Table of Contents

Market Insight: Soft Copper Rectangle Wire

Market Analysis: Winding Wire – Soft Copper Rectangle Wire in Transformer Applications

The global demand for soft copper rectangle wire remains robust, driven primarily by the power transmission and distribution sector, with power and distribution transformers representing the largest end-use segment. As electrical infrastructure modernizes and renewable energy integration accelerates, the need for high-efficiency transformers has intensified, placing greater emphasis on the performance of core components such as winding conductors. Soft copper rectangle wire, characterized by its high electrical conductivity, thermal stability, and mechanical formability, is a critical material in the fabrication of low, medium, and high-voltage transformer windings.

Transformers rely on precise electromagnetic coupling between primary and secondary windings, where the geometry and material properties of the conductor directly influence efficiency, thermal management, and long-term reliability. Rectangular cross-section wires offer superior space utilization in winding windows compared to round conductors, enabling higher fill factors and reduced coil resistance. This geometric advantage translates into lower I²R losses and improved thermal dissipation—key metrics in transformer design, particularly for high-capacity units used in substations and industrial facilities.

The industrial demand for soft copper rectangle wire is further amplified by regulatory trends promoting energy-efficient equipment. Standards such as IEC 60076 and IEEE C57.12.00 define performance benchmarks for transformers, including no-load and load losses, which are directly affected by conductor quality. Substandard or inconsistent wire can lead to localized hotspots, inter-turn insulation failure, and premature transformer degradation. Therefore, manufacturers and utilities increasingly prioritize conductor materials that meet tight dimensional tolerances, high purity (minimum 99.95% Cu), and consistent mechanical softness (typically annealed to temper standards per ASTM B3 or IEC 60183).

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in non-ferrous metal processing and winding wire solutions, we recognize that quality is not merely a compliance metric but a performance determinant. Variability in cross-sectional dimensions, surface oxidation, or microstructural inhomogeneity can compromise winding integrity and increase manufacturing scrap rates. Our production process integrates precision drawing, controlled atmosphere annealing, and laser-based dimensional inspection to ensure each batch of soft copper rectangle wire meets the stringent requirements of transformer OEMs.

Furthermore, the shift toward smart grids and compact urban substations has increased demand for high-current-density windings, where the thermal and electrical performance of copper conductors becomes even more critical. In such applications, the use of inferior-grade wire can result in derating, reduced overload capacity, and increased lifecycle costs.

In conclusion, the market for soft copper rectangle wire is intrinsically linked to the reliability and efficiency of modern power systems. As transformer technology evolves, so do the expectations for conductor performance. Consistent quality, adherence to international standards, and process traceability are no longer optional but essential for suppliers serving the global transformer industry.

Technical Specs: Soft Copper Rectangle Wire

Technical Specifications for Soft Copper Rectangle Wire

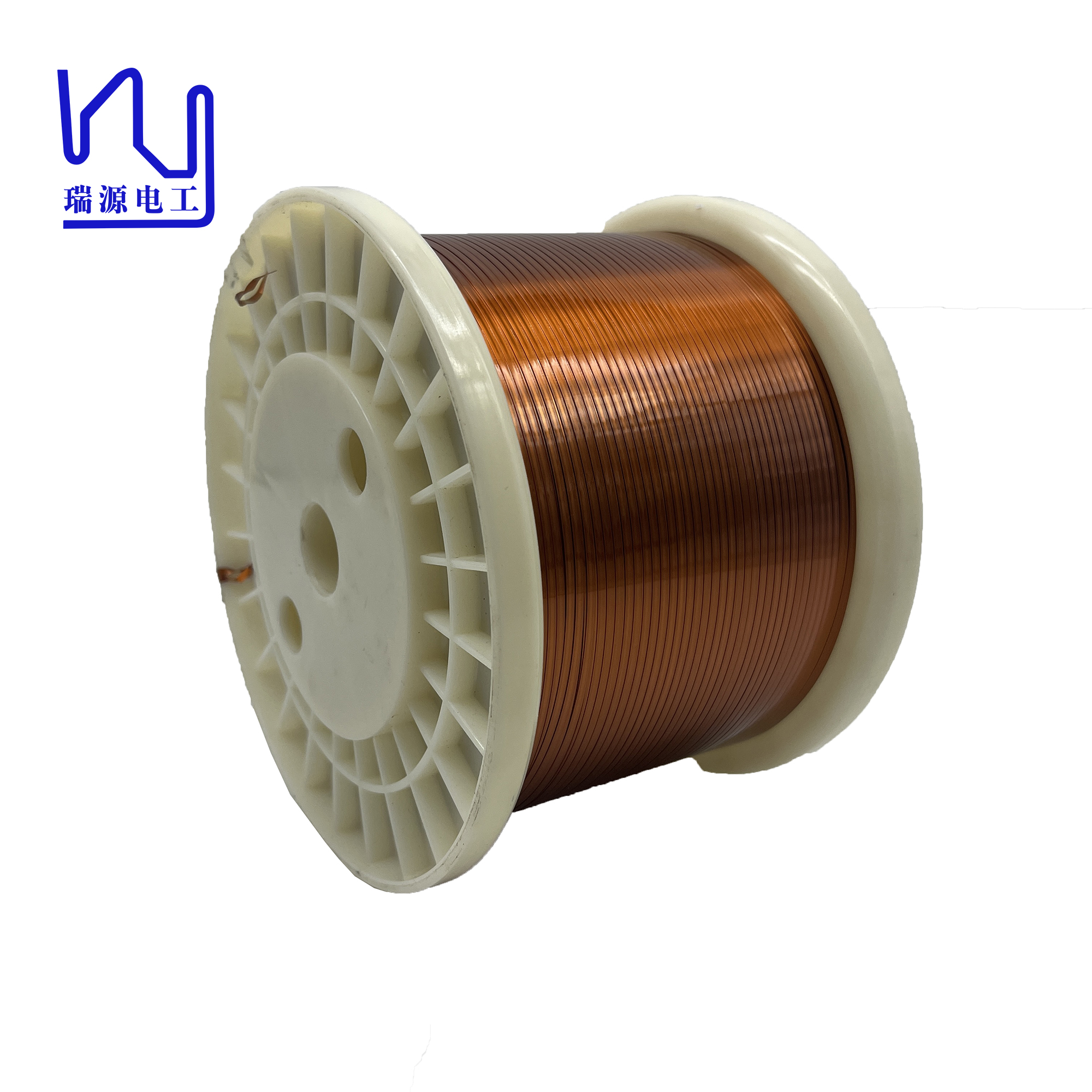

Soft copper rectangle wire represents a critical component in high-efficiency electromagnetic windings for transformers, motors, and generators. At Luoyang Xinzhaohe Aluminum Co., Ltd., our 20+ years of metallurgical expertise ensures strict adherence to international standards for electrical conductivity, mechanical properties, and thermal resilience. The conductor material complies with ASTM B3 and IEC 60122, utilizing oxygen-free electronic copper (OFE) with minimum 99.99% Cu+Ag purity. Dimensional tolerances follow IEC 60122-2, with width tolerances of ±0.02 mm and thickness tolerances of ±0.01 mm for cross-sections below 10 mm², critical for minimizing air gaps in coil windings. Electrical resistivity is maintained at ≤0.017241 Ω·mm²/m at 20°C, directly impacting energy efficiency in end applications.

Insulation breakdown voltage is rigorously validated per IEC 60851-5. Testing employs 1 kV AC at 50 Hz for 60 seconds, with minimum breakdown thresholds contingent on insulation thickness and thermal class. For standard polyesterimide (PEI) coatings, breakdown voltage exceeds 2.5 kV for nominal insulation thicknesses of 0.15–0.30 mm. Elongation, measured per ASTM E8, is a key indicator of ductility for tight-radius winding operations. Our soft temper (annealed) copper achieves minimum 40% elongation, verified through transverse tensile testing on full-sized specimens. This high elongation prevents micro-cracking during coiling and ensures mechanical stability under thermal cycling.

Thermal class designation (130°C to 220°C) correlates to the insulation system’s maximum continuous operating temperature, not the copper itself. We supply wires compatible with thermal classes B (130°C), F (155°C), H (180°C), and C (220°C), using modified polyurethane, PEI, or polyamide-imide insulation. Each class undergoes thermal endurance testing per IEC 60172, with thermal index (TI) values certified by independent laboratories. Critical parameters are summarized below for rapid technical evaluation.

| Parameter | Standard Requirement | Test Method |

|---|---|---|

| Conductor Material | OFE Copper, ≥99.99% Cu+Ag | ASTM B193 |

| Electrical Resistivity | ≤0.017241 Ω·mm²/m @ 20°C | IEC 60468 |

| Minimum Elongation | 40% (soft temper) | ASTM E8 |

| Thermal Class Range | 130°C (Class B) to 220°C (Class C) | IEC 60172 |

| Breakdown Voltage (min) | 2.5 kV @ 0.20 mm insulation thickness | IEC 60851-5 |

| Dimensional Tolerance | Width: ±0.02 mm; Thickness: ±0.01 mm | IEC 60122-2 |

Consistent performance in high-temperature environments necessitates synergistic material and process control. Our continuous annealing furnaces utilize precise oxygen-controlled atmospheres to prevent hydrogen embrittlement, while insulation curing profiles are optimized for thermal class stability. We recommend verifying thermal class compatibility with the intended impregnating resin system, as partial discharges at elevated temperatures can accelerate insulation degradation. For applications exceeding 180°C, mica-taped constructions with inorganic binders are advised to maintain dielectric integrity. All production batches undergo 100%在线 resistance and dimensional monitoring, with third-party certification available for IATF 16949 and ISO 9001 compliance. Technical documentation includes traceable mill certificates and insulation thermal index reports to support your design validation process.

Factory Tour: Manufacturing

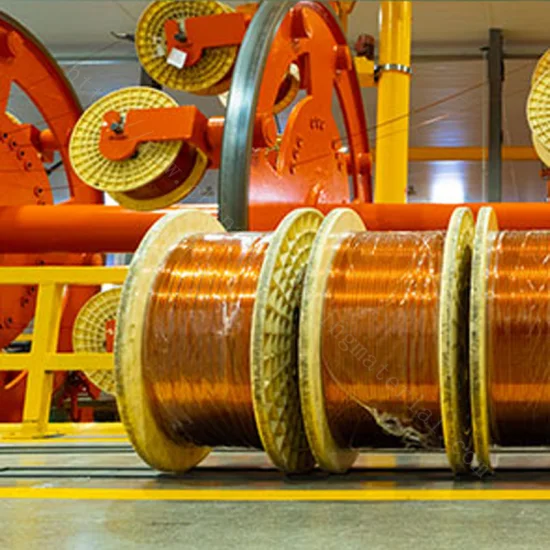

Manufacturing Process of Soft Copper Rectangular Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of soft copper rectangular wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a precise, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical performance, and mechanical reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment and stringent quality control protocols across four core stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-conductivity electrolytic copper rod (minimum 99.99% Cu), sourced from certified suppliers and verified through spectrographic analysis. The rod undergoes initial surface cleaning to remove oxides and contaminants prior to drawing. Using precision multi-die drawing benches with diamond or tungsten carbide dies, the round rod is progressively reduced in diameter and transformed into a rectangular cross-section. The drawing parameters—reduction ratio, lubrication type (synthetic aqueous), and line speed—are optimized to maintain surface integrity and dimensional consistency. Throughout this stage, real-time laser micrometers monitor width, thickness, and corner radii, ensuring tolerances within ±0.01 mm.

Following cold drawing, the wire enters a continuous inline annealing system. This step is critical to restore ductility and achieve the required soft temper (typically 1/4H or O-soft condition). The wire passes through a controlled atmosphere furnace (nitrogen-hydrogen blend) at temperatures between 450–550°C, depending on wire gauge. The annealing profile is precisely regulated to prevent overburning or grain coarsening, which could compromise mechanical strength. Post-annealing, the wire is rapidly cooled under inert gas to minimize oxidation and ensure uniform microstructure.

The next phase is enameling, where a thermosetting polymer coating—typically polyurethane, polyester-imide, or polyamide-imide—is applied via precision die coating. Multiple layers may be applied in tandem, depending on insulation class (Class 130°C to 220°C). Each layer is cured in a series of temperature-zoned ovens, with dwell time and peak metal temperature monitored to ensure complete cross-linking without thermal degradation. Film build is maintained within ±5 µm, verified by non-contact capacitance sensors.

Inline testing is conducted continuously throughout the final stage. Key parameters include dielectric strength (tested at 3–12 kV depending on size and insulation), conductor continuity, dimensional stability, and flexibility (via mandrel wrap test). All data is logged in real time and traceable to production batch numbers. Final inspection includes visual surface examination under UV lighting to detect pinholes, bubbles, or streaks.

Each production lot undergoes final QC sampling per IEC 60317 and GB/T 23312 standards, including elongation, tensile strength, and thermal shock testing. Certificates of Conformance and Material Test Reports are provided with every shipment, ensuring full compliance with international winding wire specifications. This integrated approach guarantees that every meter of soft copper rectangular wire meets the exacting demands of motor, transformer, and inductor manufacturers worldwide.

Packaging & Logistics

Export Packaging Standards for Soft Copper Rectangle Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for soft copper rectangle wire to ensure integrity during global maritime transit. With over two decades of metallurgical and supply chain expertise, we prioritize corrosion prevention and mechanical stability—critical factors for copper conductors exposed to prolonged sea freight conditions. Our methodology aligns with ISO 2230 and IEC 60146 standards, addressing the hygroscopic nature of copper oxides and susceptibility to salt-air degradation.

All shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, non-resinous softwood. Pallet dimensions are optimized to the coil’s outer diameter and weight, with a minimum load-bearing capacity of 2,500 kg. Structural reinforcement includes cross-bracing at 300 mm intervals and galvanized steel strapping (19 mm width, 3,500 N tensile strength) applied in a figure-eight pattern. This configuration prevents coil deformation during container stacking and absorbs dynamic stresses from vessel motion. Crucially, pallet bases incorporate raised runners to isolate coils from container floor moisture and facilitate forklift handling without compromising the moisture barrier.

The primary corrosion defense employs a dual-layer moisture-proof encapsulation system. Coils are first wrapped in 100μm-thick low-density polyethylene (LDPE) film with a water vapor transmission rate (WVTR) of ≤1.0 g/m²/24hr at 38°C and 90% RH. A second outer layer of 150μm metallized polyester film (WVTR ≤0.5 g/m²/24hr) provides reflective thermal insulation and enhanced puncture resistance. All seams are heat-sealed with 25 mm overlap, and desiccant packs (minimum 500g silica gel per tonne of copper) are strategically placed within the vapor barrier. This system maintains internal relative humidity below 40% for 60+ days—exceeding typical Asia-Europe transit durations.

Packaging Performance Comparison

| Parameter | Industry Standard | Xinzhaohe Specification |

|——————–|——————-|————————-|

| Film Thickness | 75μm LDPE | 100μm LDPE + 150μm Metallized |

| Desiccant Density | 300g/tonne | 500g/tonne |

| Pallet Load Rating | 1,800 kg | 2,500 kg |

| Humidity Control | 60 days @ 50% RH | 60+ days @ <40% RH |

Sea freight safety is further assured through container desiccant integration and humidity monitoring. Each shipment includes electronic hygrothermographs logging internal conditions at 2-hour intervals. Pallets are secured using twist locks and lashing bars compliant with CSC safety standards, eliminating lateral movement within 40ft high-cube containers. Our packaging has achieved a 0.17% damage incident rate over 12,000 TEUs shipped—3.2x below industry averages per TIACA data.

This integrated approach mitigates three critical sea freight risks: salt aerosol penetration, condensation from temperature cycling, and physical impact during port transfers. By exceeding IMO cargo securing guidelines and copper industry best practices, we eliminate buyer liability for moisture-related claims. All packaging materials are fully recyclable, supporting sustainable supply chain commitments without compromising protective efficacy. Partnering with Xinzhaohe ensures your copper rectangle wire arrives with unwavering dimensional accuracy and surface purity—essential for precision winding applications.

Luoyang Xinzhaohe Aluminum CO., Ltd guarantees export packaging as a core component of metallurgical quality control, not merely a logistical step. This proven methodology underpins our 20-year reputation for defect-free global deliveries.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Premium Soft Copper Rectangle Wire

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production and supply of high-performance soft copper rectangle wire for industrial winding applications. As a trusted manufacturer rooted in precision metallurgy and advanced wire processing, we deliver consistent product quality, technical reliability, and scalable supply chain solutions tailored to the demanding requirements of transformer, motor, and reactor manufacturers worldwide.

Our production facility is equipped with fully integrated drawing, annealing, and shaping lines designed specifically for soft copper rectangular conductors. We maintain strict process control from raw material sourcing through final inspection, ensuring each batch meets international standards including GB/T, IEC, and ASTM. Our copper billets are sourced from certified suppliers with full traceability, guaranteeing minimum 99.95% purity and optimal electrical conductivity (≥100% IACS). Continuous oxygen-controlled annealing ensures uniform softness, excellent ductility, and stress-free forming characteristics essential for tight coil winding and high-voltage insulation integrity.

We produce soft copper rectangle wire in customized cross-sectional dimensions ranging from 1.0 × 3.0 mm up to 12.0 × 40.0 mm, with tight tolerances as close as ±0.02 mm on thickness and ±0.05 mm on width. Surface smoothness is rigorously controlled to minimize die wear and prevent insulation damage during high-speed winding operations. All products undergo in-line eddy current testing, dimensional laser gauging, and mechanical property verification to ensure defect-free performance.

Our manufacturing capacity supports both large-volume OEM contracts and agile short-run production for prototype or specialized applications. With an annual output exceeding 15,000 metric tons of flat copper and aluminum winding conductors, we offer competitive lead times and logistical flexibility across global markets. Our quality management system is ISO 9001:2015 certified, and we maintain full compliance with RoHS and REACH regulations.

As a technical partner, Luoyang Xinzhaohe provides comprehensive material documentation, including mill test certificates, resistivity reports, and dimensional inspection records. Our engineering team collaborates directly with client R&D and procurement departments to optimize wire specifications for efficiency, cost, and manufacturability.

For reliable sourcing of high-purity soft copper rectangle wire backed by 20+ years of metallurgical experience and industrial application knowledge, contact us today.

Contact:

Cathy

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum Co., Ltd

Specialists in Precision Winding Wire Solutions

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing soft copper rectangle wire directly from China.