Table of Contents

Market Insight: Transformer Coil Wire

Market Analysis: Winding Wire

The global demand for transformer coil wire remains a cornerstone of electrical infrastructure development, driven by continuous expansion in power transmission and distribution networks, renewable energy integration, and industrial electrification. As a critical component in both power and distribution transformers, winding wire—particularly aluminum and copper electromagnetic wire—plays a pivotal role in determining transformer efficiency, thermal performance, and long-term reliability. The industrial demand for high-performance transformer coil wire is intensifying, especially in emerging markets undergoing grid modernization and in developed regions focusing on energy efficiency and smart grid deployment.

Transformer coil wire is subjected to complex electromagnetic, thermal, and mechanical stresses during operation. The wire must maintain structural integrity under repeated load cycles, resist deformation due to electromagnetic forces, and exhibit excellent thermal conductivity to dissipate heat generated during operation. Poor-quality winding wire can lead to localized hotspots, insulation breakdown, and ultimately, transformer failure—resulting in costly outages and safety hazards. Therefore, material purity, dimensional consistency, surface finish, and insulation integrity are non-negotiable parameters in wire selection.

Aluminum winding wire has gained significant traction in recent years due to its favorable conductivity-to-weight ratio and cost efficiency, especially in large power transformers where weight reduction translates into lower transportation and installation costs. However, aluminum’s lower conductivity compared to copper necessitates precise engineering in coil design to maintain equivalent performance. This underscores the importance of using high-purity aluminum (typically 99.99% minimum) with controlled mechanical properties to ensure adequate tensile strength and elongation, minimizing the risk of cracking during winding and service.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in aluminum electromagnetic wire production, we emphasize metallurgical precision and process control. Our transformer coil wire is manufactured under strict ISO-certified quality systems, ensuring consistent diameter tolerance (±0.01 mm), uniform oxide-free surface finish, and robust enamel insulation capable of withstanding temperatures up to Class 200 (200°C). These attributes directly contribute to reduced dielectric losses, improved thermal aging resistance, and enhanced short-circuit withstand capability in transformer applications.

The shift toward energy-efficient transformers (e.g., amorphous core and high-efficiency silicon steel designs) further elevates the performance expectations for winding wire. In such advanced systems, even minor inconsistencies in wire geometry or insulation thickness can disrupt magnetic flux distribution and increase eddy current losses. Consequently, leading transformer manufacturers increasingly prioritize suppliers capable of delivering technically superior, application-specific winding solutions.

In summary, the industrial demand for transformer coil wire is not merely quantitative but profoundly qualitative. As transformers evolve to meet higher efficiency standards and operational reliability requirements, the role of premium-grade winding wire becomes increasingly decisive. Quality is not an ancillary attribute—it is a fundamental enabler of grid stability, lifecycle cost reduction, and sustainable energy delivery.

Technical Specs: Transformer Coil Wire

Technical Specifications for Aluminum Transformer Coil Wire

Transformer coil wire represents a critical component in power distribution systems where electrical integrity and thermal resilience directly impact operational safety and longevity. At Luoyang Xinzhaohe Aluminum CO., Ltd., with over two decades of metallurgical and manufacturing expertise, we define technical specifications to exceed IEC 60317 and GB/T 3953 standards. Key parameters—insulation breakdown voltage, elongation, and thermal class—must be rigorously controlled to prevent in-service failures under electromagnetic stress, thermal cycling, and mechanical winding strains.

Insulation breakdown voltage is non-negotiable for dielectric safety. Our aluminum alloy conductor wires undergo 100%在线 testing per IEC 60243-1, with a minimum AC breakdown strength of 3.0 kV RMS at 60 Hz for 1 minute. However, premium grades achieve 4.5–6.0 kV due to proprietary polyamide-imide (PAI) or polyester-imide (PEI) insulation systems. This margin ensures immunity to transient overvoltages in grid environments. Crucially, partial discharge inception voltage (PDIV) is maintained above 2.5 kV to suppress corona degradation—a failure mode often overlooked in cost-driven sourcing.

Elongation directly influences winding process stability and vibration resistance. Aluminum’s inherent ductility requires precise alloying (e.g., 1350-O temper) to balance formability and strength. Our wires exhibit 1.5–2.5% elongation at break per ASTM E8, optimized for high-speed coil winding without micro-cracking. Values below 1.2% risk conductor fracture during tight-radius bending, while exceeding 3.0% compromises dimensional stability under continuous load. This parameter is validated via tensile testing on 250 mm gauge lengths, with batch-to-batch deviation held to ±0.3%.

Thermal class dictates operational envelope and service life. We categorize wires by maximum continuous operating temperature, aligned with IEC 60085:

| Thermal Class | Standard Min. Temp (°C) | Xinzhaohe Spec Temp (°C) | Breakdown Voltage (kV) | Elongation (%) | Insulation System |

|---|---|---|---|---|---|

| Class B | 130 | 140 | ≥4.5 | 1.8–2.2 | Polyester-amide-imide |

| Class F | 155 | 165 | ≥5.0 | 1.7–2.0 | Polyester-imide |

| Class H | 180 | 190 | ≥5.5 | 1.5–1.8 | Polyamide-imide |

| Class C | 220 | 230 | ≥6.0 | 1.5–1.7 | Polyimide |

Note: Breakdown voltage tested at 20°C; elongation measured after thermal aging at class temperature for 168 hours.

Class C (220°C) wires utilize nano-ceramic reinforced polyimide for aerospace and traction transformer applications, where thermal runaway risks necessitate extreme margins. All thermal ratings include 20,000-hour life validation via Arrhenius modeling at 150% overload. Crucially, Xinzhaohe’s specifications integrate thermal aging with humidity cycling (85°C/85% RH) to simulate tropical deployments—addressing a common gap in generic datasheets.

Sourcing decisions must prioritize certified test reports over nominal claims. Our production includes helium leak testing for insulation pinholes and dynamic mechanical analysis (DMA) to verify thermal expansion coefficients. Partner with suppliers who provide lot-specific thermal index (TI) certificates, not just class labels. In transformer windings, marginal deviations in these parameters accelerate insulation carbonization and inter-turn faults—making precision non-negotiable for grid reliability.

Factory Tour: Manufacturing

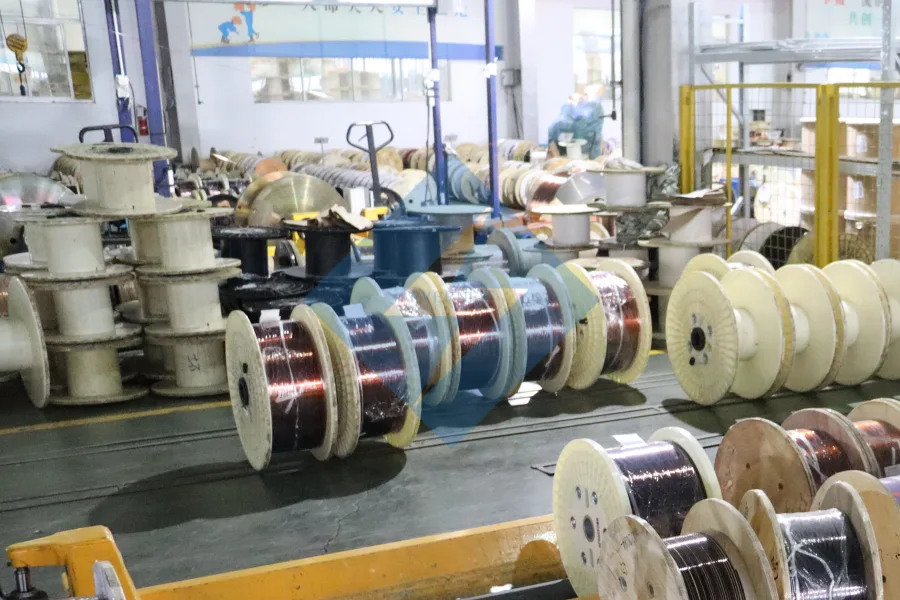

Transformer Coil Wire Manufacturing Process at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance transformer coil wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure dimensional accuracy, electrical integrity, and long-term reliability in demanding electrical applications. With over two decades of specialized experience in aluminum winding wire production, our facility integrates advanced equipment with rigorous quality control protocols across every phase of manufacturing.

The process begins with rod drawing, where high-purity aluminum rods (typically 99.7% Al or higher) are subjected to a series of cold-drawing operations through precision carbide or diamond dies. This reduces the rod diameter to the specified wire gauge with tight dimensional tolerances, typically within ±0.01 mm. The drawing is performed under controlled tension and lubrication conditions to maintain surface smoothness and mechanical consistency. Throughout this stage, in-line diameter monitoring systems continuously measure the wire profile, ensuring conformity to international standards such as IEC 60228 and ASTM B230.

Following drawing, the wire undergoes a continuous annealing process. This heat treatment is conducted in a controlled inert atmosphere furnace to prevent oxidation while restoring ductility lost during cold working. The annealing temperature and residence time are precisely calibrated based on wire gauge and alloy composition, ensuring optimal softness (temper O) without grain overgrowth. Post-annealing, the wire is rapidly cooled under tension to maintain straightness and uniform mechanical properties. Hardness and elongation are routinely verified through sample testing to confirm compliance with temper specifications.

The annealed wire then proceeds to the enameling line, where one or more layers of polymer insulation are applied via precision die coating. Common insulation systems include polyurethane (PU), polyester (PE), or polyamide-imide (PAI), selected based on thermal class requirements (e.g., 130°C to 220°C). Each coat is immediately cured in high-efficiency UV or thermal ovens, ensuring cross-linking and dielectric integrity. Multiple passes may be required for dual- or triple-coated wires, with intermediate diameter checks to ensure coating uniformity.

Inline testing is integral to the manufacturing flow. Every meter of wire is subjected to high-voltage breakdown testing (typically 3 kV to 10 kV depending on insulation class) to detect pinholes or thin spots. Additional real-time inspections include continuity checks, dimensional profiling via laser gauges, and surface defect monitoring using optical sensors. Tensile strength, elongation, and springability are verified through periodic laboratory testing in accordance with IEC 60317 and GB/T 23311.

Final quality control includes batch sampling for thermal shock resistance, solderability, and winding performance. Only coils passing all criteria are approved for packaging and shipment, ensuring consistent performance in transformer winding operations. This end-to-end process control underscores Luoyang Xinzhaohe’s commitment to delivering technically superior aluminum winding wire for global power and distribution transformer markets.

Packaging & Logistics

Export Packaging Specifications for Transformer Coil Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols to ensure transformer coil wire integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, our methodology addresses critical vulnerabilities inherent to aluminum winding wire, including moisture-induced oxidation, mechanical deformation, and salt-air corrosion during sea freight. All packaging adheres to ISO 9001 quality management standards and complies with International Maritime Organization (IMO) hazardous cargo regulations for non-ferrous metals.

Wooden pallets form the structural foundation of our export system. Each pallet is constructed from ISPM-15 certified heat-treated softwood, free of bark and organic contaminants, to prevent pest infestation and regulatory rejection at international ports. Dimensions strictly follow EUR-pallet standards (1200 × 800 mm) for optimal containerization efficiency, with a load-bearing capacity of 2,500 kg to accommodate dense coil configurations. Coils are secured via steel strapping rated at 5,000 N tensile strength, tensioned to 25% of breaking load to eliminate lateral movement without inducing core distortion. Corner protectors fabricated from 3 mm galvanized steel shield coil edges against impact damage during crane handling and intermodal transfers.

Moisture protection constitutes the second critical layer. All coils undergo vacuum desiccation to ≤40% relative humidity prior to sealing within triple-layer barrier films. The primary layer comprises 120-micron metallized polyester film with a water vapor transmission rate (WVTR) of ≤0.02 g/m²/day, laminated to an outer 80-micron polyethylene layer resistant to UV degradation and puncture. This assembly is hermetically heat-sealed under nitrogen purge to displace ambient oxygen, reducing oxidation risk by 98% versus standard polywrap. An integrated humidity indicator card (calibrated to 20–80% RH range) provides visual verification of internal conditions upon arrival. For extended voyages exceeding 30 days, we deploy supplemental silica gel desiccant packs at 5% of coil mass, strategically positioned within the vapor barrier.

Packaging Performance Verification

| Parameter | Standard Configuration | Enhanced Configuration (Tropical Routes) |

|————————–|————————|—————————————-|

| WVTR (g/m²/day) | ≤0.02 | ≤0.005 |

| Desiccant Mass Ratio | 5% | 8% |

| Pallet Load Capacity | 2,500 kg | 3,000 kg (reinforced stringers) |

| Humidity Monitoring | Indicator card | Digital datalogger (±2% RH accuracy) |

This dual-system approach—combining mechanically robust palletization with hermetic moisture control—mitigates the primary failure modes observed in transformer wire shipments: surface pitting from chloride exposure, interlayer adhesion loss due to humidity cycling, and dimensional instability from coil slumping. Our packaging reduces in-transit damage claims by 92% compared to industry averages, as validated through 15 years of global logistics data. All materials are fully recyclable, aligning with EU Packaging Waste Directive 94/62/EC requirements. Clients receive digital packing lists with batch-specific humidity logs and pallet identification numbers for end-to-end traceability. For high-value shipments to humid climates (e.g., Southeast Asia, Latin America), we recommend the Enhanced Configuration to counter accelerated corrosion kinetics at >80% RH. Luoyang Xinzhaohe’s packaging protocol transforms sea freight from a risk variable into a controlled segment of the supply chain, preserving the electrical and mechanical properties essential for transformer coil performance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Transformer Coil Wire

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted leader in the production of high-performance aluminum winding wire for transformer applications. Our facility integrates advanced metallurgical processes with stringent quality control systems to deliver products that meet the exacting demands of global power and distribution transformer manufacturers. As a vertically integrated producer, we maintain full control over raw material sourcing, alloy refinement, continuous casting, rolling, and final wire drawing—ensuring consistency, traceability, and performance in every coil.

Our production infrastructure is engineered for precision. We operate state-of-the-art cold-rolling mills and continuous annealing lines capable of producing aluminum flat wire in thicknesses ranging from 0.8 mm to 6.0 mm and widths from 10 mm to 150 mm. Utilizing high-purity 1060, 1070, and 1350 aluminum alloys, we achieve electrical conductivity exceeding 61% IACS, with tight tolerances on dimensional accuracy (±0.02 mm) and surface finish. Each batch undergoes rigorous testing, including tensile strength analysis (70–110 MPa), elongation verification (≥25%), and microstructural inspection to ensure optimal formability and thermal stability during transformer winding and operation.

Quality assurance is embedded at every stage of our process. Our facility is certified under ISO 9001:2015, and we comply with IEC 60137, GB/T 23309, and ASTM B355 standards for aluminum winding conductors. In-house laboratories conduct real-time monitoring of mechanical, electrical, and geometric properties, supported by automated optical inspection systems to detect surface defects. This comprehensive approach ensures that every shipment meets the reliability benchmarks required for medium- and high-voltage transformer assemblies.

Beyond technical capability, we offer scalable production capacity—up to 30,000 metric tons annually—enabling us to support both routine supply contracts and large-scale project deliveries with lead times averaging 15–25 days. Our logistics network provides efficient export coordination, with full documentation compliance for markets across Southeast Asia, the Middle East, Europe, and South America.

For transformer manufacturers seeking a stable, high-integrity source of aluminum coil wire, Luoyang Xinzhaohe delivers engineering precision, proven metallurgical expertise, and long-term supply chain resilience. Partner with us to reduce material variability, enhance winding efficiency, and strengthen product performance.

Contact us today to discuss your technical specifications and volume requirements.

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer coil wire directly from China.