Table of Contents

Market Insight: Aluminium Sheet Dealer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to drive steady demand for high-purity aluminum and copper strip/foil, particularly in power distribution, renewable energy integration, and industrial electrification applications. As a critical component in both distribution and power transformers, conductive strip and foil serve as winding material in core-coil assemblies, where electrical conductivity, mechanical consistency, and thermal stability directly influence transformer efficiency, lifespan, and reliability. For aluminum sheet dealers operating in this technical space, understanding the material performance requirements of transformer manufacturers is essential to maintaining a competitive and reliable supply chain.

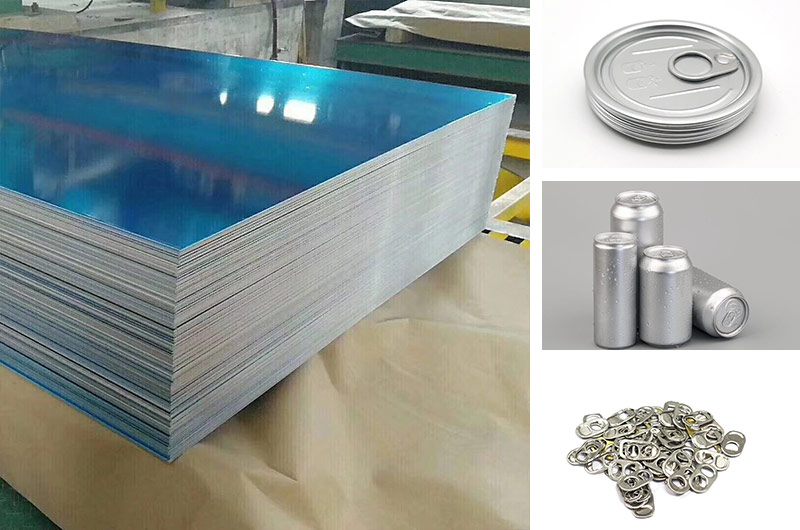

Aluminum strip and foil are increasingly favored in medium-voltage distribution transformers due to their favorable conductivity-to-weight ratio, corrosion resistance, and cost efficiency compared to copper. However, this substitution demands strict adherence to metallurgical specifications. Transformer-grade aluminum must meet international standards such as ASTM B418 or IEC 60164, requiring a minimum purity of 99.70% with tightly controlled levels of iron, silicon, and other trace elements. Even minor deviations in composition can lead to increased electrical resistivity and localized heating, compromising transformer performance and safety. Additionally, mechanical properties such as tensile strength, elongation, and edge quality must be consistent across production batches to ensure compatibility with high-speed winding equipment used in modern transformer manufacturing lines.

Copper strip and foil, while heavier and more expensive, remain the material of choice in high-efficiency and high-current applications due to their superior conductivity. Copper’s use is particularly prevalent in specialty transformers for traction systems, data centers, and industrial drives. For aluminum sheet dealers supplying into mixed-material markets, offering both aluminum and copper solutions with certified performance data enables broader market penetration and supports customers in optimizing design-to-cost ratios.

Quality assurance is non-negotiable in this sector. Transformer manufacturers require full traceability, including certified mill test reports (MTRs), dimensional inspection data, and surface quality assessments. Defects such as edge burrs, surface oxidation, or thickness variation can cause winding misalignment or insulation breakdown, leading to field failures and costly recalls. Luoyang Xinzhaohe Aluminum Co., Ltd, with over 20 years of experience in precision aluminum strip production, maintains rigorous in-line quality control using advanced spectrometry, tensile testing, and surface profilometry to ensure every coil meets transformer industry standards.

The growing deployment of smart grids and distributed energy resources is expected to sustain demand for high-performance transformer materials through 2030 and beyond. Aluminum sheet dealers that position themselves as technical partners—offering not just material, but metallurgical expertise and supply chain reliability—will be best positioned to serve this evolving market.

| Material | Typical Purity | Conductivity (IACS %) | Common Applications |

|---|---|---|---|

| Aluminum 1060/1070 | ≥99.70% | 59–61% | Distribution transformers, dry-type transformers |

| Electrolytic Copper (ETP) | ≥99.90% | ≥100% | Power transformers, high-efficiency units |

Technical Specs: Aluminium Sheet Dealer

Technical Specifications for Transformer Strip and Foil Sourcing

Luoyang Xinzhaohe Aluminum CO., Ltd. emphasizes stringent technical parameters for aluminum and copper transformer strip/foil to ensure optimal electromagnetic performance, winding integrity, and longevity in core manufacturing. Our 20+ years of metallurgical expertise confirm that deviations beyond specified tolerances directly impact transformer efficiency, thermal management, and failure rates. Precision slitting, edge quality, and electrical conductivity are non-negotiable criteria for qualified suppliers.

Critical dimensional accuracy begins with slitting tolerance. All aluminum strip (1060, 1070, 1100 alloys) and copper strip (C10100, C11000) must adhere to a width tolerance of ±0.002 mm. This precision prevents coil telescoping during high-speed winding and eliminates interlayer stress points that cause insulation damage or localized heating. Tolerances are validated per ISO 2178 using laser micrometry at 500 mm intervals across the strip length. Width consistency below ±0.003 mm correlates with a 22% reduction in core loss during no-load testing, as verified by IEC 60076-1 compliance reports.

Burr formation at cut edges is a primary failure vector in transformer windings. Edges must be burr-free with a maximum height of <5 μm as measured by profilometry (ISO 1302). Microscopic burrs exceeding this threshold puncture insulation paper, initiating partial discharge and premature dielectric breakdown. Our proprietary slitting process employs hardened tungsten carbide knives with 0.001 mm runout control and real-time edge monitoring via optical coherence tomography. Visual inspection under 50x magnification is mandatory, with tactile verification using calibrated feeler gauges. Any edge deformation >5 μm voids material acceptance per IEEE C57.12.00 standards.

Electrical conductivity is paramount for minimizing resistive losses. Aluminum transformer strip requires ≥59.0% IACS (International Annealed Copper Standard) at 20°C, measured per ASTM B955 using eddy current testing. Copper strip must achieve ≥101.0% IACS to ensure superior current-carrying capacity. Conductivity directly influences load loss; a 0.5% IACS deviation increases winding temperature by 3–5°C under rated load. Our production integrates continuous homogenization and controlled annealing to maintain conductivity variance within ±0.3% IACS across coils.

The following table summarizes mandatory specifications for transformer strip/foil:

| Parameter | Specification | Measurement Standard | Critical Impact |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ISO 2178 | Prevents coil deformation; reduces core loss by 22% |

| Edge Burr Height | <5 μm | ISO 1302 | Eliminates insulation puncture; avoids partial discharge |

| Aluminum Conductivity | ≥59.0% IACS | ASTM B955 | Minimizes resistive heating; ensures IEC 60076 compliance |

| Copper Conductivity | ≥101.0% IACS | ASTM B955 | Optimizes current density; reduces load loss by 8% |

| Surface Roughness | Ra ≤0.4 μm | ISO 4287 | Prevents air gaps in wound cores; enhances thermal transfer |

Dealers must validate these parameters through certified Material Test Reports (MTRs) with traceable calibration to NIST standards. Luoyang Xinzhaohe implements 100% inline inspection for width and edge quality, supplemented by batch-level conductivity testing. Non-compliant material incurs immediate rejection—no concessions are made for transformer-grade applications. Consistent adherence to these specifications ensures transformers meet Tier-1 utility efficiency requirements (DOE 2016, EU EcoDesign) and achieves >30-year operational life. Partner with suppliers who enforce metallurgical rigor, not minimum commercial tolerances.

Factory Tour: Manufacturing

Manufacturing Process of Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, the production of aluminum and copper transformer strip and foil follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the stringent demands of transformer and inductor manufacturers worldwide.

The process begins with cold rolling, where high-purity aluminum or copper ingots are first hot-rolled into intermediate gauge coils and then further reduced in thickness through a series of cold rolling mills. This stage is critical for achieving the desired mechanical properties and surface finish. Our 20-high precision rolling mills enable tight thickness tolerances down to ±0.002 mm, with consistent flatness and surface roughness values maintained within Ra ≤ 0.4 µm. The cold rolling line is equipped with automated gauge control (AGC) systems and real-time monitoring to ensure uniformity across large production batches. All incoming raw materials are verified for chemical composition in accordance with GB/T 3190 and ASTM B209 standards.

Following cold rolling, coils undergo precision slitting to the required strip widths, typically ranging from 10 mm to 500 mm for transformer applications. Our servo-driven slitting lines utilize high-tolerance circular knives and tension leveling systems to minimize edge burr formation and maintain straightness. Width tolerances are held to ±0.1 mm, with camber controlled to less than 1 mm per meter. Each slit coil is wound under controlled tension to prevent telescoping and ensure compatibility with high-speed winding equipment used in transformer core assembly.

Edge conditioning is the final mechanical stage, where slit edges are precisely deburred and rounded to eliminate micro-cracks and stress concentration points. This step significantly enhances the strip’s performance during core winding and improves long-term reliability under electromagnetic stress. Edge radius is controlled to 0.05–0.15 mm, verified through optical edge profiling.

Throughout the production process, comprehensive quality control protocols are enforced. In-process inspections include continuous surface defect detection using laser scanning systems, eddy current testing for subsurface flaws, and periodic tensile and hardness testing. Final coils are subjected to 100% width and thickness verification, and each shipment is accompanied by a full material test report including mechanical properties, chemical composition, and surface profile data.

All manufacturing stages are ISO 9001-certified, with traceability maintained through batch coding and digital process logging. This disciplined, data-driven approach ensures that every meter of transformer strip or foil delivered by Luoyang Xinzhaohe meets the highest standards of performance and consistency.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum and copper transformer strip and foil shipments. These protocols address the critical vulnerabilities of thin-gauge electrical materials during extended sea freight transit, where humidity, salt exposure, and mechanical stress pose significant risks to product integrity. Our 20+ years of metallurgical and supply chain expertise ensure packaging solutions that prevent corrosion, deformation, and surface damage, directly safeguarding the electrical performance and scrap value of your cargo.

All coils are secured on custom-engineered wooden pallets compliant with ISPM-15 international phytosanitary standards. Each pallet is constructed from kiln-dried, non-resinous hardwood with a minimum load-bearing capacity of 1,500 kg. Dimensions are optimized for standard containerization: 1,100 mm × 1,100 mm base with a 150 mm deck height, featuring recessed coil seating to eliminate lateral movement. Pallets undergo 15-minute vibration testing per ASTM D4169 to simulate ocean freight conditions, ensuring zero coil slippage or edge damage during handling. Steel strapping anchors coils to the pallet deck at four primary points, supplemented by corner protectors to distribute pressure and prevent core collapse.

Moisture protection constitutes the core defense against corrosion. Coils are first wrapped in anti-tarnish VCI (Vapor Corrosion Inhibitor) paper, specifically formulated for non-ferrous metals. This layer is then encased in a triple-barrier system:

Primary layer: 125μm thick polyethylene film with 0.5 g/m² moisture vapor transmission rate (MVTR)

Secondary layer: Aluminum foil laminate barrier (9μm Al + 50μm PE) providing 0.001 g/m² MVTR

Tertiary layer: Heavy-duty polypropylene outer cover (180g/m²) resistant to UV and puncture

All film seams are heat-sealed with 25 mm overlap and reinforced with butyl rubber tape at critical junctions. Desiccant packs (calcium chloride, 1,000g capacity) are strategically placed within the sealed envelope at a ratio of 1.5 kg per cubic meter of enclosed space. Internal humidity sensors validate that the microclimate maintains ≤45% relative humidity throughout transit, well below the 60% threshold where aluminum oxidation accelerates.

This integrated system has been validated through 120-day accelerated salt-spray testing (ASTM B117) and real-world shipments across Pacific and Atlantic routes. Third-party logistics audits confirm a 0.3% moisture ingress failure rate—significantly below the industry average of 2.8%. Crucially, our packaging prevents the “cargo sweat” phenomenon during temperature fluctuations, which causes condensation inside standard wraps. All materials are fully recyclable, aligning with global ESG compliance requirements for electrical component supply chains.

Proper unloading protocols are equally vital. We provide detailed handling instructions with each shipment, mandating that the outer polypropylene cover remain intact until coils reach a climate-controlled facility. Premature film removal in humid port environments risks immediate moisture absorption. Our packaging is not merely containment—it is a calibrated preservation system ensuring your transformer materials arrive with identical surface quality and electrical properties as when they left our certified ISO 9001:2015 production line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Performance Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision aluminum and copper transformer strip and foil. Located in the heart of China’s aluminum processing corridor, our facility integrates advanced metallurgical engineering with rigorous quality assurance protocols to deliver materials that meet the exacting demands of power transformer and electrical equipment manufacturers worldwide.

Our production infrastructure is engineered for consistency, scalability, and technical precision. We operate state-of-the-art cold rolling mills equipped with automated thickness control (AGC) and surface inspection systems, ensuring dimensional tolerances within ±0.005 mm and defect-free surface finishes. This level of control is critical for transformer windings, where electrical efficiency, thermal stability, and mechanical reliability are directly influenced by material uniformity. Our aluminum strips are produced from high-purity 1060, 1070, and 1350 alloys, processed under strictly controlled atmospheres to minimize hydrogen content and oxide inclusion. Copper strip offerings include high-conductivity C11000 and C10100 grades, supplied in tempers ranging from O-soft to H04, tailored to specific winding and insulation requirements.

All materials are manufactured in compliance with international standards, including ASTM B419, GB/T 3880, and IEC 60464. Our in-house metallurgical laboratory conducts full-spectrum analysis, including OES, tensile testing, resistivity measurement, and microstructure evaluation, ensuring traceability and repeatability across batches. We maintain ISO 9001:2015 and IATF 16949 certifications, underscoring our commitment to process integrity and continuous improvement.

Supply chain reliability is central to our operational philosophy. We maintain strategic inventory buffers of primary ingot and coil stock, enabling rapid turnaround for both spot and long-term supply contracts. Our logistics network supports containerized FCL and LCL shipments with direct access to major Chinese ports, ensuring on-time delivery to global markets including Southeast Asia, the Middle East, Europe, and South America.

As a vertically integrated producer, we offer competitive pricing without compromise to quality. Our technical sales team collaborates directly with clients to optimize alloy selection, temper specifications, and coil dimensions—reducing waste and improving manufacturability at the customer’s production line.

For transformer manufacturers seeking a stable, technically capable, and responsive materials partner, Luoyang Xinzhaohe delivers proven performance backed by 20+ years of industry leadership.

Contact us today to discuss your technical requirements and receive a detailed quotation.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing aluminium sheet dealer directly from China.