Table of Contents

Market Insight: Copper Foil Manufacturer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

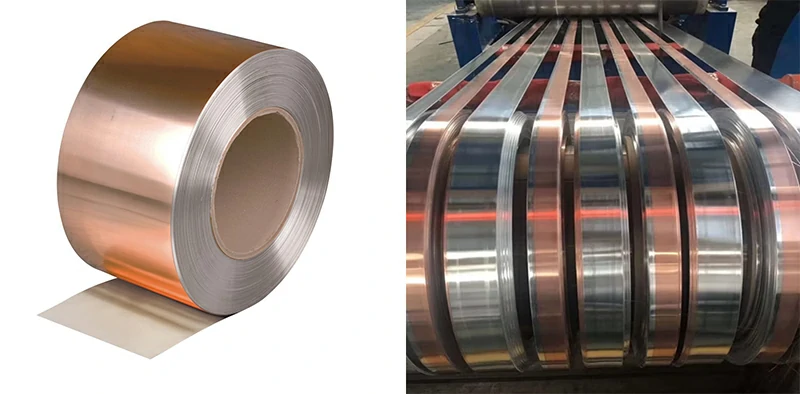

The global demand for transformer strip and foil—both aluminum and copper—continues to expand in parallel with increasing investments in power infrastructure, renewable energy integration, and industrial electrification. Within this segment, copper foil manufacturers play a critical role in supplying high-purity, dimensionally stable conductive materials essential for the efficient operation of power and distribution transformers. Copper’s superior electrical conductivity (approximately 100% IACS) makes it the preferred choice in high-efficiency and high-reliability transformer applications, particularly in urban substations, data centers, and industrial motor drives where thermal performance and current density are paramount.

Industrial demand for copper foil is driven by stringent efficiency standards such as IE4 and IE5 motor classifications, as well as regulatory frameworks like the DOE’s 2016 and 2023 transformer efficiency mandates in North America and the EU’s Ecodesign Directive. These regulations necessitate the use of low-loss, high-conductivity windings, directly increasing the demand for precision-rolled copper foil with tight tolerances and minimal surface defects. Copper foil used in transformer windings must exhibit consistent thickness uniformity (typically ranging from 0.05 mm to 3.0 mm), high tensile strength, and excellent annealing characteristics to withstand winding stresses and thermal cycling during transformer operation.

Quality in copper foil manufacturing is not merely a performance differentiator—it is a determinant of transformer reliability and lifecycle cost. Impurities, edge cracks, or thickness variation can lead to localized hot spots, increased eddy current losses, and premature insulation breakdown. Furthermore, surface oxidation or residual rolling lubricants can compromise dielectric integrity when foil layers are insulated with pressboard or polymer films. High-quality copper foil must therefore be produced under controlled atmospheric conditions, with rigorous in-line monitoring of mechanical and electrical properties.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical expertise to deliver precision transformer strip and foil products that meet international quality benchmarks, including ASTM B152 and IEC 60137. While specializing in aluminum strip, the company’s process control systems, cold-rolling technology, and quality assurance protocols are directly transferable to copper foil production, ensuring tight dimensional control and high surface integrity. Our integrated supply chain enables consistent raw material sourcing, traceability, and batch uniformity—critical factors for large-scale transformer manufacturers requiring long-term supply stability.

The shift toward smart grids and distributed energy resources further amplifies the need for reliable, high-efficiency transformers, reinforcing the strategic importance of premium-grade copper foil. As the industry moves toward digitalized asset management and predictive maintenance, the foundational quality of conductive materials becomes even more critical. Transformer failures due to substandard foil not only result in costly downtime but also undermine grid resilience.

In summary, the industrial demand for copper foil in transformers is shaped by efficiency regulations, technological advancement, and reliability requirements. Quality is non-negotiable, with material consistency, purity, and surface finish directly influencing transformer performance and longevity. Manufacturers who prioritize metallurgical precision and process control will continue to lead in this high-stakes segment of the electrical materials market.

Technical Specs: Copper Foil Manufacturer

Technical Specifications for Precision Copper Foil in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver copper foil meeting stringent transformer manufacturing requirements. Critical technical parameters must be rigorously controlled to ensure electromagnetic efficiency, thermal management, and long-term reliability in high-performance transformers. Precision slitting accuracy, edge integrity, and electrical conductivity form the cornerstone of our quality framework. Deviations beyond specified tolerances directly impact winding integrity, interlayer insulation, and overall transformer losses.

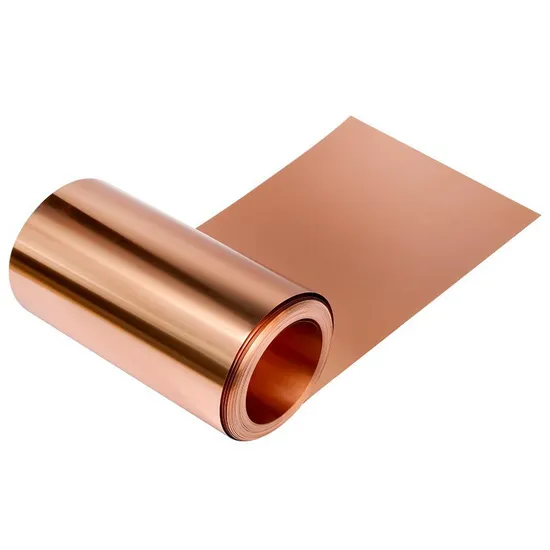

Our copper foil production adheres to the following non-negotiable specifications, validated through in-line metrology and final inspection. Thickness uniformity is maintained within ±0.002 mm across the entire coil width, achieved via closed-loop laser micrometry and adaptive tension control during cold rolling. Slit width tolerance is held to ±0.02 mm for widths ranging from 10 mm to 500 mm, utilizing servo-driven rotary shear slitters with real-time edge position feedback. Edge quality is paramount; all foils undergo 100% visual and tactile inspection to guarantee zero measurable burrs (≤ 5 μm burr height per ASTM B919). Burr formation is mitigated through precision tooling geometry, optimized clearance settings, and controlled skiving process parameters.

Electrical conductivity must consistently achieve ≥ 99.9% IACS (International Annealed Copper Standard) at 20°C, verified per ASTM E1004 using non-contact eddy current testing. This requires ultra-high-purity electrolytic tough pitch (ETP) copper (C11000) with oxygen content strictly controlled between 200–400 ppm. Surface roughness (Ra) is maintained at ≤ 0.45 μm to minimize interfacial resistance in wound coils, measured via profilometry per ISO 4287. Flatness deviations are limited to ≤ 3 mm/m to prevent winding misalignment, assessed using optical flatness scanners.

The table below summarizes mandatory technical parameters and test methodologies:

| Parameter | Specification | Measurement Standard | Frequency |

|---|---|---|---|

| Thickness Tolerance | ±0.002 mm | ASTM B9 | 100% In-line |

| Slit Width Tolerance | ±0.02 mm | ISO 7806 | Per Coil End |

| Edge Burr Height | ≤ 5 μm | ASTM B919 | 100% Visual |

| Electrical Conductivity | ≥ 99.9% IACS | ASTM E1004 | Per Melt Batch |

| Surface Roughness (Ra) | ≤ 0.45 μm | ISO 4287 | Per Coil |

| Flatness | ≤ 3 mm/m | DIN 1623-4 | Per Coil |

These specifications are non-derogable for transformer-grade copper foil. Variability in slitting accuracy induces uneven winding tension, accelerating insulation degradation. Substandard conductivity directly increases I²R losses, elevating operational temperatures and reducing transformer lifespan. Burr presence compromises dielectric barriers between winding layers, risking partial discharge and catastrophic failure. Our manufacturing process integrates continuous annealing under controlled hydrogen atmospheres to stabilize conductivity while preserving mechanical properties. All foils are supplied with full material traceability, including melt chemistry certificates and third-party conductivity validation reports.

Procurement teams must enforce these metrics during supplier qualification. Compromising on edge quality or conductivity tolerance incurs significant lifecycle costs through reduced transformer efficiency and premature field failures. Luoyang Xinzhaohe’s process discipline ensures copper foil meets the exacting demands of modern transformer design, where micron-level precision translates directly to grid reliability.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of high-performance transformer strip and foil—available in both aluminum and copper alloys—follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and surface integrity. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of power and electronic transformer applications.

The manufacturing cycle begins with cold rolling, a critical deformation process that reduces the thickness of incoming hot-rolled or cast strip to the target foil gauge. This operation is conducted under precisely regulated temperature and tension conditions to achieve uniform thickness tolerances as tight as ±0.005 mm. Cold rolling enhances the material’s mechanical properties by increasing tensile strength and improving grain structure homogeneity. High-precision rolling mills equipped with laser-based thickness gauging (X-ray or beta gauge systems) enable real-time feedback control, ensuring consistent cross-sectional profiles across the entire coil length. Both aluminum (e.g., 1060, 1100, 8011) and copper (e.g., C11000) alloys are processed through this stage, with roll force, speed, and lubrication parameters optimized for each material’s deformation characteristics.

Following cold rolling, coils undergo precision slitting to achieve the required strip widths, typically ranging from 10 mm to 600 mm, depending on customer specifications. Our servo-driven slitting lines utilize hardened circular knives with micron-level alignment accuracy to produce clean, burr-minimized edges and maintain tight width tolerances of ±0.1 mm. The slitting process is conducted under controlled tension to prevent edge waviness or coil set defects, ensuring flatness and dimensional stability essential for automated winding in transformer cores.

Edge conditioning is the final mechanical treatment in the process chain. This step involves controlled edge rolling or brushing to remove micro-burrs and sharp protrusions generated during slitting. Smooth, radius-formed edges reduce the risk of dielectric breakdown in transformer windings and prevent damage to insulating layers during coil winding. Edge quality is verified using optical profilometry and tactile measurement systems to confirm edge radius consistency and absence of surface defects.

Throughout the production sequence, comprehensive quality control protocols are enforced. In-process inspections include在线 thickness monitoring, surface defect scanning (via high-resolution CCD systems), and mechanical testing (tensile strength, elongation, and bend tests per ASTM E8 and GB/T standards). Final coils are subjected to 100% visual inspection, dimensional verification, and packaging in moisture-resistant, anti-corrosion wrapping to ensure integrity during global shipment.

This integrated manufacturing approach enables Luoyang Xinzhaohe Aluminum Co., Ltd to deliver transformer strip and foil products with superior consistency, reliability, and performance in high-efficiency electrical systems.

Packaging & Logistics

Export Packaging Specifications for Transformer Foil Shipments

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols specifically designed for copper and aluminum transformer strip/foil to ensure integrity during global sea freight. With over two decades of metallurgical and supply chain expertise, our system prioritizes corrosion prevention, structural stability, and compliance with international maritime regulations. All shipments utilize ISPM 15-certified heat-treated wooden pallets as the foundational layer. These pallets are constructed from kiln-dried softwood, free of bark and organic contaminants, to eliminate pest transmission risks and meet stringent phytosanitary requirements for entry into EU, North American, and APAC markets. Pallet dimensions and load capacities are standardized to optimize container space while preventing deformation under dynamic ocean transit conditions.

| Pallet Specification | Standard Value |

|---|---|

| Dimensions (L×W×H) | 1100×1100×150 mm |

| Max Load Capacity | 1500 kg |

| ISPM 15 Compliance | Mandatory heat-treatment stamp |

| Surface Treatment | Smooth-planed, splinter-free |

The foil coils undergo a multi-stage moisture barrier encapsulation process prior to palletization. Each coil is first wrapped in anti-tarnish VCI (Vapor Corrosion Inhibitor) paper, specifically formulated for copper’s high susceptibility to oxidation and sulfur-induced corrosion. This is followed by double-layering in 100μm-thick, metallized LDPE moisture-proof film with a water vapor transmission rate (WVTR) ≤0.5 g/m²/24hr at 38°C and 90% RH. Seams are hermetically sealed using industrial-grade impulse sealers to create a continuous barrier against salt-laden maritime atmospheres. Desiccant packs (minimum 50g per 100kg coil weight) are strategically positioned within the sealed envelope to maintain internal relative humidity below 40% throughout voyages exceeding 30 days.

Sea freight safety is systematically addressed through three critical controls. First, palletized loads are secured via steel strapping with 5000N tensile strength, anchored to pallet stringers to prevent shifting during vessel pitching. Second, humidity indicators and temperature data loggers are affixed externally for real-time monitoring, with thresholds triggering corrective action if ambient humidity exceeds 65% for >48 hours. Third, all stacked containers adhere to IMO CSC safety limits, with maximum vertical stacking restricted to 1.5 tons per pallet to avoid coil edge damage or film compromise. This integrated approach mitigates galvanic corrosion risks inherent in mixed-metal shipments (copper-aluminum contact) and aligns with ISO 11607-1:2019 standards for sterile barrier systems adapted for industrial metals.

Our packaging protocol has achieved zero moisture-related claims across 12,000+ TEU shipments since 2018, validated by third-party logistics audits. Clients receive digital packing lists detailing VCI batch codes, desiccant quantities, and seal integrity test results. For extended transits (e.g., South America or Africa routes), we recommend optional vacuum-assisted sealing at +15% cost—a solution reducing internal oxygen levels to <0.1% and extending protection to 90+ days. This precision-engineered methodology ensures your transformer foil arrives with surface roughness (Ra) and electrical conductivity properties unchanged from factory output, directly supporting downstream winding process efficiency.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Strip and Foil Solutions

With over two decades of specialized expertise in the production of transformer strip and foil, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the global supply chain for high-performance conductive materials. Our vertically integrated manufacturing platform enables us to deliver both aluminum and copper foils engineered to meet the stringent demands of power transmission, electronics, and renewable energy applications. As a certified industrial partner, we combine deep metallurgical knowledge with advanced process control to ensure consistent product integrity across high-volume production runs.

Our facility operates under ISO 9001 quality management standards, with dedicated R&D and QC laboratories equipped for mechanical, electrical, and dimensional testing. We utilize precision cold-rolling mills with automatic gauge control (AGC) systems to produce copper and aluminum foils with tight thickness tolerances, typically within ±2.5% for standard grades and ±1.5% for high-precision specifications. Surface roughness is maintained below Ra 0.45 μm, ensuring optimal winding performance and dielectric compatibility in transformer and inductor assemblies.

We specialize in custom-tailored solutions, including slit-to-width copper strip, annealed and half-hard tempers, and edge-trimmed foil coils ranging from 0.05 mm to 3.0 mm in thickness. Our copper foil offerings include electrolytic (ED) and rolled annealed (RA) types, with conductivity levels exceeding 98% IACS and tensile strength adjustable between 200–350 MPa depending on temper. For aluminum, we supply 1060, 1070, and 1100 alloys in O, H14, and H16 tempers, with widths up to 1200 mm and coil IDs of 200 mm or 508 mm as per customer requirements.

Material traceability is maintained through barcode tracking from ingot to shipment, ensuring full compliance with RoHS and REACH regulations. Our in-house metallurgical analysis includes OES, XRF, and microstructure evaluation to validate alloy composition and grain uniformity. This technical rigor supports reliability in mission-critical applications such as high-efficiency distribution transformers, traction systems, and grid-scale energy storage.

As global demand for efficient power conversion grows, Luoyang Xinzhaohe remains committed to innovation, scalability, and on-time delivery. We support clients with technical data sheets, sample provisioning, and engineering consultations to align material specifications with end-use performance criteria.

For sourcing inquiries, technical collaboration, or material testing requests, contact us directly at cathy@transformerstrip.com. Partner with a manufacturer built on precision, experience, and industrial accountability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper foil manufacturer directly from China.