Table of Contents

Market Insight: C1100 Copper Foil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for C1100 copper foil in transformer manufacturing continues robust growth, driven by critical infrastructure modernization and electrification trends. Key demand catalysts include extensive power grid upgrades requiring high-efficiency distribution transformers, the rapid integration of renewable energy sources necessitating specialized grid-tied transformers, and the expanding electric vehicle charging network infrastructure. C1100 (Electrolytic Tough Pitch Copper, UNS C11000), with its minimum 99.90% Cu + Ag content and exceptional electrical conductivity (100% IACS minimum per ASTM B152), remains the dominant material for low-voltage windings in中小型 power and distribution transformers due to its optimal balance of conductivity, formability, and cost-effectiveness. This segment represents a significant and stable market volume, with demand particularly sensitive to regional energy investment cycles and regulatory efficiency standards like DOE 2016 and IEC 60076-20.

The uncompromising quality of C1100 copper foil is non-negotiable for transformer reliability and longevity. Substandard material introduces critical failure risks during both manufacturing and operational phases. Purity deviations below 99.90% directly degrade electrical conductivity, increasing I²R losses and reducing transformer efficiency, potentially violating regulatory mandates. Surface imperfections such as pits, scratches, or residual oxides act as initiation points for partial discharge under high electrical stress, accelerating insulation degradation and leading to premature dielectric breakdown. Inconsistent mechanical properties, including inadequate tensile strength or elongation post-annealing, cause winding fractures during coil formation or vibration-induced fatigue in service. Precise dimensional control (thickness tolerance typically ±0.005mm) is equally vital; variations disrupt winding tightness, increase stray losses, and compromise thermal management. Reputable suppliers implement rigorous process controls from cathode sourcing through continuous casting, cold rolling, and final annealing to ensure homogeneity in grain structure, surface finish, and mechanical properties across every coil.

Transformer failures stemming from inferior foil incur severe downstream costs far exceeding initial material savings. Field failures necessitate costly outages, emergency replacements, and potential liability claims, damaging utility and OEM reputations. Consequently, discerning buyers prioritize suppliers with demonstrable metallurgical expertise, certified quality management systems (ISO 9001, IATF 16949), and comprehensive in-process testing protocols covering conductivity verification, surface profilometry, and mechanical property validation per ASTM/IEC standards. Luoyang Xinzhaohe Aluminum Co., Ltd leverages its 20+ years of precision strip manufacturing experience to deliver C1100 foil meeting the most stringent transformer industry specifications, ensuring operational integrity and supporting global energy transition goals through reliable core components. Supplier qualification must extend beyond datasheets to validated production consistency and supply chain transparency.

Technical Specs: C1100 Copper Foil

Technical Specifications for C1100 Copper Foil – Precision Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-purity C1100 copper foil to meet stringent demands in power transmission, high-efficiency transformers, and precision electrical systems. With over two decades of experience in non-ferrous metal strip and foil production, our C1100 copper foil is engineered for optimal electrical performance, mechanical stability, and edge quality. This section outlines the critical technical parameters governing the material’s performance, particularly in applications requiring tight dimensional tolerances and high conductivity.

C1100 copper, also known as electrolytic tough pitch (ETP) copper with ultra-high purity, is characterized by its minimal oxygen content and absence of residual alloys, ensuring superior electrical conductivity and formability. The foil is cold-rolled to precise thicknesses and undergoes precision slitting to meet exacting customer specifications. Dimensional accuracy is maintained within ±0.002 mm, achieved through advanced tension leveling and laser-guided slitting systems. This tolerance is critical in transformer winding applications where layer uniformity directly influences magnetic coupling efficiency and thermal management.

Edge quality is a defining characteristic of our C1100 copper foil. Burr-free edges are achieved through high-precision rotary shear slitting with automated blade clearance control, followed by inline edge inspection using optical profilometry. This ensures no micro-tearing or raised edges that could compromise dielectric integrity or cause interlayer shorting in wound components. The foil’s surface is free from pits, scratches, and roll marks, meeting ASTM B370 standards for copper plate, sheet, and strip.

Electrical conductivity is maintained at a minimum of 100% IACS (International Annealed Copper Standard) at 20°C, verified through four-point probe resistivity testing. This high conductivity ensures minimal resistive losses in transformer windings, directly contributing to energy efficiency and thermal performance. The foil is supplied in fully annealed (soft) temper, providing excellent flexibility for tight-radius winding without cracking or delamination.

All foils are cleaned and passivated to prevent oxidation during storage and transit, with anti-tarnish coatings applied upon request. Material traceability is maintained through batch-level certification, including chemical composition (verified via OES), mechanical properties, and dimensional reports.

The following table summarizes the key technical parameters for C1100 copper foil:

| Parameter | Specification |

|---|---|

| Material Standard | ASTM B370, C11000 (ETP Copper) |

| Thickness Range | 0.05 mm – 0.50 mm |

| Thickness Tolerance | ±0.002 mm (precision slitted) |

| Width Range | 10 mm – 300 mm |

| Width Tolerance | ±0.05 mm |

| Edge Quality | Burr-free, no micro-tears, smooth finish |

| Electrical Conductivity | ≥100% IACS at 20°C |

| Temper | O60 (Soft/Annealed) |

| Surface Condition | Clean, oxide-controlled, passivated |

| Tensile Strength | 200–250 MPa |

| Elongation (min) | 40% |

| Flatness | ≤5 I-Units (per 1000 mm) |

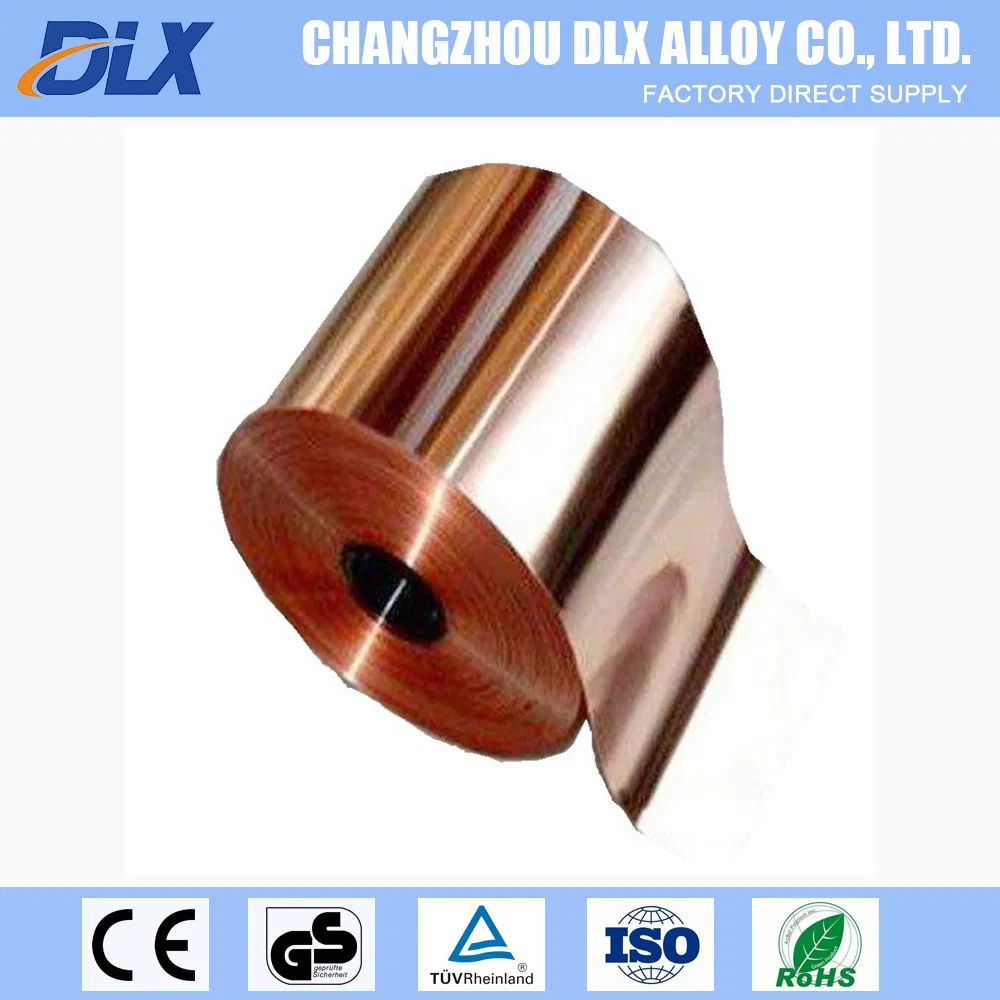

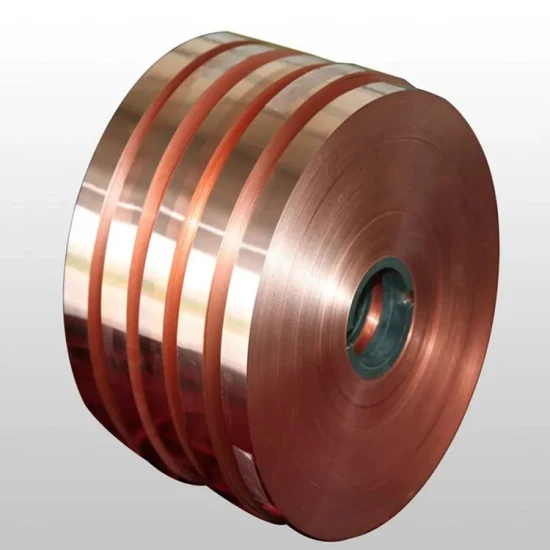

| Packaging | Reel, vacuum-sealed, anti-corrosion paper |

This specification ensures compatibility with automated winding equipment and high-reliability power systems, making our C1100 copper foil a preferred choice for OEMs in energy, rail, and industrial electronics sectors.

Factory Tour: Manufacturing

Manufacturing Process for C1100 Copper Foil

The production of C1100 copper foil for transformer applications begins with high-purity electrolytic tough pitch (ETP) copper cathodes meeting ASTM B152 specifications. Initial processing involves hot rolling to reduce ingot thickness to intermediate gauges, followed by rigorous surface cleaning to eliminate oxides and contaminants. The core cold rolling stage employs precision reversing mills with computer-controlled roll gap adjustments and tension leveling systems. This step achieves the target foil thickness, typically ranging from 0.05 mm to 0.50 mm, while maintaining a strict thickness tolerance band of ±2% across the strip width. Critical parameters monitored in real-time include rolling force, interstand tension, and coolant flow rate to ensure uniform microstructure and prevent surface defects such as scratches or roll marks. The cold rolling line incorporates continuous thickness profiling via beta-gauge sensors, with data fed into adaptive control systems for instantaneous correction.

Following cold rolling, precision slitting transforms master rolls into customer-specified widths. This operation utilizes rotary shear slitters with tungsten carbide blades maintained under strict edge sharpness protocols. Width tolerances are held to ±0.10 mm for foils below 0.20 mm thickness and ±0.15 mm for thicker gauges, verified through laser micrometer arrays positioned immediately post-cut. Tension control throughout the slitting line prevents edge waviness and maintains strip flatness, critical for subsequent winding integrity. All slit edges undergo immediate visual and tactile inspection to detect micro-burrs or irregularities before further processing.

Edge conditioning is a non-negotiable step for transformer-grade copper foil. Mechanical brushing systems with calibrated abrasive media remove residual burrs generated during slitting, while edge radius control units apply precise chamfering to achieve a consistent 0.02–0.05 mm radius. This process eliminates sharp edges that could puncture insulation layers in wound transformer cores, directly impacting product reliability. Conditioned edges are validated using optical edge profilers to ensure compliance with IEC 60404-1 surface quality requirements.

Quality control is embedded at every manufacturing phase. In-process checks include:

Cold rolling exit: Surface defect scanning via high-resolution CCD cameras

Post-slitting: Width consistency verification and edge roughness measurement (Ra ≤ 0.8 μm)

Final inspection: Full-width eddy current testing to detect subsurface inclusions or conductivity variations, coupled with destructive testing of sample coupons for tensile strength (200–260 MPa) and electrical conductivity (≥100% IACS).

All process parameters and QC results are digitally logged against batch numbers, enabling full traceability from cathode to finished foil. This integrated approach ensures C1100 foil meets the dimensional stability, surface integrity, and electrical performance demands of high-efficiency transformer windings, where even micron-level deviations can compromise core loss characteristics. Luoyang Xinzhaohe Aluminum CO., Ltd implements these protocols across 20+ years of specialized foil production, guaranteeing consistency for mission-critical power applications.

Packaging & Logistics

Export Packaging for C1100 Copper Foil: Ensuring Integrity in International Transit

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer-grade metal strips and foils, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity, especially during extended sea freight operations. For our C1100 copper foil—a high-conductivity, oxygen-free electrolytic copper product widely used in precision transformer windings and electrical applications—packaging is engineered to mitigate environmental and mechanical risks inherent in international shipping.

All export shipments of C1100 copper foil are secured on robust, ISPM-15 compliant wooden pallets. These pallets are constructed from kiln-dried hardwood or engineered laminated timber, selected for structural stability and resistance to compression under load. The use of certified wooden pallets ensures compliance with international phytosanitary standards, preventing customs delays and facilitating smooth clearance at destination ports. Each coil is precisely centered and affixed to the pallet using high-tensile steel strapping, anchored at multiple stress points to prevent axial displacement or edge damage during vessel movement, container stacking, or intermodal transfers.

Immediately following palletization, the entire assembly is wrapped in multiple layers of industrial-grade, moisture-proof polyethylene film. This co-extruded film features a metallized barrier layer that provides a dew point below -40°C, effectively inhibiting moisture ingress and preventing surface oxidation or tarnishing of the copper foil. The wrapping process employs automated tension-controlled equipment to ensure uniform coverage without over-compression, preserving the foil’s dimensional accuracy and surface finish. Seams are heat-sealed, and the base of the pallet is additionally sealed to prevent capillary moisture uptake from container floors or dock surfaces.

To further enhance protection, desiccant packs are strategically placed within the sealed film envelope, actively absorbing residual humidity during transit. For shipments destined for tropical or high-humidity regions, optional vapor corrosion inhibitors (VCI) may be integrated into the packaging matrix, offering electrochemical protection at the metal surface level.

This dual-system approach—mechanical stabilization via engineered wooden pallets and environmental isolation through hermetic moisture-proof encapsulation—ensures that C1100 copper foil arrives at its destination in as-produced condition, meeting the stringent surface and electrical performance requirements of downstream manufacturing processes. Our packaging protocols are validated through accelerated climate chamber testing and real-world performance tracking across major trade lanes, including trans-Pacific and Asia-Europe routes.

Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001 and IATF 16949 quality management standards, with packaging specifications documented and auditable. Clients receive detailed packing lists and compliance certificates with each shipment, reinforcing our commitment to reliability and transparency in global supply chain operations.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision C1100 Copper Foil Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver engineered copper foil solutions for critical transformer applications. Our facility operates under rigorous ISO 9001 and IATF 16949 quality management systems, ensuring every C1100 (ETP Copper) foil roll meets exacting electrical and mechanical performance standards. We focus exclusively on high-purity conductor materials, with C1100 production adhering to ASTM B152 specifications for 99.90% minimum copper content and controlled oxygen levels (0.02–0.04%).

Our vertically integrated manufacturing process begins with refined cathode copper sourced from audited global suppliers, processed through proprietary melting and casting systems to eliminate impurities. Precision cold rolling mills achieve tight thickness tolerances down to ±0.002mm across widths up to 1000mm, while computer-controlled annealing profiles optimize grain structure for superior ductility and thermal stability. This granular process control ensures consistent tensile strength (200–240 MPa) and elongation (≥5%) critical for transformer winding integrity under thermal cycling.

Supply chain resilience is engineered into our operations. Dedicated slitting lines support rapid customization of slit widths (10–500mm) with edge burr minimized to ≤0.01mm, reducing scrap during customer coil processing. We maintain strategic raw material buffers and flexible production scheduling to guarantee 15-day lead times for standard orders, with expedited options for urgent requirements. All material batches undergo full traceability via MTRs detailing chemical composition, mechanical properties, and surface roughness (Ra ≤0.45μm).

Key technical capabilities for C1100 copper foil are summarized below:

| Parameter | Specification Range | Control Tolerance |

|---|---|---|

| Thickness | 0.05 mm – 0.50 mm | ±0.002 mm |

| Width | 100 mm – 1000 mm | ±0.1 mm |

| Tensile Strength | 200 – 240 MPa | ±10 MPa |

| Elongation | ≥5% | ±1% |

| Surface Roughness | Ra ≤ 0.45 μm | ±0.05 μm |

| Edge Burr | ≤ 0.01 mm | Verified per lot |

Our engineering team collaborates directly with transformer OEMs to resolve material challenges, from optimizing foil flatness for high-speed winding to enhancing surface cleanliness for improved varnish adhesion. We provide comprehensive technical documentation including RoHS/REACH compliance certificates and detailed process capability studies (Cp/Cpk ≥1.67).

For sourcing managers requiring guaranteed material consistency and responsive supply chain execution, Luoyang Xinzhaohe offers a proven partnership model backed by metallurgical rigor. Contact our technical sales team to discuss your C1100 copper foil specifications and receive a production readiness assessment.

Initiate your precision copper foil procurement with validated expertise. Contact Cathy Zhang at cathy@transformerstrip.com for engineered solutions and volume pricing.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing C1100 copper foil directly from China.