Table of Contents

Market Insight: Varnished Copper Wire

Market Analysis: Winding Wire Demand for Transformers

Industrial demand for varnished copper winding wire remains robust and structurally critical, primarily driven by the global power infrastructure sector. Power transformers, essential for transmission and distribution networks, constitute the largest single application segment. This demand is underpinned by continuous grid modernization programs, particularly in emerging economies, and the accelerating integration of renewable energy sources requiring extensive new substation infrastructure. Distribution transformers, deployed in vast quantities across urban and rural settings to step down voltage for end-users, represent another massive, steady-state market. The shift towards higher efficiency standards globally, such as DOE Level 4 in the US and IE4/IE5 in the EU, directly increases the required volume and performance specifications of winding wire per unit, as lower losses necessitate larger conductor cross-sections and superior insulation systems. Furthermore, the proliferation of power electronics in applications like solar inverters and EV charging stations drives demand for smaller, specialized transformers requiring high-frequency capable wire with exceptional dielectric integrity.

Quality in varnished copper wire is not merely a specification checkbox; it is a fundamental determinant of transformer reliability, lifespan, and operational efficiency. Substandard wire introduces multiple failure vectors with severe financial and safety consequences. Copper purity is paramount; conductivity must consistently exceed 100% IACS (International Annealed Copper Standard), typically requiring oxygen-free electronic (OFE) copper with minimum 99.97% purity. Impurities like sulfur or phosphorus create localized hotspots under load, accelerating thermal degradation and potentially initiating catastrophic failures. The enamel insulation system must exhibit exceptional thermal endurance (rated Class 155, 180, or 200 per IEC 60851), maintaining dielectric strength and adhesion through repeated thermal cycling inherent in transformer operation. Inadequate thermal class or poor adhesion leads to insulation embrittlement, cracking, and eventual inter-turn or layer-to-layer short circuits. Mechanical properties are equally critical; precise elongation control (typically 2-5%) ensures the wire withstands the significant tensile stresses during high-speed winding without breakage or permanent deformation, which compromises coil integrity and thermal performance. Crucially, the insulation must possess high partial discharge inception voltage (PDIV) to resist the damaging effects of micro-discharges within voids, a key factor in long-term reliability especially under the demanding duty cycles of modern grids and renewable integration.

The consequences of compromised wire quality manifest as premature transformer failures, unplanned outages, costly field replacements, and significant energy losses over the asset’s lifetime. A mere 0.1% reduction in conductivity across a national grid translates to megawatts of wasted energy annually. Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical and enameling process control to ensure every reel meets the stringent demands of transformer manufacturers. Our rigorous in-process monitoring of copper microstructure, enamel cure profiles, and final product testing against IEC 60317 standards provides the assurance that the winding wire forms the reliable, efficient core essential for next-generation power infrastructure resilience. Supplier capability in consistent quality execution directly correlates with the end-user’s asset performance and total cost of ownership.

Technical Specs: Varnished Copper Wire

Technical Specifications for Varnished Copper Wire

Varnished copper wire, also known as magnet wire or winding wire, is a critical component in electrical and electronic equipment requiring high-efficiency electromagnetic performance. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and wire manufacturing expertise, we ensure strict adherence to international standards—such as IEC 60317, GB/T 6109, and ASTM B286—for the production of high-purity electrolytic tough pitch (ETP) copper conductors with precision-applied polymer insulation systems. The core technical parameters defining performance include insulation breakdown voltage, elongation, and thermal class, each directly influencing reliability, durability, and operational safety.

Insulation breakdown voltage is a key indicator of dielectric strength, measuring the maximum voltage the insulation layer can withstand before electrical failure occurs. For varnished copper wire, this value is determined under standardized test conditions (typically at room temperature with a ramp rate of 500 V/s). Higher breakdown voltages correlate with improved insulation integrity, essential in high-voltage windings used in motors, transformers, and generators. Our standard enamel systems—comprising single, heavy, or multiple coatings of polyurethane, polyester, or polyamide-imide—deliver breakdown voltages ranging from 3,000 V to over 10,000 V, depending on wire diameter and insulation build.

Elongation, expressed as a percentage, reflects the ductility of the copper conductor and its ability to withstand mechanical deformation during winding operations without fracturing. A minimum elongation of 10% is required for most industrial applications, though our premium-grade wires achieve 20–40% elongation due to optimized annealing processes and oxygen-controlled drawing environments. High elongation ensures crack resistance in tight coil bends and reduces in-service failures due to vibration or thermal cycling.

Thermal class defines the maximum continuous operating temperature the insulation system can endure while maintaining dielectric and mechanical properties over a 20,000-hour service life. Our varnished copper wires are engineered for thermal classes from 130°C to 220°C. Lower classes (130, 155) typically use polyester or polyester-imide coatings, while higher classes (180, 200, 220) employ advanced polyamide-imide or self-supporting ceramic coatings. Each thermal class is validated through accelerated aging tests per IEC 60172, ensuring long-term thermal stability and resistance to thermal shock.

The following table outlines representative technical parameters across our product range:

| Parameter | Test Standard | Typical Range | Units |

|---|---|---|---|

| Conductor Purity | GB/T 5231, ASTM B1 | ≥ 99.90% Cu | % |

| Insulation Breakdown Voltage | IEC 60317-0-1 | 3,000 – 10,000 (depending on Ø) | V RMS |

| Elongation | GB/T 4909.4 | 20 – 40 | % |

| Thermal Class | IEC 60172, GB/T 11021 | 130, 155, 180, 200, 220 | °C |

| Tensile Strength | GB/T 4909.3 | 200 – 350 | MPa |

| Solderability (260°C, 5s) | IEC 60317-0-8 | Smooth, continuous wetting | Pass/Fail |

These specifications are maintained through rigorous in-line monitoring, including laser diameter gauging, spark testing, and automated thermal profiling. Luoyang Xinzhaohe Aluminum Co., Ltd guarantees consistency across production batches, supporting OEMs with reliable, high-performance varnished copper wire suitable for demanding industrial environments.

Factory Tour: Manufacturing

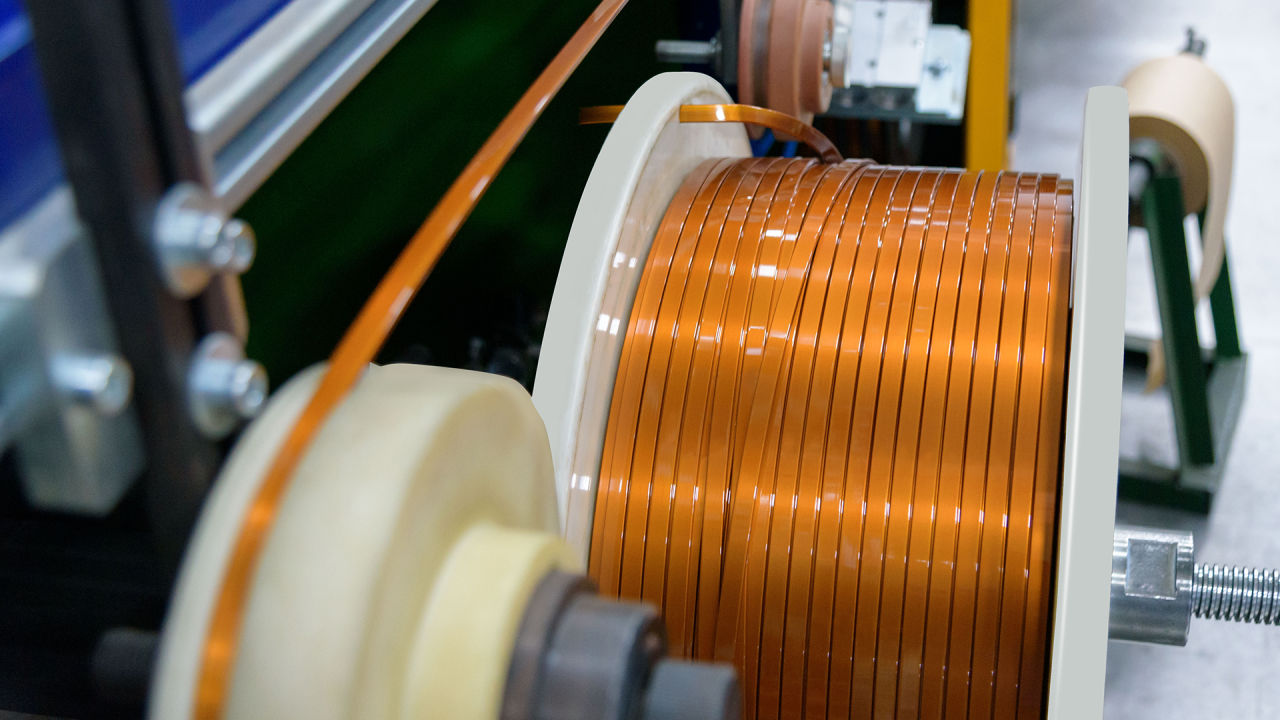

Manufacturing Process for Precision Varnished Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO.,LTD leverages over two decades of metallurgical and process engineering expertise to produce high-reliability varnished copper winding wire. Our vertically integrated production line strictly adheres to international quality standards, ensuring consistent electrical, thermal, and mechanical performance for demanding motor, transformer, and coil applications. The core manufacturing sequence comprises four critical, interdependent stages with embedded quality control checkpoints.

Rod drawing initiates the process using high-purity electrolytic tough pitch (ETP) or oxygen-free high-conductivity (OFHC) copper rod meeting ASTM B3/B350 specifications. Rods undergo rigorous incoming inspection for chemical composition (Cu ≥ 99.90%, Ag ≤ 0.03%, O ≤ 0.04%) and surface integrity. Drawing occurs through precision tungsten carbide or diamond dies in multi-pass continuous blocks under controlled tension and lubrication. Critical parameters include die geometry, reduction ratio per pass (typically 10-25%), and drawing speed. In-process QC verifies wire diameter tolerance (±0.002 mm for fine gauges), surface smoothness via optical inspection, and absence of scratches or pits after each reduction stage. Final drawn wire is spooled under constant tension to prevent looping.

Annealing follows immediately via a continuous in-line resistance or induction furnace system. This critical thermal treatment restores ductility lost during drawing by recrystallizing the copper grain structure. Temperature is precisely controlled between 450°C and 600°C in an inert nitrogen-hydrogen atmosphere (dew point ≤ -40°C) to prevent oxidation and ensure optimal conductivity recovery. Residence time is calibrated to the wire gauge and line speed. Post-annealing QC includes mandatory 100% conductivity verification (≥ 100% IACS per ASTM E8) using eddy current testing and microhardness spot checks (target 60-85 HV) to confirm uniform softening.

The enameled coating application employs advanced multi-layer die coating technology. Wire traverses a precision applicator die where liquid polymer resin (typically polyester, polyamide-imide, or solderable polyurethane) is metered under controlled viscosity and pressure. Multiple coating and curing stages may be used for complex insulation systems. Curing occurs in high-temperature ovens (300°C – 450°C) with precise dwell time and oxygen-controlled atmospheres to achieve complete polymerization without degradation. Critical QC measurements include dry film thickness (DFT) via laser micrometry (±2.5% tolerance), pinhole detection via high-voltage spark testing (minimum 3kV for 0.5mm wire), and adhesion testing per NEMA MW 1000.

Final inline testing constitutes the last barrier before spooling. Every meter undergoes 100% electrical integrity validation through spark testing at specified voltages. Simultaneously, diameter consistency is monitored via laser gauging with real-time feedback to the coating system. Finished reels are labeled with traceable lot numbers and subjected to destructive sampling for thermal endurance (class rating verification), solderability, and flexibility per IEC 60851. Comprehensive batch documentation, including process parameter logs and QC certificates, accompanies all shipments to ensure full supply chain transparency and compliance.

Packaging & Logistics

Export Packaging for Varnished Copper Winding Wire – Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wire products, we recognize that packaging is not merely a logistical necessity but a critical component in preserving the integrity of varnished copper wire during international transit. Our export packaging protocols are engineered to meet the rigorous demands of sea freight, where extended exposure to humidity, temperature fluctuations, and mechanical stress can compromise product quality if not properly mitigated.

All varnished copper wire destined for export is systematically wound onto high-strength cardboard or plastic spools, which are then secured to robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to support heavy coil weights while maintaining structural integrity under dynamic loading conditions typical in containerized shipping. The use of treated timber ensures compliance with international phytosanitary standards, preventing delays at customs and minimizing the risk of pest infestation during long-haul ocean transport.

Once spooled and palletized, each wire assembly is wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier is critical in protecting the enamel insulation from moisture absorption, which can degrade dielectric strength and lead to premature failure in end-use applications such as motors, transformers, and electromechanical devices. The film is heat-sealed at all seams to form a continuous enclosure, significantly reducing the potential for condensation within the package—common during tropical transits or when crossing climatic zones.

In addition to film wrapping, desiccant packs are strategically placed within the sealed envelope to absorb residual moisture and maintain a low-humidity microenvironment throughout the shipment’s journey. For orders requiring enhanced protection, vacuum-sealed packaging or the inclusion of humidity indicator cards can be implemented upon customer request.

All packaged units are clearly labeled with permanent, weather-resistant markings indicating product specifications, batch numbers, net weight, handling instructions, and orientation arrows to prevent inversion during loading. This traceability ensures full compliance with ISO 9001 quality management standards and facilitates efficient inventory management upon arrival at the destination facility.

Our packaging methodology has been validated through years of successful deliveries across Southeast Asia, the Middle East, Europe, and South America. By integrating structural durability with advanced moisture control, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every coil of varnished copper wire arrives in the same condition as it left our facility—ready for immediate processing and integration into high-performance electrical systems.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Varnished Copper Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise and vertically integrated supply chain management to deliver industry-leading varnished copper winding wire. Our facility operates as a specialized copper wire production hub within our broader non-ferrous metals ecosystem, ensuring strict control over raw material sourcing, processing, and final product integrity. Unlike generalist suppliers, we focus exclusively on high-performance electromagnetic wire for demanding applications including transformers, motors, and industrial coils, where dimensional precision and insulation reliability are non-negotiable.

Our production capacity exceeds 50,000 metric tons annually across three automated manufacturing lines. Each line integrates continuous annealing, precision drawing, and multi-layer enamel application under ISO 9001-certified protocols. We process only oxygen-free copper (OFC) with minimum 99.99% purity, achieving conductivity of 100% IACS ±1% as verified by in-house spectrometry and eddy current testing. Wire diameters range from 0.05 mm to 5.0 mm, with enamel systems including polyesterimide (PEI), polyamide-imide (PAI), and self-bonding variants rated for 130°C to 240°C thermal classes. Critical process parameters—tensile strength, elongation, dielectric strength, and thermal shock resistance—are monitored in real-time via PLC-controlled systems, ensuring batch-to-batch consistency within ±0.001 mm tolerance.

Quality assurance extends beyond compliance. Our laboratory conducts accelerated aging tests per IEC 60851 standards, including 100% spark testing at 3x operating voltage and solvent resistance validation. All wire undergoes 100% visual inspection via high-speed cameras detecting surface defects as small as 10 microns. This rigorous approach yields a field failure rate below 50 PPM, significantly below industry benchmarks. Our supply chain advantage stems from direct partnerships with copper cathode producers in Chile and Zambia, mitigating raw material volatility. We maintain strategic inventory buffers for 30+ enamel formulations, enabling 15-day lead times for standard orders and JIT delivery coordination for volume contracts.

For global clients, we provide full documentation traceability from cathode lot to finished spool, including MTRs, RoHS/REACH compliance certificates, and custom packaging for export logistics. Our engineering team collaborates on application-specific formulations—such as low-skin-effect wire for high-frequency transformers or moisture-resistant enamels for marine environments—reducing your R&D cycle time by up to 40%.

Partner with Luoyang Xinzhaohe to eliminate supply chain bottlenecks and elevate product performance. Contact Cathy Zhang, Technical Sales Manager, at cathy@transformerstrip.com to request our full technical datasheet, sample reels, or a customized capacity allocation plan. Specify your required wire grade, annual volume, and application parameters for a targeted solution within 24 business hours.

| Key Performance Indicator | Luoyang Xinzhaohe Standard | Industry Average |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm | ±0.003 mm |

| Dielectric Strength | 6 kV/min (min) | 4.5 kV/min |

| Thermal Shock Resistance | Pass 20 cycles (200°C) | Pass 15 cycles |

| Lead Time (Standard Order) | 15 days | 25-30 days |

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing varnished copper wire directly from China.