Table of Contents

Market Insight: Enamel Covered Copper Wire

Industrial Demand Drivers for Enamel Covered Copper Wire in Transformers

Global transformer manufacturing is experiencing sustained growth, driven by renewable energy integration, electric vehicle charging infrastructure expansion, and aging power grid modernization. Enamel covered copper wire (ECCW) remains the dominant conductor material for transformer windings due to copper’s superior electrical conductivity (100% IACS minimum) and mechanical stability under electromagnetic stress. The International Electrotechnical Commission (IEC) estimates annual ECCW consumption for power and distribution transformers exceeds 1.2 million metric tons, with compound annual growth of 4.7% projected through 2030. This demand is particularly acute in high-efficiency transformer segments (IE3/IE4 classes), where precise winding geometry and thermal management necessitate stringent wire specifications.

Quality parameters in ECCW directly dictate transformer performance, longevity, and safety compliance. Core failure modes stem from enamel defects: insufficient thermal class rating (e.g., Class 155°C vs. required 180°C) accelerates thermal aging, reducing operational lifespan by 40–60% under continuous overload conditions. Dielectric strength below 6 kV/mm permits partial discharges, initiating insulation breakdown. Inconsistent enamel thickness—deviating beyond ±0.005 mm from nominal—creates hotspots during high-frequency operation, increasing no-load losses by 8–12%. Metallurgical purity is equally critical; oxygen-free copper (OFC) with residual oxygen <10 ppm prevents hydrogen embrittlement during vacuum pressure impregnation, whereas impurities like sulfur induce interfacial corrosion between copper and polyester-imide enamel.

The economic impact of substandard ECCW manifests in elevated total cost of ownership. A single transformer failure due to insulation degradation incurs costs 15–20× higher than the initial wire investment, factoring in grid downtime, replacement hardware, and remediation labor. Industry data indicates transformers using ECCW meeting IEC 60317-0 specifications achieve 30–40% lower failure rates over 25-year service cycles compared to non-compliant alternatives. Key quality verification protocols include thermal shock testing (200°C for 30 minutes without cracking), mandrel bend tests per NEMA MW 1000, and accelerated aging per ASTM D2307 to validate thermal index consistency.

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical process control and supply chain rigor to address these quality imperatives. While specializing in aluminum conductor solutions, our cross-material expertise ensures rigorous third-party certification validation for copper wire sourcing—prioritizing suppliers with ISO 9001-certified drawing processes, real-time enamel thickness monitoring via beta-ray gauges, and traceable copper cathode pedigrees. This technical diligence mitigates supply chain volatility while guaranteeing ECCW that meets the thermal, electrical, and mechanical demands of next-generation transformer design. Selecting verified ECCW is not a cost variable but a foundational requirement for grid resilience and lifecycle efficiency.

Technical Specs: Enamel Covered Copper Wire

Technical Specifications for Enamel Covered Copper Wire

Enamel covered copper wire, also known as magnet wire, is a critical component in the manufacturing of electromagnetic devices such as motors, transformers, inductors, and generators. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in winding wire production and metallurgical engineering, we emphasize stringent adherence to technical parameters to ensure reliability, performance, and compliance with international standards including IEC 60317, GB/T 6109, and NEMA MW 1000.

The electrical insulation integrity of enamel covered copper wire is primarily evaluated through insulation breakdown voltage, a measure of the dielectric strength of the polymer coating under specified test conditions. This parameter indicates the maximum voltage the insulation can withstand before electrical failure occurs. For standard applications, breakdown voltage is tested using a step-voltage method at room temperature, with values increasing proportionally with wire diameter. High-performance insulation systems must maintain consistent breakdown performance even after thermal aging and mechanical stress, ensuring long-term operational safety in demanding environments.

Elongation is another key mechanical property, reflecting the ductility of the copper conductor. It is defined as the percentage increase in length before fracture during a tensile test. A minimum elongation of 10% is typically required for most magnet wire grades, with high-flexibility variants exceeding 20%. Adequate elongation ensures the wire can withstand winding processes without cracking the enamel insulation or fracturing the conductor, particularly in tight-radius coil formations.

Thermal classification defines the maximum continuous operating temperature for which the insulation system retains its dielectric and mechanical properties over a 20,000-hour service life. Thermal classes range from 130°C to 220°C, with common grades including 155, 180, 200, and 220. Higher thermal classes utilize advanced polymer coatings such as polyimide, polyamide-imide, or polyester-imide, offering superior thermal stability and chemical resistance. The selection of thermal class is directly tied to the application’s thermal management design and expected service conditions.

The following table outlines the core technical parameters for enamel covered copper wire as manufactured and supplied by Luoyang Xinzhaohe Aluminum Co., Ltd:

| Parameter | Test Method | Typical Range / Value | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-1 | 1.5 kV to 8.0 kV (depending on diameter) | Measured at 90% probability of no failure |

| Elongation (min) | GB/T 4909.4 | 10% – 25% | Depends on temper and diameter |

| Thermal Class | IEC 60085 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on insulation system |

| Conductor Resistivity | GB/T 3048.2 | ≤ 0.017241 Ω·mm²/m at 20°C | High-purity electrolytic copper |

| Winding Mandrel Ratio | IEC 60317 | 1x to 5x conductor diameter | Mandrel test for enamel adhesion |

These specifications are maintained through rigorous in-process quality control, including continuous monitoring of drawing tension, enamel coating thickness, and cure oven profiles. Consistency in these parameters ensures uniform performance across production batches and compatibility with automated winding equipment used in industrial manufacturing.

Factory Tour: Manufacturing

Manufacturing Process for Enamel Covered Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to produce high-reliability enamel covered copper wire for demanding winding applications. Our vertically integrated process ensures stringent control from raw material to finished product, adhering to IEC 60317 and ASTM B117 standards. The production sequence comprises four critical phases: Rod Drawing, Annealing, Enameling, and Inline Testing, each incorporating multi-stage quality verification.

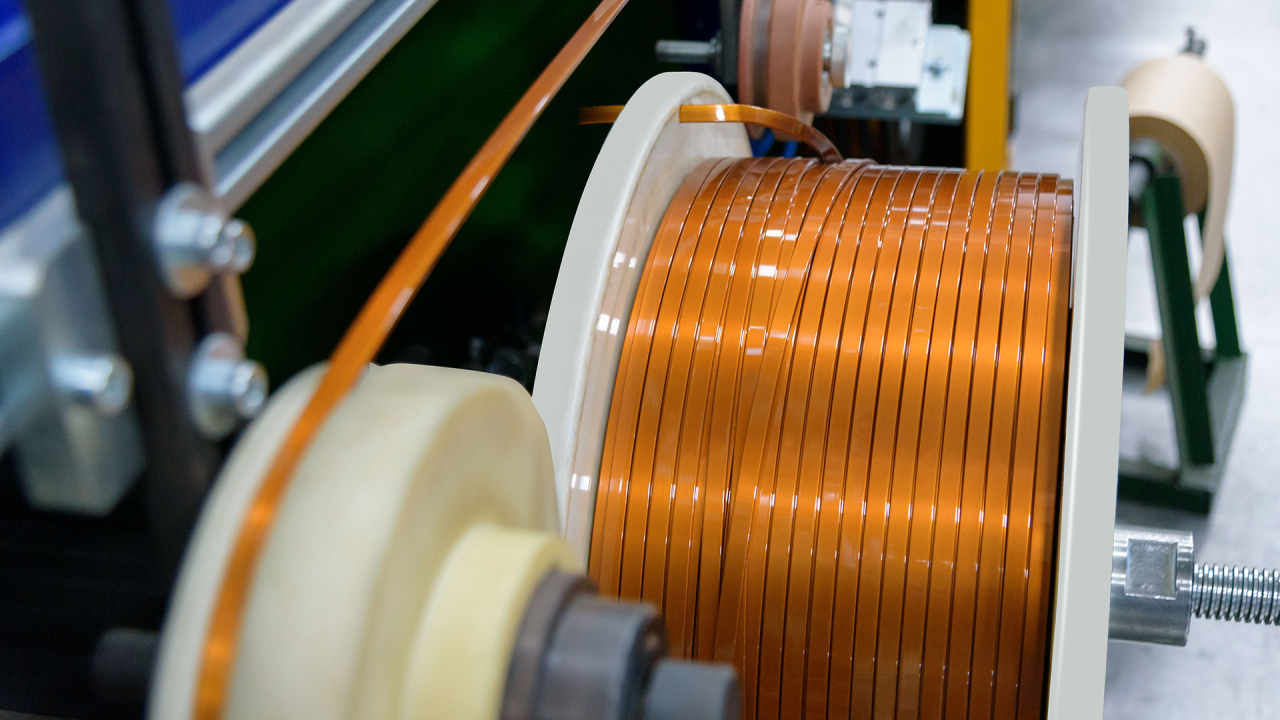

Rod Drawing initiates with oxygen-free copper rod (minimum 101% IACS conductivity) processed through precision diamond or tungsten carbide dies. This cold-working stage reduces diameter to the target wire gauge under controlled tension and lubrication, minimizing surface defects. Continuous laser micrometry monitors dimensional tolerance within ±0.003 mm, while在线 ultrasonic inspection detects subsurface inclusions. Rod surface cleanliness is validated via automated optical scanning to prevent enamel adhesion failure.

Annealing follows to restore ductility and electrical properties after cold working. Wire traverses a nitrogen-purged, resistance-heated furnace at 450–550°C, precisely regulating time-temperature profiles to achieve full recrystallization without grain coarsening. Post-anneal conductivity is verified at 100% IACS minimum using eddy current sensors, with tensile strength maintained at 200–250 MPa. Oxygen content is held below 10 ppm to prevent oxide formation, critical for subsequent enamel bonding.

Enameling applies polymer insulation via multi-zone die coating systems. Single or multiple layers of polyester, polyamide-imide, or self-bonding resins are deposited with micron-level accuracy. Solvent evaporation and polymerization occur in staged ovens (250–450°C), with viscosity and solids content continuously adjusted to ensure uniform coverage. Critical enamel parameters are validated through inline quality checks:

| Parameter | Test Method | Tolerance |

|---|---|---|

| Thickness | Laser micrometer | ±5% of nominal |

| Pinholes | High-voltage spark test | 0 defects per 1000m |

| Adhesion | Mandrel wrap test | No flaking at 6x diameter bend |

| Thermal Class | Thermal endurance oven | Meets 130°C–240°C rating |

Final Inline Testing subjects every meter to 100% electrical and mechanical validation. High-frequency eddy current systems detect micro-cracks, while tensile testers confirm elongation (≥15%) and yield strength. Voltage breakdown tests at 3x operating voltage ensure dielectric integrity, and automated vision systems inspect for surface irregularities. All data is logged per batch for full traceability, with statistical process control (SPC) charts monitoring Cp/Cpk indices in real time.

This integrated approach—combining metallurgical precision with closed-loop quality control—delivers enamel wire with exceptional thermal stability, solderability, and winding performance. Luoyang Xinzhaohe’s process discipline guarantees zero-defect supply for motors, transformers, and EV components where failure is not an option.

Packaging & Logistics

Export Packaging for Enamel Covered Copper Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wire products, we recognize that the performance and reliability of enamel covered copper wire begin long before it reaches the production floor. A critical yet often underestimated component of product integrity is export packaging—specifically engineered to withstand the rigors of international sea freight while preserving the wire’s electrical and mechanical properties.

For all export shipments of enamel covered copper wire, we employ a robust, multi-layer packaging system centered on wooden pallets and high-performance moisture-proof film. This system is designed to meet the stringent demands of maritime logistics, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress are inherent risks.

Each coil of enamel covered copper wire is first wound on precision-machined spools that prevent deformation during handling. The coil is then sealed with a transparent, multi-laminated moisture-proof film that acts as a vapor barrier, protecting against salt-laden air and condensation commonly encountered during ocean transport. This film is heat-shrunk to ensure a tight, tamper-resistant enclosure that maintains a controlled micro-environment around the product.

The sealed coils are then securely mounted onto custom-engineered wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to distribute load evenly, resist compression under stacking, and endure repeated forklift handling at ports and warehouses. All wooden components are treated to prevent infestation and comply with international phytosanitary regulations, ensuring smooth customs clearance across global markets.

Coils are arranged on the pallet in configurations that optimize space utilization without compromising structural stability. Additional edge protectors and corner boards are applied where necessary to reinforce the load, and the entire assembly is unitized using steel or polyester strapping anchored to the pallet base. This ensures that the load remains intact even under dynamic stress conditions such as vessel pitching or container swaying.

All packaged units are clearly labeled with essential shipment data, including batch number, wire specification, net weight, and handling instructions. Hazard and orientation labels are applied in accordance with IMDG and IATA regulations where applicable, further enhancing transport safety.

This packaging methodology has been validated through years of successful deliveries to North America, Europe, Southeast Asia, and the Middle East. It reflects our commitment to delivering enamel covered copper wire in optimal condition, regardless of transit duration or route complexity.

By integrating material science, logistics engineering, and international regulatory compliance, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every meter of wire arrives with the same performance characteristics as when it left our facility.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Precision Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical engineering expertise to deliver rigorously controlled enamel covered copper winding wire for mission-critical electromagnetic applications. Our vertically integrated production ecosystem—spanning raw material refinement to final coating—ensures uncompromising adherence to IEC 60317 and ASTM B994 standards. Unlike commodity suppliers, we deploy proprietary annealing protocols that optimize copper grain structure for enhanced ductility and thermal fatigue resistance, directly impacting end-product lifespan in transformers, motors, and inductors.

Our ISO 9001-certified facility houses six fully automated enamel application lines with real-time viscosity and film thickness monitoring. This precision enables consistent production across 0.08 mm to 3.00 mm wire diameters, supporting thermal classes from 130°C (Class B) to 240°C (Class C). Key differentiators include triple-layer polyurethane-polyester-imide (PEI) formulations for superior chemical resistance and partial discharge suppression, alongside halogen-free options meeting RoHS 3 and REACH compliance. Every batch undergoes 100% spark testing at 3x operating voltage and mandrel winding verification per IEC 60851-5, with traceable certificates of conformance detailing conductivity (≥98% IACS), elongation (≥12%), and dielectric strength (≥6 kV).

Supply chain resilience is engineered into our operational framework. We maintain strategic partnerships with Tier-1 electrolytic tough pitch (ETP) copper suppliers, enabling full material traceability from cathode to finished coil. Our dual-warehouse system in Henan Province guarantees 15-day lead times for standard orders up to 50 MT, with JIT delivery coordination for OEMs. For high-reliability sectors like automotive and renewable energy, we implement PPAP Level 3 documentation and APQP-aligned process validation, reducing qualification cycles by 30% versus industry averages.

| Parameter | Standard Range | Xinzhaohe Precision Tolerance |

|---|---|---|

| Diameter Tolerance | IEC ±2.5% | ±1.8% (0.10–1.00 mm) |

| Elongation | Min. 8% (IEC Class 180) | 12–18% (Controlled Annealing) |

| Thermal Shock | Pass at 200°C | Pass at 220°C (Class 220) |

| Solvent Resistance | 3/5 cycles | 5/5 cycles (MEK Rub Test) |

Partnering with Xinzhaohe eliminates supply volatility through metallurgical oversight you cannot replicate externally. We co-engineer solutions for challenging thermal management scenarios—such as high-frequency inverters requiring Class 240 stability—using in-house thermal gravimetric analysis (TGA) and dynamic mechanical testing. Request our technical datasheets or schedule a metallurgical consultation to validate wire performance against your specific flux density and thermal cycling requirements. Contact Cathy Zhang directly at cathy@transformerstrip.com to initiate material qualification or discuss custom enamel formulations for next-generation power systems. Our engineering team stands ready to deliver wire that meets your exacting electrical and mechanical specifications.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamel covered copper wire directly from China.