Table of Contents

Market Insight: Electrical Steel Price

Market Analysis: Silicon Steel (Electrical Steel)

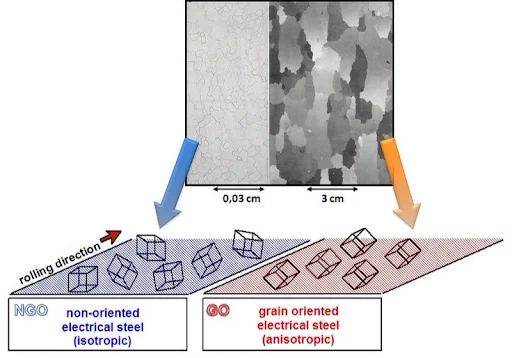

The global demand for silicon steel, commonly referred to as electrical steel, continues to grow in parallel with the expansion of power infrastructure and the increasing efficiency requirements of electrical equipment. As a critical magnetic material, silicon steel is predominantly used in the cores of transformers, electric motors, and generators, where its electromagnetic properties directly influence system performance and energy efficiency. In the transformer industry, electrical steel accounts for a significant portion of core losses, making it a focal point for both design optimization and cost management.

Transformer manufacturers are under continuous pressure to meet evolving energy efficiency standards, such as those defined by IEC 60076, DOE 2016, and other regional regulations. These standards mandate lower no-load and load losses, which can only be achieved through the use of high-quality grain-oriented electrical steel (GOES). The magnetic flux density and core loss characteristics of GOES are directly influenced by alloy composition, grain alignment, and coating integrity—factors that vary significantly between production batches and suppliers. As a result, sourcing decisions must balance cost considerations with long-term performance requirements.

Industrial procurement of electrical steel is highly sensitive to price volatility, which is driven by fluctuations in raw material costs—particularly high-purity iron ore, silicon, and alloying elements—as well as energy-intensive manufacturing processes. Global supply chain dynamics, including trade policies and logistical constraints, further contribute to price instability. However, selecting material based solely on initial cost can lead to higher total cost of ownership due to increased energy losses, reduced equipment lifespan, and potential reliability issues. For instance, inferior electrical steel may exhibit higher hysteresis and eddy current losses, resulting in elevated operating temperatures and decreased transformer efficiency over time.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in advanced metal materials supply, we emphasize the importance of material traceability, consistent quality control, and adherence to international standards. Our silicon steel products undergo rigorous testing for magnetic properties, including core loss (W/kg at 1.7 T, 50 Hz) and magnetic polarization (B800), ensuring compliance with transformer design specifications. We supply both grain-oriented and non-grain-oriented grades, tailored to customer requirements for distribution, power, and specialty transformers.

The following table outlines typical performance parameters for common electrical steel grades used in transformer applications:

| Grade | Core Loss (P1.7/50) (W/kg) | Magnetic Flux Density (B800) (T) | Application |

|---|---|---|---|

| M47-35A | ≤ 1.35 | ≥ 1.90 | Medium-power transformers |

| M35-30A | ≤ 1.15 | ≥ 1.92 | High-efficiency distribution |

| M27-27A | ≤ 0.95 | ≥ 1.95 | Large power transformers |

In conclusion, while electrical steel price remains a key factor in procurement strategy, the technical performance and long-term reliability of the material must not be compromised. A comprehensive sourcing approach considers total lifecycle costs, regulatory compliance, and supply chain stability—factors where Luoyang Xinzhaohe Aluminum Co., Ltd provides measurable value through consistent product quality and technical support.

Technical Specs: Electrical Steel Price

Technical Specifications Governing Electrical Steel Price Determination

Electrical steel price is fundamentally driven by measurable technical performance parameters that directly impact end-product efficiency and manufacturing yield. As a metallurgical supplier with two decades of experience in silicon steel production and supply chain management, Luoyang Xinzhaohe Aluminum Co., Ltd. emphasizes that core loss, magnetic flux density, and flatness are non-negotiable specifications demanding precise evaluation during sourcing. These parameters are intrinsically linked to material composition, processing control, and final application performance, forming the bedrock of cost structure. Procurement professionals must prioritize these quantifiable metrics over generic grade names to ensure value alignment and avoid costly performance shortfalls in motor or transformer cores.

Core loss, or iron loss, measured in watts per kilogram (W/kg) at specific frequencies (typically 50/60 Hz) and peak inductions (e.g., 1.0T, 1.5T, 1.7T), is the single most significant cost driver. It quantifies energy dissipated as heat due to hysteresis and eddy currents during magnetic cycling. Lower core loss values indicate superior magnetic efficiency, achieved through stringent control of silicon content (typically 2.0-3.5%), grain orientation, and insulating coating quality. A reduction of 0.1 W/kg in core loss at 1.5T/50Hz can increase raw material cost by 3-5% due to the complex annealing processes and tighter compositional tolerances required. Suppliers must provide certified test reports per IEC 60404-2 or ASTM A343/A343M; deviations here directly correlate to higher operational energy costs for the end-user.

Magnetic flux density (B₈ or B₅₀), expressed in Tesla (T), defines the maximum magnetic induction achievable under a specified magnetic field strength (e.g., 800 A/m or 5000 A/m). Higher flux density enables smaller, lighter magnetic components but requires precise control of crystallographic texture, particularly in grain-oriented electrical steel (GOES). Non-oriented electrical steel (NOES) typically ranges from 1.50T to 1.75T at 5000 A/m, while high-grade GOES can exceed 1.90T. Achieving flux density above 1.70T necessitates advanced secondary recrystallization processes, significantly impacting production yield and cost. Underspecifying flux density risks core saturation and inefficiency, while overspecifying incurs unnecessary material expense.

Flatness, quantified in I-Units (a dimensionless measure of waviness), is critical for high-speed lamination stamping and core stacking. Excessive flatness deviation causes burrs, misalignment, and increased vibration/noise in assembled cores. Tight flatness tolerances (e.g., < 15 I-Units for critical applications) demand exceptional rolling mill control and tension leveling, directly affecting production throughput and scrap rates. While less impactful on base material cost than core loss, poor flatness escalates downstream manufacturing costs significantly through reduced yield and rework.

The following table summarizes key parameters, their measurement standards, typical ranges, and direct price impact mechanisms:

| Parameter | Measurement Standard | Typical Range (NOES Example) | Primary Price Impact Mechanism |

|---|---|---|---|

| Core Loss (P1.5/50) | IEC 60404-2 | 2.50 – 4.00 W/kg | Tighter loss reduction requires complex annealing, lower yield |

| Flux Density (B50) | IEC 60404-2 | 1.50 – 1.75 T | Higher values demand precise texture control, reduced throughput |

| Flatness | ASTM A688 | 10 – 30 I-Units | Tighter tolerances increase rolling/leveling process complexity |

Procurement strategies must anchor negotiations on certified test data for these parameters against application-specific requirements. Luoyang Xinzhaohe Aluminum Co., Ltd. provides full material traceability and third-party verification to ensure specifications translate directly into predictable performance and lifecycle cost savings, avoiding the hidden premiums of underspecified or inconsistently manufactured electrical steel. Understanding these technical levers is paramount for optimizing total cost of ownership.

Factory Tour: Manufacturing

Manufacturing Process of Electrical Steel at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance electrical steel at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled sequence of precision engineering and metallurgical processing, ensuring compliance with international standards for magnetic efficiency, dimensional accuracy, and surface integrity. With over two decades of experience in advanced metal processing, our manufacturing workflow is optimized for consistency and reliability in supplying silicon steel to the transformer, motor, and generator industries.

The process begins with slitting, where master coils of cold-rolled grain-oriented (CRGO) or non-grain-oriented (CRNGO) silicon steel are unwound and longitudinally cut into narrower strips according to customer specifications. This operation is performed on high-precision slitting lines equipped with servo-controlled tension management systems to prevent edge burring and maintain uniform strip width. Tolerance control during slitting is maintained within ±0.1 mm, ensuring compatibility with downstream processing and final assembly requirements.

Following slitting, the coils undergo annealing in a continuous controlled-atmosphere furnace. This critical thermal treatment relieves internal stresses induced during cold rolling and prior processing, while promoting grain growth and magnetic domain refinement. For grain-oriented materials, the annealing cycle includes a high-temperature soak (up to 1,100°C) under a hydrogen-nitrogen atmosphere to optimize the Goss texture (110)[001], significantly enhancing magnetic permeability and reducing core loss. The annealing profile is precisely programmed based on steel grade, thickness, and silicon content, with real-time monitoring of dew point, temperature uniformity, and furnace atmosphere composition.

After annealing, the material proceeds to insulation coating application. A thin, uniform layer of inorganic or semi-organic insulating coating is applied via roll-coating or spray techniques. This coating serves dual purposes: it provides interlaminar electrical resistance to minimize eddy current losses and enhances mechanical durability during stamping and core assembly. Coating weight is tightly controlled between 0.8–1.5 g/m² per side, with adhesion and dielectric strength rigorously tested. Our proprietary coating formulations are designed for compatibility with varnish-bonding processes used in core manufacturing.

The final stage is precision cutting, where annealed and coated strips are cut into laminations or segments using high-speed turret presses or laser-cutting systems. Tooling is maintained under strict preventive schedules to ensure edge quality and dimensional repeatability. Blank dimensions are verified using optical measurement systems, with tolerances held to ±0.05 mm on critical features.

Throughout the production chain, quality control is integrated at each stage. Incoming material is verified for chemical composition and magnetic properties. During processing, samples are subjected to core loss (W1.5/50), permeability, coating weight, and surface roughness testing. Final inspection includes 100% visual surface scanning and batch sampling per IEC 60404-2 and ASTM A876 standards. All data is documented for full traceability.

Packaging & Logistics

Export Packaging Specifications for Silicon Steel Coil Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to preserve the critical surface integrity and magnetic properties of silicon steel coils during international maritime transport. Decades of metallurgical expertise and global supply chain experience inform our standardized approach, which centers on robust wooden palletization combined with multi-layer moisture barrier protection. This system is non-negotiable for mitigating the primary risk factor in sea freight: moisture-induced corrosion, which irreversibly degrades core loss performance.

Coils are secured onto custom-fabricated, ISPM-15 compliant hardwood pallets. These pallets feature a minimum load-bearing capacity of 2500 kg per coil, engineered with cross-bearers and stringers to distribute weight evenly and prevent deformation under stack loads during vessel stowage. The pallet base incorporates elevated runners, ensuring a minimum 100 mm clearance from the container floor. This elevation is critical for facilitating air circulation beneath the coil package and preventing direct contact with potential condensation or residual moisture within the shipping container. All wooden components undergo kiln-drying to a maximum 20% moisture content prior to assembly, eliminating internal moisture sources.

The primary moisture protection system utilizes a triple-layer wrapping sequence. An initial layer of high-density polyethylene (HDPE) film, minimum 125 microns thick, is tightly wound around the coil face and outer diameter, creating the first physical barrier. This is followed by the strategic placement of industrial-grade desiccant packs (minimum 500g per tonne of steel) within the wrap envelope to actively absorb any residual or ingress moisture. The final and most critical layer is a specialized metallized moisture-proof film. This film provides an exceptional oxygen transmission rate (OTR) below 5 cm³/m²/day and a water vapor transmission rate (WVTR) under 0.5 g/m²/day, forming an impermeable vapor barrier essential for transoceanic voyages exceeding 30 days. All film layers are heat-sealed at seams using calibrated industrial equipment to ensure complete hermeticity, with no gaps or punctures permitted.

This integrated packaging solution is explicitly validated for standard ISO containerized sea freight. It withstands the dynamic stresses of vessel motion, significant humidity fluctuations (0-100% RH), and wide temperature ranges (-25°C to +55°C) encountered during global shipping routes. The pallet dimensions are optimized for efficient container loading (20ft and 40ft HC), maximizing cube utilization while maintaining mandatory clearance from container walls to prevent abrasion. Rigorous internal quality control verifies seal integrity, desiccant placement, and pallet stability for every shipment batch prior to container stuffing. Documentation includes a packing list detailing the specific film specifications and desiccant quantity used.

Key Packaging Parameter Summary

| Parameter | Specification | Purpose |

|---|---|---|

| Pallet Material | ISPM-15 Compliant Hardwood | Regulatory compliance, structural integrity |

| Minimum Load Capacity | 2500 kg per coil | Prevents deformation under stack load |

| Base Clearance | ≥ 100 mm | Enables air circulation, isolates from floor moisture |

| Primary Film Thickness | ≥ 125 microns HDPE | Initial physical moisture barrier |

| Moisture-Proof Film WVTR | < 0.5 g/m²/day | Critical vapor barrier for long voyages |

| Desiccant Quantity | ≥ 500g per tonne of steel | Absorbs residual/internal moisture |

| Container Compatibility | Optimized for 20ft/40ft HC ISO units | Ensures efficient, secure stowage |

This standardized export packaging methodology, refined over 20+ years of global shipments, is fundamental to delivering silicon steel that meets the stringent surface cleanliness and magnetic property requirements demanded by transformer and motor manufacturers worldwide. Partnering with Luoyang Xinzhaohe ensures your electrical steel arrives in optimal condition, ready for immediate processing. Consult our technical team for project-specific packaging validation.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Your Trusted Source for High-Performance Silicon Steel

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-quality silicon steel, also known as electrical steel, to global industrial markets. As a vertically integrated manufacturer with advanced processing capabilities, we deliver precision-engineered materials optimized for magnetic performance, energy efficiency, and long-term reliability in demanding electrical applications.

Our production facility is equipped with state-of-the-art rolling, annealing, and insulating lines designed specifically for non-oriented and grain-oriented silicon steel. These controlled processes ensure tight tolerances in thickness, consistent magnetic flux density (B8), and minimized core loss (W1.5/50), meeting or exceeding international standards such as IEC 60404, GB/T 2521, and JIS C 2550. With an annual production capacity exceeding 150,000 metric tons, we are structured to support both large-volume OEM contracts and specialized batch requirements with reliable lead times.

Material traceability and process control are central to our quality management system. Each coil undergoes rigorous testing for chemical composition, lamination loss, surface insulation resistance, and dimensional accuracy. Our in-house metallurgical laboratory is certified to ISO/IEC 17025 standards, enabling precise characterization of magnetic properties under simulated operating conditions. This technical rigor ensures that our silicon steel performs consistently in critical applications such as power transformers, electric motors, generators, and high-efficiency distribution systems.

We specialize in narrow strip processing, offering slit widths from 10 mm to 1,050 mm and thicknesses ranging from 0.18 mm to 0.65 mm, tailored to customer specifications. Our precision slitting and blanking services reduce downstream processing costs and improve yield for motor lamination stacks and transformer cores. Additionally, we provide customized packaging solutions for international logistics, including moisture-resistant wrapping and ISO-compliant wooden pallets, to maintain material integrity during transit.

As a strategic partner, Luoyang Xinzhaohe combines technical depth with supply chain resilience. We maintain buffer stock of key grades including 50W470, 35W300, and 27W105, enabling rapid fulfillment for urgent projects. Our engineering team collaborates directly with customers to optimize material selection based on operating frequency, core design, and efficiency targets—ensuring cost-performance balance without compromising reliability.

For procurement managers and design engineers seeking a stable, technically capable source of electrical steel, Luoyang Xinzhaohe offers a proven track record in quality consistency, on-time delivery, and responsive technical support. We serve clients across Asia, Europe, and North America, with documentation packages including mill test certificates (MTC), material compliance reports, and RoHS/REACH declarations.

Contact us today to discuss your silicon steel requirements and receive a competitive quotation based on current electrical steel price benchmarks.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum Co., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing electrical steel price directly from China.