Table of Contents

Market Insight: Copper Wire With Enamel

Market Analysis: Winding Wire Demand and Quality Imperatives for Transformer Applications

Global demand for high-performance copper wire with enamel insulation (magnet wire) remains robust, driven primarily by the critical need for efficient power transformation across expanding electrical infrastructure. Transformers represent a dominant application segment, consuming significant volumes of magnet wire globally. Key demand drivers include the ongoing modernization of aging power grids, particularly in developed economies, and the massive build-out of new transmission and distribution networks supporting renewable energy integration (solar/wind farms) and electric vehicle charging infrastructure. Stringent international energy efficiency regulations, such as the DOE 2016 standards in the US and the EU Ecodesign Directive, mandate lower no-load and load losses in distribution transformers. Achieving these efficiency targets necessitates the use of magnet wire with superior electrical conductivity, precise dimensional tolerances, and exceptional thermal stability – directly increasing demand for premium-grade enameled copper wire. The proliferation of high-frequency electronic transformers in consumer electronics, industrial automation, and electric vehicle powertrains further fuels demand for magnet wire capable of handling complex winding geometries and elevated operating temperatures.

The operational integrity and longevity of transformers are fundamentally dependent on the quality of the enameled copper wire employed. Substandard wire introduces significant, often latent, failure risks that compromise transformer performance, safety, and lifecycle cost. Enamel insulation must provide consistent dielectric strength to prevent catastrophic turn-to-turn or layer-to-layer short circuits under high-voltage stress and transient conditions. Poor adhesion between the enamel and copper substrate leads to insulation delamination during the rigorous coil winding process or under thermal cycling in service, creating weak points prone to electrical failure. Inadequate thermal class performance (e.g., using 130°C wire where 180°C is required) accelerates thermal degradation of the insulation, drastically reducing transformer lifespan through embrittlement, cracking (“crazing”), and loss of dielectric properties. Dimensional inconsistencies, such as out-of-tolerance outer diameter or non-circularity, directly impact fill factor within the winding window, increasing DC resistance, copper losses, and operating temperature. Furthermore, insufficient flexibility or elongation properties cause enamel cracking during tight-radius winding, especially in complex coil shapes common in modern compact transformers. Mechanical damage during handling or winding introduces microscopic flaws that become initiation sites for electrical treeing and eventual insulation breakdown under operational stress.

Quality assurance in magnet wire is therefore non-negotiable for transformer manufacturers. Rigorous adherence to international standards (IEC 60317 series, ASTM B 328/B 468) for electrical, thermal, and mechanical properties is the baseline requirement. Comprehensive in-process and final testing protocols, including thermal endurance index determination, dielectric breakdown voltage, scrape abrasion resistance, solderability, and thermal shock testing, are essential to verify material suitability for the intended application. The cost of transformer failure in the field – encompassing equipment replacement, downtime, potential safety hazards, and reputational damage – vastly exceeds any marginal savings from procuring lower-grade magnet wire. Luoyang Xinzhaohe Aluminum Co., Ltd leverages its 20+ years of metallurgical and precision material processing expertise to emphasize that consistent, certified magnet wire quality is a critical enabler of transformer reliability, efficiency, and compliance with evolving global energy standards.

Thermal Class Comparison for Transformer Magnet Wire

| Thermal Class (IEC 60317) | Maximum Hot Spot Temp (°C) | Typical Base Polymer | Key Application Driver |

|---|---|---|---|

| 130 (B) | 130 | Polyester | Standard distribution transformers, cost-sensitive applications |

| 155 (F) | 155 | Polyester-imide | Higher efficiency distribution, general industrial transformers |

| 180 (H) | 180 | Polyamide-imide | High-efficiency distribution, traction transformers, demanding industrial |

| 200 (N) / 220 (R) | 200 / 220 | Polyimide | High-frequency electronics, aerospace, specialized high-temp applications |

Technical Specs: Copper Wire With Enamel

Technical Specifications for Enamel-Coated Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-performance enamel-insulated copper winding wire designed for demanding electrical and thermal environments. With over two decades of metallurgical and process engineering expertise, our products meet international standards including IEC 60317, GB/T 6109, and NEMA MW 1000. The primary technical parameters governing performance in electromagnetic applications are insulation breakdown voltage, elongation, and thermal class. These characteristics directly influence reliability, efficiency, and service life in motors, transformers, solenoids, and other coil-wound devices.

Insulation breakdown voltage is a critical dielectric property, defined as the maximum voltage the enamel layer can withstand before electrical failure occurs. This parameter ensures operational safety under transient overvoltages and long-term insulation integrity. Our standard enamel coatings achieve breakdown voltages ranging from 1,800 V to over 6,000 V, depending on wire diameter and insulation thickness grade (typically single, heavy, or double build). Testing is conducted using AC voltage at 50 Hz with controlled ramp rates per standard procedures. Consistent dielectric strength is maintained through precision extrusion and curing processes that eliminate pinholes and coating defects.

Elongation, measured as a percentage of original length at the point of fracture under tensile loading, reflects the ductility of the copper substrate. High elongation values are essential for withstanding winding stresses during coil formation, particularly in automated high-speed winding operations. Our fully annealed electrolytic tough pitch (ETP) copper conductors exhibit elongation values of no less than 10% for diameters up to 1.0 mm, with finer wires (below 0.5 mm) achieving up to 25%. This mechanical resilience reduces the risk of conductor breakage and ensures uniform coil geometry.

Thermal class defines the maximum continuous operating temperature at which the insulation retains its dielectric and mechanical properties over a 20,000-hour service life. Our product range spans thermal classes from 130°C to 220°C, utilizing advanced polymer systems such as polyurethane (PU), polyester (PE), polyester-imide (PEI), and polyamide-imide (PAI). Higher thermal classes provide superior thermal stability, chemical resistance, and thermal shock performance. For example, PEI-coated wires (Class 180) and PAI-coated wires (Class 220) are preferred in high-efficiency motors and automotive applications where thermal management is critical.

The following table summarizes key technical parameters across our standard product offerings:

| Parameter | Test Standard | Value Range | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-1 | 1,800 V – 6,000 V (depending on build) | Measured at room temperature, 50 Hz AC |

| Elongation | GB/T 4909.4 | ≥10% – 25% (depending on diameter) | Minimum value after annealing |

| Thermal Class | IEC 60172 / NEMA MW | 130°C to 220°C | Based on thermal endurance life |

| Conductor Material | GB/T 5584.1 | ETP Copper (Cu ≥ 99.90%) | Fully annealed |

| Insulation Types | IEC 60317 Series | PU, PE, PEI, PAI | Single to triple build available |

These specifications are validated through in-house quality control systems, including continuous monitoring of tensile strength, springback, thermal shock, and solderability. Luoyang Xinzhaohe ensures batch-to-batch consistency through strict raw material sourcing and process parameter control.

Factory Tour: Manufacturing

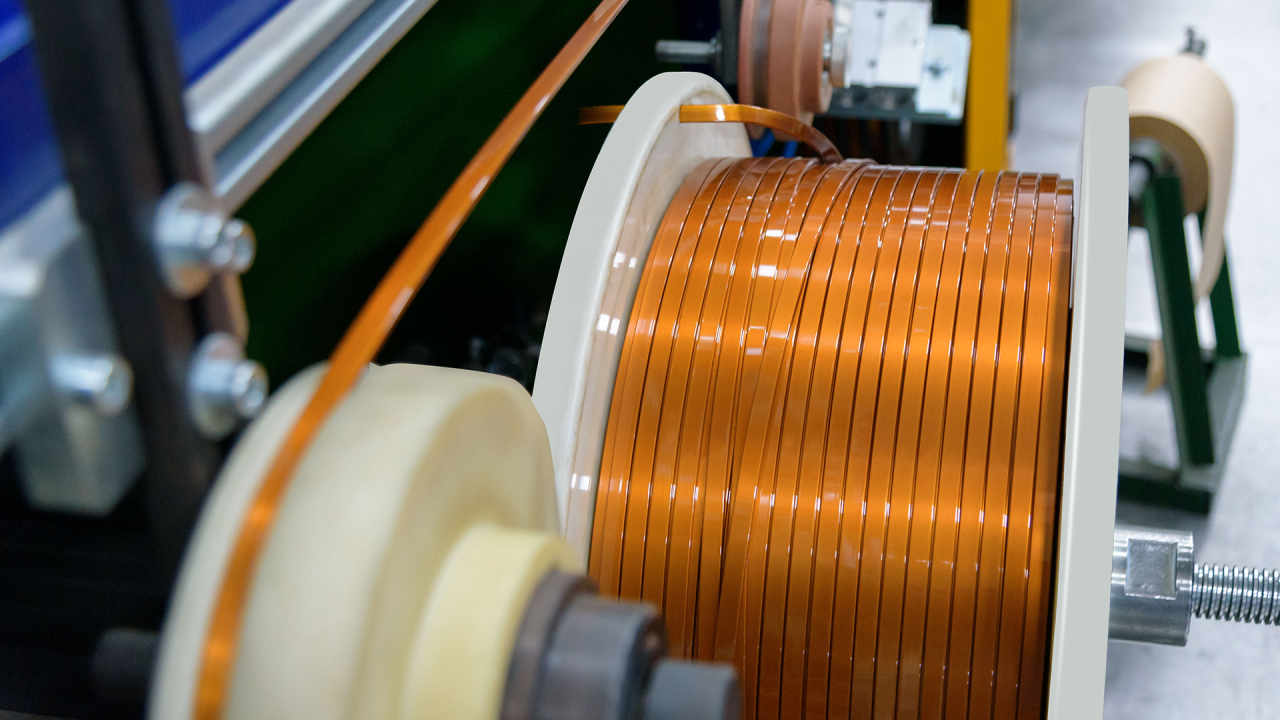

Manufacturing Process for Enamelled Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd. applies stringent metallurgical and process control principles to produce high-reliability enamelled copper winding wire. Our production sequence ensures optimal electrical, mechanical, and thermal performance for demanding motor, transformer, and inductor applications. The core process flow integrates precision metalworking with advanced polymer application and rigorous quality verification.

Rod Drawing initiates the process, transforming high-conductivity electrolytic tough pitch (ETP) copper rod (typically 8mm diameter) into the precise wire gauge required. Utilizing multi-die continuous drawing blocks under controlled tension and lubrication, the rod undergoes significant cold working. This stage critically establishes the wire’s dimensional accuracy and surface integrity. Diameter tolerance is maintained within ±0.005mm through laser micrometer feedback systems. Continuous surface inspection identifies micro-scratches or pits that could compromise subsequent enamel adhesion. The drawn wire exhibits high tensile strength but reduced ductility, necessitating the next phase.

Annealing follows drawing to restore ductility and achieve the target electrical conductivity. Wire passes through a continuous inert atmosphere furnace, typically using nitrogen or nitrogen-hydrogen mixtures to prevent oxidation. Precise temperature profiling (typically 450-550°C) and dwell time are paramount; insufficient annealing leaves the wire brittle, while excessive exposure risks grain growth and surface oxidation. Post-annealing, conductivity is verified via eddy current testing, ensuring compliance with IACS standards (minimum 100% IACS for Class 1). Tensile strength and elongation are also sampled to confirm mechanical property targets.

Enameling applies the insulating polymer coating via a continuous multi-pass process. The clean, annealed wire traverses a series of applicator dies followed by precision metering rings, controlling the wet film thickness for each layer. Solvent-based or 100% solids resins (commonly polyurethane, polyester-imide, or polyamide-imide) are applied. Between coats, the wire enters high-temperature curing ovens where controlled pyrolysis drives off solvents and fully crosslinks the polymer. Critical parameters include viscosity control, oven temperature zones, line speed, and atmosphere purity. Multiple layers are often applied to achieve the required total thickness and voltage breakdown strength. Thickness is monitored in-line using beta-gauge or capacitance sensors.

Inline Testing provides real-time quality assurance throughout enameling and final spooling. Mandatory checks include:

High-potential (Hi-Pot) testing at specified voltages (e.g., 1500-3000V AC) to detect pinholes or thin spots.

Thermal shock testing per IEC 60851-5, where coiled samples undergo rapid cooling to -65°C followed by flexing to verify enamel integrity.

Solderability testing to confirm clean enamel removal at termination points.

Continuous diameter measurement including enamel thickness.

Visual inspection for surface defects like bubbles or streaks.

Final QC involves destructive sampling per IEC 60317 standards, including adhesion, elongation, and thermal endurance classification. This integrated process, honed over 20+ years, delivers consistent enamelled copper wire meeting global specifications for reliability in critical electromagnetic components.

Packaging & Logistics

Export Packaging for Enamel Insulated Copper Winding Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in the production and global distribution of high-performance winding wire, we recognize that export packaging is not merely a logistical necessity but a critical component in preserving product integrity during international transit. Enamel insulated copper wire, due to its hygroscopic insulation layer and sensitivity to mechanical stress, demands a packaging solution engineered for durability, moisture resistance, and compliance with maritime shipping standards.

All export shipments of enamel coated copper wire are systematically wound onto precision-engineered spools fabricated from high-strength composite or metal-reinforced materials, ensuring dimensional stability under load. These spools are then secured to robust wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. The use of certified wooden pallets ensures compliance with international phytosanitary regulations, preventing customs delays and enabling seamless clearance at destination ports. Each pallet is designed to support the total coil weight while maintaining structural integrity during stacking and container handling.

To mitigate the risk of moisture ingress—a primary concern during prolonged sea freight—the entire palletized unit is hermetically sealed using multilayer moisture-proof film. This film consists of a co-extruded laminate incorporating aluminum foil and polyethylene layers, providing a vapor transmission rate of less than 0.1 g/m²·24h at 38°C and 90% relative humidity. The wrapping process is performed in a climate-controlled environment to eliminate condensation trapped within the package. Seams are heat-sealed and overlapped to ensure continuity, forming a fully enclosed barrier against salt-laden air, humidity, and atmospheric contaminants common in marine environments.

Additionally, desiccants are strategically placed within the sealed enclosure to absorb any residual moisture and buffer against micro-climate fluctuations during temperature cycling in transit. Each package is labeled with humidity indicator cards to provide visual confirmation of internal conditions upon arrival, enabling receiving parties to verify environmental exposure history.

Mechanical protection is further enhanced through the integration of edge protectors and corner boards made from high-density corrugated fiberboard, which resist compression forces during container loading and unloading. Pallets are unitized using steel or polyester strapping to prevent lateral displacement, ensuring stability during crane lifts and intermodal transfers.

Our packaging protocol is validated through rigorous simulation testing, including vibration, drop, and compression trials that replicate real-world shipping conditions. This approach ensures that enamel insulation remains free from micro-cracking, delamination, or dielectric degradation upon delivery.

Luoyang Xinzhaohe Aluminum Co., Ltd. adheres to ISO 9001 and IEC 60317 standards throughout the packaging workflow, aligning with global best practices for electrical conductor logistics. By integrating material science, regulatory compliance, and freight engineering, our export packaging system guarantees that every coil of copper winding wire arrives at its destination with uncompromised electrical and mechanical performance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and process engineering expertise to deliver copper winding wire with enamel meeting the most stringent industrial demands. Our vertically integrated manufacturing ecosystem, grounded in rigorous material science, ensures consistent performance for critical applications in transformers, motors, and inductors where thermal stability, dielectric strength, and mechanical reliability are non-negotiable. Partnering with us mitigates supply chain volatility while guaranteeing adherence to international standards including IEC 60317, NEMA MW, and UL specifications.

Metallurgical Purity Control

Our foundation lies in precise copper refinement. We utilize oxygen-free electronic copper (OFE) rod processed through proprietary continuous casting and rolling systems, achieving minimum 99.99% Cu purity with controlled grain structure. This eliminates micro-voids and inclusions that compromise wire drawability and thermal aging resistance. In-house spectrometry and conductivity testing (100% IACS minimum) validate material integrity at every production stage, ensuring optimal electrical performance and solderability.

Precision Enamel Application

Advanced multi-zone curing ovens and computer-controlled extrusion heads enable micron-level enamel thickness uniformity across diameters from 0.05mm to 3.00mm. We specialize in high-temperature polymer systems including polyesterimide (PEI), polyamide-imide (PAI), and dual-coated combinations for Classes 180°C (F) through 240°C (C). Real-time infrared pyrometry and laser micrometry monitor cure profiles and dimensional tolerances, achieving ±2% coating thickness control and eliminating pinholes or fisheyes that cause dielectric failure.

Quality Assurance Systems

Every production lot undergoes comprehensive validation per IEC 60851 protocols. Our accredited laboratory conducts 100% spark testing at 3kV, thermal shock analysis (-65°C to 220°C), mandrel wrap tests, and solvent resistance verification. Full traceability from copper ingot to finished coil is maintained via blockchain-enabled batch records, providing customers with certified material test reports (CMTRs) documenting tensile strength, elongation, and thermal index data.

Supply Chain Integration

Strategic partnerships with Tier-1 polymer suppliers and dedicated logistics hubs in Zhengzhou ensure 99.2% on-time delivery. Our 50,000-ton annual capacity includes just-in-sequence (JIS) kitting for OEM assembly lines, with dual sourcing for critical raw materials to eliminate disruption risks. Lean manufacturing principles drive a 0.12% average defect rate—37% below industry benchmarks.

Key technical specifications for our standard product lines include:

| Parameter | Class 155 (A) | Class 180 (F) | Class 200 (H) | Class 220 (N) |

|---|---|---|---|---|

| Max Temp (°C) | 155 | 180 | 200 | 220 |

| Dielectric Strength | 2500 Vrms | 3000 Vrms | 3500 Vrms | 4000 Vrms |

| Tensile Strength | 250-350 MPa | 280-380 MPa | 300-400 MPa | 320-420 MPa |

| Elongation | ≥15% | ≥12% | ≥10% | ≥8% |

For mission-critical winding applications requiring uncompromised material integrity and supply chain resilience, Luoyang Xinzhaohe provides engineered solutions backed by 20 years of metallurgical excellence. Contact our technical sales team to discuss custom formulations, qualification testing, or volume procurement strategies. Email Cathy directly at cathy@transformerstrip.com to initiate a capability review and receive sample reels for performance validation within 72 hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire with enamel directly from China.