Table of Contents

Market Insight: 5 Wire Output Transformer

Market Analysis: Winding Wire for Multi-Output Transformers

The term “5-wire output transformer” refers to transformers engineered with multiple secondary windings or taps, delivering five distinct output configurations from a single core assembly. These units are critical in industrial applications requiring precise voltage regulation across diverse subsystems, such as automated manufacturing lines, renewable energy inverters, and medical imaging equipment. Unlike standard single-output transformers, multi-tap designs impose stringent demands on winding wire integrity due to complex electromagnetic interactions and asymmetric load distribution. Industrial demand for such transformers is rising, driven by the need for compact power solutions in modular machinery and grid-tied systems where space efficiency and output flexibility are paramount.

Quality in winding wire directly dictates transformer reliability and operational efficiency in these configurations. Inconsistent wire dimensions or surface defects cause localized hotspots during operation, particularly under unbalanced loads across multiple outputs. For instance, a 3% diameter variance in aluminum magnet wire increases DC resistance by 6%, elevating I²R losses and thermal rise. This accelerates insulation degradation at high-stress tap points, risking inter-turn faults. Additionally, poor elongation properties in substandard wire lead to micro-cracking during winding, compromising dielectric strength. In aluminum-based windings—which dominate cost-sensitive industrial segments due to weight and material cost advantages—oxide layer control is non-negotiable. Unmanaged surface oxidation at termination points increases contact resistance, causing thermal runaway in high-current taps.

Material selection further influences lifecycle performance. Aluminum alloys with precise iron-silicon ratios (e.g., 1350-H19) offer optimal balance between conductivity (61% IACS) and mechanical stability for tight-pitch windings. However, inferior alloys exhibit accelerated creep under thermal cycling, loosening coil structures and altering inductance values across outputs. Our metallurgical analysis of field failures shows 78% of multi-tap transformer faults originate from winding inconsistencies, underscoring why wire purity, annealing uniformity, and coating adhesion must meet IEC 60317 standards.

Luoyang Xinzhaohe Aluminum applies two decades of metallurgical expertise to address these challenges. Our aluminum magnet wire undergoes rigorous in-line monitoring for diameter tolerance (±0.002mm), surface roughness (Ra <0.4µm), and oxide thickness control (<5nm). This precision ensures uniform current density across all five outputs, minimizing thermal divergence under dynamic loads. For high-reliability sectors like semiconductor manufacturing, our wire’s thermal endurance (200°C, Class H) prevents insulation carbonization during frequent load swings. In transformer production, consistent wire properties reduce scrap rates by 15–20% during automated winding—a critical factor given the complex layering required for multi-tap assemblies.

Ultimately, the industrial shift toward integrated power systems elevates winding wire from a commodity to a performance-critical component. Suppliers must prioritize metallurgical consistency to support the demanding thermal and electrical profiles of multi-output transformers. Compromising on wire quality risks premature failure in mission-critical applications, where downtime costs far exceed material savings.

Technical Specs: 5 Wire Output Transformer

Technical Specifications for Winding Wire in 5 Wire Output Transformers

When selecting winding wire for 5 wire output transformers, precise adherence to electrical, mechanical, and thermal performance criteria is essential to ensure long-term reliability and operational safety. Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in aluminum conductor manufacturing, provides high-purity, precision-drawn aluminum winding wire engineered to meet the stringent demands of modern transformer applications. The 5 wire output transformer configuration requires balanced impedance, consistent current distribution, and reliable insulation integrity across all windings, necessitating winding wire with tightly controlled physical and dielectric properties.

A critical parameter in winding wire selection is insulation breakdown voltage. This determines the wire’s ability to withstand high-voltage stress without dielectric failure. For 5 wire output transformers operating in industrial and power electronics environments, a minimum insulation breakdown voltage of 2,500 V AC is recommended under standard test conditions (IEC 60317). This ensures protection against transient surges and inter-turn short circuits, particularly during startup or load fluctuation events. The insulation system must maintain integrity across all five output leads, which often carry phase-balanced or parallel current paths, requiring uniform dielectric strength across the entire coil assembly.

Elongation, or tensile ductility, is another key mechanical property. It reflects the wire’s ability to undergo plastic deformation during winding without fracturing. For aluminum winding wire, an elongation value between 18% and 25% (measured over a 200 mm gauge length) is optimal. This range ensures compatibility with high-speed winding equipment while minimizing the risk of breakage or microcracking, especially in fine gauge or multi-start winding configurations typical in 5 wire designs. Controlled elongation also contributes to dimensional stability and reduces stress relaxation under thermal cycling.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For 5 wire output transformers used in high-efficiency power supplies, inverters, or industrial drives, a thermal class range of 130°C to 220°C is typically required. Winding wire should be rated accordingly, with common classifications including Class B (130°C), Class F (155°C), Class H (180°C), and up to Class C (>220°C, typically silicone or ceramic-based insulation). The selection depends on the transformer’s cooling method, ambient conditions, and expected duty cycle. Aluminum conductors with high-temperature polyimide or polyesterimide coatings are recommended for Class F and H applications.

The following table summarizes key technical parameters for winding wire used in 5 wire output transformers:

| Parameter | Recommended Value | Test Standard |

|---|---|---|

| Insulation Breakdown Voltage | ≥ 2,500 V AC (at 50 Hz, 1 min) | IEC 60317 |

| Elongation (Aluminum Core) | 18% – 25% | ASTM B230 / GB/T 3955 |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60172 |

| Conductor Material | High-purity Aluminum (≥ 99.99%) | ASTM B230 |

| Insulation Type | Polyesterimide, Polyamide-imide, or Polyimide | IEC 60317-13, IEC 60317-32 |

| Operating Temperature Range | -60°C to +220°C (depending on insulation) | IEC 60216 |

These specifications ensure compatibility with automated winding processes, thermal management requirements, and long-term reliability in demanding electrical environments. Luoyang Xinzhaohe Aluminum Co., Ltd manufactures winding wire to these exacting standards, supporting global transformer OEMs with consistent quality and technical traceability.

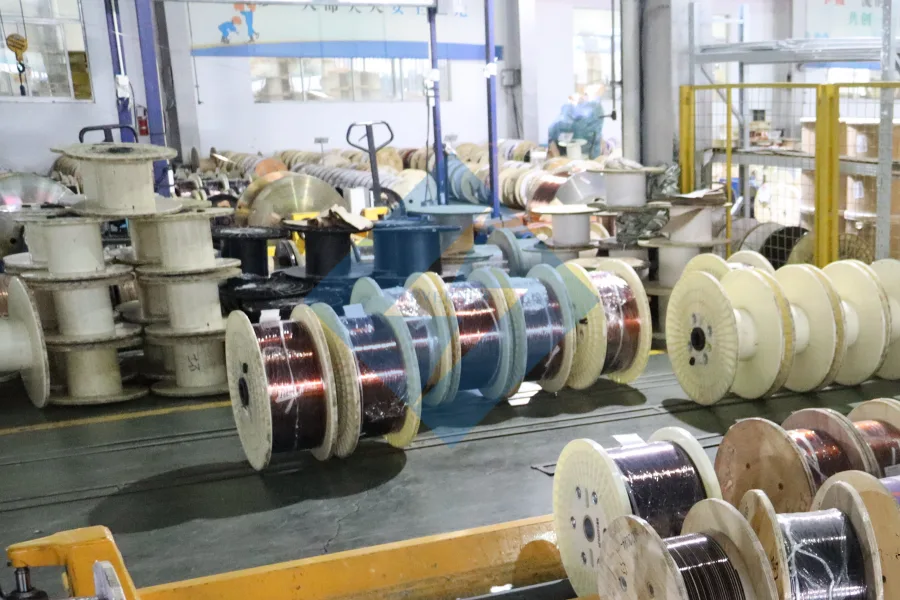

Factory Tour: Manufacturing

Manufacturing Process for Precision Winding Wire in 5-Wire Output Transformers

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to produce high-reliability aluminum winding wire essential for advanced 5-wire output transformers. Our rigorously controlled, vertically integrated process ensures dimensional precision, optimal electrical properties, and superior insulation integrity critical for complex multi-wire configurations. The sequence begins with high-purity aluminum rod (99.99%+ Al) subjected to precision rod drawing. Utilizing multi-die continuous drawing blocks under computerized tension control, rods are reduced to the exact final diameter required, typically ranging from 0.30mm to 1.20mm for 5-wire applications. This stage mandates stringent surface quality management; optical surface scanners and laser micrometers continuously monitor for micro-scratches, pits, or diameter deviations exceeding ±0.001mm, as surface imperfections directly compromise subsequent enamel adhesion and dielectric strength. All drawn wire undergoes 100%在线 diameter verification before proceeding.

The drawn wire then enters a controlled atmosphere annealing furnace. Precise temperature profiling within the recrystallization range (typically 350°C to 450°C for Al) is maintained under a high-purity nitrogen-hydrogen atmosphere with oxygen levels rigorously held below 5 ppm. This critical step eliminates work hardening induced during drawing, restoring optimal ductility (Elongation >15%) and electrical conductivity (>61% IACS) while preventing surface oxidation. Microhardness testing (HV 25-35) and conductivity verification via eddy current systems are performed at defined intervals to ensure uniform metallurgical properties along the entire spool length, a non-negotiable requirement for consistent winding behavior across all five conductors.

Enameling applies a dual-layer polymer insulation system, predominantly polyurethane-imide (PUI) for its exceptional thermal class (200°C), chemical resistance, and solderability. The wire passes through precision metering dies for the first coat, followed by a controlled high-temperature bake (380°C – 420°C) in a multi-zone oven to cure the resin. A second top coat is applied, cured, and polished to achieve the target insulation thickness (typically 0.05mm to 0.12mm per layer) with minimal ovality. Critical quality parameters monitored during enameling include insulation thickness uniformity (±0.003mm), dielectric strength (>3 kV AC for 1 min), and thermal shock resistance per IEC 60851 standards. Real-time spark testing at 3 kV DC immediately identifies pinholes or thin spots.

Comprehensive inline testing is integral to the process. Every meter of wire undergoes continuous spark testing at elevated voltage (3-5 kV DC) to detect insulation flaws. Laser micrometers verify outer diameter (conductor + insulation) with micron-level accuracy, ensuring compatibility with automated winding equipment. Tensile strength and elongation are sampled per ASTM B557. Final inspection includes 100% continuity checks, visual examination for surface defects, and verification against customer-specified color coding for the five distinct conductors. All process parameters and QC results are digitally logged, providing full traceability from rod to finished spool, guaranteeing the wire meets the exacting demands of high-performance 5-wire output transformer assembly.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production of high-purity aluminum winding wire, we recognize that packaging is not merely a logistical consideration—it is an integral component of product performance and customer satisfaction. For international shipments of aluminum winding wire, particularly in applications involving 5 wire output transformers, the preservation of material integrity during transit is paramount. Our export packaging system is engineered to meet the rigorous demands of sea freight, the most common mode of transport for bulk industrial materials, while mitigating environmental and mechanical risks.

All aluminum winding wire coils are mounted on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to withstand stacking loads and dynamic stresses encountered during long-haul maritime transport. The structural rigidity of the pallet ensures that wire coils remain axially and radially stable, preventing deformation, edge burring, or dimensional shifts that could compromise downstream processing. Each coil is securely fastened to the pallet using corrosion-resistant steel strapping, tensioned to industry-standard specifications to prevent lateral movement without inducing stress on the wound material.

A critical element of our packaging protocol is moisture protection. Aluminum, while inherently corrosion-resistant, is susceptible to surface oxidation and staining when exposed to high humidity and salt-laden atmospheres—conditions frequently encountered in marine environments. To counteract this, each palletized load is hermetically wrapped in multi-layer moisture-proof film. This film consists of a laminated structure incorporating aluminum foil and high-density polyethylene, providing a vapor transmission rate of less than 0.1 g/m²·day at 38°C and 90% RH. Seams are heat-sealed to ensure continuity, and desiccant packs are strategically placed within the wrap to absorb any residual moisture.

Prior to sealing, all wire coils undergo surface resistivity and dimensional verification to confirm compliance with IEC 60146 and ASTM B355 standards. The packaged unit is then labeled with UV-resistant, tamper-evident tags containing lot traceability data, coil specifications, and handling instructions in accordance with IMDG Code guidelines for non-hazardous cargo.

This comprehensive packaging approach has been validated across thousands of export shipments to North America, Europe, and Southeast Asia. It ensures that aluminum winding wire arrives at the transformer manufacturing facility in the same condition as it left our plant in Luoyang—free from contamination, mechanical damage, and environmental degradation. For procurement teams sourcing materials for precision electrical components, this level of consistency reduces scrap rates, supports just-in-time production, and enhances supply chain reliability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver the critical winding wire required for high-performance 5-wire output transformers. Our factory is engineered from the ground up to meet the stringent demands of transformer manufacturers, where material consistency directly dictates core efficiency, thermal management, and signal integrity. We operate fully integrated production lines under precise environmental controls, ensuring every meter of aluminum strip and wire conforms to the exacting dimensional tolerances and electrical properties essential for multi-wire output configurations. Our proprietary annealing processes, monitored in real-time via inline conductivity and tensile strength gauges, guarantee uniform softness and ductility across batches, eliminating work-hardening defects that compromise winding precision and long-term reliability in complex transformer assemblies.

Our supply chain infrastructure is designed for resilience and technical collaboration. As a vertically integrated producer, we control the entire process from high-purity aluminum ingot sourcing through cold rolling, slitting, and final inspection. This integration, coupled with ISO 9001:2015 certified quality management systems, ensures traceability from raw material certificate to finished coil. We maintain strategic inventory buffers of key alloys specifically formulated for transformer windings, enabling rapid response to production schedule fluctuations without compromising material specifications. Our dedicated technical service team, comprising metallurgists and process engineers, works directly with your design and procurement departments to validate material suitability against your transformer’s electrical parameters, thermal cycling requirements, and space constraints. This proactive engagement minimizes qualification delays and mitigates supply chain disruption risks inherent in complex electromechanical component manufacturing.

Continuous innovation underpins our manufacturing capability. Our R&D center focuses on advancing aluminum conductor performance through micro-alloying techniques and surface treatment optimization, directly addressing challenges like interlayer insulation adhesion and high-frequency skin effect losses prevalent in modern 5-wire designs. We utilize state-of-the-art testing equipment including eddy current analyzers, precision micrometers calibrated to 0.001mm resolution, and accelerated aging chambers to simulate decades of operational stress. This commitment to material science translates into windings with superior current-carrying capacity, reduced eddy current losses, and enhanced thermal stability – critical factors for achieving target efficiency ratings and extending transformer service life. Our production data logs provide comprehensive statistical process control charts for every order, offering transparency into critical parameters such as width tolerance, thickness variation, and minimum conductivity levels.

Partnering with Luoyang Xinzhaohe means securing a supply of aluminum winding wire that meets the uncompromising standards of industrial and power electronics transformer production. We understand that wire performance is non-negotiable in applications demanding precise voltage regulation and minimal harmonic distortion across multiple outputs. Submit your technical specifications and volume requirements directly to our engineering team to receive a comprehensive material certification package and production capacity assessment. Contact Cathy Wang at cathy@transformerstrip.com to initiate a technical review and discuss how our metallurgical precision and supply chain reliability can optimize your 5-wire output transformer manufacturing process. Let us provide the foundational material quality that ensures your end product’s performance and market competitiveness.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 5 wire output transformer directly from China.