Table of Contents

Market Insight: 1Mm Copper Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Luoyang Xinzhaohe Aluminum CO., Ltd. clarifies that while our corporate name emphasizes aluminum expertise, our metallurgical and supply chain capabilities comprehensively cover high-purity copper transformer strip, including 1mm gauge, leveraging 20+ years of precision rolling experience. Industrial demand for 1mm copper strip in transformer manufacturing remains robust, driven by global energy efficiency mandates and grid modernization. This thickness is optimal for low-voltage windings in distribution transformers (50 kVA to 2500 kVA), where precise cross-sectional area balances current density, thermal management, and manufacturability. Rising adoption of amorphous metal cores and high-efficiency IE4/IE5 transformers further intensifies demand for copper strip meeting exacting electrical and mechanical tolerances, as copper’s superior conductivity (100% IACS minimum) directly reduces no-load and load losses compared to aluminum alternatives.

Quality is non-negotiable in transformer copper strip due to direct impacts on operational reliability and lifecycle costs. Substandard material introduces critical failure vectors: impurities (e.g., oxygen > 10 ppm) accelerate intergranular corrosion during varnishing, while inconsistent thickness (±0.02mm tolerance exceeded) causes uneven winding tension, leading to partial discharges or insulation breakdown. Crucially, electrical resistivity deviations directly translate to energy loss; a mere 0.5% reduction in conductivity (99.5% IACS vs. 100% IACS) increases resistive losses by approximately 0.8% per transformer, accumulating significant financial and environmental costs at scale. Hydrogen embrittlement risks from inadequate oxygen control during annealing further compromise mechanical integrity under thermal cycling.

The following table defines critical quality parameters for 1mm transformer copper strip per industry benchmarks:

| Parameter | Target Specification | Consequence of Deviation |

|---|---|---|

| Thickness Tolerance | 1.00 ± 0.015 mm | Winding misalignment, increased eddy currents |

| Conductivity | ≥ 100.5% IACS | Elevated resistive losses, thermal runaway risk |

| Oxygen Content | ≤ 5 ppm | Hydrogen embrittlement, reduced ductility |

| Tensile Strength | 200-240 MPa | Poor winding stability, layer deformation |

| Surface Roughness | Ra ≤ 0.4 µm | Insulation damage, partial discharge initiation |

Supply chain resilience hinges on consistent quality adherence. Variability in strip properties forces transformer manufacturers to implement costly in-process inspections or scrap rates exceeding 5%, directly inflating production costs. Luoyang Xinzhaohe’s integrated quality control—spanning cathode sourcing, continuous casting, and precision cold rolling with inline conductivity gauging—ensures lot-to-lot uniformity. This mitigates supply disruption risks while supporting transformer OEMs in achieving mandated efficiency tiers (e.g., DOE 2016, EU EcoDesign). Ultimately, premium 1mm copper strip is not a commodity input but a performance-critical component; its metallurgical integrity dictates transformer efficiency, longevity, and compliance with evolving global energy standards. Partnering with a supplier possessing deep process mastery is essential to optimize total cost of ownership beyond initial material pricing.

Technical Specs: 1Mm Copper Strip

Technical Specifications for 1mm Copper Strip – Precision Transformer Grade

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-purity 1mm copper strip to meet the stringent demands of the transformer and electrical equipment industries. With over two decades of metallurgical expertise and advanced precision slitting technology, our copper strips are engineered for optimal electrical performance, dimensional accuracy, and edge quality. Each batch is produced under ISO-certified quality control protocols to ensure consistency and reliability in high-current and high-efficiency applications.

The base material for our 1mm copper strip is electrolytic tough pitch (ETP) copper, meeting ASTM B187 and GB/T 5231 standards, with a minimum copper content of 99.90%. This ensures excellent electrical conductivity, essential for minimizing resistive losses in transformer windings and busbar systems. Conductivity is rigorously tested and consistently achieves 98% to 101% IACS (International Annealed Copper Standard), depending on temper and processing conditions. The strips are available in both soft (annealed) and hard (as-rolled) tempers, allowing customization based on formability and mechanical strength requirements.

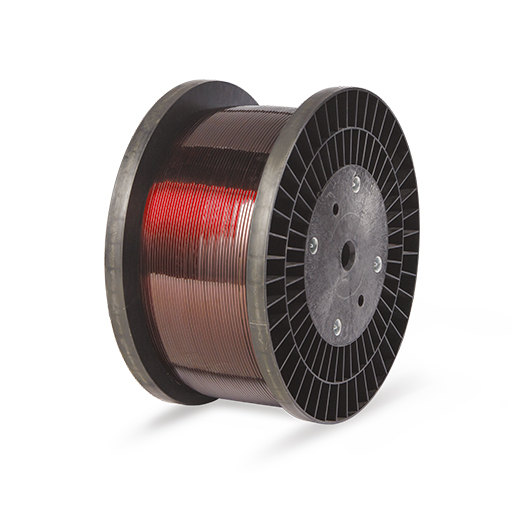

Dimensional precision is critical in transformer applications where tight winding tolerances and uniform layer stacking are required. Our 1mm copper strip is precision slit using high-tolerance rotary shear slitters with automatic edge guiding systems, ensuring a thickness tolerance of ±0.002 mm across the full strip length. Width tolerances are maintained within ±0.05 mm, with customizable slit widths ranging from 10 mm to 300 mm based on customer design specifications. The strip is supplied in straight lengths or on reels, with core diameters of 300 mm or 500 mm, depending on order volume and handling requirements.

Edge quality is a key performance factor, particularly in automated winding processes where burrs can lead to insulation damage, short circuits, or equipment downtime. Our slitting process is optimized to produce burr-free edges, with a maximum edge burr height of ≤0.005 mm. This is achieved through computer-controlled blade clearance adjustment, real-time monitoring, and post-slitting edge inspection using optical profilometry. All strips undergo 100% visual and dimensional inspection prior to shipment.

Surface finish is maintained at a clean, oxide-minimized level, with a typical roughness (Ra) of 0.4 to 0.8 µm. The strips are packaged in moisture-resistant wrapping with anti-tarnish paper to prevent oxidation during storage and transit.

| Parameter | Specification |

|---|---|

| Material Grade | ETP Copper (Cu ≥ 99.90%) |

| Standard Compliance | ASTM B187, GB/T 5231 |

| Thickness | 1.000 mm (±0.002 mm) |

| Width Range | 10–300 mm (customizable) |

| Width Tolerance | ±0.05 mm |

| Temper Options | Soft (Annealed), Hard (As-Rolled) |

| Electrical Conductivity | 98%–101% IACS |

| Edge Burr Height | ≤0.005 mm (burr-free) |

| Surface Roughness (Ra) | 0.4–0.8 µm |

| Packaging | Reels or straight lengths, anti-tarnish protection |

All specifications are subject to customer technical agreements and can be further refined for specialized transformer designs. Luoyang Xinzhaohe Aluminum Co., Ltd. supports full material traceability and provides mill test certificates with every shipment.

Factory Tour: Manufacturing

Manufacturing Process for 1mm Copper Strip: Precision Engineering for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to produce high-integrity 1mm copper strip essential for transformer windings. Our rigorous manufacturing sequence ensures dimensional accuracy, superior surface quality, and edge integrity critical for reliable transformer performance and dielectric strength. The core process integrates Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating stringent quality control protocols.

Cold Rolling forms the foundational step, transforming electrolytic tough pitch (ETP) copper cathode into precise strip geometry. Starting material undergoes initial hot rolling to intermediate thickness, followed by multiple cold reduction passes in a reversing mill. Critical process parameters include controlled reduction per pass (typically 30-50%), precise roll gap calibration, and optimized rolling speed to manage work hardening and thermal effects. Interpass annealing in controlled atmosphere furnaces (550-650°C) is strategically applied to restore ductility and eliminate residual stresses, preventing cracking during further reduction. Final cold rolling achieves the target 1.00mm nominal thickness with a tight tolerance band of ±0.02mm. Inline X-ray gauges continuously monitor thickness profile across the strip width, ensuring uniformity within 5μm. Surface inspection systems simultaneously detect defects such as scratches, pits, or inclusions, triggering immediate process correction.

Precision Slitting follows, where the master coil is longitudinally cut into customer-specified widths. This operation utilizes high-precision razor slitting lines equipped with servo-controlled tension management systems. Tension uniformity across the strip width is paramount to prevent edge waviness or width variation. Slitting knives are maintained to exacting sharpness standards and set with micron-level accuracy to achieve width tolerances of ±0.05mm. Critical to transformer reliability, the slitting process is optimized to minimize edge burr formation. Real-time laser micrometers continuously measure edge burr height, with our process consistently maintaining levels below 5μm. Any coil segment exceeding this threshold is automatically quarantined.

Edge Conditioning represents a vital final stage specifically for transformer-grade material. The freshly slit edges undergo controlled mechanical brushing or light grinding. This process removes microscopic burrs, smooths micro-tears from slitting, and imparts a consistent, slightly radiused edge profile. The target edge radius is maintained between 0.05mm and 0.10mm. This conditioning is non-negotiable for transformer applications, as sharp edges can puncture interlayer insulation during winding, leading to catastrophic dielectric failure. Post-conditioning, edges are meticulously inspected using optical comparators and scanning electron microscopy (SEM) to verify the absence of protrusions and confirm the specified radius.

Quality control is intrinsically embedded throughout the entire production flow, not confined to endpoint testing. Key verification points include:

| Process Stage | Key QC Parameter | Measurement Method | Acceptance Criterion |

|---|---|---|---|

| Cold Rolling | Thickness Profile | Inline X-ray Gauge | ±0.02mm; Max 5μm variation |

| Cold Rolling | Surface Defects | Automated Vision System | Zero critical defects |

| Precision Slitting | Edge Burr Height | Laser Micrometer | < 5μm |

| Edge Conditioning | Edge Radius Profile | Optical Comparator / SEM | 0.05mm – 0.10mm |

| Final Product | Tensile Properties | Destructive Test (Per ASTM B557) | Yield: 60-90 MPa; UTS: 220-250 MPa |

Final product certification includes comprehensive mechanical property testing, dimensional verification per ISO 6892-1, and 100% surface inspection. This integrated, process-driven approach guarantees the 1mm copper strip meets the exacting demands of modern transformer manufacturing.

Packaging & Logistics

Export Packaging for 1mm Copper Strip: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in transformer-grade aluminum and copper strip production, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity during international transit. For the export of 1mm copper strip, our packaging methodology is engineered to counteract the primary risks associated with sea freight: mechanical impact, humidity, salt exposure, and prolonged storage conditions.

All 1mm copper strip shipments are secured on high-grade wooden pallets constructed from durable, kiln-dried hardwood. These pallets are designed to ISO 15537 standards, ensuring structural resilience under stacking loads and compatibility with global handling equipment. The wood is treated in compliance with ISPM 15 regulations to prevent the spread of quarantine pests, a mandatory requirement for cross-border shipments. Each pallet is dimensionally optimized to match the coil outer diameter and weight, minimizing overhang and reducing the risk of edge deformation during lifting and transport.

Prior to palletization, every copper strip coil is wrapped in multiple layers of moisture-proof polyethylene film with a minimum thickness of 125 microns. This film provides a vapor barrier with a water vapor transmission rate (WVTR) below 5 g/m²·24h, effectively shielding the copper from ambient humidity and condensation common in marine environments. The film is heat-sealed at all seams to ensure continuity and is overlapped by no less than 50 mm per wrap to eliminate potential ingress points.

An additional layer of corrosion-inhibiting VCI (Vapor Corrosion Inhibitor) film is applied directly against the copper surface when specified by customer requirements or in high-humidity route scenarios. This molecular layer passivates the metal surface, offering electrochemical protection against oxidation without altering the strip’s surface conductivity or solderability.

Coils are further secured with galvanized steel strapping, applied in a cross-pattern across the pallet, meeting ASTM D3953 standards for tensile strength and elongation. Edge protectors made from laminated cardboard or steel are fitted at critical contact points to prevent localized deformation during strapping and handling.

All packaged units are labeled with UV-resistant, tamper-evident tags containing essential shipment data: coil ID, dimensions, weight, alloy grade (e.g., T2 copper), temper, and handling instructions. Hazard communication, where applicable, complies with IMDG Code for sea transport.

This comprehensive packaging system has been validated through accelerated salt spray testing (ASTM B117) and real-world shipping trials across major trade lanes, including trans-Pacific and Asia-Europe routes. It ensures that 1mm copper strip arrives at destination facilities with zero degradation in flatness, surface quality, or electrical performance—critical for downstream transformer winding operations.

Luoyang Xinzhaohe Aluminum Co., Ltd treats export packaging as an extension of our quality control protocol, guaranteeing that every meter of copper strip meets the exacting standards demanded by the global power transmission and distribution sector.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Strip Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and high-volume production expertise to deliver exceptional 1mm copper strip critical for demanding transformer and electrical applications. Our integrated manufacturing ecosystem, purpose-built for transformer strip and foil, ensures consistent material performance, supply chain resilience, and technical partnership beyond standard sourcing. We address core industry challenges: stringent dimensional tolerances, absolute surface integrity, guaranteed electrical properties, and reliable just-in-time delivery.

Our vertically integrated facility houses state-of-the-art continuous casting-rolling lines coupled with precision cold rolling mills featuring automatic gauge control (AGC) and tension leveling systems. This enables us to consistently achieve the tight tolerances and surface finishes essential for high-efficiency transformer cores and windings. Production capacity exceeds 15,000 metric tons annually for copper strip, with dedicated lines optimized for the 0.1mm to 3.0mm thickness range, ensuring scalability for large-volume transformer manufacturers without compromising on quality.

Production Capabilities for 1mm Copper Strip (C11000/C10100 Standard)

| Parameter | Specification | Measurement Method |

|---|---|---|

| Thickness | 1.00 mm ± 0.01 mm | Laser Micrometer (Online) |

| Width Tolerance | ± 0.5 mm | Ultrasonic Sensor |

| Conductivity | ≥ 100% IACS | Eddy Current Tester |

| Surface Roughness (Ra) | ≤ 0.4 µm | Profilometer |

| Tensile Strength | 200 – 240 MPa | Universal Tester |

| Elongation | ≥ 40% | Universal Tester |

Metallurgical control is paramount. We implement rigorous raw material traceability from certified LME-grade cathodes through a proprietary multi-stage refining and continuous casting process. This guarantees superior purity (min 99.90% Cu+Ag), exceptional metallurgical homogeneity, and minimized oxide inclusions. Every coil undergoes 100% automated surface inspection via high-resolution line-scan cameras to detect micro-scratches, pits, or roll marks invisible to the naked eye – defects that cause catastrophic core losses in transformers. Comprehensive quality assurance includes in-line eddy current conductivity testing, periodic spectrographic analysis, and mechanical property verification per ASTM B111/B224 standards, maintaining a documented defect rate below 0.5%.

Our supply chain infrastructure is engineered for transformer industry demands. Strategically located in Henan Province with direct rail access to major ports, we offer flexible logistics solutions including containerized flatbed shipments and custom coil packaging to prevent transit damage. ERP-integrated production scheduling ensures transparent order tracking and reliable on-time delivery performance exceeding 98.5%. We provide full material test reports (MTRs) with every shipment, including heat number traceability and batch-specific conductivity data.

Partnering with Luoyang Xinzhaohe means securing a supplier whose metallurgical rigor directly translates to your transformer’s efficiency, yield, and reliability. We eliminate material-related production bottlenecks and quality variances through engineered consistency. For certified 1mm copper strip meeting the most exacting transformer specifications, contact our technical sourcing team. Cathy Wang provides direct engineering support and quotation services. Reach out today at cathy@transformerstrip.com to discuss your specific performance requirements and volume needs.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 1mm copper strip directly from China.