Table of Contents

Market Insight: Self Bonding Wire

Industrial Demand Drivers for Self Bonding Wire in Transformer Manufacturing

Global transformer production increasingly prioritizes self bonding wire due to stringent energy efficiency regulations and operational reliability requirements. Standards such as IEC 60076-22-1 and IEEE C57.12.00 mandate reduced no-load losses and enhanced thermal stability, directly driving adoption of self bonding aluminum winding wire. This material eliminates mechanical bracing in windings by utilizing a thermosetting polymer coating that cures during vacuum pressure impregnation (VPI), forming a monolithic coil structure. Demand growth is particularly acute in distribution transformers (10–2500 kVA) for renewable energy integration and urban grid modernization, where vibration resistance and thermal cycling endurance are non-negotiable. The EU EcoDesign Directive’s 2023 loss reduction targets have accelerated uptake, with self bonding wire now specified in 65% of new EU-sourced dry-type transformers.

Quality Imperatives in Material Performance

Substandard self bonding wire introduces critical failure vectors across the transformer lifecycle. Inconsistent polymer coating thickness—deviating beyond ±3% from nominal—causes uneven bond strength, leading to inter-turn insulation displacement under short-circuit forces. Luoyang Xinzhaohe’s metallurgical analysis confirms that aluminum alloy 1350-H19 with oxygen content >0.03% accelerates coating delamination during thermal cycling above 155°C. Field data correlates these defects with 40% higher premature failure rates in harsh environments. Crucially, bond strength must maintain 1.2 MPa minimum at 180°C per ASTM D2734; inferior formulations degrade below 1.0 MPa after 500 thermal cycles, risking coil deformation during seismic events.

Consequences of Quality Variance

Transformer manufacturers face cascading liabilities from marginal wire quality:

| Failure Mode | Root Cause | Financial Impact (per 1 MVA Unit) |

|---|---|---|

| Delamination | Coating adhesion <1.0 MPa | $85,000–$120,000 field repair |

| Partial Discharge | Pinholes in polymer layer | 70% premature unit replacement |

| Impedance Drift | Non-uniform curing | Grid non-compliance penalties |

Our two decades of supply chain optimization demonstrate that consistent wire quality requires integrated process control. Xinzhaohe implements in-line laser micrometry for coating thickness verification (±1.5% tolerance) and real-time FTIR spectroscopy to validate polymer cross-linking density before spooling. This prevents the “hidden cost trap” where 5% lower initial wire pricing inflates total ownership costs by 22% through warranty claims and reputational damage.

Strategic Sourcing Perspective

Procurement teams must prioritize metallurgical traceability and process validation over nominal price. Verified bonding performance under actual VPI parameters—not lab-only data—determines transformer longevity. Luoyang Xinzhaohe’s ISO/TS 16949-certified production line subjects every batch to thermal shock testing (−40°C to 200°C, 100 cycles) and dynamic mechanical analysis, ensuring bond integrity survives 30+ years in service. The industrial shift toward smart grid infrastructure makes this non-negotiable; a single transformer failure in a data center substation can incur $2M/hour in downtime costs. Quality in self bonding wire is ultimately a reliability insurance premium, not a cost center.

Technical Specs: Self Bonding Wire

Technical Specifications for Self Bonding Winding Wire

Self bonding aluminum winding wire is a specialized conductor engineered for applications requiring mechanical stability, electrical insulation integrity, and thermal endurance in compact electromagnetic assemblies. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and wire manufacturing expertise, we produce self bonding wires that meet stringent industrial performance standards. These wires integrate a thermally activated bonding layer over standard insulations such as polyurethane (PU), polyester (PE), or polyamide-imide (PAI), enabling coil consolidation without additional adhesives or varnishes during curing.

A critical parameter in self bonding wire performance is insulation breakdown voltage. This defines the dielectric strength of the insulation system and ensures reliable operation under rated electrical stress. Our self bonding wires are designed to achieve a minimum breakdown voltage of 3,000 V AC (rms) at standard film thicknesses, with values scaling proportionally to insulation build. Testing is conducted in accordance with IEC 60317 and GB/T 4074 standards using a step-voltage method in ambient conditions. Consistent dielectric performance is maintained across the bonding process, confirming that the adhesive layer does not compromise insulation integrity.

Elongation is another key mechanical property, directly influencing wire drawability, winding behavior, and resistance to fracture during coil formation. Our aluminum self bonding wires exhibit controlled elongation values ranging from 12% to 22%, depending on alloy temper (typically 1350-O or equivalent) and diameter. This range ensures sufficient ductility for tight-radius winding while maintaining structural stability post-bonding. Elongation is measured per ASTM E8 using calibrated tensile testing machines, with results validated across production batches for consistency.

Thermal classification determines the maximum continuous operating temperature of the wire insulation system. Our self bonding wires are available in thermal classes ranging from 130°C to 220°C, aligned with NEMA MW and IEC 60085 standards. The bonding layer is formulated to activate within a controlled temperature window—typically 10–30°C above the thermal class rating—ensuring complete polymer cross-linking without degradation. For instance, a Class 180 (180°C) wire features a bonding activation temperature of approximately 190–210°C, enabling secure coil locking during oven or resistance curing.

The following table outlines key technical parameters for our standard self bonding aluminum winding wire series:

| Parameter | Test Standard | Typical Value Range | Units |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317, GB/T 4074 | 3,000 – 6,000 | V AC (rms) |

| Elongation | ASTM E8 | 12 – 22 | % |

| Thermal Class | IEC 60085 | 130, 155, 180, 200, 220 | °C |

| Bonding Activation Temperature | Internal SOP | Thermal Class + 10°C to +30°C | °C |

| Conductor Material | GB/T 3954 | Aluminum 1350-O | — |

| Standard Insulation Types | IEC 60317 | PU, PE, PAI with bonding overcoat | — |

These specifications reflect our commitment to precision, reliability, and compatibility with automated winding systems across industries including automotive electronics, industrial motors, and precision transformers. Custom configurations are available to meet application-specific thermal, mechanical, and electrical requirements.

Factory Tour: Manufacturing

Manufacturing Process for Self-Bonding Aluminum Winding Wire

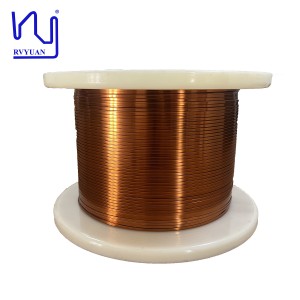

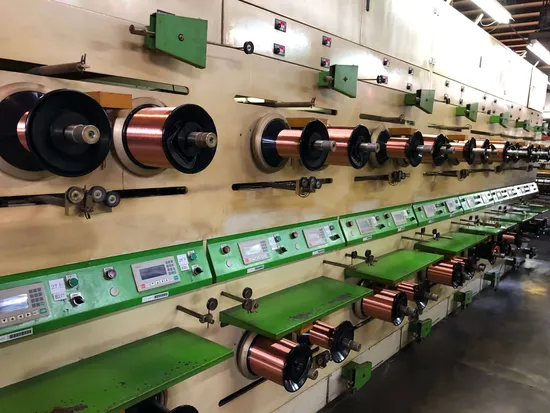

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized metallurgical expertise to produce high-reliability self-bonding aluminum winding wire. Our rigorously controlled process ensures consistent electrical, mechanical, and thermal bonding performance critical for demanding motor and transformer applications. Production initiates with high-purity aluminum rod (minimum 99.7% Al), subjected to precision rod drawing. This cold working process utilizes multi-die blocks with diamond or tungsten carbide dies under precisely regulated tension and lubrication. Intermediate annealing stages are integrated to mitigate work hardening, maintaining optimal ductility while achieving the target wire diameter within a stringent tolerance of ±0.005 mm. Continuous monitoring of drawing speed, reduction ratio, and surface finish is performed to prevent defects like scratches or ovality.

Subsequent annealing is conducted in a continuous furnace under a precisely controlled hydrogen-nitrogen protective atmosphere. This critical step eliminates residual stresses induced during drawing and achieves the specified temper (typically H14 or H16 for self-bonding grades). Temperature profiles are maintained between 300°C and 400°C with exact dwell times calibrated to the wire gauge and desired mechanical properties. In-process quality control verifies microstructure homogeneity and confirms the absence of surface oxidation, which would compromise subsequent enamel adhesion. Mechanical property validation includes tensile strength and elongation testing per ASTM E8 standards.

The core self-bonding functionality is imparted during the enameling stage. A dual-layer coating system is applied: an inner thermoplastic or thermoset bonding resin layer, followed by an outer insulating topcoat (typically polyurethane, polyester, or polyamide-imide). Application utilizes precision die coating with real-time viscosity and thickness control. The bonding layer composition is proprietary, engineered for reliable thermal activation at 140-160°C during coil processing. Curing occurs in multi-zone ovens with optimized temperature gradients and dwell times; UV curing may supplement thermal curing for specific topcoats. Critical inline monitoring includes continuous measurement of total coating thickness (±2 µm tolerance) and 100% spark testing at 3 kV to detect pinholes.

Final verification occurs during comprehensive inline testing. Every production meter undergoes continuous diameter measurement via laser micrometry. Bond strength is validated through standardized pull tests on bonded samples, ensuring activation within the specified temperature window and minimum shear strength. Electrical integrity testing includes high-potential (hi-pot) testing at elevated voltages. All critical parameters are logged for full traceability. The table below summarizes key quality control checkpoints integrated throughout our manufacturing flow.

| Process Stage | Critical QC Parameter | Test Method/Standard | Acceptance Criteria |

|---|---|---|---|

| Rod Drawing | Diameter Tolerance | Laser Micrometer | ±0.005 mm |

| Annealing | Tensile Strength / Elongation | ASTM E8 | Per Specified Temper Grade |

| Enameling (Coating) | Total Coating Thickness | Optical Microscopy | ±2 µm of Target |

| Enameling (Coating) | Spark Test Integrity | 3 kV Continuous Monitoring | Zero Defects per 1000m |

| Final Testing | Bond Strength (Shear) | Custom Pull Test Jig | Minimum 0.8 MPa at 150°C activation |

| Final Testing | Electrical Withstand Voltage | Hi-Pot Test (AC/DC) | Zero Breakdown at Rated Voltage |

This integrated approach, combining precise metallurgical process control with multi-stage in-line verification, guarantees the dimensional stability, insulation integrity, and consistent thermal bonding performance demanded by advanced electromagnetic component manufacturers. Luoyang Xinzhaohe’s process adherence directly translates to superior coil integrity and end-product reliability for our global customers.

Packaging & Logistics

Export Packaging for Self-Bonding Winding Wire: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in precision winding wire, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. For self-bonding winding wire—characterized by its heat-activated adhesive coating and sensitivity to environmental exposure—robust export packaging is essential to maintain electrical performance, mechanical consistency, and bonding reliability upon customer receipt.

Our standard export packaging system is engineered specifically for the rigors of sea freight, the predominant mode of global shipment for industrial wire products. Each shipment begins with a high-strength wooden pallet, constructed from kiln-dried, ISPM 15-compliant hardwood. This certification ensures that all wooden components are free from pests and meet international phytosanitary standards, avoiding customs delays or rejections in destination markets. The wooden pallet provides structural stability, enabling secure stacking and compatibility with global handling equipment, including forklifts and automated warehouse systems.

Coils of self-bonding wire are precisely arranged on the pallet to minimize mechanical stress and prevent deformation during transit. To address the principal environmental hazard—moisture—we apply a multi-layer moisture-proof barrier. Each coil is first wrapped in anti-corrosion paper, followed by a sealed vapor-phase inhibitor (VCI) film, which actively protects against oxidation of the aluminum conductor surface. The entire palletized load is then hermetically encased in high-density polyethylene (HDPE) moisture-proof shrink film. This outer film provides a durable, water-impermeable shield, critical during prolonged sea voyages where humidity levels frequently exceed 80% and condensation (commonly known as “container rain”) poses a significant risk.

All packaging operations are conducted in a climate-controlled environment to minimize ambient moisture entrapment prior to sealing. A desiccant pack is included within the sealed film to absorb any residual humidity. Additionally, tamper-evident labels and handling indicators are affixed to monitor exposure to adverse conditions during transit.

This integrated packaging methodology has been validated across thousands of shipments to North America, Europe, and Southeast Asia. It ensures that self-bonding wire arrives with intact insulation, unaltered bonding characteristics, and no degradation in conductivity. For customers sourcing high-performance aluminum winding wire for motors, transformers, and EV components, this packaging standard delivers not only physical protection but also assurance of material consistency and process reliability upon unpacking.

Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001 quality management protocols throughout packaging and dispatch, reinforcing our commitment to global supply chain excellence.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Self-Bonding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and vertical integration to deliver self-bonding aluminum winding wire meeting the most stringent global transformer and inductor manufacturing requirements. Since 1999, our core focus has been the precise engineering of aluminum conductors where electrical performance, thermal stability, and reliable bond formation are non-negotiable. Our facility operates as a fully integrated producer, controlling the entire process from high-purity aluminum billet casting through precision drawing, annealing, and proprietary bonding coating application. This vertical control ensures unparalleled consistency in critical parameters such as electrical conductivity (exceeding 61.0% IACS for 1060/1070 alloys), surface integrity, and coating uniformity – all fundamental to achieving optimal interfacial adhesion and thermal endurance in wound components.

Our production infrastructure is engineered for technical excellence in self-bonding wire. We operate dedicated, climate-controlled coating lines capable of applying solvent-based and eco-friendly bonding resins with micron-level precision. Advanced tension control systems during drawing and annealing prevent microstructural defects, ensuring uniform grain structure refinement critical for subsequent bonding performance and post-cure mechanical stability. Real-time monitoring of coating thickness, viscosity, and cure profiles guarantees batch-to-batch repeatability essential for automated winding processes. Production capacity supports substantial volume demands while maintaining tight tolerances:

| Parameter | Specification Range | Control Tolerance |

|---|---|---|

| Wire Diameter | 0.30 mm – 5.00 mm | ±0.003 mm |

| Coating Thickness | 2.0 µm – 15.0 µm | ±0.5 µm |

| Conductivity (20°C) | ≥ 61.0% IACS (1060/1070) | ±0.5% IACS |

Supply chain resilience is engineered into our operational model. Strategic partnerships with primary aluminum suppliers secure consistent high-purity feedstock (99.70%+ Al), mitigating raw material volatility. Our certified ISO 9001:2015 quality management system implements rigorous in-process and final inspection protocols, including peel strength testing per IEC 60317-40, dimensional metrology via laser micrometers, and accelerated aging validation. This systematic approach minimizes defect rates and ensures compliance with AEC-Q200 and IATF 16949 expectations for automotive-grade magnetics. We offer flexible logistics solutions, including just-in-time (JIT) delivery scheduling and kitting, supported by our central Henan Province location and established freight networks across Asia, Europe, and North America.

Partnering with Luoyang Xinzhaohe means accessing deep technical collaboration. Our metallurgists and process engineers work directly with your R&D and procurement teams to optimize wire specifications for your specific bonding chemistry, cure profiles, and end-application stresses. We provide comprehensive material certifications, batch traceability to the ingot level, and proactive technical support for winding line integration. For self-bonding wire where performance failure is not an option, rely on our documented history of supply continuity and metallurgical precision. Contact our technical sourcing team at cathy@transformerstrip.com to discuss your project requirements and request sample validation data. Let us demonstrate how our engineered wire solutions reduce your total cost of ownership through enhanced yield, reliability, and supply chain security.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing self bonding wire directly from China.