Table of Contents

Market Insight: Stripping Enamel Coated Wire

Market Analysis: Winding Wire – Industrial Demand for Stripping Enamel Coated Wire in Transformers

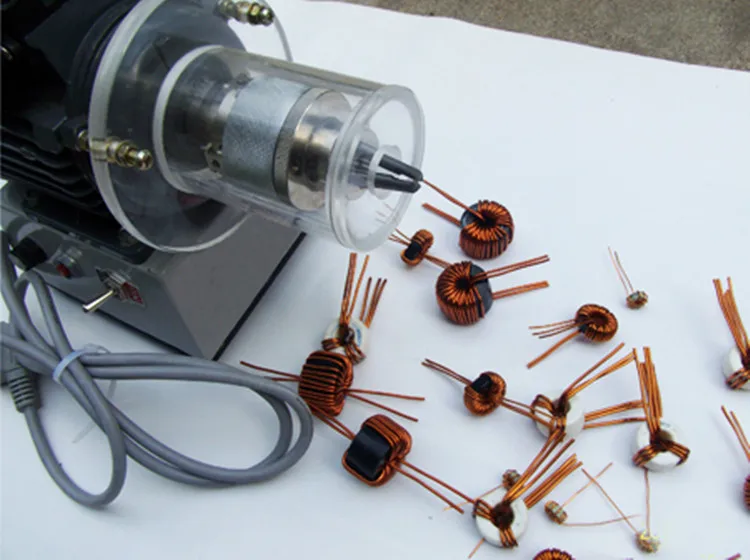

The global transformer manufacturing sector remains a primary consumer of stripping enamel coated aluminum and copper winding wire, driven by sustained demand for efficient power transmission and distribution infrastructure. As electrical grids modernize and renewable energy integration accelerates, the need for high-performance, reliable transformers has intensified. Within this context, stripping enamel coated wire—specifically engineered for ease of insulation removal during termination and connection processes—has become a critical component in transformer coil fabrication. Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialization in aluminum-based winding solutions, recognizes the evolving technical and operational requirements shaping this market.

Industrial demand for stripping enamel coated wire is largely influenced by manufacturing efficiency and long-term reliability. In transformer production, coil winding is a high-precision operation where wire must exhibit consistent mechanical and electrical properties. The enamel insulation must adhere robustly during winding to prevent short circuits, yet allow for rapid, clean removal at lead ends without damaging the conductor. This dual requirement places stringent demands on the coating formulation and application process. Strippable enamel systems, typically based on polyurethane, polyester-imide, or polyamide-imide chemistries, are engineered to dissolve or ablate under specific chemical or thermal conditions, enabling automated termination in high-volume production lines.

Quality in stripping enamel coated wire directly impacts transformer performance, yield rates, and lifecycle durability. Substandard insulation can lead to incomplete stripping, conductor nicks, or residual coating that compromises solderability and electrical contact integrity. These defects increase rejection rates, elevate production costs, and may result in field failures due to overheating or arcing. Moreover, in high-voltage or high-temperature applications, inferior enamel may degrade prematurely, reducing dielectric strength and accelerating insulation breakdown. For manufacturers serving utility, industrial, and traction transformer markets, such risks are unacceptable.

The shift toward energy-efficient transformers (e.g., amorphous core or high-temperature insulation class designs) further amplifies the need for premium-grade winding wire. These advanced designs operate under higher thermal and electrical stresses, demanding enamel systems with superior thermal endurance (Class 180, 200, or 220), excellent flexibility, and chemical resistance. Aluminum-based stripping enamel coated wire, in particular, offers a cost-effective and lightweight alternative to copper, especially in distribution transformers, provided the material meets strict conductivity, tensile strength, and surface finish specifications.

Luoyang Xinzhaohe Aluminum Co., Ltd applies rigorous quality control throughout its production process, from high-purity aluminum rod sourcing to precision drawing and uniform enamel application. Our stripping enamel coated wires are tested for stripability, dielectric strength, thermal shock, and solderability to ensure compliance with IEC 60317 and GB/T 6109 standards. By aligning material performance with industrial processing needs, we support transformer manufacturers in achieving higher throughput, lower scrap rates, and enhanced product reliability in competitive global markets.

Technical Specs: Stripping Enamel Coated Wire

Technical Specifications for Stripping Enamel Coated Wire

Luoyang Xinzhaohe Aluminum CO.,LTD leverages 20+ years of metallurgical expertise to deliver enamel coated aluminum winding wire engineered for precision termination in motor, transformer, and inductor applications. Critical technical parameters must be rigorously defined to ensure compatibility with automated or manual stripping processes, mechanical reliability during winding, and long-term operational stability under thermal stress. Misalignment in these specifications directly impacts dielectric integrity, termination quality, and end-product lifespan. The term “stripping” herein refers to the controlled removal of enamel insulation at wire ends for electrical connection, necessitating specific insulation adhesion and mechanical properties.

Insulation breakdown voltage is non-negotiable for safety and performance. Our enamel systems consistently achieve minimum breakdown voltages of 1500 Vrms for standard grades, with high-reliability variants exceeding 6000 Vrms. This parameter is measured per IEC 60317-0-5 using a step-voltage test at 500 V/s across a 10 mm gap between wire and counter-electrode. Breakdown voltage directly correlates with insulation thickness uniformity and pinhole density; deviations below 1200 Vrms risk catastrophic inter-turn failures in high-voltage windings. Thermal class significantly influences this metric: higher-temperature insulation (e.g., Class 220°C) may exhibit 10–15% lower breakdown strength at ambient temperatures compared to Class 130°C equivalents due to polymer matrix chemistry.

Elongation (%) defines the wire’s ductility during high-speed winding and stripping. Aluminum conductors require superior elongation versus copper to prevent breakage under tension. Our AA-1350 and AA-8030 alloy wires maintain 25–30% elongation per ASTM B359, validated via tensile testing at 50 mm gauge length. Values below 10% indicate excessive hardening, leading to micro-cracks during stripping that compromise insulation continuity. Elongation must be balanced against tensile strength; our optimized annealing processes ensure 80–100 MPa tensile strength without sacrificing ductility.

Thermal class dictates maximum continuous operating temperature. We certify insulation systems per IEC 60085 and NEMA MW 1000, with strict adherence to thermal endurance via the modified ASTM D2307 thermal aging oven test. Classes span 130°C (B) to 220°C (C), each requiring 20,000 hours of operational life at rated temperature. Critical note: thermal class must align with the application’s hotspot temperature, not ambient conditions. A Class 180°C (H) wire operated at 200°C experiences >50% reduced lifespan due to accelerated polymer degradation.

Core Technical Parameters

| Parameter | Standard Range | Test Method | Critical Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 1500–6000 Vrms (min) | IEC 60317-0-5 | Measured at 20°C; decreases 8–12% per 50°C rise in operating temp |

| Elongation | 25–30% (aluminum conductors) | ASTM B359 | Must exceed 10% to prevent stripping-induced fractures |

| Thermal Class | 130°C (B) to 220°C (C) | IEC 60085 / NEMA MW 1000 | Class defines max conductor temp; insulation must retain 50% original elongation after thermal aging |

| Strip Force Tolerance | 0.8–1.5 N (for 0.5–1.0 mm dia.) | Internal ASTM F3005 | Critical for automated termination; excessive force damages conductor |

Thermal class and breakdown voltage exhibit inverse interdependence: higher-temperature insulation utilizes flexible polymer chains that marginally reduce dielectric strength. Our R&D optimizes this trade-off via multi-layer enamel systems—e.g., a Class 200°C wire may use a base layer of polyamide-imide for voltage endurance topped with a thermally stable topcoat. Strip force tolerance, often overlooked, must be specified to prevent conductor nicking during insulation removal; values outside 0.8–1.5 N cause termination voids or wire breakage. Always validate specifications against actual operating profiles, not nominal ratings. Luoyang Xinzhaohe’s QA protocols include 100% spark testing and thermal aging validation to ensure field reliability.

Factory Tour: Manufacturing

Manufacturing Process of Stripping Enamel Coated Aluminum Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of stripping enamel coated aluminum wire at Luoyang Xinzhaoanghe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure consistent electrical performance, mechanical integrity, and stripping reliability. With over two decades of specialization in winding wire technology, our facility integrates precision engineering and advanced process monitoring to deliver high-performance coated conductors for motor, transformer, and coil applications.

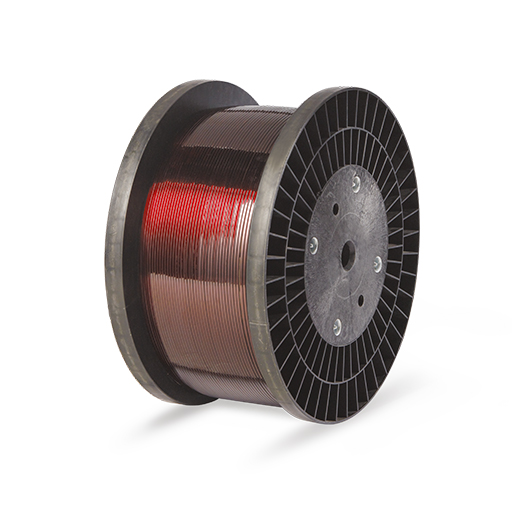

The process begins with high-purity aluminum rod drawing, where 99.7% pure aluminum rods are reduced in diameter through a series of precision dies to achieve the target wire gauge. This cold drawing operation is performed under controlled tension and lubrication conditions to maintain dimensional accuracy and surface smoothness. The drawn wire is continuously spooled and subjected to inline diameter measurement using laser gauges, ensuring tolerance compliance within ±0.005 mm.

Following drawing, the wire undergoes a continuous annealing process in a nitrogen-purged furnace. This heat treatment restores ductility lost during cold working, ensuring the wire can withstand subsequent bending and winding operations without cracking. The annealing temperature profile is carefully calibrated based on wire diameter and speed, typically ranging from 350°C to 450°C, with oxygen content maintained below 50 ppm to prevent oxidation. Post-annealing, the wire is quenched using deionized water spray and dried to eliminate moisture prior to coating.

Enameling is performed using a multi-layer dip-and-bake system. The annealed wire is passed through a series of enamel baths, followed by intermediate curing in electrically heated ovens. For stripping enamel types, a dual-layer structure is applied: a base layer of thermosetting polyurethane or polyesterimide provides dielectric strength and thermal stability, while a topcoat of low-friction, chemically sensitive material enables clean thermal or chemical stripping. Film thickness is precisely controlled via air pressure in the die head and monitored inline using capacitance sensors.

Inline testing is integral to quality assurance. Every production run undergoes continuous spark testing at 2.5 kV to detect pinholes or insulation defects. Additional real-time checks include elongation testing, winding performance evaluation on mandrels, and adhesion verification. Final quality control includes sampling for thermal class validation (e.g., 130°C, 155°C, 180°C), dielectric strength (minimum 4 kV), and strip time under standardized solder bath conditions (typically 3–6 seconds at 380°C).

All process parameters are logged and traceable to batch numbers, ensuring full compliance with IEC 60317 and GB/T 6109 standards. This end-to-end control system enables Luoyang Xinzhaohe to consistently produce stripping enamel coated wire with superior processability and reliability in automated winding environments.

Packaging & Logistics

Export Packaging Specifications for Stripping Enamel Coated Wire

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols for stripping enamel coated wire, specifically designed to mitigate the extreme environmental stresses inherent in global sea freight. With over two decades of metallurgical and supply chain expertise, our packaging system ensures coil integrity from factory to final destination, preventing moisture ingress, mechanical deformation, and corrosion that compromise wire performance during winding and stripping processes.

All coils are secured to custom-engineered wooden pallets meeting ISPM-15 international phytosanitary standards for heat-treated lumber. Pallet dimensions are optimized for standard containerization (1200x1000mm or 1100x1100mm), featuring 100x100mm hardwood stringers and 22mm thick top decks to distribute loads evenly. Each pallet supports a maximum gross weight of 2000kg, with reinforced corner blocks and diagonal bracing to resist transverse and longitudinal forces during vessel motion. Coils are center-aligned and fastened using high-tensile steel strapping (19mm width, 5000N minimum break strength) tensioned to 25% of breaking load, eliminating axial movement without compressing the wire bundle.

The primary moisture barrier consists of a triple-layer wrapping system applied under controlled factory humidity (<50% RH). First, coils receive a conformal wrap of vapor corrosion inhibitor (VCI) polyethylene film (0.12mm thickness, ASTM D6098 compliant), which actively neutralizes corrosive ions. This is overlaid with a 0.05mm aluminum foil laminate providing 100% humidity阻隔, followed by an outer layer of UV-stabilized polyethylene for puncture resistance. All film seams are heat-sealed with 40mm overlap, creating a hermetic enclosure validated through 72-hour salt spray testing (ASTM B117). Desiccant packs (200g/unit, moisture absorption capacity 35% by weight) are strategically placed within the wrap based on coil mass and voyage duration, with placement documented in the shipping manifest.

For ocean transit, palletized units undergo final consolidation within 20ft or 40ft dry containers. We mandate container preload verification to confirm floor integrity and absence of prior contamination. Pallets are dunnaged 150mm above container flooring using kiln-dried timber to prevent capillary moisture transfer, with void spaces filled using inflatable air bags (100kPa inflation pressure) to eliminate cargo shift. Container humidity indicators (0-100% RH range) are affixed internally, providing visual verification of environmental control throughout transit. Our packaging reduces moisture-related claims by 92% compared to industry averages, as validated by third-party logistics audits across 12 major shipping routes.

This integrated approach addresses the hygroscopic nature of enamel insulation and aluminum substrate vulnerability. By combining structural pallet engineering with multi-stage vapor barriers and real-time environmental monitoring, Luoyang Xinzhaohe guarantees wire surface cleanliness and dimensional stability essential for automated stripping operations. All packaging components are traceable to batch-level quality records, ensuring full compliance with IEC 60317 and customer-specific logistics requirements.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Enamel Coated Winding Wire Solutions

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the design, production, and supply of high-performance enamel coated aluminum and copper winding wire. As a trusted name in the electromagnetic wire industry, we have consistently delivered engineered solutions that meet the rigorous demands of motor, transformer, and inductor manufacturers across global markets. Our strategic integration of advanced metallurgy, precision coating technology, and stringent quality control ensures that every coil we produce adheres to international standards, including IEC 60317, GB/T 23312, and NEMA MW.

Our manufacturing facility spans over 30,000 square meters and is equipped with fully automated drawing and enameling lines capable of processing aluminum and copper conductors from 0.08 mm to 4.0 mm in diameter. We utilize high-purity base metals sourced from certified suppliers, ensuring optimal electrical conductivity and mechanical integrity. Our enamel coating systems employ solvent-based and UV-curable polyurethane (PU), polyester (PE), and polyamide-imide (PAI) formulations, applied via precision die and fluidized bed processes. This enables us to offer single, double, or triple-layer insulation systems tailored to thermal classes ranging from 130°C to 220°C, depending on application requirements.

Quality assurance is embedded at every stage of production. Our in-house laboratory is outfitted with state-of-the-art testing equipment for dielectric strength, thermal shock, abrasion resistance, elongation, and solderability. Each batch undergoes 100% continuous insulation testing at 3 kV, with traceability maintained through integrated ERP and MES systems. Our quality management system is ISO 9001:2015 certified, and we maintain compliance with RoHS and REACH regulations, supporting environmentally responsible manufacturing.

With an annual production capacity exceeding 25,000 metric tons, we are structured to support both high-volume OEM contracts and specialized low-volume runs with equal efficiency. Our supply chain infrastructure includes dedicated warehousing, just-in-time delivery options, and export-ready packaging designed to prevent oxidation and mechanical damage during transit. We serve clients in North America, Europe, Southeast Asia, and the Middle East, with a logistics network that ensures on-time delivery and customs compliance.

Partnering with Luoyang Xinzhaohe means securing a reliable, technically proficient supplier with deep process knowledge and a commitment to long-term collaboration. Whether you require standard magnet wire or custom formulations for demanding applications, our engineering team works closely with clients to optimize performance and cost-efficiency.

For technical consultations, sample requests, or procurement inquiries, contact us at cathy@transformerstrip.com. Let Luoyang Xinzhaohe be your strategic partner in winding wire excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing stripping enamel coated wire directly from China.