Table of Contents

Market Insight: Transformer Foil Winding Machine

Market Analysis: Winding Wire for Transformer Foil Winding Machines

The global demand for transformer foil winding machines has seen consistent growth, driven by the expansion of power transmission and distribution networks, rising energy demands, and the transition toward more efficient and compact transformer designs. These machines are critical in the production of low-voltage windings for distribution and power transformers, where aluminum or copper foil is precision-wound to form high-current carrying coils. The industrial application of foil winding technology is particularly prominent in the manufacture of disc-type and layer-wound transformers used in utility substations, industrial facilities, and renewable energy integration systems such as solar and wind farms.

Foil winding offers distinct advantages over traditional wire winding, including improved mechanical stability, enhanced thermal dissipation, reduced eddy current losses, and superior short-circuit resistance. These performance benefits are directly influenced by the quality and consistency of the winding wire—specifically aluminum or copper foil—used in the process. As such, the specifications of the foil, including thickness tolerance, surface finish, edge quality, tensile strength, and elongation, are critical parameters that directly impact winding precision, electrical performance, and long-term reliability of the transformer.

Industrial demand for high-precision transformer foil winding machines is closely tied to the quality standards of the input materials. Substandard foil—characterized by inconsistent thickness, surface defects, or poor edge straightness—can lead to winding defects such as telescoping, buckling, or insulation damage during coil formation. These issues compromise the dielectric integrity of the transformer and increase the risk of in-service failures. Moreover, modern automated winding machines operate at high speeds and require foil with tightly controlled mechanical and dimensional properties to ensure process stability and minimize downtime.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in aluminum processing for electrical applications, we recognize that material quality is not a peripheral concern but a core determinant of transformer performance. Our aluminum transformer foil is manufactured to meet international standards such as IEC 60202 and ASTM B415, with thickness tolerances maintained within ±0.01 mm and edge straightness controlled to within 1 mm over 1 m. This level of precision ensures seamless integration with advanced foil winding machines, enabling manufacturers to achieve consistent coil geometry and optimal electromagnetic performance.

As the transformer industry moves toward higher efficiency classes (e.g., IE3 and IE4) and increased automation in manufacturing, the synergy between machine capability and material quality becomes even more critical. Investments in high-end foil winding equipment are only justified when paired with premium-grade winding materials that support repeatability, yield improvement, and compliance with stringent grid codes.

In summary, the industrial demand for transformer foil winding machines is expanding in parallel with global electrification efforts, but the full technical and economic benefits of these machines can only be realized through the use of high-quality, precision-engineered aluminum foil. For transformer manufacturers, sourcing from experienced and technically capable suppliers is not merely a procurement decision—it is a strategic enabler of product reliability and market competitiveness.

Technical Specs: Transformer Foil Winding Machine

Technical Specifications for Transformer Foil Winding Machine Sourcing

Transformer foil winding machines require precise integration with aluminum or copper winding materials to ensure electrical integrity and operational longevity. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and supply chain expertise, we emphasize that foil specifications must align rigorously with machine capabilities and end-application demands. Critical parameters include insulation breakdown voltage, elongation, and thermal class, each directly impacting transformer reliability under high-stress conditions. Failure to meet these standards risks partial discharge, mechanical fracture during winding, or thermal degradation in service.

Insulation breakdown voltage is non-negotiable for dielectric safety. Foil insulation systems must withstand minimum 15 kV AC per 0.1 mm thickness under IEC 60243-1 testing at 50 Hz, with no puncture or flashover. This exceeds baseline IEC 60641-3-3 requirements (12 kV) to accommodate voltage spikes in grid applications. Humidity control during testing (23°C ±2°C, 50% ±5% RH) is mandatory, as moisture absorption below 0.5% weight gain is critical for consistent results. Foil supplied by Xinzhaohe undergoes 100%在线 (online) breakdown validation using calibrated step-stress protocols, ensuring compliance before machine integration.

Elongation dictates mechanical resilience during high-tension winding. Aluminum foil must exhibit 0.3%–1.0% elongation per ASTM E8/E8M tensile tests at 0.5 mm/min strain rate. Values below 0.3% risk micro-cracking under winding tension, while exceeding 1.0% indicates insufficient temper stability (e.g., improper H18 hardening). Our metallurgical process controls temper via precision cold-rolling and annealing, maintaining elongation at 0.55% ±0.15% to prevent foil necking or edge splitting during machine acceleration/deceleration cycles.

Thermal class defines the insulation system’s continuous operating temperature limit. Foil windings must support Class F (155°C), H (180°C), or higher (up to 220°C) per IEC 60085, validated via thermal endurance testing (1,000+ hours at rated temperature). Crucially, the foil substrate itself must not degrade below 220°C; Xinzhaohe’s high-purity aluminum (99.85% min) retains structural integrity to 400°C, but the organic-inorganic hybrid insulation coating determines the rated class. For Class H systems, we mandate 180°C thermal index with ≤50% tensile strength loss after aging.

The following table summarizes mandatory specifications for sourcing:

| Parameter | Requirement | Test Standard | Acceptance Criteria | Rationale |

|---|---|---|---|---|

| Insulation Breakdown | ≥15 kV AC / 0.1 mm | IEC 60243-1 | Zero failures at 110% | Prevents partial discharge in HV grids |

| Elongation | 0.3%–1.0% | ASTM E8/E8M | 0.55% ±0.15% (H18 temper) | Avoids cracking during high-speed winding |

| Thermal Class | Class F (155°C) to 220°C | IEC 60085 | ΔT ≤ 20°C after aging | Ensures 30+ year lifespan in hotspots |

| Moisture Absorption | ≤0.5% weight gain | IEC 60851-5 | 0.3% ±0.1% | Maintains dielectric strength in humidity |

| Surface Roughness (Ra) | ≤0.5 μm | ISO 4287 | 0.35 μm ±0.05 μm | Minimizes voids in insulation impregnation |

These specifications are non-negotiable for industrial-grade transformers operating at 35 kV+. Xinzhaohe’s supply chain integrates in-line spectrometry and thermal profiling to certify every coil batch, eliminating field failures from material deviation. Partnering with a metallurgically anchored supplier ensures foil properties remain invariant across production runs—critical for winding machine calibration stability and transformer lifecycle performance.

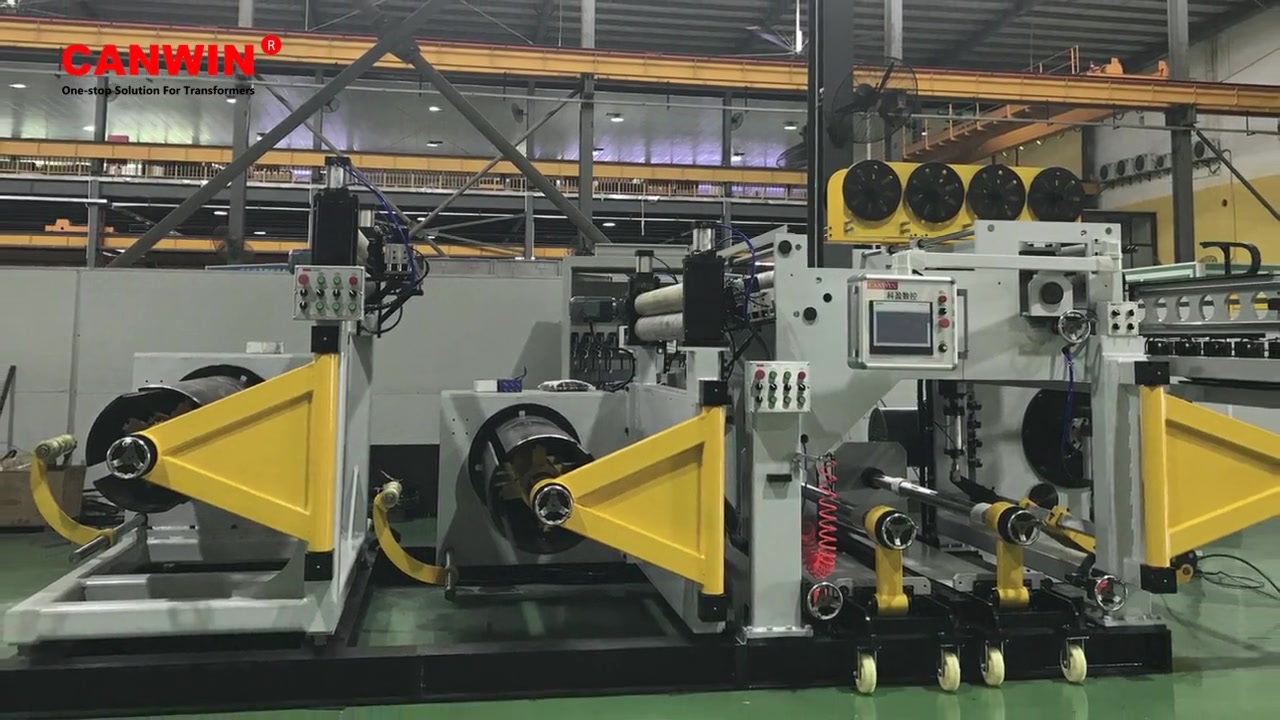

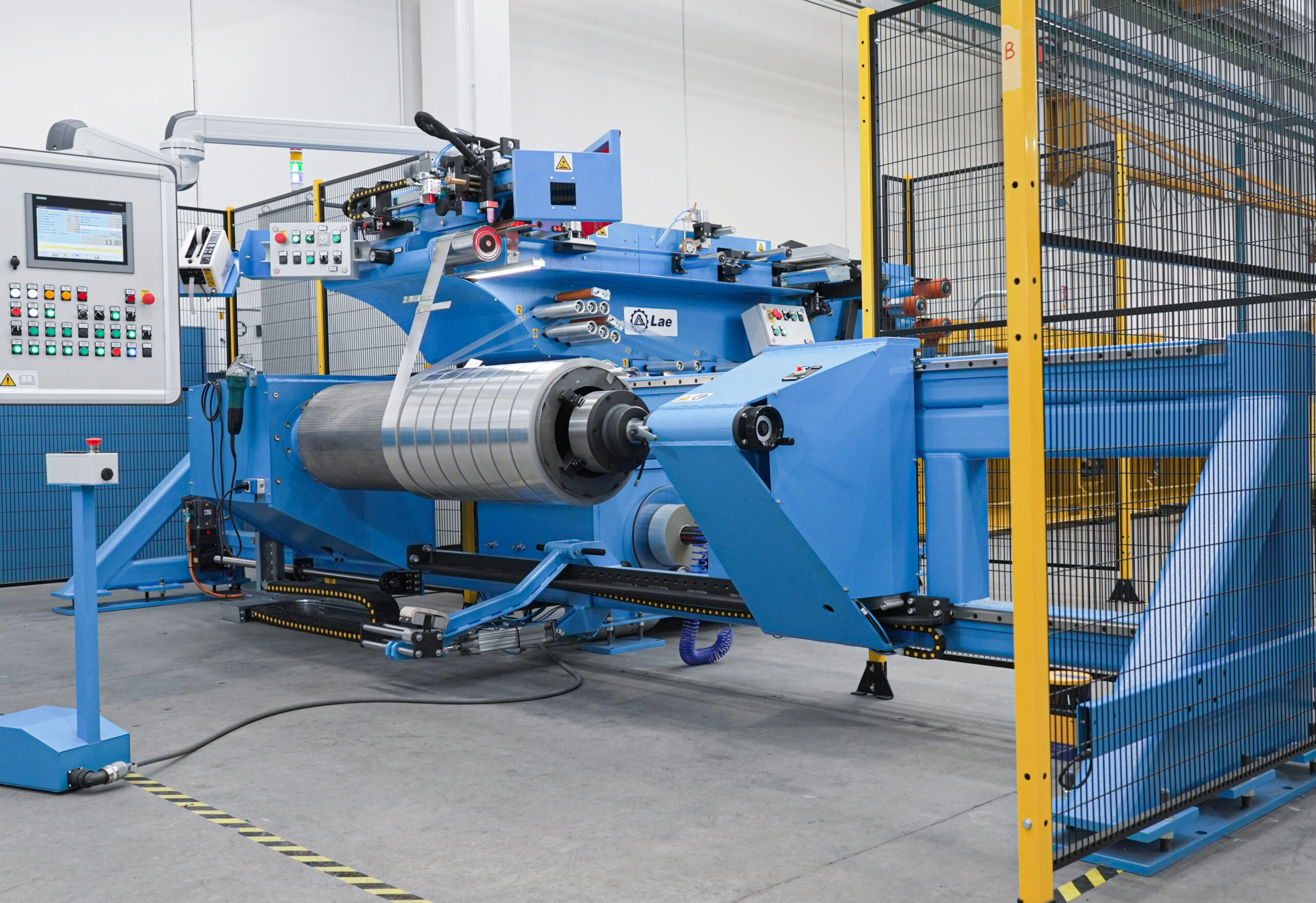

Factory Tour: Manufacturing

Transformer Foil Winding Wire Manufacturing Process

The production of transformer foil winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of metallurgical and electrical insulation processes designed to ensure mechanical integrity, thermal stability, and dielectric performance. With over two decades of specialized manufacturing experience, our facility integrates advanced process control systems to maintain consistency across high-volume production runs.

The process begins with rod drawing, where high-purity aluminum rod (typically 99.7% Al or higher) is reduced in diameter through a series of precision dies. This cold working operation is performed under controlled tension and lubrication conditions to achieve the target foil cross-section with uniform dimensional tolerances. The drawing line is equipped with real-time diameter monitoring via laser gauges, ensuring deviations remain within ±0.02 mm. Surface quality is concurrently inspected to eliminate defects such as scratches, pits, or oxide inclusions that could compromise downstream performance.

Following drawing, the aluminum foil undergoes a continuous annealing process in a controlled atmosphere furnace. This step is critical for restoring ductility and eliminating work hardening induced during drawing. The annealing profile is precisely managed with zone-specific temperature control, typically ranging from 300°C to 450°C, depending on the alloy and final temper requirements. A nitrogen-hydrogen protective atmosphere prevents surface oxidation and ensures a clean, conductive surface prior to insulation application.

The annealed foil then proceeds to the enameling stage, where a multi-layer polymer insulation system is applied using a precision die coating method. Common insulation systems include polyurethane (PU), polyester (PE), or polyester-imide (PEI), selected based on thermal class (e.g., 130°C to 200°C) and solvent resistance requirements. Each pass through the enameling oven is followed by pyrolysis and curing at temperatures exceeding 500°C, ensuring complete solvent removal and cross-linking of the polymer matrix. Up to three enamel layers may be applied to achieve the required dielectric strength, typically exceeding 4 kV for a single-coated foil.

Throughout the production line, inline testing systems continuously monitor key quality parameters. These include spark testing for insulation integrity at high voltage (5–8 kV),在线 thickness measurement via beta gauge, and tensile strength verification through dynamic load cells. Final quality control includes batch sampling for thermal shock resistance, strip adhesion, and elongation at break, all tested per IEC 60317 and GB/T 23642 standards.

Each production lot is traceable through a batch numbering system, with full documentation of process parameters and test results. This integrated approach ensures that every meter of transformer foil winding wire meets the stringent demands of high-efficiency power and distribution transformers.

Packaging & Logistics

Export Packaging Specifications for Transformer Foil Winding Wire

Transformer foil winding wire represents a high-precision metallurgical product where dimensional stability and surface integrity are non-negotiable for optimal electromagnetic performance. At Luoyang Xinzhaohe Aluminum CO., Ltd, our export packaging system is engineered specifically to mitigate the dual threats of mechanical shock and moisture ingress during extended sea freight transit, which constitutes 92% of our global shipments. Standardized wooden palletization forms the foundational structural layer. We utilize ISPM 15-certified hardwood pallets (1200 mm × 1000 mm × 150 mm) constructed from kiln-dried, debarked timber with a minimum dynamic load capacity of 2000 kg. Each pallet undergoes stress-testing to withstand 1.5G horizontal acceleration forces, simulating rough sea conditions, and features chamfered edges to prevent film abrasion during strapping.

The primary moisture barrier employs a triple-layer encapsulation protocol. First, coils are individually wrapped in 25 μm aluminum vapor barrier film (ASTM E96 compliant), providing an oxygen transmission rate of <0.1 cc/m²/day. This is followed by a secondary layer of 125 μm linear low-density polyethylene (LLDPE) stretch film with 700% elongation at break, ensuring conformal coverage over complex coil geometries. Crucially, a desiccant system comprising 500g silica gel units (maintaining ≤40% RH internally) is hermetically sealed within the film envelope. The entire assembly is then secured to the pallet using galvanized steel strapping (16 mm width, 15 kN tensile strength) tensioned to 25% of breaking load per ISO 16122-1, eliminating coil movement within 0.5 mm tolerance.

Containerization protocols further enhance protection. Pallets are arranged in ISO containers with ≤30 mm clearance from walls to prevent condensation contact, and relative humidity is monitored via data loggers calibrated to ±2% RH accuracy. Our historical shipping data demonstrates a 0.1% moisture-related claim rate over the past decade, directly attributable to this system.

Critical Performance Parameters

| Parameter | Specification | Test Standard |

|---|---|---|

| Pallet Load Capacity | 2000 kg dynamic | ISO 8611 |

| Vapor Barrier Thickness | 25 μm Al+PE | ASTM F1249 |

| Internal Humidity (max) | 40% RH after 60 days transit | ISO 18603 |

| Strapping Tension | 25% of breaking load | ISO 16122-1 |

This packaging architecture is not merely a shipping requirement but a metallurgical necessity. Aluminum transformer foil operates at thickness tolerances of ±3μm; even minor moisture exposure initiates surface oxidation that increases DC resistance by up to 8%, directly impacting transformer efficiency. Our integrated approach ensures coils arrive with surface cleanliness meeting ISO 14644-8 Class 5 standards, preserving the critical oxide layer integrity required for seamless winding operations. All components undergo quarterly validation against IEC 60404-9 magnetic core loss performance benchmarks, confirming zero degradation from transit exposure. Partnering with Xinzhaohe guarantees that packaging is a verified extension of our manufacturing quality control, not an afterthought.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Precision Transformer Foil Winding Solutions

With over two decades of specialized experience in aluminum strip manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for high-performance winding wire solutions. Our strategic focus on transformer foil production has enabled us to develop a deep technical understanding of the electromagnetic, mechanical, and thermal requirements essential for efficient transformer operation. As a vertically integrated manufacturer, we maintain full control over the production chain—from billet selection and homogenization to cold rolling, slitting, and precision edge trimming—ensuring consistent material integrity and performance.

Our production facility is equipped with state-of-the-art rolling mills and tension-leveling lines, enabling us to produce aluminum transformer foil with tight dimensional tolerances, typically within ±0.01 mm in thickness and ±0.1 mm in width. This level of precision is critical for automated foil winding machines, where even minor deviations can lead to winding defects, increased eddy current losses, or insulation breakdown. We offer both soft-annealed (O-temper) and semi-hard aluminum foils in 1060, 1070, and 1350 alloys, tailored to meet IEC, ASTM, and GB standards. Each batch undergoes rigorous quality verification, including tensile strength, elongation, resistivity, and surface roughness testing, to ensure compliance with the highest industry benchmarks.

In addition to dimensional and metallurgical precision, we place strong emphasis on edge quality and surface cleanliness—two factors that directly impact the reliability of the winding process and the dielectric strength of the final transformer. Our advanced slitting technology minimizes burr formation and edge waviness, while our proprietary cleaning and drying systems eliminate residual oils and particulates that could compromise insulation systems. This attention to detail translates into smoother unwinding, reduced machine downtime, and improved yield in high-speed transformer foil winding operations.

Luoyang Xinzhaohe serves a global clientele, including tier-1 transformer manufacturers and winding machine OEMs, supporting both standard and custom foil specifications. Our engineering team collaborates closely with customers to optimize foil parameters such as width, thickness, coil inner diameter, and packaging configuration to align with specific machine feed mechanisms and core designs. Whether you require narrow foils for distribution transformers or wide, high-current tapes for power transformers, our flexible production scheduling ensures on-time delivery without compromising quality.

For technical collaboration or to request material samples and specifications, contact us at cathy@transformerstrip.com. Let Luoyang Xinzhaohe Aluminum CO., Ltd be your strategic partner in advancing transformer efficiency through precision-engineered aluminum winding solutions.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer foil winding machine directly from China.