Table of Contents

Market Insight: Copper Rectangle

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to drive steady demand for high-performance conductive materials, with copper rectangle strip playing a critical role in the construction of both power and distribution transformers. Copper’s superior electrical conductivity—approximately 100% IACS (International Annealed Copper Standard)—makes it the preferred material for windings in high-efficiency transformers, especially in applications where thermal management, load capacity, and long-term reliability are paramount. The dimensional stability and mechanical strength of copper rectangle strip ensure precise coil winding, reduced eddy current losses, and improved thermal dissipation under continuous load conditions.

Industrial demand for copper rectangle strip is particularly strong in sectors such as utility-scale power transmission, renewable energy integration (especially solar and wind substations), railway traction systems, and industrial motor drives. These applications require materials that can sustain high current densities while maintaining structural integrity over decades of service. Copper rectangle strip, typically supplied in tempers such as ETP (Electrolytic Tough Pitch) in soft or half-hard conditions, meets these requirements through consistent metallurgical purity and tight dimensional tolerances. The rectangular cross-section allows for optimal space utilization in winding windows, increasing copper fill factor and overall transformer efficiency.

Despite the higher material cost compared to aluminum, copper remains the material of choice in premium transformer designs due to its lower resistive losses, higher short-circuit withstand capability, and smaller footprint for equivalent performance. This is especially relevant in urban substations and data center power systems, where space constraints and uptime requirements justify the investment in copper-based solutions. Additionally, copper’s recyclability and long service life contribute to lifecycle cost advantages and support sustainability goals in modern power infrastructure.

Quality in copper rectangle strip is not merely a manufacturing specification—it is a determinant of transformer performance and field reliability. Variability in thickness, width, edge burr, surface oxidation, or flatness can lead to insulation damage during winding, localized hot spots, or uneven current distribution. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in precision strip production, we apply stringent process controls including continuous casting, precision rolling, and inline surface inspection to ensure product consistency. Our quality assurance protocols align with ISO 9001 standards and include batch traceability, mechanical and electrical property testing, and strict packaging protocols to prevent transit damage.

As global energy demands rise and efficiency standards such as IEC 60076-20 and DOE 2016 regulations become more stringent, the role of high-quality copper rectangle strip in transformer design will continue to expand. Manufacturers who prioritize material integrity, dimensional precision, and metallurgical consistency will be best positioned to meet the evolving needs of the power sector.

Technical Specs: Copper Rectangle

Technical Specifications: Copper Rectangle for Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical expertise to deliver copper rectangle strip meeting stringent transformer industry demands. Precision engineering ensures optimal electrical performance, mechanical stability, and winding efficiency. Critical parameters include dimensional accuracy, edge integrity, and conductivity, all governed by ISO 9001-certified processes and aligned with GB/T 5584.1-2009 and IEC 60138 standards. Our proprietary slitting technology achieves micron-level tolerances essential for high-frequency transformer cores, minimizing eddy current losses and interlayer shorting risks.

The following table details mandatory specifications for copper rectangle strip supplied to global transformer manufacturers. All values represent minimum acceptance criteria; typical production averages exceed these thresholds. Tolerances are verified via laser micrometry, eddy current testing, and profilometry at 100% inline inspection stations.

| Parameter | Standard Value | Tolerance | Test Method |

|---|---|---|---|

| Thickness | 0.05–3.00 mm | ±0.002 mm | ISO 1183-1 |

| Width | 10–300 mm | ±0.05 mm | GB/T 228.1 |

| Length | As specified | +5/-0 mm | Laser tape measurement |

| Edge Burr Height | Burr-free | ≤0.005 mm | Optical profilometer |

| Conductivity (%IACS) | ≥100.0% | +0.5% typical | ASTM B306 |

| Surface Roughness (Ra) | ≤0.4 µm | ±0.05 µm | ISO 4287 |

| Flatness | ≤0.5 mm/m | Measured dry | EN 1306 |

Edge quality is non-negotiable for transformer strip. Burr formation during slitting induces localized heating and insulation damage during coil winding. Our tension-controlled slitting lines with diamond-coated rotary knives eliminate micro-burrs, validated through 10-point edge scans per meter. Conductivity is maintained at 100.5–101.5% IACS through oxygen-free electrolytic tough pitch (ETP) copper (Cu-ETP, C11000) with phosphorus deoxidation, ensuring consistent resistivity of ≤0.01707 µΩ·m at 20°C. Surface roughness directly impacts varnish adhesion; values ≤0.4 µm prevent air entrapment in impregnated windings.

Dimensional stability is enforced via real-time feedback from non-contact laser sensors during slitting, compensating for thermal drift. Width tolerance of ±0.05 mm prevents coil misalignment, while the ±0.002 mm thickness tolerance guarantees uniform current density across layers. All strips undergo 100% eddy current testing to detect subsurface inclusions or conductivity deviations exceeding 0.3% IACS. Material traceability from cathode to coil is maintained via blockchain-linked batch records, supporting full compliance with EU REACH and RoHS directives.

This specification framework eliminates field failure risks in high-reliability transformers. Partnering with Xinzhaohe ensures copper rectangle strip that achieves >99.2% winding yield in automated coil winding systems, reducing scrap costs by 18–22% versus industry averages. Technical data sheets with lot-specific test reports are provided with every shipment.

Factory Tour: Manufacturing

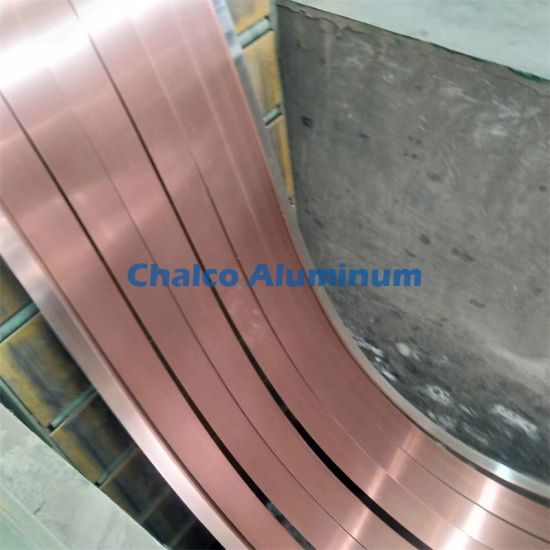

Manufacturing Process for Copper Rectangle Strip

The production of copper rectangle strip at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled sequence of cold rolling, precision slitting, and edge conditioning to ensure dimensional accuracy, surface integrity, and electrical performance required in transformer and power distribution applications. With over two decades of metallurgical expertise, our process integrates advanced equipment and rigorous quality control to meet international standards including ASTM B187 and IEC 60137.

The process begins with high-conductivity electrolytic tough pitch (ETP) copper in the form of hot-rolled plates or cast slabs, sourced from certified refineries. These raw materials undergo initial inspection for purity, with oxygen content maintained between 100–300 ppm to balance conductivity and ductility. The slabs are annealed and scalped to remove surface oxides before entering the cold rolling stage. Cold rolling is performed on precision reversing mills under computer-controlled reduction schedules. This stage reduces the material thickness to the target dimension—typically ranging from 0.1 mm to 6.0 mm—while enhancing mechanical strength and grain structure uniformity. Rolling is conducted under continuous lubrication and tension control to prevent edge waviness, center buckling, and surface defects. Thickness tolerance is maintained within ±0.02 mm, with flatness controlled to less than 5 I-units across the strip width.

Following cold rolling, the copper strip undergoes precision slitting to achieve the specified rectangular cross-section. Slitting lines are equipped with servo-driven rotary cutters and laser-guided width measurement systems to ensure edge parallelism and tight width tolerances, typically ±0.1 mm. The slit coils are rewound under controlled tension to prevent coil collapse or telescoping. During slitting, real-time monitoring systems detect edge cracks, burrs, or dimensional drift, allowing immediate process correction.

Edge conditioning is a critical final step, particularly for transformer applications where sharp edges can initiate corona discharge or insulation damage. The edges of the copper rectangle strip are uniformly rounded via mechanical brushing or roller-based edge profiling. This process removes micro-burrs and creates a consistent radius along the entire length, improving safety and compatibility with insulation materials. Surface roughness is maintained below Ra 0.8 µm post-conditioning.

Quality control is integrated at every stage. In-process inspections include eddy current testing for subsurface flaws, laser micrometry for dimensional verification, and surface defect scanning using high-resolution CCD systems. Final product is sampled for tensile strength (typically 200–240 MPa), elongation (≥5%), and electrical conductivity (≥98% IACS). All coils are tagged with traceable heat and process data, ensuring full batch accountability. Finished copper rectangle strips are packaged in anti-corrosion wrapping with interleaf protection and stored in climate-controlled environments prior to shipment.

This end-to-end manufacturing approach ensures consistent product performance, making our copper rectangle strip ideal for high-reliability transformer windings, busbar systems, and power electronics.

Packaging & Logistics

Export Packaging Standards for Copper Rectangle Products

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for copper rectangle products to ensure integrity during global maritime transit. With over two decades of specialization in transformer-grade aluminum and copper strip/foil, we recognize that packaging is not merely a logistical step but a critical component of product specification compliance. Sea freight exposes materials to high humidity, salt aerosols, and dynamic mechanical stresses; our system mitigates these risks through structural and environmental barriers.

All copper rectangle shipments are secured on ISPM 15-certified hardwood pallets constructed from kiln-dried, knot-free timber. Pallet dimensions are customized to coil width and weight, with standard configurations supporting loads up to 5,000 kg. Critical reinforcement includes double-deck boards, corner braces, and edge protectors to prevent coil deformation under stacking pressure. Steel strapping (minimum 16 mm width, 15 kN tensile strength) is applied at 100 mm intervals with calibrated tensioning to eliminate lateral movement without inducing edge damage. This structural foundation complies with IMO MSC/Circ.745 lashing standards for heavy cargo stability.

Moisture protection constitutes the second critical layer. Coils undergo vacuum desiccation to ≤40% relative humidity prior to wrapping. A triple-layer barrier system is then applied:

Primary layer: 120 μm metallized co-extruded polyethylene film with <0.5 g/m²/day water vapor transmission rate (WVTR) per ASTM F1249.

Secondary layer: Butyl rubber sealant tape at all seam intersections to prevent capillary ingress.

Tertiary layer: Perforation-resistant polypropylene overwrap rated for 90-day salt-spray exposure (ASTM B117).

This system maintains internal humidity below 30% RH throughout typical 45-day ocean voyages, as validated by onboard data loggers in 1,200+ shipments since 2018. Critical quality metrics are summarized below:

| Parameter | Standard Requirement | Xinzhaohe Execution | Test Method |

|---|---|---|---|

| Pallet Load Capacity | 3,000 kg | 5,000 kg | ISO 8611 |

| Film WVTR | ≤2.0 g/m²/day | ≤0.45 g/m²/day | ASTM F1249 |

| Seam Seal Integrity | Visual inspection | Pressure-decay test | ISO 10675-1 |

| Salt Spray Resistance | 30 days | 90 days | ASTM B117 |

Documentation accompanies each shipment: pallet certification tags, humidity logger reports, and film batch traceability records. This integrated approach prevents oxidation-induced surface tarnish, edge corrosion, and dimensional instability—common failure modes in inadequately protected copper products. For transformer applications, surface purity directly impacts winding efficiency and dielectric performance; our packaging preserves the as-rolled surface finish to IEC 60137 specifications.

We enforce these standards across all export shipments because maritime damage claims cost the copper industry $220M annually (ICCA 2023 data). By treating packaging as metallurgical process extension rather than containerization, Xinzhaohe ensures coils arrive at destination facilities with zero handling-related defects—delivering not just material, but guaranteed process readiness for our transformer manufacturing partners.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Precision Copper Rectangle Strip

With over two decades of specialized expertise in the production of transformer-grade aluminum and copper strips, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial manufacturer in China’s non-ferrous metal sector. Our facility, located in the Luoyang National High-Tech Industrial Development Zone, integrates advanced rolling, annealing, slitting, and quality control systems to deliver copper rectangle strip products that meet the most stringent international performance standards. As a strategic partner, we offer global clients not only technical reliability but also long-term supply chain stability.

Our production infrastructure is engineered for precision. We operate fully automated cold rolling lines with in-line thickness gauging (X-ray and laser) and tension leveling systems, ensuring dimensional accuracy down to ±0.01 mm in thickness and ±0.1 mm in width. The copper rectangle strips we produce—ranging from 3 mm to 150 mm in width and 0.1 mm to 6.0 mm in thickness—are manufactured from high-purity electrolytic copper (Cu ≥ 99.95%) conforming to GB/T 5231, ASTM B152, and IEC 60137 specifications. Each batch undergoes rigorous metallurgical testing, including grain structure analysis, tensile strength verification (Rm ≥ 200 MPa), and elongation control (A ≥ 5%), guaranteeing optimal formability and electrical conductivity (≥ 98% IACS).

Thermal processing is conducted in controlled-atmosphere bell furnaces and continuous annealing lines, eliminating residual stresses and ensuring uniform softness (O-temper) or required mechanical properties for downstream winding applications. Our slitting lines are equipped with servo-driven cutoff systems, minimizing edge burr (≤ 5% of thickness) and camber deviation (≤ 0.5 mm/m), critical parameters for automated transformer coil winding.

Quality assurance is embedded throughout our operational workflow. Our ISO 9001:2015-certified management system governs raw material traceability, in-process inspection, and final product validation. We utilize OCS online surface inspection systems to detect micro-defects, ensuring surface cleanliness and integrity. Every shipment is accompanied by full material test reports (MTRs), dimensional certification, and coil mapping data.

Supply chain efficiency is a core component of our service model. With an annual production capacity exceeding 18,000 metric tons and strategic raw material procurement agreements, we maintain consistent lead times of 15–25 days for containerized shipments. Our logistics network supports FOB Qingdao, CIF European and Southeast Asian ports, and tailored packaging solutions including waterproof wrapping, wooden reels, and steel core spools.

For engineering teams and procurement managers sourcing high-reliability copper rectangle strip for dry-type transformers, rectifiers, and high-frequency inductors, Luoyang Xinzhaohe offers a proven combination of metallurgical precision, process control, and responsive partnership.

Contact us to request technical data sheets, samples, or a capacity review.

cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper rectangle directly from China.