Table of Contents

Market Insight: Copper Strip 50X6

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to drive significant demand for high-performance conductive materials, particularly copper and aluminum strips used in winding and busbar applications. Among these, copper strip 50×6 (50 mm width, 6 mm thickness) is a standardized profile widely utilized in medium to high-capacity power transformers, rectifier systems, and industrial switchgear. Its dimensional consistency and high electrical conductivity make it particularly suitable for low-impedance current transfer in core electrical infrastructure.

Industrial demand for copper strip 50×6 is primarily concentrated in power distribution networks, renewable energy integration systems (such as solar inverters and wind turbine converters), and heavy industrial equipment. As electrical grids modernize and renewable penetration increases, the need for reliable, efficient, and thermally stable conductive components has intensified. Copper strip 50×6 meets these requirements due to its high conductivity (typically ≥ 98% IACS for ETP copper), excellent thermal dissipation characteristics, and mechanical rigidity under sustained electromagnetic loading.

While aluminum strips offer a lightweight and cost-effective alternative in certain transformer designs, copper remains the preferred material where space constraints, efficiency targets, and long-term reliability are critical. The 50×6 cross-section provides an optimal balance between current-carrying capacity and formability, allowing for tight winding radii and secure termination in compact transformer cores. This has led to increased adoption in urban substations and industrial facilities where footprint efficiency is paramount.

Quality assurance in copper strip 50×6 production is non-negotiable. Variations in thickness tolerance, surface oxidation, edge burring, or microstructural inhomogeneity can lead to hotspots, increased eddy current losses, and premature insulation failure. At Luoyang Xinzhaohe Aluminum Co., Ltd., we apply stringent process controls derived from over 20 years of metallurgical and supply chain expertise. Each batch of copper strip undergoes comprehensive testing for dimensional accuracy, electrical resistivity, tensile strength, and bend ductility to ensure compliance with international standards such as GB/T 5584 and IEC 60464.

Furthermore, surface finish quality directly impacts insulation adhesion and dielectric performance. Poor surface integrity can accelerate partial discharge degradation, reducing transformer lifespan. High-purity, oxygen-free copper (OF-Cu) with a smooth, oxide-free surface finish is recommended for high-voltage and high-reliability applications. Consistent annealing profiles are also critical to maintain optimal grain structure, ensuring uniform elongation and fatigue resistance during coil winding and operational thermal cycling.

In the competitive transformer materials market, sourcing from suppliers with integrated quality management systems, traceability protocols, and technical support capabilities is essential. As demand for energy-efficient and digitally monitored transformers grows, the role of precision-engineered copper strip 50×6 will expand, reinforcing the need for technically rigorous material specifications and reliable supply chains.

Technical Specs: Copper Strip 50X6

Technical Specifications for Copper Strip 50×6 in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd delivers copper strip conforming to the critical dimensional and material property requirements essential for high-performance transformer windings. The designation 50×6 specifies a strip width of 50.00 mm and a nominal thickness of 6.00 mm. Achieving the stringent tolerances demanded by modern transformer manufacturing necessitates advanced precision slitting technology and rigorous process control. Our production process guarantees a width tolerance of ±0.002 mm across the entire coil length. This level of precision is non-negotiable for consistent layer-to-layer alignment during automated winding operations, directly impacting core fill factor, magnetic performance, and thermal management within the transformer assembly. Deviations exceeding this tolerance risk misalignment, increased eddy current losses, and potential mechanical stress on the winding structure.

Edge quality is paramount for preventing insulation damage during high-speed winding and ensuring long-term operational reliability. All copper strip 50×6 supplied by Luoyang Xinzhaohe undergoes a proprietary edge conditioning process resulting in consistently burr-free edges. Measured burr height is maintained below 5 micrometers (μm) across the full strip length. This specification is validated through routine optical and tactile profilometry. Burr-free edges eliminate the risk of piercing magnet wire insulation or transformer paper during winding, a critical failure mode that leads to inter-turn shorts and premature transformer failure. Surface integrity is further assured through controlled surface roughness parameters.

Electrical conductivity is a fundamental property for transformer efficiency. Our copper strip 50×6 utilizes high-purity Electrolytic Tough Pitch (ETP) copper (C11000) meeting or exceeding ASTM B152 standards. Minimum conductivity is guaranteed at 100% IACS (International Annealed Copper Standard) at 20°C, with typical production values ranging from 100.5% to 101.0% IACS. This high conductivity minimizes resistive (I²R) losses within the windings, directly contributing to the transformer’s overall energy efficiency and thermal performance. Consistent conductivity is achieved through strict raw material sourcing and controlled annealing processes, verified via four-point probe measurements on every production lot. Surface cleanliness is maintained to prevent oxidation prior to customer processing, with a maximum surface roughness average (Ra) of 0.8 μm.

The following table details the comprehensive technical parameters for copper strip 50×6:

| Parameter | Specification | Standard/Test Method |

|---|---|---|

| Material Grade | C11000 (ETP Copper) | ASTM B152 |

| Nominal Dimensions | 50.00 mm (W) x 6.00 mm (T) | – |

| Width Tolerance (W) | ±0.002 mm | ISO 7438 / In-line Laser |

| Thickness Tolerance (T) | ±0.015 mm | ISO 7438 / Micrometer |

| Edge Burr Height | ≤ 5 μm | Optical Profilometry |

| Surface Roughness (Ra) | ≤ 0.8 μm | Contact Profilometer |

| Conductivity | ≥ 100.0% IACS (Typ. 100.5-101.0%) | ASTM B193 (4-Point Probe) |

| Tensile Strength | 200 – 250 MPa | ASTM E8 |

| Elongation | ≥ 40% | ASTM E8 |

| Flatness | ≤ 5 mm/m deviation | Straightedge Measurement |

| Surface Condition | Clean, Oxide-Free, Burr-Free | Visual & Microscopic Inspect |

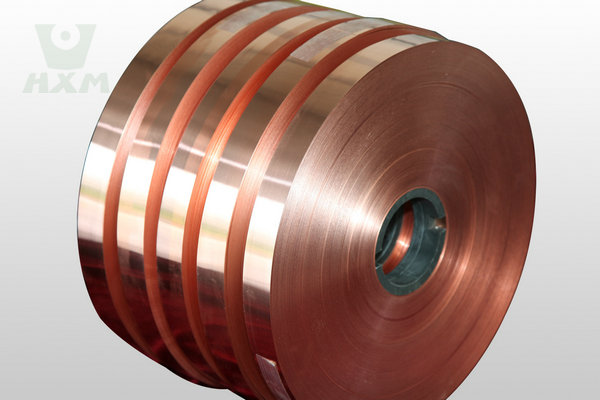

| Coil ID / OD | Standard 508 mm / Max 1200 mm | Customer Specification |

These specifications represent the baseline requirements for reliable transformer strip performance. Luoyang Xinzhaohe Aluminum CO., Ltd implements comprehensive in-process and final quality control checks, including 100% width verification via laser gauging and statistical sampling for all other parameters, ensuring every shipment meets the exacting demands of transformer manufacturers focused on efficiency, reliability, and manufacturability.

Factory Tour: Manufacturing

Manufacturing Process for Copper Strip 50×6

The production of copper strip 50×6 at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and consistent electrical and mechanical performance. As a specialized supplier with over 20 years of experience in transformer-grade aluminum and copper strip and foil, our process leverages advanced rolling technologies and precision finishing to meet the stringent demands of power transformer and electrical equipment manufacturers.

The process begins with cold rolling, where high-conductivity electrolytic tough pitch (ETP) copper ingots are first hot-rolled into intermediate strips and then subjected to cold rolling in reversing rolling mills. This stage is critical for achieving the target thickness of 6 mm with tight tolerances, typically within ±0.05 mm. Cold rolling enhances the material’s strength through work hardening while maintaining uniform grain structure. Rolling parameters such as roll gap, rolling speed, and interpass annealing (if required) are precisely monitored using automated control systems to prevent thickness deviation and surface defects.

Following cold rolling, the copper strip undergoes precision slitting to achieve the final width of 50 mm. This operation is performed on high-accuracy slitting lines equipped with rotary shear blades that minimize edge burr formation and maintain straightness. Tension leveling is integrated into the slitting process to eliminate coil set and edge wave, ensuring flatness essential for downstream winding operations in transformer manufacturing. Slit strips are wound under controlled tension to prevent telescoping and maintain coil integrity during handling and transport.

Edge conditioning is the final mechanical processing step, critical for preventing damage during coil handling and transformer winding. The edges of the 50 mm wide strip are rounded and deburred using precision edge grinding or roller-based edge rounding systems. This reduces the risk of insulation layer damage when the strip is used in low-voltage winding applications. Edge radius is typically maintained between 0.1 mm and 0.3 mm, depending on customer specifications.

Throughout the manufacturing process, comprehensive quality control measures are implemented. In-process inspections include在线 thickness measurement via X-ray gauges, surface defect detection using high-resolution optical scanning systems, and periodic tensile and conductivity testing. Final QC includes visual inspection for surface defects such as scratches, pits, or oxidation, dimensional verification using calibrated micrometers and profilometers, and batch sampling for microstructure analysis. Each coil is tagged with a traceability label containing heat number, mechanical properties, and processing history.

This integrated approach—combining cold rolling, precision slitting, and edge conditioning with rigorous quality assurance—ensures that our copper strip 50×6 meets international standards such as GB/T 5584 and IEC 60317, delivering reliable performance in high-demand transformer applications.

Packaging & Logistics

Export Packaging Specifications for Copper Strip 50×6: Ensuring Maritime Integrity

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed for the secure global shipment of copper strip 50×6 (50mm width x 6mm thickness). With over two decades of metallurgical and supply chain expertise in transformer conductor materials, our system prioritizes absolute protection against physical damage and environmental degradation during extended sea freight transit, which constitutes the predominant export channel for our international clients. This methodology is non-negotiable for maintaining the critical surface quality and dimensional tolerances required in transformer winding applications.

All copper strip coils undergo a multi-stage packaging sequence beginning with secure mounting onto custom-engineered wooden pallets. These pallets comply strictly with ISPM 15 international phytosanitary standards for heat-treated lumber, eliminating pest transmission risks and ensuring customs clearance globally. Pallet construction utilizes robust, kiln-dried hardwood components rated for heavy static and dynamic loads encountered in containerized shipping. Key structural parameters are standardized to guarantee stability:

| Parameter | Specification |

|---|---|

| Pallet Dimensions | 1200mm x 1000mm x 150mm |

| Max Load Capacity | 3500 kg |

| Deck Board Thickness | 22mm (Top), 18mm (Bottom) |

| Stringer Dimensions | 100mm x 100mm |

Following palletization, each coil receives comprehensive environmental encapsulation. A primary layer of high-density polyethylene (HDPE) moisture-proof film, minimum 125 microns thick, is hermetically sealed around the coil and pallet base using industrial-grade heat welding. This film incorporates advanced vapor barrier technology with a water vapor transmission rate (WVTR) of ≤ 1.0 g/m²/24hr at 38°C and 90% RH, effectively isolating the copper from ambient humidity. A secondary overwrap of reinforced polypropylene (PP) woven fabric provides critical puncture and abrasion resistance against container handling stresses and shifting cargo. All seams are triple-sealed, and the package base incorporates moisture-absorbing desiccant packs (50g per 100kg coil weight) strategically placed within the vapor barrier to neutralize any residual internal humidity.

This integrated packaging system is validated for standard 40-foot high cube container voyages exceeding 45 days, including exposure to tropical maritime climates with sustained 95%+ relative humidity and salt-laden air. Copper strip is exceptionally susceptible to atmospheric corrosion; even minor moisture ingress causes surface oxidation (tarnishing) or pitting, rendering the material unsuitable for precision transformer laminations where low electrical resistance and clean surfaces are mandatory. Our packaging eliminates this risk by maintaining an internal microclimate below 60% RH throughout transit, as verified by third-party accelerated climate chamber testing simulating worst-case sea routes.

Final handling protocols include mandatory top-lid strapping with steel bands tensioned to 1500 kgf and corner protectors to prevent edge damage during crane lifts. Each pallet bears a weather-resistant label detailing product ID, net/gross weights, handling symbols per ISO 780, and critical “Fragile” and “This Side Up” indicators. Documentation explicitly states the moisture barrier integrity period (90 days from sealing) and required storage conditions upon destination port arrival. This comprehensive approach, refined through 20+ years of global logistics execution, ensures your copper strip 50×6 arrives at the destination transformer manufacturing facility in pristine, ready-to-process condition, safeguarding your production schedule and component quality. Non-compliant packaging represents an unacceptable risk to material integrity; our certified system is the benchmark for secure copper conductor export.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Strip 50×6

At Luoyang Xinzhaohe Aluminum CO., Ltd, we bring over two decades of specialized expertise in the production and supply of precision transformer strips and foils, including high-conductivity copper strip 50×6. As a trusted industrial partner, we combine advanced metallurgical engineering with rigorous quality control to deliver materials that meet the exacting demands of transformer, inductor, and power electronics manufacturing.

Our manufacturing infrastructure is engineered for precision and consistency. The production of copper strip 50×6 leverages fully automated rolling lines with closed-loop thickness control, ensuring dimensional accuracy within ±0.02 mm. Our cold-rolling process is optimized to achieve uniform grain structure and enhanced mechanical properties, critical for efficient winding and long-term reliability in transformer cores. Each batch undergoes inline eddy current testing and offline tensile, hardness, and conductivity verification to guarantee compliance with GB/T 2040 and ASTM B152 standards.

We operate a vertically integrated production model, sourcing high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%) from certified suppliers and refining in-house to minimize impurities. This control over the supply chain ensures batch-to-batch consistency and reduces lead times. Our annealing furnaces utilize controlled hydrogen atmospheres to prevent oxidation and maintain optimal ductility, resulting in copper strip with superior formability and surface finish—essential for high-speed coil winding applications.

Environmental and process sustainability are embedded in our operations. Our facility in Luoyang is equipped with energy recovery systems on rolling mills and recycles 98% of process water. All products are RoHS and REACH compliant, with full material traceability provided through mill test certificates (EN 10204 3.1 available upon request).

With an annual production capacity exceeding 15,000 metric tons for copper and aluminum transformer materials, we support both high-volume OEM contracts and specialized low-volume runs. Our technical team collaborates directly with clients to optimize strip specifications for lamination stacking, thermal performance, and electrical efficiency.

For procurement managers and engineering teams sourcing copper strip 50×6, partnering with Luoyang Xinzhaohe means access to stable supply, technical depth, and manufacturing precision honed over 20 years in the power electronics sector.

Contact us today to request samples, technical datasheets, or a customized quotation.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Precision Strip Division – Transformer Materials

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper strip 50×6 directly from China.