efficiency standards are stringent.

However, the performance of copper strip in transformer applications is not solely determined by material type; metallurgical quality, dimensional consistency, and surface integrity are equally critical. Variations in thickness tolerance beyond ±0.05mm can lead to uneven magnetic fields, increased eddy current losses, and localized heating. Similarly, surface defects such as scratches, pits, or oxidation can compromise insulation integrity when the strip is wound with varnish or polymer films, potentially leading to dielectric breakdown under operational stress.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialization in transformer-grade strip and foil production, we emphasize strict process control from raw material sourcing to final packaging. Our 3mm copper strip is produced from high-purity (99.99% min) electrolytic tough pitch (ETP) copper, processed through precision rolling mills with laser-guided thickness monitoring. Each batch undergoes rigorous testing for conductivity, tensile strength, and surface roughness to ensure compliance with international standards such as ASTM B187 and IEC 60137.

The shift toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) further elevates the importance of material quality. High-quality copper strip directly contributes to lower no-load and load losses, extending transformer lifespan and reducing total cost of ownership. In high-reliability sectors such as utilities, rail traction, and data centers, the risk of failure due to substandard materials is unacceptable, making certified, traceable supply chains essential.

The following table summarizes key technical parameters for high-grade 3mm copper strip used in transformer applications:

| Parameter | Typical Value | Standard Requirement |

|---|---|---|

| Thickness | 3.0 mm ± 0.05 mm | ASTM B187 |

| Conductivity | ≥ 100% IACS | IEC 60137 |

| Tensile Strength | 200–250 MPa | EN 13605 |

| Elongation | ≥ 4% | GB/T 5231 |

| Surface Roughness (Ra) | ≤ 1.6 µm | Internal Quality Protocol |

In conclusion, while aluminum foil and strip have gained traction in cost-sensitive applications, copper remains the benchmark for performance-critical transformer components. The demand for 3mm copper strip is sustained by technical requirements that prioritize efficiency, durability, and safety. As a specialized supplier, Luoyang Xinzhaohe Aluminum Co., Ltd. supports this demand with engineered materials that meet the highest industrial standards.

Technical Specs: 3Mm Copper Strip

Technical Specifications for Precision 3mm Copper Strip Sourcing

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of specialized metallurgical expertise in high-conductivity transformer strip and foil production to define critical specifications for 3mm copper strip. This thickness is predominantly utilized in high-current busbar assemblies, transformer lead-outs, and structural grounding components where dimensional stability and electrical performance are non-negotiable. Sourcing must prioritize three interdependent technical parameters: precision slitting tolerance, edge integrity, and electrical conductivity. Deviations directly impact winding efficiency, thermal management, and long-term reliability in demanding power applications.

Precision slitting at 3mm thickness requires advanced tension control and ultra-sharp rotary shear technology to achieve the industry-critical ±0.002 mm thickness tolerance. Standard slitting processes often induce micro-deformation at this cross-section, leading to camber or width variation exceeding 0.05 mm. Our proprietary slitting line employs real-time laser micrometry feedback and servo-driven blade positioning to maintain consistent width within ±0.025 mm. Crucially, edge quality must be burr-free with a maximum burr height of 0.005 mm as measured per ASTM B913. Uncontrolled burrs cause insulation puncture during coil winding and create localized heating points under load. We implement dual-stage edge conditioning with precision-ground tungsten carbide blades and post-slit edge brushing to eliminate micro-burrs while preserving the strip’s flatness.

Electrical conductivity must meet or exceed 100% IACS (International Annealed Copper Standard) per ASTM E8, verified at 20°C. This necessitates oxygen-free electronic (OFE) copper with residual element limits strictly controlled: Oxygen ≤ 0.0005%, Phosphorus ≤ 0.0003%, and total impurities < 50 ppm. Lower conductivity grades (e.g., 98% IACS) increase resistive losses by 2-3% in continuous operation, directly reducing transformer efficiency. Surface finish requires a clean, oxide-free profile with Ra ≤ 0.4 µm to ensure optimal solderability and interfacial contact in busbar joints. Mechanical properties must balance formability and rigidity: tensile strength 200-240 MPa and elongation ≥ 40% per ASTM E8.

Critical Parameter Compliance Table

| Parameter | Requirement | Test Standard | Measurement Method |

|---|---|---|---|

| Thickness | 3.000 ± 0.002 mm | ASTM B3 | Laser micrometer (10-point scan) |

| Width Tolerance | ± 0.025 mm | ASTM B3 | Precision calipers + optical comparator |

| Edge Burr Height | ≤ 0.005 mm | ASTM B913 | Optical profilometry |

| Electrical Conductivity | ≥ 100% IACS | ASTM E8 | Eddy current conductivity meter |

| Surface Roughness (Ra) | ≤ 0.4 µm | ASTM B603 | Stylus profilometer |

| Tensile Strength | 200-240 MPa | ASTM E8 | Universal testing machine |

| Elongation | ≥ 40% | ASTM E8 | Universal testing machine |

| Oxygen Content | ≤ 0.0005% | ASTM E1019 | Inert gas fusion analysis |

Material must be supplied in annealed temper (ETP or OFE grade) on non-marring poly-core reels with vacuum-sealed moisture-barrier packaging to prevent surface oxidation during transit. Reels require individual lot traceability via certified mill test reports (MTRs) documenting chemical composition, mechanical properties, and conductivity validation. Non-compliance in any parameter necessitates immediate rejection—particularly edge burrs exceeding 0.005 mm or conductivity below 100% IACS—as these defects propagate catastrophic failure modes in final assembly. Luoyang Xinzhaohe enforces these specifications through in-line SPC monitoring and third-party verification, ensuring zero-defect delivery for mission-critical power infrastructure.

Factory Tour: Manufacturing

Manufacturing Process of 3mm Copper Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 3mm copper strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, mechanical integrity, and surface quality required for high-performance applications in transformers and electrical systems. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology, precision slitting, and edge conditioning, all supported by rigorous quality control protocols.

The process begins with high-purity electrolytic copper cathodes, which are melted and cast into slabs using controlled atmosphere induction furnaces to minimize oxide inclusions and hydrogen embrittlement. These slabs undergo homogenization heat treatment to relieve internal stresses and ensure uniform microstructure before being hot-rolled to intermediate thicknesses. The hot-rolled strips are then pickled to remove surface oxides and scale, preparing them for the cold rolling phase.

Cold rolling is the core stage in achieving the final 3mm thickness. Using computer-controlled 4-high or 6-high rolling mills, the strip is reduced incrementally under precise tension and roll gap settings. This process enhances the material’s mechanical properties by increasing tensile strength and hardness through strain hardening, while maintaining tight thickness tolerances (±0.05mm typical). Roll surface finish is maintained to achieve a consistent surface roughness (Ra ≤ 0.4µm), critical for downstream lamination and insulation compatibility in transformer windings.

Following cold rolling, the copper strip undergoes precision slitting on servo-driven rotary shear lines. Slitting is performed under continuous tension control to prevent edge wave or camber deviation. The strip is cut to the specified width with tolerances held within ±0.1mm, ensuring compatibility with automated winding equipment used by our customers. Knives are inspected and replaced based on a predictive maintenance schedule to avoid burr formation or edge irregularities.

Edge conditioning is the next critical step, particularly for strips intended for transformer coil fabrication. The slit edges are subjected to brushing and edge rounding to remove micro-burrs and sharp asperities that could compromise insulation integrity or cause localized current concentration. This process significantly reduces the risk of dielectric breakdown in service.

Throughout the production flow, in-line and offline quality control measures are enforced. These include continuous laser micrometer monitoring for thickness profile, eddy current testing for subsurface defects, surface inspection via high-resolution cameras, and periodic mechanical testing (tensile strength, elongation, hardness). Each production lot is accompanied by a full material test report (FMTR) compliant with ISO 9001 standards and customer-specific specifications.

This integrated manufacturing approach ensures that every 3mm copper strip produced at Luoyang Xinzhaohe meets the highest standards of performance, reliability, and consistency required in modern power transmission and distribution systems.

Packaging & Logistics

Export Packaging Specifications for 3mm Copper Strip

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for 3mm copper strip shipments, specifically designed to mitigate corrosion and physical damage during extended sea freight transit. With over two decades of experience in transformer-grade strip and foil logistics, our methodology prioritizes material integrity through standardized wooden pallet systems and multi-layer moisture barriers, ensuring compliance with global maritime regulations and client quality expectations.

All copper strip coils are secured to ISPM 15-certified hardwood pallets constructed from kiln-dried tropical species, featuring minimum dimensions of 1100mm x 1100mm x 150mm and a static load capacity of 2500kg. Pallet design incorporates reinforced stringers and chamfered edges to prevent coil deformation during handling, while steel strapping (minimum 16mm width, 500kg tensile strength) anchors coils at four critical points. This structural foundation withstands stacking forces up to 4.5m in containerized cargo holds and absorbs dynamic stresses from vessel motion, eliminating lateral shift risks.

Moisture protection employs a three-tiered barrier system critical for copper’s susceptibility to oxidation and chloride-induced corrosion in marine environments. Primary wrapping utilizes 2.5mm-thick vapor corrosion inhibitor (VCI) polyethylene film, heat-sealed to exclude ambient humidity. Secondary encapsulation adds 0.15mm metallized moisture-proof film with aluminum oxide coating, providing electromagnetic shielding and reducing water vapor transmission rates to <0.5g/m²/day. Finally, desiccant units (minimum 300g per 1m³ enclosed volume) are strategically placed within the sealed cavity to maintain internal relative humidity below 40% throughout voyages exceeding 45 days. This layered approach prevents condensation during tropical-to-temperate climate transitions, a leading cause of surface tarnishing in copper shipments.

Sea freight safety is non-negotiable in our packaging architecture. Ocean transport exposes cargo to salt-laden atmospheres, temperature fluctuations exceeding 40°C, and relative humidity spikes above 95%. Our system counters these hazards through ISO container compatibility—pallets fit precisely within 20ft and 40ft high-cube units with 100mm clearance for ventilation channels. All film seams undergo hermetic sealing verified via vacuum decay testing (≤5% pressure loss over 24 hours), while pallet bases include elevated timber runners to isolate coils from container floor moisture. Crucially, copper strip surface cleanliness is validated pre-packaging per ASTM B348 standards, as residual oils or particulates accelerate electrochemical corrosion under humid conditions.

Quality assurance integrates traceability at every stage. Each pallet receives a serialized QR code linking to material certificates, humidity logs from desiccant indicators, and third-party inspection reports. This protocol has maintained a 99.8% damage-free delivery rate across 12,000+ TEUs shipped since 2015. For clients requiring enhanced protection in ultra-humid routes (e.g., Southeast Asia to South America), we offer nitrogen-purged packaging with real-time IoT humidity monitoring at marginal cost increase.

Our export packaging is not merely a containment solution but a calibrated corrosion management system, reflecting Luoyang Xinzhaohe’s metallurgical expertise in preserving the electrical conductivity and surface finish essential for transformer core lamination. Partnering with our supply chain team ensures seamless integration of these standards into your procurement workflow, eliminating transit-related quality disputes and safeguarding your production continuity.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision 3mm Copper Strip Solutions

With over two decades of specialized experience in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for global manufacturers requiring high-performance conductive materials. Our expertise in metallurgical processing, combined with rigorous quality assurance systems, enables us to deliver 3mm copper strip products that meet exacting international standards for electrical conductivity, mechanical strength, and dimensional consistency.

Our manufacturing facility integrates advanced rolling, annealing, and surface treatment technologies specifically optimized for copper strip production. Utilizing high-purity electrolytic copper (typically ≥99.99% Cu), we ensure minimal impurity levels, which directly enhances conductivity and reduces thermal losses in transformer and inductor applications. The 3mm thickness is maintained within tight tolerances—typically ±0.05mm—through precision cold-rolling under computer-controlled conditions, ensuring uniform cross-sectional profiles and consistent flatness across extended coil lengths.

All copper strips are processed under strictly controlled atmosphere environments to prevent oxidation and surface degradation. Our in-house annealing lines use hydrogen-nitrogen protective atmospheres to achieve optimal recrystallization, resulting in soft, ductile strips with excellent formability and solderability. Surface quality is further enhanced through precision cleaning and passivation, minimizing oxide formation and ensuring compatibility with insulation varnishes and bonding agents used in coil winding processes.

Quality assurance is embedded throughout our production chain. Every batch of 3mm copper strip undergoes comprehensive testing, including tensile strength, elongation, Vickers hardness, and electrical resistivity measurements. Our laboratory is equipped with OES (Optical Emission Spectrometry) for compositional analysis, eddy current testing for surface defect detection, and profilometry for surface roughness evaluation. These protocols ensure compliance with ASTM B187, GB/T 5584, and IEC 60164 standards, making our products suitable for use in high-efficiency transformers, power distribution systems, and industrial electromagnets.

As a vertically integrated supplier, we maintain full control over raw material sourcing, processing, and logistics. This allows us to offer competitive lead times, flexible order volumes, and customized solutions—such as tailored temper conditions (soft, 1/4 hard, or hard), slit widths, and coil IDs/ODs—to meet specific OEM requirements.

Partnering with Luoyang Xinzhaohe means gaining access to a stable, high-capacity supply chain backed by technical expertise in non-ferrous metal processing. We support our clients with material certification packages, technical documentation, and responsive engineering consultation to ensure seamless integration into your production workflows.

For reliable, high-quality 3mm copper strip engineered for performance and consistency, contact us today at cathy@transformerstrip.com. Let Luoyang Xinzhaohe be your strategic supplier in advancing electrical efficiency and manufacturing excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 3mm copper strip directly from China.