Table of Contents

Market Insight: Aluminium Foil For Transformer Winding

Market Analysis: Aluminium Foil Demand for Transformer Winding Applications

Global demand for high-purity aluminium foil dedicated to transformer winding applications continues robust growth, directly tied to expanding electrical infrastructure and renewable energy integration. The transition toward higher-efficiency distribution and power transformers, particularly driven by stringent global energy regulations like IEC 60076-12 and regional efficiency mandates, necessitates superior conductor materials. Aluminium foil offers significant weight and cost advantages over copper, making it indispensable for large power transformers (100 MVA+) and increasingly prevalent in medium-voltage distribution units. Critical growth vectors include solar and wind farm interconnection transformers, electric vehicle charging infrastructure, and grid modernization projects across Asia-Pacific and emerging markets. This sustained demand trajectory underscores the strategic importance of securing reliable, high-specification aluminium foil supply chains capable of meeting evolving technical requirements.

The electrical and mechanical performance of the transformer winding is fundamentally dependent on the metallurgical integrity and dimensional precision of the aluminium foil. Quality is not merely a preference; it is a non-negotiable engineering requirement. Foil purity must consistently exceed 99.7% Al to ensure optimal electrical conductivity (minimizing I²R losses) and prevent detrimental intermetallic compound formation during service. Surface finish is paramount; microscopic defects, scratches, or residual rolling lubricants act as initiation points for partial discharge under high electrical stress, accelerating insulation degradation and potentially leading to catastrophic failure. Precise thickness tolerance control (typically ±0.003 mm for critical applications) is essential for uniform current distribution and preventing localized hot spots. Furthermore, controlled annealing is critical to achieve the required ductility for tight winding without cracking while maintaining sufficient tensile strength to withstand electromagnetic forces during short-circuit events. Inconsistent mechanical properties lead to dimensional instability and vibration-induced damage.

Substandard foil introduces severe operational and financial risks. Variability in thickness or conductivity directly compromises transformer efficiency ratings, potentially violating regulatory compliance and incurring penalties. Surface imperfections significantly reduce the dielectric strength of the oil-impregnated paper insulation system, increasing the probability of in-service failures with associated costs far exceeding the initial material savings – including equipment replacement, grid downtime, and reputational damage. Poorly controlled annealing can cause foil fracture during winding, leading to production line stoppages and scrap. The transformer’s operational lifespan, often designed for 30-40 years, is critically dependent on the initial quality of core materials like winding foil; premature failure due to material defects represents a substantial lifecycle cost burden.

Luoyang Xinzhaohe Aluminum leverages two decades of specialized metallurgical expertise to address these critical quality imperatives. Our production process employs rigorous in-line monitoring of purity, precise thickness profiling via laser gauges, and controlled atmosphere annealing to guarantee consistent mechanical and electrical properties meeting IEC 60137 and customer-specific technical dossiers. We understand that sourcing decisions impact transformer reliability at the system level; our commitment is to deliver foil where dimensional accuracy, surface perfection, and material homogeneity are engineered parameters, not variables. Partnering with a supplier possessing deep technical validation capabilities is essential for mitigating supply chain risk and ensuring the long-term performance of critical power assets.

| Critical Foil Parameter | Industry Standard Requirement | Impact of Non-Compliance |

|---|---|---|

| Minimum Purity | ≥ 99.7% Al | Reduced conductivity, increased losses, intermetallic formation |

| Thickness Tolerance | ±0.003 mm (typical critical) | Uneven current density, localized heating, efficiency loss |

| Surface Roughness (Ra) | ≤ 0.3 µm | Partial discharge initiation, insulation degradation |

| Tensile Strength | 40-60 MPa (annealed) | Winding damage, vibration failure during operation |

| Elongation | ≥ 25% | Cracking during tight winding processes |

Technical Specs: Aluminium Foil For Transformer Winding

Technical Specifications for Aluminium Foil Used in Transformer Winding

Aluminium foil employed in transformer winding applications must meet stringent technical requirements to ensure reliable dielectric performance, mechanical durability, and thermal stability under continuous operational stress. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and industrial manufacturing expertise, we produce high-purity, precision-rolled aluminium foils engineered specifically for use in dry-type and oil-immersed transformers. The foil must exhibit consistent thickness tolerance, high surface cleanliness, and optimized mechanical properties to withstand the rigors of winding, impregnation, and long-term service in high-voltage environments.

A critical performance parameter is the insulation breakdown voltage, which directly impacts the dielectric integrity of the transformer winding. Our aluminium foils are manufactured to support insulation systems capable of withstanding breakdown voltages in excess of 2.5 kV per layer when combined with standard insulating papers or films. This performance is achieved through precise surface passivation and strict control over edge burrs and micro-defects during slitting operations. The foil surface is free from rolling marks, inclusions, and oxidation that could serve as nucleation points for partial discharge under high electric field stress.

Elongation is another essential mechanical property, influencing the foil’s ability to endure plastic deformation during the coiling and winding processes without cracking or necking. Our standard product range delivers a minimum elongation of 1.8% in the longitudinal direction, with high-ductility grades reaching up to 3.0%. This ensures uniform strain distribution during helical or layer winding, particularly in large power transformers where tensile forces are significant. Elongation is maintained through controlled annealing cycles and alloy purity, with Fe+Si content kept below 0.12% to balance strength and formability.

Thermal performance is defined by the Thermal Class rating, which indicates the maximum continuous operating temperature the insulation system—including the aluminium conductor—can endure without degradation. Our foils are compatible with insulation systems rated from Class B (130°C) up to Class H (180°C), with special grades supporting extended thermal endurance up to 220°C when integrated with silicone or mica-based insulation. The aluminium substrate itself remains dimensionally stable and oxidation-resistant within this range, contributing to the long-term reliability of the winding assembly.

The following table summarizes key technical parameters for standard and high-performance grades of aluminium foil used in transformer winding:

| Parameter | Standard Grade | High-Performance Grade | Test Standard |

|---|---|---|---|

| Thickness Range | 0.8 mm – 3.2 mm | 0.8 mm – 4.0 mm | ASTM B479 |

| Tensile Strength | 80 – 100 MPa | 75 – 95 MPa | ASTM E8 |

| Elongation (min) | 1.8% | 3.0% | ASTM E8 |

| Insulation Breakdown Voltage | ≥ 2.5 kV (per layer) | ≥ 3.0 kV (per layer) | IEC 60243-1 |

| Thermal Class Compatibility | 130°C – 180°C | Up to 220°C | IEC 60085 |

| Surface Roughness (Ra) | ≤ 1.2 µm | ≤ 0.8 µm | ISO 4287 |

| Edge Burr Height | ≤ 15 µm | ≤ 10 µm | Internal Specification |

| Alloy/Purity | 1060 / ≥ 99.6% Al | 1070 / ≥ 99.7% Al | GB/T 3880.1 |

All products are subject to 100% eddy current testing and visual inspection to ensure defect-free performance. Custom temper, slit width, and coil ID/OD configurations are available to meet specific OEM winding equipment requirements.

Factory Tour: Manufacturing

Manufacturing Process for Aluminum Foil in Transformer Winding Applications

The production of aluminum foil for transformer winding at Luoyang Xinzhaohe Aluminum CO., Ltd. adheres to a rigorously controlled sequence designed to ensure metallurgical integrity, dimensional precision, and electrical reliability. With over two decades of specialization in winding wire materials, our process integrates advanced metallurgical engineering with real-time quality verification. The core stages—Rod Drawing, Annealing, Enameling, and Inline Testing—are executed under stringent environmental and procedural controls to meet IEC 60204 and ASTM B470 standards.

Rod Drawing Process

High-purity aluminum rod (minimum 99.7% Al, Fe+Si ≤ 0.12%) undergoes multi-pass drawing through precision tungsten carbide dies. This cold-working stage reduces diameter from 9.5mm to the target foil thickness (typically 0.06–0.30mm) while maintaining surface smoothness and edge consistency. Critical parameters—drawing speed (8–12 m/s), reduction ratio per pass (≤15%), and lubricant viscosity (ISO VG 32)—are continuously monitored. Surface defects exceeding 2µm depth are rejected via inline laser profilometry, ensuring zero micro-cracks that could compromise winding integrity. Tensile strength is maintained at 120–150 MPa through controlled strain hardening, verified by hourly tensile tests per ASTM E8.

Annealing Stage

Drawn foil enters a continuous hydrogen-nitrogen atmosphere annealing furnace (dew point ≤ -40°C) to eliminate residual stresses and optimize ductility. Temperature profiles are calibrated between 300–350°C with precise dwell times (60–90 seconds) to achieve 55–65% IACS conductivity and elongation of ≥3%. Oxygen ingress is restricted to <10 ppm to prevent oxide formation, which would impair enamel adhesion. Post-annealing, foil undergoes eddy current testing to confirm uniform conductivity deviation within ±1.5% across the coil.

Enameling Application

A dual-layer polymer enamel system (typically polyurethane base with polyamide-imide topcoat) is applied via precision die coating. The process ensures 10–15µm total coating thickness with ±1µm tolerance, critical for dielectric strength (≥8 kV/0.1mm). Curing occurs in a multi-zone infrared oven (280–320°C), where cross-linking density is validated through solvent rub tests (≥100 double-rubs with methyl ethyl ketone). Adhesion is quantified at 0.5 N/mm via peel testing, exceeding IEC 60851-5 requirements.

Integrated Inline Testing Protocol

Quality verification is embedded at every stage. Key metrics include:

| Parameter | Test Method | Tolerance | Frequency |

|---|---|---|---|

| Thickness | Beta gauge | ±0.002 mm | Continuous |

| Pinholes | Spark tester (5 kV) | 0 defects/m² | Continuous |

| Elongation | ASTM E8 tensile | ≥3% | Hourly |

| Enamel continuity | High-voltage surge test | 0 breakdowns | Per coil end |

Final coils undergo 100% eddy current scanning for subsurface inhomogeneities and are wound under tension control (±2% of setpoint) to prevent telescoping. All data is logged in our ERP system for full traceability, enabling root-cause analysis if deviations occur. This closed-loop manufacturing approach minimizes field failures by ensuring foil meets the thermal class (180°C), flexibility, and dielectric demands of modern dry-type transformers. Luoyang Xinzhaohe’s process yields foil with ≤0.5% scrap rate—significantly below industry averages—directly enhancing our customers’ production efficiency and end-product reliability.

Packaging & Logistics

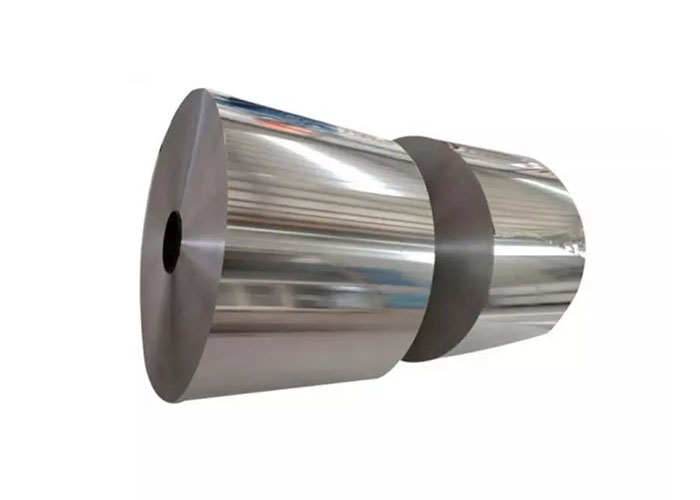

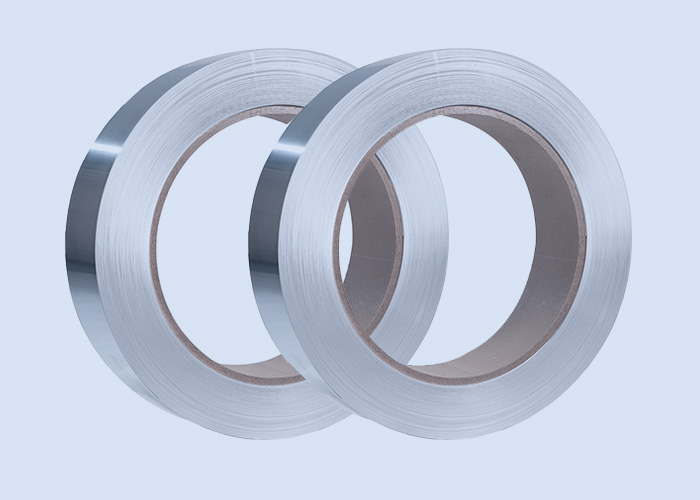

Export Packaging for Aluminium Foil Used in Transformer Winding

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production and international supply experience, we ensure that every shipment of aluminium foil for transformer winding meets the highest standards of integrity and reliability during global transit. Export packaging is a critical phase in the logistics chain, particularly for sensitive conductive materials exposed to prolonged sea freight conditions. Our packaging methodology is engineered to prevent mechanical damage, moisture ingress, and contamination—three primary risks during maritime transport.

All aluminium foil reels designated for export are mounted on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to ISO 15598:2015 standards for international wood packaging material, ensuring compliance with ISPM 15 regulations. Each pallet is structurally reinforced to support the full weight of tightly wound foil coils, which can range from several hundred kilograms to over two metric tons depending on coil dimensions and thickness. The wooden base provides dimensional stability, resists compression under load, and facilitates secure strapping during containerization.

Immediately after core mounting and final inspection, each coil is wrapped in multiple layers of industrial-grade moisture-proof film. This multilayer polyethylene laminate includes an integrated aluminium vapour barrier, offering a water vapour transmission rate (WVTR) of less than 0.5 g/m²·24h at 38°C and 90% relative humidity. The wrapping process is conducted in a climate-controlled environment to minimize ambient humidity exposure prior to sealing. All seams are heat-sealed to ensure continuity of the moisture barrier, preventing condensation and galvanic corrosion during temperature fluctuations typical in intercontinental shipping.

Additional protection is provided through the application of edge protectors made from corrugated plastic or laminated cardboard, which are affixed to the outer diameter of the coil to prevent abrasion and deformation during handling. The entire packaged unit is then secured with galvanized steel or polyester strapping, tensioned to industry-standard specifications, and anchored to the pallet to prevent lateral movement.

For container loading, we adhere to best practices in stowage and weight distribution. Each pallet is positioned to avoid direct contact with container walls and is separated using dunnage where necessary. Desiccant packs are placed within the sealed packaging envelope to absorb any residual moisture, further enhancing product protection over extended voyages.

This comprehensive packaging system has been validated through years of successful deliveries to markets in Southeast Asia, Europe, and North America. It ensures that upon arrival, the aluminium foil retains its surface finish, dimensional accuracy, and electrical performance characteristics—critical parameters for downstream processing in transformer winding operations.

Luoyang Xinzhaohe Aluminum Co., Ltd treats packaging not as a logistical afterthought, but as an extension of our metallurgical quality control. By integrating material science with logistics engineering, we deliver globally, reliably.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminium Foil in Transformer Windings

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver aluminium foil engineered explicitly for the demanding requirements of transformer winding applications. Our deep-rooted understanding of the interplay between material properties, electrical performance, and winding process efficiency positions us as a critical enabler for transformer manufacturers seeking reliability and performance optimization. We move beyond standard foil supply, functioning as a technical partner committed to solving the unique challenges inherent in high-voltage and power transformer core construction.

Metallurgical Precision for Electrical Performance

Our core strength lies in rigorous control over the aluminium alloy composition, primarily utilizing high-purity 1060 and 1070 grades. We meticulously manage trace elements to minimize electrical resistivity and ensure exceptional surface cleanliness, directly impacting the dielectric strength and partial discharge characteristics of the final transformer insulation system. Precise control over grain structure through proprietary homogenization and thermal treatment processes guarantees consistent mechanical properties essential for high-speed, defect-free winding operations. Typical foil properties achieved include thickness tolerances of ±0.003mm within the critical 0.2mm to 0.5mm range, tensile strength of 80-110 MPa, and elongation of 2-5%, tailored to specific winding line requirements.

Integrated Production Infrastructure

Operating a vertically integrated facility, we control the entire value chain from molten metal casting through cold rolling, slitting, and precision rewinding. Our dedicated transformer foil production line features state-of-the-art 20-high rolling mills and continuous annealing lines, ensuring unparalleled dimensional stability and surface finish. Advanced tension control systems and laser-based thickness monitoring operate in real-time, maintaining strict adherence to customer specifications batch after batch. This infrastructure, combined with a dedicated R&D team focused solely on electrical conductor materials, allows for rapid prototyping and process refinement to meet evolving industry standards and bespoke customer needs.

Robust Quality Assurance System

Quality is embedded into every process step, not merely inspected at the endpoint. Our ISO 9001 and IATF 16949 certified systems implement stringent in-line and final inspection protocols. Critical parameters including thickness profile, surface roughness (Ra typically <0.4µm), edge quality, mechanical properties, and residual stress are monitored using calibrated metrology equipment. Comprehensive chemical analysis via OES and meticulous surface defect scanning ensure zero non-conforming material reaches the winding machine, directly reducing scrap rates and downtime for our partners.

Supply Chain Reliability and Technical Collaboration

We understand that transformer production schedules are inflexible. Our strategic raw material inventory management, coupled with flexible production scheduling and dedicated logistics coordination, guarantees on-time delivery performance exceeding 99%. More importantly, our engineering team proactively collaborates with customers during the design and qualification phases, providing metallurgical insights and process recommendations to optimize foil performance within the specific winding and impregnation processes. This partnership approach minimizes risk and accelerates time-to-market for new transformer designs.

Partnering with Luoyang Xinzhaohe means securing a supplier whose technical depth, manufacturing rigor, and commitment to electrical performance are proven across global transformer manufacturing. We ensure your winding process operates with maximum efficiency and your final product achieves the highest levels of reliability and longevity. Contact our technical sales team today to discuss your specific aluminium foil requirements and receive a detailed capability statement. Reach Cathy directly at cathy@transformerstrip.com to initiate a technical consultation and secure a performance-driven supply solution.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium foil for transformer winding directly from China.