Table of Contents

Market Insight: Enamel Copper Wire Gauge Chart

Market Analysis: Winding Wire – Industrial Demand for Enamel Copper Wire Gauge Charts in Transformer Applications

The global demand for precision-engineered winding wire, particularly enamel copper wire, continues to grow in response to increasing requirements in power transmission, industrial automation, and renewable energy infrastructure. Within this domain, transformers represent one of the most critical applications, where the selection of appropriate wire gauge—guided by standardized enamel copper wire gauge charts—is essential for achieving optimal electrical performance, thermal stability, and mechanical reliability. As a trusted supplier with over two decades of experience, Luoyang Xinzhaohe Aluminum Co., Ltd emphasizes the technical significance of accurate gauge selection and material integrity in transformer manufacturing.

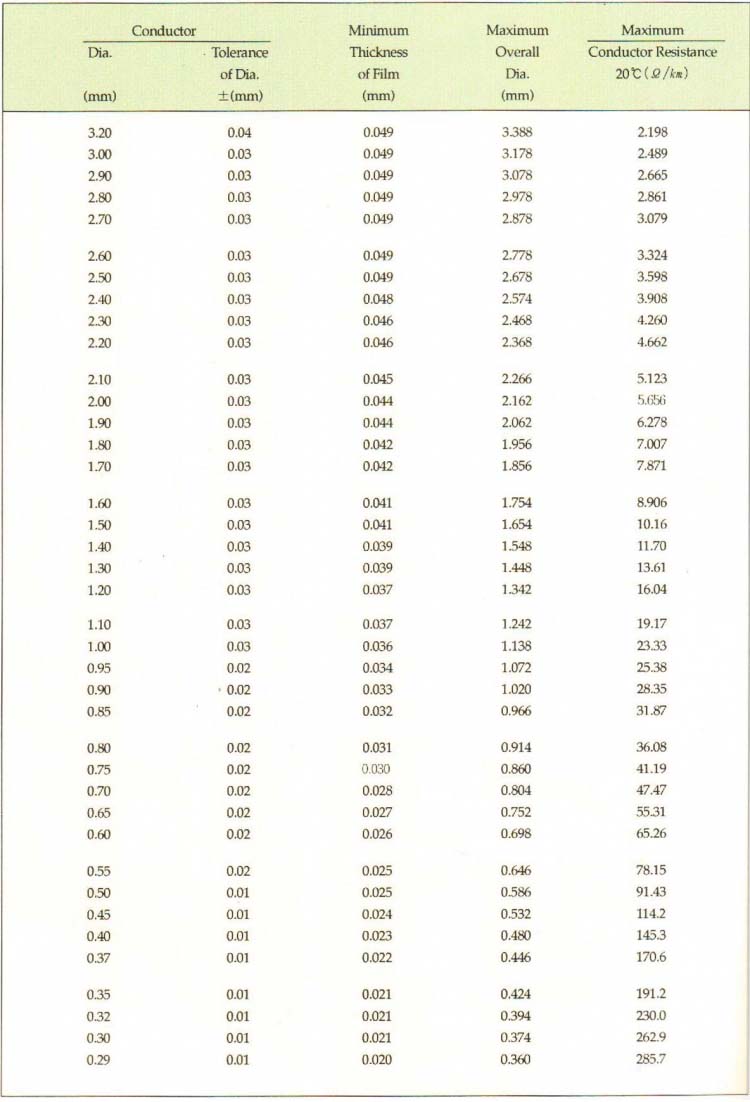

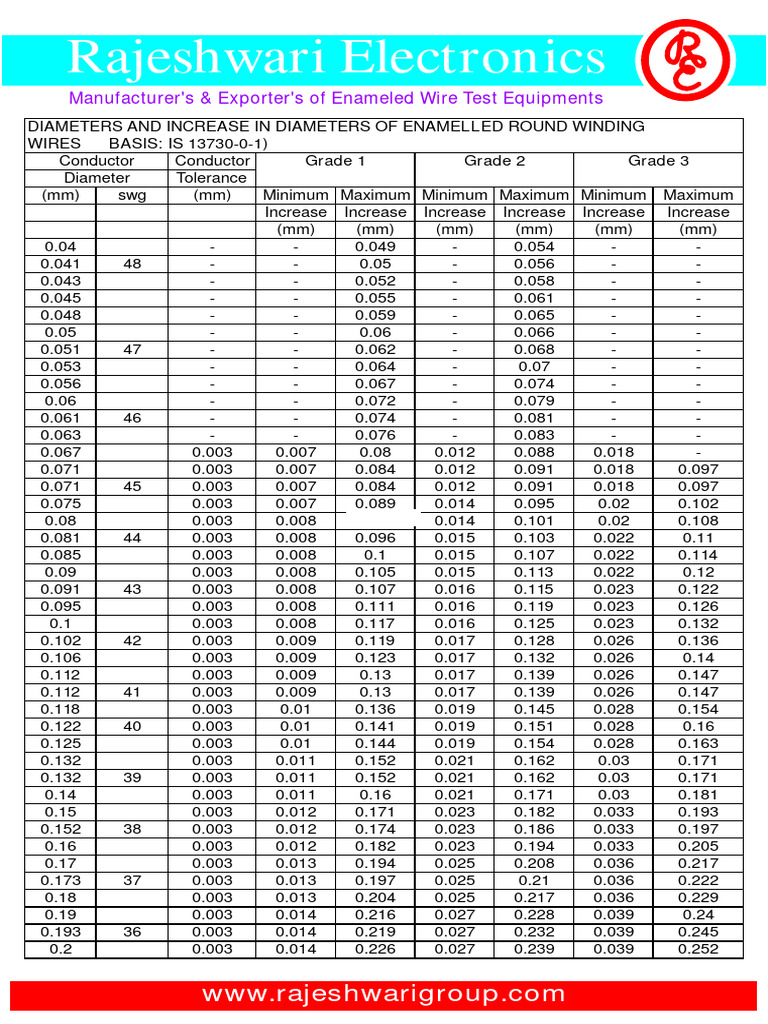

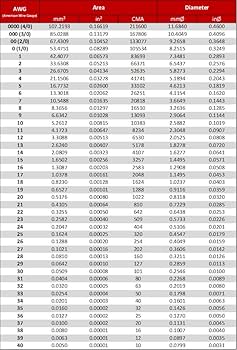

Enamel copper wire gauge charts serve as fundamental engineering references, correlating wire diameter, cross-sectional area, resistance per unit length, and current-carrying capacity. In transformer design, these parameters directly influence core loss, copper loss, and overall efficiency. Selecting a wire gauge that deviates even slightly from design specifications can result in elevated operating temperatures, reduced insulation life, and potential failure under load. For instance, undersized wire increases resistive losses, leading to excessive heat generation, while oversized wire may cause inefficient core utilization and increased material costs. Therefore, adherence to precise gauge standards—such as AWG (American Wire Gauge) or IEC 60122—is not merely a logistical consideration but a core determinant of transformer performance and compliance with international efficiency benchmarks like IE3 and IE4.

Quality in enamel copper wire extends beyond dimensional accuracy. The integrity of the enamel insulation system—typically composed of polyurethane, polyester, or polyamide-imide—is critical for dielectric strength, thermal endurance (rated up to Class 200°C or higher), and resistance to mechanical abrasion during coil winding. Inferior insulation may crack or delaminate under thermal cycling, leading to short circuits between turns. Additionally, surface smoothness and roundness of the copper conductor affect winding density and inter-turn spacing, both of which influence magnetic coupling and leakage inductance. High-purity electrolytic tough pitch (ETP) copper with oxygen content controlled below 10 ppm ensures minimal resistivity and superior conductivity, further enhancing transformer efficiency.

From a supply chain perspective, industrial buyers are increasingly prioritizing traceability, consistency, and certification. Manufacturers sourcing enamel copper wire for transformers require not only precise gauge conformity but also full documentation of material test reports (MTRs), insulation thickness verification, and thermal aging performance data. At Luoyang Xinzhaohe Aluminum Co., Ltd, our production processes are aligned with ISO 9001 and IATF 16949 standards, ensuring batch-to-batch uniformity and compliance with global transformer OEM specifications.

In conclusion, the enamel copper wire gauge chart is not a mere reference tool but a cornerstone of reliable transformer engineering. As energy efficiency regulations tighten and demand for compact, high-performance transformers rises, the market increasingly rewards suppliers who deliver not only precision gauging but also uncompromised material quality and technical support.

Technical Specs: Enamel Copper Wire Gauge Chart

Technical Specifications for Enamel Copper Wire Gauge Selection

Luoyang Xinzhaohe Aluminum CO., Ltd. provides precision enameled copper winding wire adhering to stringent international standards for electromagnetic applications. While our corporate name reflects historical scope, our magnet wire division exclusively utilizes high-conductivity electrolytic-tough-pitch (ETP) copper meeting ASTM B3/B3A specifications, ensuring optimal electrical and mechanical performance. Critical parameters governing wire selection extend beyond mere diameter (AWG) and include insulation integrity, mechanical resilience, and thermal endurance. These factors directly impact winding process yield, coil longevity, and operational safety in motors, transformers, and inductors. Understanding the interrelationship between gauge, insulation breakdown voltage, elongation, and thermal class is paramount for reliable design and manufacturing.

Insulation breakdown voltage defines the maximum electrical stress the enamel layer withstands before failure, measured in kilovolts (kV) RMS. This value is intrinsically linked to both wire gauge and insulation build (single, heavy, triple). Thinner gauges inherently possess higher dielectric strength per unit thickness due to reduced defect probability, yet absolute breakdown voltage decreases with smaller diameters. Elongation, expressed as a percentage, quantifies the wire’s ductility during the winding process. Adequate elongation (typically 10-30% for magnet wire) prevents breakage under tension, especially critical for fine gauges and complex coil geometries. Thermal class, designated by maximum continuous operating temperature (°C) per IEC 60085 and UL 1446, dictates the insulation system’s chemical composition and thermal stability. Higher thermal classes (e.g., 200°C, 220°C) utilize advanced polymer chemistries like polyamide-imide but often exhibit slightly reduced elongation compared to lower-class insulations (e.g., 130°C polyester).

The following table summarizes key technical parameters correlated with standard AWG sizes for common thermal classes. Values represent typical minimums or ranges achievable with our manufacturing processes under controlled conditions. Actual performance must be verified against specific project requirements and relevant standards (IEC 60317, NEMA MW).

| AWG Gauge | Nominal Conductor Diameter (mm) | Min. Insulation Breakdown Voltage (kV RMS) | Typical Elongation Range (%) | Standard Thermal Classes (IEC 60085) |

|---|---|---|---|---|

| 10 | 2.588 | 6.0 | 20 – 30 | 130 (B), 155 (F), 180 (H) |

| 18 | 1.024 | 4.0 | 18 – 28 | 130 (B), 155 (F), 180 (H), 200 |

| 24 | 0.511 | 3.0 | 15 – 25 | 130 (B), 155 (F), 180 (H), 200, 220 |

| 30 | 0.255 | 2.0 | 12 – 22 | 155 (F), 180 (H), 200, 220 |

| 36 | 0.127 | 1.5 | 10 – 20 | 180 (H), 200, 220 |

Note that breakdown voltage testing follows standardized ramp rates (e.g., 500 V/s) on wound samples. Elongation is measured per ASTM D3800 on bare conductor post-insulation removal. Thermal class certification requires rigorous thermal endurance testing (10,000+ hours) of the complete insulated wire system. Selecting the appropriate gauge necessitates balancing electrical load requirements (dictating cross-sectional area), manufacturability (requiring sufficient elongation), spatial constraints, and the operational thermal environment. Luoyang Xinzhaohe’s engineering team collaborates with clients to optimize these parameters, ensuring the selected enameled wire specification meets the precise demands of high-reliability electromagnetic components. Consistent material purity (99.97% Cu min) and proprietary annealing processes underpin the repeatability of these critical properties across production batches.

Factory Tour: Manufacturing

Manufacturing Process of Enamel Copper Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance enamel copper wire at Luoyang Xinzhaoanghe Aluminum Co., Ltd follows a rigorously controlled sequence of stages, beginning with rod drawing and culminating in final inspection. With over two decades of metallurgical and process engineering expertise, our facility ensures dimensional precision, electrical integrity, and mechanical reliability across all wire gauges per international standards.

The process initiates with high-conductivity electrolytic tough pitch (ETP) copper rod, conforming to IEC 60068 and ASTM B3 specifications. These rods, typically 8 mm in diameter, undergo rod drawing through a series of tungsten carbide or diamond dies in a multi-pass wet drawing system. Lubrication with water-soluble emulsions ensures surface smoothness and prevents work hardening. The drawing operation reduces the rod diameter incrementally to the target gauge, ranging from AWG 8 (8.366 mm) down to AWG 50 (0.018 mm), with tight tolerances maintained per IEC 60173 and NEMA MW 1000 standards.

Following drawing, the copper wire enters a continuous annealing line. The wire is passed through a high-frequency induction heating zone under an inert nitrogen atmosphere to prevent oxidation. Controlled thermal treatment restores ductility by relieving internal stresses induced during cold drawing. The annealing temperature is precisely regulated between 450°C and 600°C, depending on wire gauge and desired temper (soft, semi-hard, or hard). Post-annealing, the wire is quenched using deionized water to stabilize microstructure and ensure uniform elongation, typically exceeding 35% for soft temper grades.

The annealed wire then proceeds to the enameling stage, where a thin, electrically insulating polymer coating is applied via multiple passes. Common insulation systems include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or dual-layer combinations (e.g., PE-PAI) to meet thermal class requirements from 130°C (Class B) up to 220°C (Class H). The wire passes through a precision die to control coating thickness, followed by staged curing in tubular ovens at temperatures between 350°C and 500°C. Each layer is applied and cured sequentially to achieve the desired build (single, heavy, or triple). Coating concentricity is maintained within ±5% to ensure consistent dielectric strength.

Inline quality control is integrated throughout the production line. Real-time diameter monitoring via laser gauges ensures compliance with ±0.002 mm tolerances. Electrical continuity and pinhole defects are detected using high-voltage spark testing at 1.5–6 kV depending on wire size and insulation class. Tensile strength, elongation, and springback are verified through periodic mechanical testing. Adhesion, heat shock, and thermal endurance are validated per IEC 60851 standards. Final spooling is conducted under controlled tension to prevent deformation.

All process parameters are logged and traceable, supporting full batch accountability. This systematic approach ensures that every coil of enamel copper wire meets the stringent demands of motors, transformers, and electromagnetic devices in industrial and automotive applications.

Packaging & Logistics

Export Packaging Specifications for Enamel Copper Wire: Ensuring Maritime Integrity

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for enamel copper winding wire, specifically designed to mitigate the extreme environmental hazards of maritime transport. With over two decades of specialization in precision wire manufacturing, our packaging system addresses critical failure points inherent in ocean freight: moisture ingress, mechanical shock, and salt-laden atmospheric exposure. This methodology is non-negotiable for preserving the dimensional accuracy and dielectric integrity of enameled wire across all gauges, from ultra-fine 44 AWG to heavy-duty 10 AWG conductors.

All export shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, heat-treated softwood. Pallet dimensions adhere to global containerization standards (1200mm x 1000mm), with a minimum load-bearing capacity of 2500 kg to prevent structural deformation during stacking. Critical reinforcement includes steel strapping at 50mm intervals and edge protectors on all four sides to resist impact damage during cargo handling. The wooden substrate undergoes mandatory moisture content verification (<18% MC) prior to assembly, eliminating internal vapor sources that could compromise the wire’s hygroscopic polymer coating during transit.

The primary moisture barrier consists of a triple-layer aluminized co-extruded polyethylene film (125μm thickness) with a water vapor transmission rate (WVTR) of ≤0.5g/m²/day per ASTM F1249. This film is hermetically sealed using industrial-grade impulse sealers, creating a continuous enclosure that isolates the wire coils from ambient humidity fluctuations. Crucially, desiccant packs (silica gel, 33% capacity, 500g/m³) are strategically placed within the sealed cavity, alongside humidity indicator cards calibrated to IEC 60068-2-78 standards. This dual-defense system actively absorbs residual moisture and provides visual verification of internal conditions upon arrival.

Stacking configurations strictly follow gauge-dependent load distribution tables to prevent coil deformation. Exceeding maximum stack heights risks enamel abrasion and dimensional distortion, directly impacting winding performance in motors and transformers.

| Wire Gauge Range (AWG) | Max Coils per Pallet | Max Stack Height (mm) |

|---|---|---|

| 10–20 | 18 | 1800 |

| 21–30 | 24 | 1500 |

| 31–44 | 36 | 1200 |

Secondary containment employs marine-grade stretch wrap (70μm) applied at 300% elongation, providing additional resistance against container rain and salt spray penetration. Each pallet receives a weatherproof shipping label with QR-coded traceability to our ISO 9001:2015-certified production batch records. This integrated approach ensures enamel copper wire arrives with verified coating adhesion, tensile strength, and flexibility—meeting IEC 60317 and ASTM B888 specifications upon unloading. For extended voyages exceeding 30 days, we recommend supplementary vapor corrosion inhibitors (VCI) within the primary seal, a service included in our premium export package. Trust Xinzhaohe’s packaging science to eliminate field failures attributable to transit exposure.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd – Your Trusted Source for High-Performance Enamel Copper Winding Wire

With over two decades of specialized expertise in the production and supply of precision winding wires, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a leading industrial manufacturer in China’s electromagnetic wire sector. Our core competency lies in the development and mass production of high-purity enamel copper wire, engineered to meet the rigorous demands of transformers, motors, inductors, and other critical electrical applications. As a vertically integrated facility, we maintain full control over raw material sourcing, extrusion, enameling, testing, and packaging processes, ensuring consistent product integrity across every gauge and specification.

Our manufacturing infrastructure is built around advanced continuous annealing and multi-layer coating systems, enabling precise control over wire diameter tolerance, insulation thickness, and thermal class performance. We produce enamel copper wire across a comprehensive gauge range, from AWG 8 to AWG 40, aligned with international standards including IEC 60317, GB/T 23312, and NEMA MW. Each batch undergoes stringent quality verification through automated diameter monitoring, high-voltage breakdown testing, thermal shock resistance evaluation, and winding flexibility assessments. This commitment to metrology ensures that every spool shipped meets the exacting requirements of high-efficiency electromagnetic design.

Luoyang Xinzhaohe operates a 30,000-ton annual production capacity facility equipped with state-of-the-art drawing and enameling lines, allowing for rapid turnaround on both standard and custom orders. Our technical team specializes in tailoring insulation systems to specific thermal classes—ranging from 130°C (Class B) to 220°C (Class H)—using advanced polymer coatings such as polyurethane (PU), polyester (PE), polyester-imide (PEI), and polyamide-imide (PAI). This flexibility supports clients in optimizing performance for applications involving high temperature rise, compact winding geometries, or enhanced dielectric requirements.

As a strategic partner, we emphasize long-term reliability, supply chain stability, and technical collaboration. Our logistics network supports containerized FOB shipments from Qingdao or Shanghai ports, with documentation compliant with global customs and import regulations. We maintain ISO 9001:2015 and ISO 14001:2015 certifications, reflecting our adherence to international quality and environmental management systems.

For engineering teams and procurement managers seeking a dependable source of technically validated enamel copper wire, Luoyang Xinzhaohe offers both scale and precision. We invite you to integrate our capabilities into your supply chain and elevate the performance of your electromagnetic components.

Contact us today to request technical datasheets, gauge-specific tolerance charts, or sample reels for qualification testing.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamel copper wire gauge chart directly from China.