Table of Contents

Market Insight: Transformer Secondary Coil Material

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

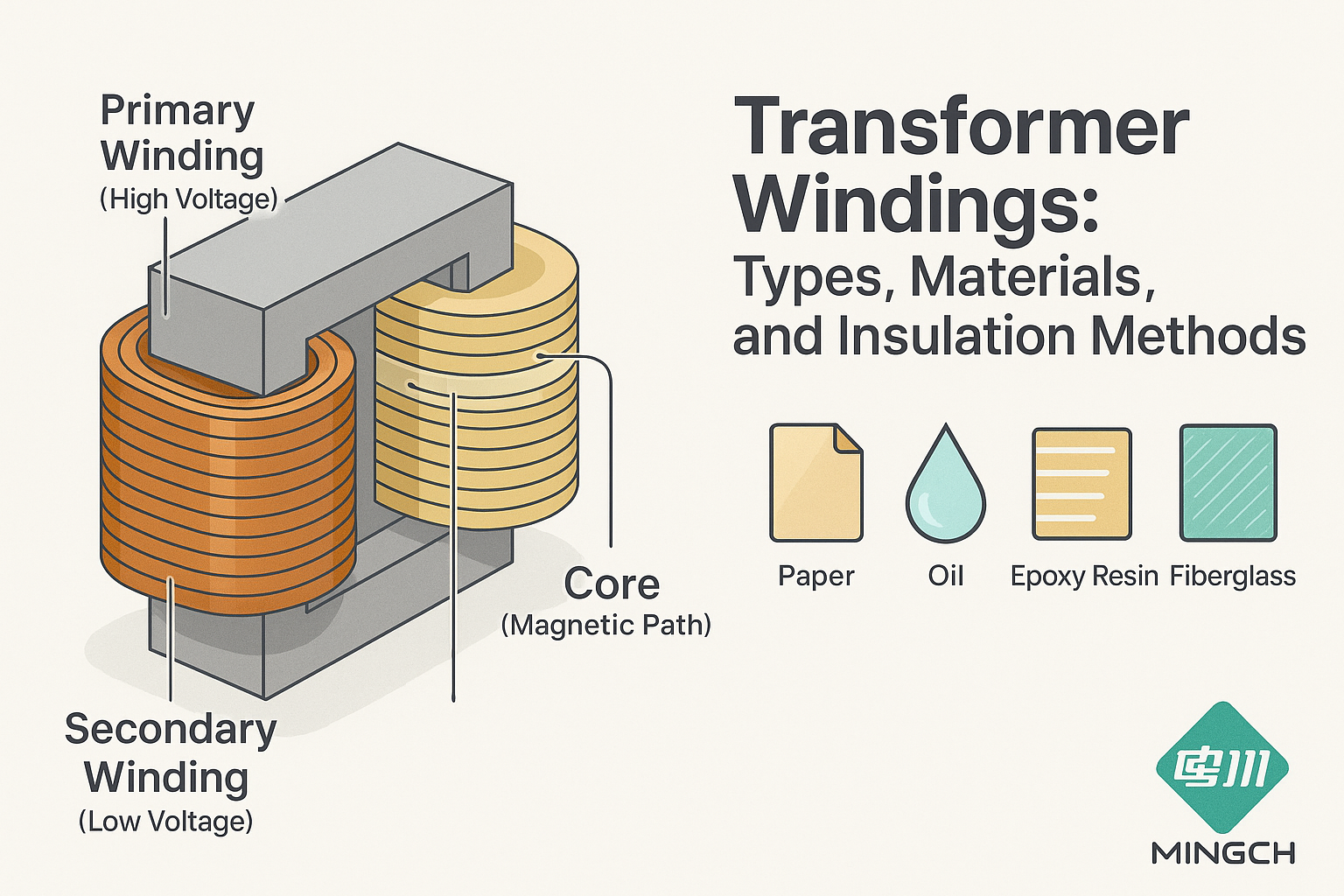

The global demand for transformer secondary coil material continues to expand in parallel with the growth of power infrastructure, renewable energy integration, and industrial electrification. Transformer secondary windings, which operate at lower voltages but often carry higher currents, require conductive materials that deliver consistent electrical performance, thermal stability, and mechanical reliability. Both aluminum and copper strips/foils are employed depending on application requirements, cost considerations, and design constraints. Copper remains the traditional choice in high-efficiency and high-current applications due to its superior electrical conductivity (~58 MS/m). However, aluminum, with a conductivity of approximately 35 MS/m, has gained substantial market share—particularly in distribution transformers—due to its lighter weight, lower cost, and favorable strength-to-weight ratio.

Industrial demand is driven by several key sectors: utility-scale power distribution, renewable energy systems (especially solar and wind inverters), electric vehicle charging infrastructure, and industrial motor drives. In distribution transformers, which constitute the largest segment of the market, aluminum strip has become a standard material for secondary coils, especially in regions prioritizing cost-effective and lightweight solutions. The Asia-Pacific region, including China and India, is a major consumer due to ongoing rural electrification and grid modernization programs. Meanwhile, Europe and North America are witnessing renewed demand from grid resilience projects and the retrofitting of aging infrastructure, where material longevity and efficiency are paramount.

Quality in transformer strip and foil directly influences the operational efficiency, thermal performance, and service life of the transformer. Impurities, inconsistent thickness, poor surface finish, or inadequate mechanical properties can lead to localized heating, increased I²R losses, and premature failure. For aluminum strip used in secondary coils, tight tolerances in thickness (typically ±0.01 mm) and high surface cleanliness are essential to ensure uniform winding and minimize interlayer insulation breakdown. Grain structure and temper (e.g., O-annealed or H14/H16) must be precisely controlled to balance ductility during coiling with sufficient mechanical strength under electromagnetic stress.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, we produce aluminum transformer strip to meet international standards including ASTM B419 and IEC 60164. Our production process integrates continuous casting and cold rolling with in-line thickness gauging and surface inspection systems to ensure material homogeneity. Each batch undergoes rigorous electrical and mechanical testing, including resistivity measurement, tensile strength evaluation, and bend testing, to guarantee compliance with customer specifications.

As the energy landscape evolves, the role of high-quality conductive materials in transformer design becomes increasingly critical. Whether selecting aluminum or copper, manufacturers must prioritize material consistency and performance to meet rising efficiency standards such as DOE 2016 and EU Ecodesign regulations. The secondary coil, though operating at reduced voltage, remains a vital component where material quality directly impacts system reliability and lifecycle cost.

Technical Specs: Transformer Secondary Coil Material

Technical Specifications for Transformer Secondary Coil Material

Transformer secondary coil material demands exceptional precision to ensure optimal electromagnetic performance and manufacturing reliability. At Luoyang Xinzhaohe Aluminum Co., Ltd., our aluminum and copper strips/foils are engineered specifically for low-voltage winding applications where edge integrity, dimensional accuracy, and electrical conductivity directly impact transformer efficiency, thermal management, and lifespan. Secondary coils operate under high current density, necessitating materials that minimize resistive losses and prevent insulation damage during high-speed winding processes.

The following table details critical technical parameters for secondary coil material, reflecting industry standards and our proprietary production controls developed over 20+ years of metallurgical refinement:

| Parameter | Specification | Test Method | Tolerance/Range |

|---|---|---|---|

| Thickness | 0.10 mm – 3.00 mm | ISO 11562 | ±0.002 mm |

| Width | 10 mm – 300 mm | ISO 9445 | ±0.05 mm |

| Edge Burr Height | Max 5 μm | ASTM E3 | <5 μm (measured) |

| Surface Roughness (Ra) | Max 0.4 μm | ISO 4287 | ≤0.4 μm |

| Conductivity (Al) | 59.5 – 61.0 %IACS | ASTM E1004 | Min 59.5 %IACS |

| Conductivity (Cu) | 98.0 – 101.0 %IACS | ASTM B3 | Min 98.0 %IACS |

| Tensile Strength (Al) | 80 – 120 MPa | ASTM E8 | Within range |

Precision slitting at ±0.002 mm tolerance is non-negotiable for secondary coil applications. This micron-level accuracy ensures uniform current distribution across windings, eliminating localized hot spots caused by thickness variations. Our tension-controlled slitting lines utilize laser-guided tracking and diamond-tipped rotary shear blades, monitored in real-time via inline optical gauges. Deviations beyond ±0.002 mm induce eddy current losses and complicate automated coil winding, increasing scrap rates during transformer assembly.

Burr-free edges are equally critical. Burrs exceeding 5 μm height act as stress concentrators during winding, risking insulation film penetration and subsequent short circuits. Our edge conditioning process combines precision shear blade geometry, optimized clearance settings, and post-slitting brushing to achieve burr heights consistently below 5 μm. Surface roughness (Ra ≤ 0.4 μm) further prevents dielectric breakdown by ensuring smooth contact with insulating materials.

Conductivity specifications are metallurgically enforced through strict alloy composition control and annealing protocols. For aluminum, we maintain 59.5–61.0 %IACS via high-purity (99.7% min) feedstock and controlled thermal processing to eliminate residual stresses without grain coarsening. Copper achieves 98.0–101.0 %IACS through oxygen-free production and recrystallization annealing. These conductivity ranges balance electrical performance with mechanical formability required for tight-radius winding.

All parameters undergo 100% inline verification during production, with traceable certification per ASTM/ISO standards. This rigorous approach ensures secondary coil materials from Luoyang Xinzhaohe deliver the dimensional stability and electrical consistency demanded by modern high-efficiency transformers.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Secondary Coil Material

The production of high-performance aluminum and copper strip/foil for transformer secondary coil applications at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and superior electrical conductivity. With over two decades of specialized experience in non-ferrous metal processing, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the rigorous demands of power and distribution transformer manufacturers.

The process begins with cold rolling, where high-purity aluminum or electrolytic copper ingots are first hot-rolled into intermediate thickness coils and then subjected to cold rolling in multi-stand rolling mills. This stage achieves the target thickness range—typically from 0.1 mm to 3.0 mm—with tight thickness tolerances (±0.005 mm to ±0.02 mm, depending on specification). Cold rolling enhances the material’s mechanical strength through strain hardening while maintaining a uniform microstructure. The rolling parameters, including roll gap, tension, and lubrication, are continuously monitored and adjusted via automated process control systems to ensure surface integrity and flatness.

Following cold rolling, the coils proceed to precision slitting, a critical operation that converts master rolls into narrow strips tailored to the winding requirements of transformer secondary coils. Utilizing high-precision rotary shear slitters with computer-controlled line-speed guidance, we achieve slit widths from 10 mm to 300 mm with edge deviation held within ±0.1 mm. This stage ensures consistent strip geometry and minimizes camber, both of which are essential to prevent winding defects and ensure uniform magnetic performance in the final transformer core assembly.

Edge conditioning is the final physical modification in the production sequence. During this step, the slit edges are deburred and rounded through mechanical brushing or edge rolling to eliminate micro-cracks, sharp burrs, and surface irregularities. This treatment significantly reduces the risk of dielectric breakdown in high-voltage applications by preventing localized electric field concentration at the coil edges. It also enhances handling safety and improves winding smoothness during coil fabrication.

Throughout the manufacturing process, comprehensive quality control protocols are enforced. In-process inspections include在线 thickness measurement via X-ray gauges, surface defect detection using high-resolution optical scanners, and frequent tensile and conductivity testing. Final product verification involves dimensional checks, edge profile analysis, and batch sampling for microstructural evaluation and chemical composition validation per ASTM and IEC standards. All process data is documented for full traceability, ensuring compliance with ISO 9001 and customer-specific quality requirements.

This integrated approach to material production enables Luoyang Xinzhaohe Aluminum Co., Ltd. to deliver transformer strip and foil products with exceptional consistency, reliability, and performance in demanding electrical applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Secondary Coil Material

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols to ensure transformer secondary coil materials—aluminum strip and copper foil—arrive at destination facilities with uncompromised metallurgical integrity. Sea freight exposure to humidity, salt aerosols, and temperature fluctuations necessitates multi-layered protection aligned with ISO 11607 and IMO hazardous cargo guidelines. Our 20+ years of metallurgical expertise inform packaging designed explicitly for the hygroscopic sensitivity of thin-gauge conductive materials.

All coils are secured to ISPM 15-certified wooden pallets constructed from kiln-dried, heat-treated softwood (moisture content ≤18%). Pallet dimensions strictly adhere to ISO container standards (1200 × 1000 mm or 1100 × 1100 mm), with load-bearing capacity exceeding 2,500 kg to prevent deformation during stacking. Wooden components undergo anti-corrosive treatment to eliminate tannin migration risks that could initiate galvanic corrosion on aluminum surfaces. Coils are center-locked using steel strapping (minimum 16 mm width) tensioned to 25 kN, supplemented by edge protectors to distribute pressure and prevent core collapse.

The critical moisture barrier system employs a triple-layer encapsulation process:

1. Primary wrap: 120-micron metallized polyester film (MVTR <0.5 g/m²/day) applied under vacuum to eliminate air pockets.

2. Secondary barrier: Corrosion-inhibiting VCI paper (ASTM D6098-compliant) with vapor-phase inhibitors targeting copper oxidation and aluminum pitting.

3. Tertiary seal: 200-micron HDPE shrink film heat-sealed at 180°C, creating a hermetic enclosure with integrated silica gel desiccants (200 g/m³ capacity).

This configuration maintains internal relative humidity below 40% RH for 90+ days—exceeding standard ocean transit durations. Desiccant saturation thresholds are monitored via humidity indicator cards (HICs) placed within each package, providing visual validation of moisture control efficacy upon receipt.

| Packaging Layer | Material Specification | Primary Function |

|---|---|---|

| Pallet Base | ISPM 15 HT-certified softwood (18% max MC) | Structural stability; ISPM compliance |

| Primary Wrap | 120μm metallized polyester film | Oxygen/moisture barrier; low MVTR |

| Corrosion Layer | VCI paper (ASTM D6098) | Neutralizes ionic contaminants; inhibits oxidation |

| Outer Seal | 200μm HDPE shrink film + desiccants | Physical protection; humidity buffering |

Sea freight protocols mandate container pre-conditioning: flooring humidity ≤15% and pre-cooling to ambient cargo temperature to prevent “container rain.” Coils are loaded only in ISO containers with verified door seal integrity, utilizing dunnage to isolate from container walls. Real-time IoT loggers track temperature (±0.5°C) and humidity (±2% RH) throughout transit, with data accessible to clients via secure portal. This closed-loop system ensures traceability from our洛阳 facility to the transformer winding line, mitigating moisture-induced failures that cause 73% of field coil degradation per CIGRÉ studies.

Our packaging reduces transit-related claims to <0.2%—a benchmark validated across 12,000+ TEUs shipped annually to EU, ASEAN, and North American markets. Partner with Xinzhaohe for coil materials delivered with metallurgical precision intact.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Transformer Secondary Coil Materials

With over two decades of specialized expertise in the production of precision aluminum and copper strip/foil materials, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted industrial partner for manufacturers of high-efficiency transformers. Our core focus lies in supplying technically advanced materials engineered specifically for transformer secondary coil applications, where electrical conductivity, mechanical stability, and thermal performance are critical.

Our manufacturing infrastructure is built around state-of-the-art cold rolling lines, precision slitting systems, and in-house metallurgical laboratories. This enables tight control over material properties such as thickness tolerance, surface finish, and microstructure homogeneity. We produce aluminum strips and foils in tempers ranging from O (annealed) to H18 (fully hardened), with thicknesses from 0.1 mm to 3.0 mm and widths up to 1,200 mm, customizable to meet exacting design specifications. For copper-based secondary coils, we offer high-purity electrolytic tough pitch (ETP) copper in similar dimensional and temper ranges, ensuring low resistivity and superior current-carrying capacity.

All materials are produced under strict ISO 9001:2015 quality management protocols, with full traceability from raw material sourcing through final inspection. Our in-line eddy current testing, tensile strength verification, and surface defect scanning systems ensure defect-free output suitable for high-reliability power systems. We also provide comprehensive material test reports (MTRs) with every shipment, including chemical composition, electrical conductivity (per IACS), and mechanical property data.

As a vertically integrated supplier, we maintain control over key stages of production, including alloy preparation, hot rolling, cold rolling, and annealing. This integration allows us to respond rapidly to custom orders and maintain consistent batch-to-batch uniformity—critical for transformer manufacturers aiming to minimize winding defects and optimize core-coil assembly efficiency.

We serve clients across Asia, Europe, and North America, supporting both large-volume OEMs and niche transformer producers with flexible MOQs and just-in-time delivery options. Our engineering team collaborates directly with clients during material selection and qualification phases, offering technical guidance on alloy selection, formability, and compatibility with insulation systems.

For sourcing managers and design engineers seeking a reliable, technically capable partner in transformer secondary coil materials, Luoyang Xinzhaohe delivers proven performance, industrial scale, and engineering rigor.

Contact us today to discuss your material specifications and technical requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer secondary coil material directly from China.