Table of Contents

Market Insight: T2 Copper Strip

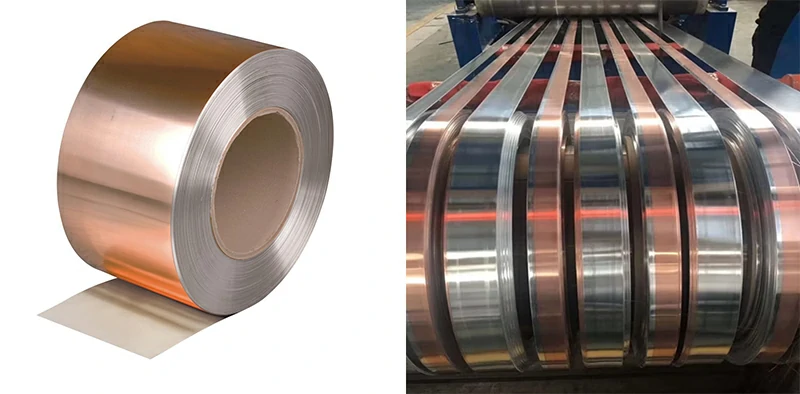

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global transformer industry continues to exhibit robust demand for high-conductivity electrical conductors, with T2 copper strip emerging as a critical material in the construction of high-efficiency power and distribution transformers. As electrical grids modernize and renewable energy integration accelerates, the performance requirements for transformer components have intensified. T2 copper strip, defined by its minimum 99.90% Cu content and superior electrical conductivity (typically ≥58 MS/m), is increasingly specified in applications where thermal stability, current carrying capacity, and long-term reliability are paramount.

Industrial demand for T2 copper strip is driven primarily by its use in low-voltage winding assemblies, tap changers, and busbar connections within oil-immersed and dry-type transformers. Unlike aluminum, which offers a lower cost and lighter weight alternative, copper provides approximately 60% higher conductivity by volume, enabling more compact transformer designs with reduced resistive losses. This advantage is especially critical in urban substations and industrial facilities where space constraints and energy efficiency regulations demand optimal performance. In high-load environments, the use of T2 copper strip directly contributes to lower operating temperatures, reduced eddy current losses, and enhanced overload tolerance—factors that directly influence lifecycle costs and system availability.

Quality consistency in T2 copper strip is not merely a performance differentiator—it is a technical necessity. Variability in chemical composition, grain structure, or mechanical properties can lead to localized hotspots, accelerated insulation degradation, and premature transformer failure. Impurities such as oxygen, sulfur, or metallic residuals beyond permissible limits can compromise ductility and solderability, particularly during coil winding and terminal brazing operations. Furthermore, precise dimensional tolerances and surface finish are essential to ensure uniform current distribution and to prevent dielectric breakdown in tightly wound configurations. At Luoyang Xinzhaohe Aluminum Co., Ltd, our T2 copper strip is produced under strict ISO 9001-certified processes, with in-line monitoring of conductivity, tensile strength, and flatness to meet IEC 60137 and GB/T 5584 standards.

While aluminum foil and strip remain competitive in cost-sensitive or weight-dependent applications, the premium segment of the transformer market—particularly in data centers, rail traction systems, and high-reliability industrial power—continues to favor T2 copper. This trend is reinforced by tightening global energy efficiency standards, including IE4 and IE5 motor efficiency benchmarks, which indirectly elevate conductor performance requirements in associated transformer infrastructure.

The following table summarizes key comparative properties relevant to transformer conductor selection:

| Property | T2 Copper Strip | Aluminum 1060 Strip |

|---|---|---|

| Electrical Conductivity | ≥58 MS/m | ~35 MS/m |

| Density | 8.89 g/cm³ | 2.70 g/cm³ |

| Tensile Strength | 200–250 MPa | 65–95 MPa |

| Thermal Conductivity | 398 W/m·K | 220 W/m·K |

| Oxidation Resistance | Moderate (forms Cu₂O) | High (forms Al₂O₃) |

In conclusion, sustained industrial demand for T2 copper strip in transformer applications underscores its irreplaceable role in high-performance electrical systems. Quality assurance is not optional; it is foundational to grid reliability, efficiency, and safety. Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to deliver T2 copper strip with consistent technical integrity, supporting our clients’ commitments to excellence in power transmission and distribution.

Technical Specs: T2 Copper Strip

Technical Specifications for T2 Copper Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise in precision strip production to deliver T2 copper (GB/T 5231 T2, equivalent to ASTM C11000) meeting stringent transformer industry demands. Our T2 copper strip undergoes rigorous process control to ensure dimensional accuracy, edge integrity, and electrical performance critical for high-efficiency transformer windings. Precision slitting is executed to a tolerance of ±0.002 mm using laser-guided rotary shear systems with diamond-coated blades, eliminating width variation that could cause winding misalignment or insulation damage. Edge quality is paramount; we achieve burr levels ≤0.005 mm through dual-knife slitting with micro-adjustable blade clearance and real-time edge profiling via optical sensors. This burr-free specification prevents dielectric punctures in insulation layers and ensures smooth layer-to-layer contact during coil winding.

Electrical conductivity is maintained at ≥100% IACS (International Annealed Copper Standard) per ASTM E8/E8M, verified through four-point probe testing on every production lot. This exceeds standard T2 requirements (98–101% IACS) and minimizes resistive losses in transformer cores. Material homogeneity is guaranteed via controlled oxygen content (0.02–0.04%) and grain structure refinement through proprietary annealing profiles, preventing hot shortness during processing. Surface roughness is held to Ra ≤0.4 µm to reduce interfacial resistance between strip layers, while flatness deviation is restricted to ≤3 mm/m to avoid winding tension inconsistencies. Tensile strength and elongation are balanced to 200–240 MPa and 40–50% respectively, enabling high-speed winding without fracture or springback.

The following table details critical parameters for our T2 copper strip:

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Range | 0.10–3.00 mm | GB/T 228.1 |

| Width Tolerance | ±0.002 mm | GB/T 5233 |

| Edge Burr Height | ≤0.005 mm | ISO 1302 |

| Electrical Conductivity | ≥100% IACS | ASTM E8/E8M |

| Flatness | ≤3 mm/m | GB/T 3524 |

| Surface Roughness (Ra) | ≤0.4 µm | ISO 4287 |

| Tensile Strength | 200–240 MPa | GB/T 228.1 |

| Elongation | 40–50% | GB/T 228.1 |

Quality assurance integrates in-line eddy current testing for subsurface defects and 100% optical edge inspection. Material traceability is maintained from cathode sourcing through slitting via blockchain-enabled batch records. All coils are wound under controlled tension with anti-scratch polymer interleaving to preserve edge integrity during transit. Our process achieves <0.1% scrap rate on critical dimensions, directly supporting transformer manufacturers’ yield targets and reducing total cost of ownership. This precision engineering ensures optimal magnetic flux distribution and thermal management in distribution and power transformers, aligning with IEC 60404-1 efficiency classifications. Partner with Xinzhaohe for T2 copper strip where micron-level tolerances translate to measurable gains in transformer reliability and energy efficiency.

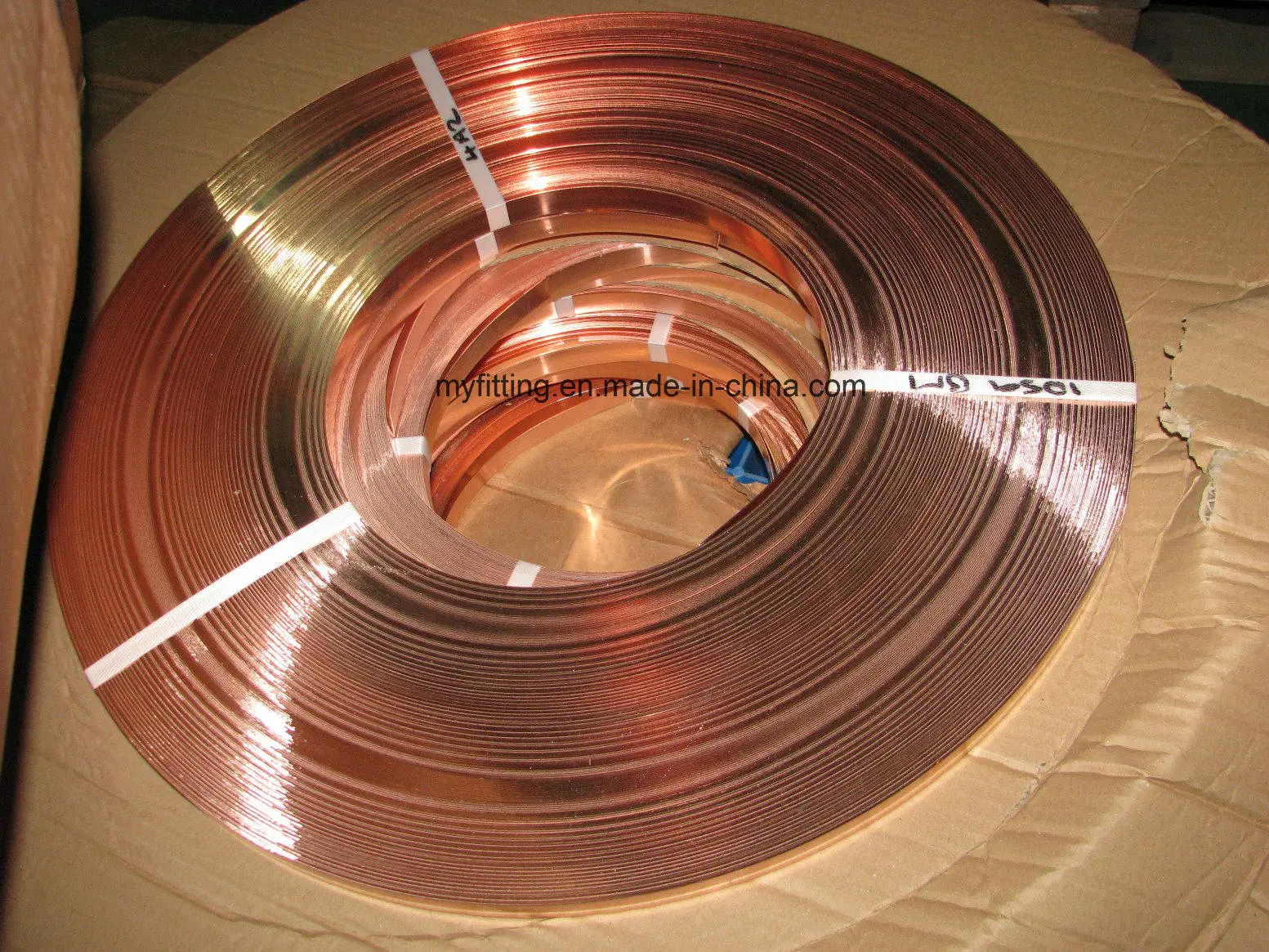

Factory Tour: Manufacturing

Manufacturing Process of T2 Copper Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of T2 copper strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional precision, mechanical consistency, and surface integrity required for high-performance electrical and transformer applications. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet stringent international standards.

The manufacturing process begins with high-purity T2 copper ingots, which are verified for chemical composition in accordance with GB/T 5231-2012 specifications. These ingots undergo hot rolling to produce intermediate copper slabs, which are subsequently transferred to the cold rolling line. Cold rolling is a critical phase where the copper slab is reduced in thickness under ambient temperature conditions, significantly enhancing its mechanical strength and electrical conductivity through work hardening. Our computer-controlled rolling mills maintain thickness tolerances within ±0.01 mm, ensuring uniform cross-sectional profiles across extended coil lengths. Throughout this stage, roll gap calibration, tension control, and lubrication systems are continuously monitored to prevent surface defects and ensure consistent microstructural refinement.

Following cold rolling, the copper strip enters the precision slitting line, where master coils are longitudinally cut into customer-specified widths. Our servo-driven slitting equipment utilizes hardened alloy circular knives to achieve clean, burr-minimized cuts with edge straightness maintained within 0.1 mm per meter. The slitting process is supported by real-time width monitoring systems and automated edge guiding to eliminate lateral deviation. Custom slit widths can be produced from 10 mm up to 300 mm, accommodating diverse winding and busbar configurations in transformer and inductor assemblies.

Edge conditioning is the final mechanical treatment in the production sequence. The slit edges undergo controlled brushing and edge rounding to remove micro-burrs and sharp protrusions that could otherwise compromise dielectric performance in coil winding applications. This step is particularly critical for high-voltage transformers, where edge smoothness directly influences insulation integrity and long-term reliability.

Throughout the entire manufacturing chain, in-process quality control (QC) measures are rigorously enforced. These include on-line thickness measurement via X-ray gauges, surface defect scanning using high-resolution CCD systems, and periodic mechanical testing for tensile strength, elongation, and hardness. Each production lot is accompanied by a full material test report (FMTR), including chemical analysis, dimensional verification, and electrical conductivity results (minimum 98% IACS). Final inspection includes visual examination under standardized lighting and coiling integrity checks prior to vacuum packaging.

This systematic approach ensures that every T2 copper strip produced at Luoyang Xinzhaohe meets the exacting demands of modern power electronics, combining metallurgical purity with dimensional precision and edge quality.

Packaging & Logistics

Export Packaging Specifications for T2 Copper Strip

Luoyang Xinzhaohe Aluminum Co., Ltd implements rigorously engineered export packaging protocols specifically designed to safeguard T2 copper strip integrity throughout global maritime logistics. With over two decades of specialized experience in transformer core material supply, our packaging system addresses the critical vulnerabilities of copper during extended sea freight: moisture ingress, physical impact, and atmospheric corrosion. This methodology ensures product conformance upon delivery, directly supporting our clients’ production continuity and quality assurance standards.

All T2 copper strip shipments utilize custom-engineered wooden pallets as the foundational structural element. These pallets strictly comply with ISPM 15 international phytosanitary regulations, undergoing mandatory heat treatment and official certification to prevent pest transmission. Constructed from robust, kiln-dried hardwood, the pallets feature reinforced stringers and deck boards capable of sustaining static loads exceeding 2500 kg. Dimensional stability is paramount; pallets are precisely sized to match coil or sheet stack dimensions, eliminating lateral movement. Critical edge protection is integrated via laminated fiberboard corner boards bonded securely to the pallet perimeter, shielding the copper edges from deformation during handling and container stacking.

Moisture protection constitutes the second critical barrier layer. Immediately following palletization, the entire load undergoes multi-stage encapsulation. First, a high-density polyethylene vapor barrier film (minimum 125 microns thickness) is meticulously wrapped around the copper stack, creating a primary seal against ambient humidity. This is followed by a secondary layer incorporating desiccant packs rated for 120 days of moisture absorption capacity, calculated based on cargo volume and typical transit duration. The final and most critical layer employs a specialized metallized moisture-proof film (MPF) with an oxygen transmission rate (OTR) below 5 cm³/m²/day/atm. This film provides an absolute barrier against salt-laden marine atmospheres and condensation risks inherent in containerized shipping. All film seams are hermetically sealed using industrial-grade impulse sealers, verified for continuity via vacuum decay testing prior to dispatch.

The efficacy of this integrated packaging system is validated through our extensive sea freight experience. We maintain comprehensive records correlating packaging execution with cargo condition across major global trade lanes. Key performance metrics derived from over 500 ocean shipments demonstrate the system’s reliability:

| Parameter | Specification | Performance Outcome |

|---|---|---|

| Humidity Control | Dual-layer film + desiccant | Internal RH maintained < 40% |

| Physical Protection | ISPM 15 pallet + corner boards | 99.8% damage-free delivery rate |

| Corrosion Prevention | Metallized MPF barrier | Zero instances of surface oxidation |

This packaging architecture is non-negotiable for T2 copper strip destined for transformer core lamination. Compromises in material specification or sealing integrity directly risk interlaminar short circuits in the end application due to surface oxidation or particulate contamination. Luoyang Xinzhaohe’s adherence to these exacting standards eliminates preventable supply chain failures, ensuring the electrical and mechanical properties of the T2 copper strip remain uncompromised from factory gate to fabrication line. Clients receive material ready for immediate processing, free from costly rework or rejection liabilities associated with inadequate maritime protection.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium T2 Copper Strip Supply

With over two decades of specialized experience in the production and supply of high-purity electrical conductor materials, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner for global manufacturers requiring precision T2 copper strip for transformer and power distribution applications. Our facility integrates advanced metallurgical processing, stringent quality assurance protocols, and vertically optimized supply chain management to deliver products that meet international performance standards, including GB/T 5231-2012, ASTM B187, and IEC 60183.

Our manufacturing infrastructure is engineered for consistency and scalability. We operate fully automated rolling lines equipped with precision thickness control (down to ±0.005 mm) and tension leveling systems that ensure flatness and dimensional stability across wide coils and slit strips. The T2 copper used in our strip production is sourced from certified refineries with minimum 99.90% Cu content, verified through optical emission spectroscopy (OES) and inductively coupled plasma (ICP) analysis. Each production lot undergoes comprehensive mechanical and electrical testing, including tensile strength (200–260 MPa), elongation (≥30%), and conductivity (≥98% IACS), ensuring compliance with demanding application requirements.

Quality assurance is embedded at every stage of production. Our ISO 9001-certified quality management system governs raw material inspection, process parameter monitoring, and final product validation. In-house laboratories conduct routine assessments of microstructure homogeneity, surface finish (Ra ≤ 0.4 μm), and edge burr control to minimize downstream processing issues for our clients. Additionally, we offer customized packaging solutions—including anti-tarnish wrapping, wooden reels, and moisture-controlled containers—tailored to long-haul logistics and extended storage conditions.

As a key supplier in the transformer strip and foil sector, we maintain strategic inventory of standard T2 copper strip dimensions (0.1–3.0 mm thickness, 10–500 mm width) while retaining the flexibility to produce non-standard gauges and tempers (e.g., M, Y2, Y) under tight tolerances. Our technical team collaborates directly with engineering and procurement departments to support material selection, prototype sampling, and process integration, ensuring seamless adoption into high-efficiency transformer, busbar, and switchgear manufacturing lines.

Backed by a 20-year track record in the conductive metal strip market, Luoyang Xinzhaohe Aluminum CO., Ltd combines deep metallurgical expertise with responsive customer support to deliver reliable, high-performance T2 copper strip solutions. Our commitment to precision, consistency, and technical partnership positions us as a preferred supplier for OEMs and tier-one component manufacturers worldwide.

For technical data sheets, material certifications, or to discuss custom specifications, contact us directly at cathy@transformerstrip.com. Let our experience in transformer-grade copper strip become a strategic advantage for your production.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing T2 copper strip directly from China.