Table of Contents

Market Insight: Copper Strips

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to exhibit strong demand for high-conductivity metallic strips, particularly copper and aluminum, driven by expanding power infrastructure, renewable energy integration, and industrial electrification. Copper strips remain a critical material in the construction of high-efficiency transformers, especially in applications where maximum electrical conductivity, thermal stability, and mechanical reliability are paramount. Despite aluminum’s growing adoption due to cost and weight advantages, copper maintains a dominant position in high-performance and mission-critical transformer designs, including distribution, power, and specialty transformers used in traction, marine, and industrial settings.

Industrial demand for copper strips in transformer windings is directly linked to their role in minimizing resistive losses and ensuring long-term operational efficiency. Copper offers approximately 60% higher electrical conductivity than aluminum on a volumetric basis, enabling tighter winding configurations and reduced I²R losses. This performance advantage translates into improved energy efficiency, compliance with international standards such as IEC 60076 and IEEE C57, and lower total cost of ownership over the transformer’s lifecycle. As global energy regulations tighten—particularly in the EU, North America, and parts of Asia—the demand for high-efficiency transformers continues to rise, reinforcing the strategic importance of premium-grade copper strip materials.

Quality in copper strip production is not merely a matter of material purity but encompasses dimensional precision, surface finish, mechanical properties, and consistency across production batches. Impurities, inclusions, or microstructural inconsistencies can lead to localized heating, reduced current-carrying capacity, and premature insulation failure. Furthermore, precise thickness tolerances (typically ±0.01 mm to ±0.03 mm) and flatness control are essential for automated winding processes and uniform coil packing. Surface defects such as scratches, pits, or oxidation can compromise insulation integrity, particularly in vacuum pressure impregnated (VPI) or resin-rich systems.

At Luoyang Xinzhaohe Aluminum Co., Ltd., we apply stringent metallurgical controls and advanced rolling technologies to ensure material consistency across both aluminum and copper strip products. Our quality assurance protocols include continuous oxygen analysis, eddy current testing, and mechanical property validation to meet the exacting demands of transformer manufacturers. While aluminum strip remains a core focus due to its economic and lightweight benefits, our technical expertise extends to copper-based solutions where performance requirements justify the material selection.

The transformer supply chain increasingly prioritizes traceability, process stability, and compliance with environmental and safety standards. As such, sourcing copper strip from suppliers with verifiable process controls, material certifications (e.g., RoHS, REACH), and a proven track record in power electronics applications is essential. In high-reliability sectors such as utilities, rail, and data centers, the cost of failure far exceeds material savings, making quality a non-negotiable parameter in material selection.

| Parameter | Typical Requirement for Transformer Copper Strip |

|---|---|

| Purity (Cu + Ag) | ≥ 99.95% |

| Electrical Conductivity | ≥ 100% IACS (International Annealed Copper Standard) |

| Thickness Tolerance | ±0.01 mm to ±0.03 mm |

| Tensile Strength | 200–300 MPa (depending on temper) |

| Elongation | ≥ 4% |

| Surface Roughness (Ra) | ≤ 1.0 µm |

In summary, while aluminum offers compelling advantages in specific transformer applications, copper strips remain indispensable in high-efficiency and high-reliability systems. The industrial demand for copper is sustained by performance requirements that cannot be met by alternative materials without compromising efficiency or longevity. Quality, therefore, is not an incremental benefit but a foundational requirement in the selection of copper strip for transformer manufacturing.

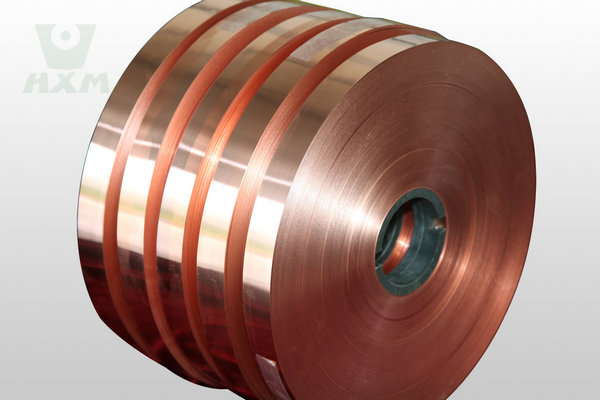

Technical Specs: Copper Strips

Technical Specifications for Copper Transformer Strips

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical and supply chain expertise to deliver precision copper strips for high-efficiency transformers. Our copper strips adhere to stringent global standards, with dimensional accuracy and electrical properties optimized for critical power applications. Precision slitting at ±0.002 mm tolerance is non-negotiable to ensure consistent core stacking factor and minimize eddy current losses. Deviations beyond this threshold directly compromise transformer efficiency and thermal performance. Edge quality is equally critical; burrs exceeding 0.005 mm risk insulation puncture during winding, leading to premature failure. We achieve burr-free edges through proprietary tension leveling and high-precision shear slitting systems with automated edge monitoring. Conductivity must meet 100–101% IACS minimum, requiring oxygen-free high-conductivity (OFHC) copper with oxygen content ≤0.0005% and strict control of trace elements like Fe, P, and Ag. Substandard conductivity increases resistive losses, directly elevating operational costs over the transformer’s lifecycle.

The following table details mandatory technical parameters for copper strips supplied by Luoyang Xinzhaohe:

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Range | 0.10–3.00 mm | ASTM B9 |

| Thickness Tolerance | ±0.002 mm | IEC 60404-9 |

| Width Tolerance | ±0.05 mm | ASTM E29 |

| Edge Burr Height | ≤0.005 mm | IEC 60137 |

| Electrical Conductivity | 100–101% IACS | ASTM B193 |

| Flatness | ≤2 mm/m | ISO 2768-1 |

| Surface Roughness (Ra) | ≤0.4 µm | ISO 4287 |

| Material Grade | C10100/C10200 (OFHC) | ASTM B152 |

| Production Lot Traceability | Full MTR documentation | EN 10204 3.1 |

Surface integrity is validated via profilometry and optical edge inspection, with conductivity verified through four-point probe testing at 20°C. Thickness and width tolerances are maintained using laser micrometers in real-time during slitting, ensuring compliance across 500+ meter coils. Material homogeneity is confirmed through spectrographic analysis of each melt batch, with phosphorus content held below 5 ppm to prevent hydrogen embrittlement. Flatness is controlled via precision tension leveling post-annealing, critical for automated winding processes.

Our supply chain integrates metallurgical process control with end-to-end traceability. Copper billets originate from certified LME Grade A suppliers, with in-house annealing under inert atmospheres to prevent oxidation. Every production lot undergoes 100% dimensional validation and statistical conductivity sampling per AQL 1.0. This rigor eliminates field failures linked to edge defects or conductivity drift, directly supporting transformer manufacturers’ goals for >99.5% efficiency ratings under IEC 60076-20. Partnering with Xinzhaohe ensures copper strips that meet the exacting demands of modern grid infrastructure, where micron-level precision translates to megawatt-scale reliability.

Factory Tour: Manufacturing

Manufacturing Process for Copper Strips at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of copper strips at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, superior surface quality, and consistent mechanical and electrical properties. With over two decades of specialization in transformer-grade aluminum and copper strip and foil production, our facility integrates advanced metallurgical practices with precision engineering to meet the rigorous demands of power transmission and electronic applications.

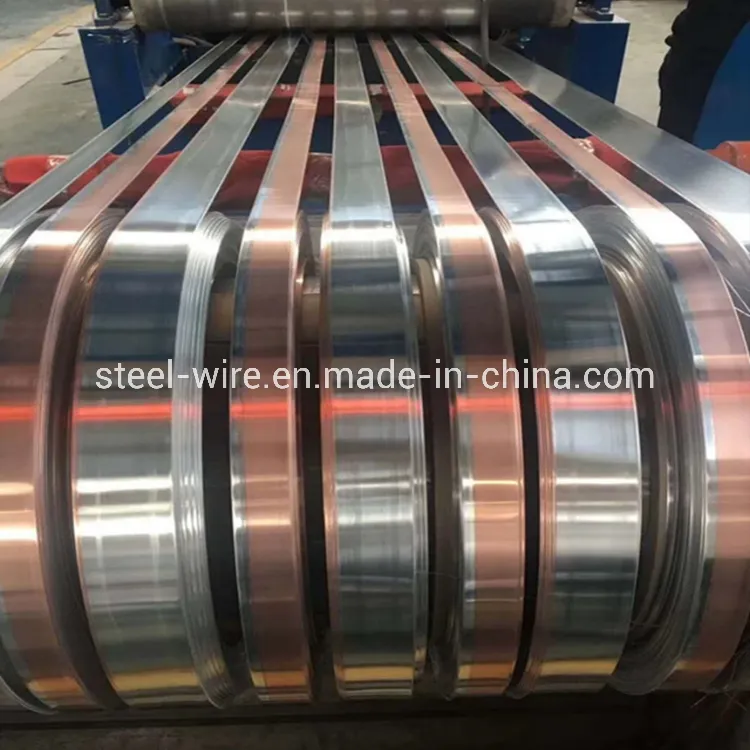

The process begins with cold rolling, which is fundamental in achieving the required thickness uniformity and microstructural refinement. High-purity copper ingots, sourced from certified suppliers and verified through incoming material inspection, are first hot-rolled to intermediate gauges and then subjected to cold rolling in reversing rolling mills. This stage reduces the material to the final target thickness, typically ranging from 0.05 mm to 3.0 mm, depending on customer specifications. Cold rolling imparts increased tensile strength and hardness through strain hardening while maintaining tight thickness tolerances, typically within ±0.01 mm. The rolling parameters—roll force, reduction ratio, and interstand tension—are continuously monitored and adjusted via automated process control systems to ensure consistency across coils.

Following cold rolling, precision slitting is performed to achieve the specified strip width. Utilizing high-precision rotary shear slitters equipped with tungsten carbide blades, coils are longitudinally cut into multiple strips with edge straightness maintained within ±0.1 mm per meter. The slitting line is configured with automatic edge guiding and tension control systems to prevent edge wave, camber, or burr formation. Each slit strip is wound under controlled tension to avoid telescoping and ensure stable coil geometry for downstream handling.

Edge conditioning is the next critical step, particularly for applications involving winding or electrical insulation. The slit edges undergo a proprietary deburring and rounding process to eliminate micro-cracks, sharp edges, and surface protrusions that could compromise dielectric integrity in transformer windings. This is achieved through a combination of mechanical brushing, edge rolling, and precision grinding, resulting in a smooth, radius-formed edge profile that enhances safety and performance in high-voltage environments.

Throughout the manufacturing flow, in-process quality control (QC) checkpoints are implemented at each stage. These include on-line thickness measurement via beta-gauge systems, surface defect scanning using high-resolution CCD cameras, and periodic mechanical testing for tensile strength, elongation, and electrical conductivity. Every coil undergoes final inspection for dimensional conformance, surface cleanliness, and edge quality prior to packaging. Test certificates, including chemical composition (verified by OES) and mechanical property reports, are provided with each shipment to ensure full traceability and compliance with international standards such as GB/T, ASTM, and IEC.

This disciplined, technology-driven manufacturing approach ensures that our copper strips deliver optimal performance in demanding transformer and electrical applications.

Packaging & Logistics

Export Packaging Specifications for Copper Transformer Strips

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for copper transformer strips to ensure integrity during global maritime transit. Copper’s electrochemical sensitivity to moisture, sulfides, and mechanical stress necessitates a multi-barrier approach exceeding standard industrial practices. Our system integrates certified wooden pallets with advanced moisture-proofing, validated across 20+ years of international shipments to Europe, North America, and Southeast Asia.

All export loads utilize ISPM-15 compliant heat-treated wooden pallets constructed from kiln-dried hardwood. Pallet dimensions adhere to ISO 13356 standards (1200 × 1000 mm or 1100 × 1100 mm), with a minimum load-bearing capacity of 2,500 kg. Cross-blocks and stringers are reinforced to prevent deformation under dynamic cargo stress during vessel motion. Critical edges feature chamfered corners to eliminate film puncture risks during strapping. Each pallet undergoes pre-shipment moisture content verification (≤18% via oven-dry testing per ASTM D4442), preventing in-transit warping or microbial growth.

The primary moisture barrier comprises a triple-layer encapsulation system:

1. Strips are interleaved with acid-free kraft paper (80 g/m²) to absorb residual surface moisture.

2. A 120-micron multilayer co-extruded polyethylene film (LDPE/LLDPE blend) provides vapor transmission resistance. This film meets ASTM E96 Class A specifications (<0.1 g/m²/day water vapor transmission rate at 38°C, 90% RH).

3. Vacuum-sealed secondary wrapping incorporates silica gel desiccants (minimum 300 g/m³ cargo volume) with humidity indicator cards (calibrated 0–100% RH).

This configuration maintains internal relative humidity below 40% for 60+ days—exceeding IMDG Code moisture thresholds for non-ferrous metals. All film seams are thermally welded (seal strength ≥80 N/15mm per ASTM F88), eliminating adhesive contamination risks. External protection includes UV-stabilized polypropylene strapping (5,000 N tensile strength) and corner boards of 5 mm recycled cardboard (BCT ≥12 kN).

Sea freight safety is further ensured through:

Dynamic Load Simulation: Packaging validated via ISTA 3A vibration testing (0.5–5 Hz, 0.5G amplitude) replicating ocean swell conditions.

Corrosion Inhibitors: VCI (Vapor Corrosion Inhibitor) emitters integrated for copper-specific protection against sulfur compounds.

Documentation: Each shipment includes a moisture control certificate detailing desiccant placement, humidity logs, and film batch traceability.

The following table summarizes critical packaging performance metrics:

| Parameter | Specification | Test Standard |

|---|---|---|

| Pallet Moisture Content | ≤18% (dry basis) | ASTM D4442 |

| Film Thickness | 120 ± 5 microns | ASTM D2103 |

| WVTR | <0.1 g/m²/day | ASTM E96 |

| Desiccant Capacity | 300 g/m³ minimum | ISO 22196 |

| Internal RH Limit | ≤40% for 60 days | IEC 60068-2-78 |

This methodology eliminates oxidation, staining, and dimensional instability—critical for copper strip conductivity (≥100% IACS) and surface finish requirements. Clients receive EXW/FOB documentation confirming compliance with ISO 11607-1 for medical-grade barrier integrity, underscoring our commitment to zero defect delivery. Partnering with certified freight forwarders, we enforce stowage protocols prohibiting deck storage and proximity to refrigerated containers to mitigate condensation risks. All packaging materials are recyclable, aligning with EU Packaging Directive 94/62/EC.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for High-Performance Copper and Aluminum Transformer Strips

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted leader in the production of precision aluminum and copper transformer strips and foils. Our facility integrates advanced metallurgical engineering with rigorous quality assurance protocols to deliver materials that meet the exacting demands of power transmission, distribution, and industrial electronics applications. As a vertically integrated producer, we maintain full control over the production chain—from raw material sourcing and alloy formulation to cold rolling, heat treatment, and final slitting—ensuring consistency, traceability, and compliance with international standards including GB/T, ASTM, and IEC.

Our production infrastructure is anchored by state-of-the-art cold rolling mills and continuous annealing lines, enabling precise thickness control down to ±0.01 mm and superior surface finish critical for minimizing eddy current losses in transformer windings. We offer copper strips in C11000, C12200, and other high-conductivity grades, available in tempers ranging from soft (annealed) to hard-drawn, with widths from 10 mm to 600 mm and thicknesses between 0.1 mm and 6.0 mm. Each batch undergoes comprehensive mechanical and electrical testing, including tensile strength, elongation, conductivity (≥98% IACS for soft copper), and dimensional stability under thermal cycling.

In parallel, our aluminum strip production leverages high-purity Al 1060, 1070, and 1350 alloys, optimized for weight-sensitive transformer designs requiring high conductivity-to-density ratios. Our dual-material capability allows clients to evaluate both copper and aluminum solutions under identical processing and quality benchmarks, facilitating informed material selection based on performance, cost, and regulatory requirements.

Quality management is certified under ISO 9001:2015, with in-house laboratories equipped for metallographic analysis, hydrogen content testing, and surface profilometry. All coils are individually tagged with batch-specific mill test certificates, supporting full supply chain transparency and compliance with utility-grade procurement standards.

We serve OEMs, winding manufacturers, and utility contractors across Asia, Europe, and North America, with an export footprint spanning over 30 countries. Our logistics network ensures on-time delivery via FOB Qingdao or CIF major global ports, with packaging designed to prevent oxidation and mechanical damage during transit.

For technical collaboration, material sampling, or custom specification development, contact us directly. Our engineering team is available to support material selection, cross-compliance documentation, and production scaling for high-volume contracts.

Contact us at cathy@transformerstrip.com to request product specifications, pricing, or arrange a factory audit. Partner with Luoyang Xinzhaohe for reliable, high-precision transformer strip supply backed by 20 years of metallurgical expertise.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper strips directly from China.