Table of Contents

Market Insight: Copper Windings

Market Analysis: Winding Wire – Industrial Demand for Copper Windings in Transformers

The global demand for copper winding wire in power and distribution transformers remains a cornerstone of modern electrical infrastructure. As a critical component in electromagnetic energy conversion, copper windings provide the conductive pathway necessary for efficient voltage transformation and power transmission. Over the past two decades, industrialized and emerging economies alike have driven sustained growth in transformer manufacturing, primarily fueled by grid expansion, renewable energy integration, and industrial electrification. Copper, due to its superior electrical conductivity, thermal stability, and mechanical durability, continues to be the material of choice for high-performance windings in both oil-immersed and dry-type transformers.

Transformers operate under continuous electrical load, often in thermally challenging environments. The performance and longevity of these systems are directly influenced by the quality of the winding material. Copper windings with high purity (typically ≥99.97% Cu) ensure minimal resistive losses, which translates to higher energy efficiency and reduced operating temperatures. This is particularly critical in large power transformers where even a 0.5% reduction in losses can yield significant energy savings over the equipment’s operational life, often exceeding 30 years. International standards such as IEC 60317 and ASTM B3 govern the dimensional tolerances, electrical properties, and surface quality of copper winding wire, underscoring the need for strict compliance in manufacturing.

Quality deviations in copper winding wire—such as inconsistent temper, surface oxidation, or non-uniform enamel insulation—can lead to localized hotspots, partial discharges, and ultimately, premature transformer failure. In high-voltage applications, the dielectric integrity of the insulation system is paramount. Enamel-coated copper wire must exhibit excellent adhesion, thermal class compatibility (typically Class 130°C to 220°C), and resistance to thermal aging and mechanical stress during coil winding and impregnation processes. Poor-quality wire may crack during bending or delaminate under thermal cycling, compromising the transformer’s reliability.

From a supply chain perspective, manufacturers and OEMs are increasingly prioritizing traceability, batch consistency, and long-term technical support from winding wire suppliers. With growing regulatory emphasis on energy efficiency (e.g., EU Ecodesign Directive, DOE efficiency standards), the role of high-quality copper windings in meeting Tier 1 and Tier 2 efficiency benchmarks cannot be overstated. Additionally, the rise of smart grids and distributed generation systems has introduced new operational dynamics, including frequent load cycling and harmonic distortions, further stressing the need for robust winding materials.

Luoyang Xinzhaohe Aluminum Co., Ltd brings over 20 years of metallurgical and industrial materials expertise to the winding wire sector. While specializing in aluminum-based solutions, the company maintains a comprehensive understanding of copper winding applications and supports clients with technical consultation on material selection, performance optimization, and compliance with international specifications. As the energy landscape evolves, the imperative for high-integrity copper windings will remain central to reliable, efficient, and sustainable power systems.

Technical Specs: Copper Windings

Technical Specifications for Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical and supply chain expertise to deliver copper winding wire meeting stringent industrial demands. Critical technical parameters ensure operational reliability in motors, transformers, and electromagnetic devices under thermal, mechanical, and electrical stress. This section details non-negotiable specifications for insulation integrity, mechanical resilience, and thermal endurance, aligned with IEC 60317 standards.

Insulation breakdown voltage defines the dielectric strength threshold before catastrophic failure. Our polyurethane, polyester, or polyamide-imide insulated wires undergo rigorous testing per IEC 60851-5, submerging samples in transformer oil at 23°C. The minimum breakdown voltage must exceed 155 V for 130°C thermal class wires, scaling to 300 V for 220°C classes. This ensures immunity to voltage spikes during motor startup or grid fluctuations. Values below these thresholds risk partial discharges, accelerating insulation degradation and shortening equipment lifespan. Consistent thickness control via precision extrusion and laser gauging maintains this critical property across diameters from 0.05 mm to 3.00 mm.

Elongation at break quantifies ductility during winding processes. Tested per IEC 60851-4, our fully annealed electrolytic-tough-pitch (ETP) copper achieves 3–8% elongation. Lower values (<3%) indicate excessive hardness, causing wire fracture during tight coil formation; values >8% suggest inadequate tensile strength, leading to dimensional instability under electromagnetic forces. Precise annealing profiles in controlled atmospheres optimize this balance, ensuring seamless high-speed winding without microcracks that compromise insulation adhesion.

Thermal class dictates maximum continuous operating temperature. We supply wires rated from Class B (130°C) to Class C (220°C), validated via IEC 60317 thermal endurance testing. Samples endure accelerated aging at 150°C, 180°C, and 220°C, with insulation life extrapolated to 20,000 hours. Class H (180°C) wires, common in traction motors, require thermal indices ≥180. Higher classes utilize aromatic polyamide or ceramic coatings, resisting thermal oxidation and maintaining flexibility after repeated thermal cycling.

The following table summarizes core technical parameters:

| Parameter | Standard Test Method | Minimum Value | Application Context |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60851-5 | 155 V (130°C) | Prevents arcing in low-voltage windings |

| 250 V (180°C) | Ensures reliability in industrial motors | ||

| 300 V (220°C) | Critical for high-temperature aerospace | ||

| Elongation at Break | IEC 60851-4 | 3% | Minimum for complex coil geometries |

| 8% | Maximum for dimensional stability | ||

| Thermal Class | IEC 60317 | 130°C (Class B) | General-purpose appliances |

| 180°C (Class H) | EVs, industrial pumps, compressors | ||

| 220°C (Class C) | Aerospace, military systems |

Rigorous batch testing via certified laboratories validates all parameters. Traceability from copper cathode sourcing to finished wire—monitored through our integrated supply chain platform—guarantees compliance. Partnering with Xinzhaohe mitigates field failure risks by embedding metallurgical precision into every meter of winding wire, directly enhancing end-product longevity and efficiency. Technical data sheets with lot-specific certifications accompany all shipments.

Factory Tour: Manufacturing

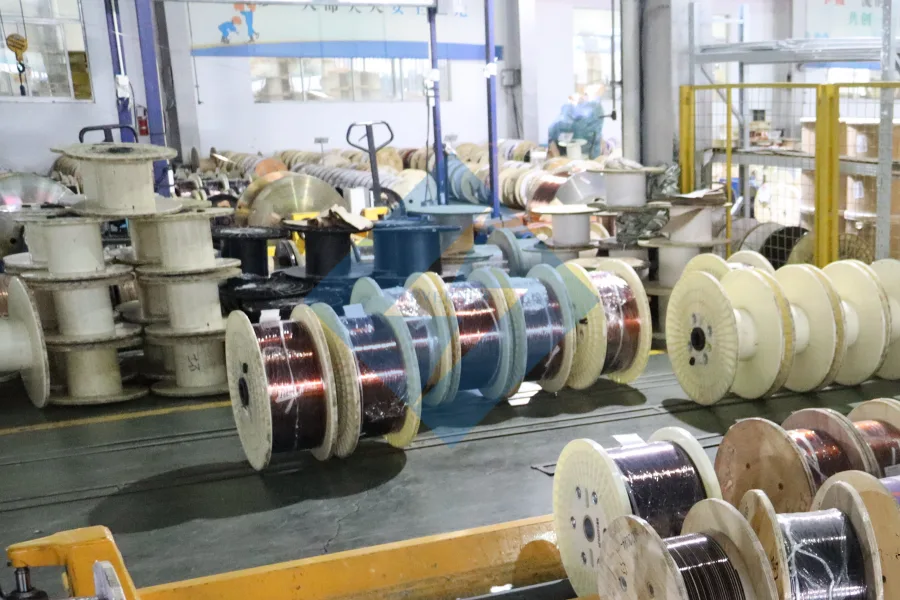

Manufacturing Process for Copper Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a strictly controlled, multi-stage manufacturing process designed to ensure optimal electrical conductivity, mechanical strength, and insulation integrity. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment and rigorous quality control protocols across four core stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity electrolytic copper rod (minimum 99.99% Cu), sourced from certified suppliers and verified through spectrographic analysis. The rod undergoes continuous fine drawing through a series of tungsten carbide or diamond dies, progressively reducing diameter to meet specified wire gauge tolerances. Drawing is performed under controlled tension and lubrication conditions to minimize work hardening and surface defects. Throughout this stage, diameter consistency is monitored using laser micrometers, ensuring dimensional accuracy within ±0.005 mm.

Following drawing, the copper wire enters a controlled atmosphere annealing furnace. This continuous in-line annealing process restores ductility by relieving internal stresses induced during cold drawing. The wire is heated to a precise temperature range of 450–550°C in a nitrogen-hydrogen reducing atmosphere, preventing oxidation and ensuring a clean, oxide-free surface essential for subsequent enamel adhesion. Temperature uniformity and residence time are continuously logged and adjusted via PLC control systems to maintain metallurgical consistency.

The annealed wire then proceeds to the enameling section, where multiple layers of polymer insulation are applied using precision die coating systems. Depending on the product specification, insulation materials may include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or combinations thereof, applied in single or dual-layer configurations. Each coat is immediately cured in a series of high-efficiency UV or thermal ovens, with temperature profiles optimized for cross-linking density and dielectric strength. Film thickness is maintained within ±5% of target values through real-time feedback loops.

Inline quality control is embedded throughout the manufacturing line. Key inspection points include spark testing at 3–15 kV to detect pinholes, diameter monitoring via laser gauges, and tensile strength and elongation verification through automated sampling. Additional off-line tests conducted per batch include thermal shock resistance, softening point, abrasion resistance, and dielectric breakdown voltage, all in accordance with IEC 60317 and GB/T 6109 standards.

Final spooling is performed under constant tension control to ensure uniform winding density and prevent deformation. Each spool is labeled with traceable batch data, including melt number, process parameters, and QC results. This integrated approach ensures that every meter of copper winding wire meets the stringent reliability requirements of motors, transformers, and electromechanical devices in industrial and automotive applications.

Packaging & Logistics

Export Packaging Specifications for Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. implements rigorously engineered export packaging protocols for copper winding wire to ensure integrity during international maritime transport. With over two decades of metallurgical and supply chain expertise, we recognize that copper’s susceptibility to oxidation and hygroscopic degradation demands specialized protection against marine environmental stressors. Standard packaging fails under prolonged exposure to salt-laden air, temperature fluctuations, and condensation inherent in sea freight. Our solution integrates structural stability with multi-layered moisture barriers, validated through 20+ years of global logistics experience.

All copper winding wire shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, pest-free hardwood. These pallets provide critical mechanical resilience against dynamic forces during vessel loading, unloading, and stacking. Pallet dimensions and load capacities are standardized to optimize container space while preventing deformation:

| Parameter | Specification |

|---|---|

| Pallet Dimensions | 1200 mm × 1000 mm × 150 mm |

| Max Load Capacity | 2,500 kg per pallet |

| Stacking Limit | 2 high in container (max 3m height) |

| Treatment | Heat-treated per ISPM 15 |

Immediately after coiling, wire reels undergo hermetic sealing using 125-micron triple-layer moisture-proof film. This film comprises an outer polyethylene layer for abrasion resistance, a central aluminum foil barrier for 0.1 g/m²/24hr water vapor transmission rate (WVTR), and an inner polypropylene layer for heat-seal integrity. The film is vacuum-shrunk to eliminate air pockets, preventing internal condensation during thermal cycling. Each sealed reel incorporates silica gel desiccant packs (500g per 500kg coil) calibrated to absorb residual moisture and ambient humidity for voyages exceeding 45 days.

Critical to our methodology is the elimination of electrochemical corrosion risks. Copper windings are isolated from direct contact with wooden pallets using polyethylene sheeting, avoiding galvanic reactions with wood preservatives. All metal fasteners on reels are passivated to prevent ionic contamination. Humidity indicators (0–60% RH range) are affixed externally to monitor barrier integrity without breaching the seal. Our packaging complies with ASTM D3078 for vacuum integrity testing and ISO 9227 for salt-spray resistance validation.

Sea freight safety is further assured through mandatory pre-shipment climate conditioning. Coils are stabilized at ≤40% relative humidity for 72 hours prior to sealing, minimizing trapped moisture. Palletized units are secured via steel strapping (min. 15 kN tension) to prevent shifting, with corner boards reinforcing edges against forklift impact. Documentation includes a moisture control certificate verifying in-seal RH levels ≤15% at dispatch. This system has maintained a 99.8% damage-free transit record across 12,000+ TEUs shipped to EU, ASEAN, and North American markets since 2010.

Luoyang Xinzhaohe Aluminum Co., Ltd. treats packaging as an extension of metallurgical quality control. By harmonizing material science with freight logistics, we deliver copper windings with uncompromised electrical conductivity and surface finish—regardless of voyage duration or climatic exposure. Partner with us for packaging engineered to preserve value from factory to final assembly.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Copper Windings

With over two decades of specialized expertise in the design and production of precision winding wire, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted partner for global manufacturers requiring reliable, high-conductivity copper windings. Our vertically integrated manufacturing platform, located in the industrial hub of Luoyang, Henan Province, enables tight control over material sourcing, process engineering, and final product quality—ensuring consistency and performance in every coil we produce.

Our factory operates a fully automated copper drawing and annealing line, capable of processing electrolytic tough pitch (ETP) copper to exacting dimensional tolerances. We produce round and rectangular copper winding wire with cross-sectional dimensions ranging from 0.8 mm² to 250 mm², meeting international standards including IEC 60317, GB/T 3953, and ASTM B3. Each batch undergoes rigorous electrical resistivity testing, tensile strength analysis, and elongation verification to guarantee compliance with thermal class requirements up to 200°C when insulated. Our in-house laboratory is equipped with state-of-the-art spectrometry, micro-ohmmeters, and thermal aging chambers to validate material purity and long-term reliability.

We specialize in magnet wire solutions for power transformers, traction inductors, and high-efficiency motors, where consistent conductivity and mechanical formability are critical. Our proprietary annealing process ensures uniform softness and low residual stress, minimizing deformation during coil winding and enhancing end-product performance. In addition to standard bare and enameled copper conductors, we offer customized surface treatments—including tin, silver, and nickel plating—for applications requiring enhanced solderability or oxidation resistance.

Quality assurance is embedded at every stage of production. Our facility is certified under ISO 9001:2015, with documented process controls from billet inspection through final packaging. Traceability is maintained via batch-coded labeling and digital process logs, enabling full auditability for regulated industries. With an annual production capacity exceeding 30,000 metric tons, we support both large-volume contracts and agile low-volume runs tailored to prototype or niche market demands.

Strategic logistics partnerships ensure timely delivery to ports across China, including Qingdao, Shanghai, and Shenzhen, with established export channels to Southeast Asia, Europe, and North America. Our technical sales team collaborates directly with engineering and procurement departments to align material specifications with application requirements, reducing risk and accelerating time-to-market.

For sourcing managers and design engineers seeking a stable, technically capable supplier of copper winding wire, Luoyang Xinzhaohe offers the operational maturity and metallurgical expertise required in today’s demanding power systems. We invite you to contact us to discuss your technical specifications and volume requirements.

Contact us at cathy@transformerstrip.com to initiate a technical review and sample request.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper windings directly from China.