Table of Contents

Market Insight: Transformer Winding Wire

Market Analysis: Transformer Winding Wire Demand and Quality Imperatives

Global transformer manufacturing exhibits sustained growth, driven by expanding power infrastructure, renewable energy integration, and grid modernization initiatives. The International Energy Agency (IEA) projects a 4.5% compound annual growth rate (CAGR) in global transformer demand through 2030, with aluminum winding wire capturing significant market share due to its cost efficiency and weight advantages over copper. Industrial applications span power transmission (110kV+), distribution transformers (11kV–66kV), and specialized units for solar/wind farms, where aluminum’s 60% lower density reduces structural load and transportation costs—critical factors in large-scale projects. Rising electrification in emerging economies further accelerates demand, particularly for distribution transformers utilizing aluminum conductors.

Aluminum winding wire dominates cost-sensitive segments without compromising core functionality when engineered to exacting standards. While copper offers higher conductivity (100% IACS), aluminum provides 61% IACS at half the density, enabling equivalent current-carrying capacity with optimized cross-sectional design. This balance makes aluminum the material of choice for 90% of distribution transformers globally, per CIGRÉ data. However, material substitution intensifies quality scrutiny; substandard aluminum wire introduces systemic risks including elevated resistive losses, thermal instability, and premature failure. Impurities (iron, silicon exceeding 0.12%), inconsistent temper, or surface defects directly impact electrical performance and mechanical integrity during winding operations.

Quality adherence is non-negotiable for operational safety and lifecycle economics. Transformer windings operate under continuous electrical stress, thermal cycling, and mechanical vibration. Inadequate wire purity or inconsistent annealing causes localized hotspots, accelerating insulation degradation and increasing no-load losses by 15–20% in worst-case scenarios. Dimensional tolerances (±0.01mm for diameter) are equally critical; deviations induce uneven magnetic flux distribution, raising stray losses and audible noise levels beyond IEC 60076-10 limits. International standards (IEC 60137, ASTM B548) mandate rigorous testing for elongation (25–35%), tensile strength (60–90 MPa), and surface smoothness to ensure reliable coil formation and long-term dielectric integrity.

The cost of quality failure extends far beyond material replacement. A single transformer failure in a transmission substation can incur $2M+ in downtime, repair, and grid instability penalties. Leading utilities now enforce second-party audits of wire suppliers, prioritizing traceability from smelter to finished coil. Luoyang Xinzhaohe Aluminum leverages two decades of metallurgical expertise to produce AA-1350 and AA-8030 alloy wires with certified purity (99.7% min), precision-drawn tolerances, and proprietary annealing controls—directly addressing these industrial imperatives.

Key Material Comparison for Transformer Windings

| Property | Aluminum (AA-1350) | Copper (ETP) | Industrial Implication |

|————————-|——————–|————–|————————————–|

| Conductivity (% IACS) | 61 | 100 | Requires 56% larger cross-section |

| Density (g/cm³) | 2.70 | 8.96 | 65% weight reduction in windings |

| Relative Cost (vs Cu) | 0.35 | 1.00 | Significant CAPEX savings per unit |

| Thermal Expansion (µm/m·K) | 23.0 | 16.5 | Critical for thermal cycling design |

Ultimately, sourcing decisions must prioritize wire that meets stringent electro-thermal specifications. Inferior aluminum conductors compromise transformer efficiency, reliability, and compliance with energy efficiency regulations (e.g., DOE 2016, EU EcoDesign). For industrial buyers, the premium for certified, high-purity aluminum wire represents a necessary investment against catastrophic operational risk and lifecycle cost escalation.

Technical Specs: Transformer Winding Wire

Transformer winding wire is a critical component in the construction of power and distribution transformers, where electrical performance, thermal stability, and mechanical integrity directly influence operational reliability and service life. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience, our aluminum-based transformer winding wire is engineered to meet stringent international standards, including IEC 60317 and GB/T 23679. The following technical specifications detail key performance parameters essential for informed sourcing and application engineering.

A primary performance indicator for transformer winding wire is insulation breakdown voltage, which determines the dielectric strength of the enamel coating under high electrical stress. Our standard enamel-insulated aluminum winding wires exhibit a minimum breakdown voltage of 3,000 V AC, tested at room temperature with a ramp rate of 100 V/s. This ensures reliable insulation integrity during transient overvoltage events and continuous operation under rated load conditions. Higher-grade variants, designed for medium-voltage applications, achieve breakdown voltages up to 6,000 V AC, utilizing multi-layer insulation systems comprising polyurethane, polyester, or polyamide-imide coatings.

Elongation, a measure of ductility, is crucial for winding processes that involve tight coiling and mechanical shaping. Our aluminum alloy conductors, typically based on 1350-O or equivalent soft temper, demonstrate a minimum elongation of 25% as measured per ASTM E8. This high elongation capacity prevents cracking or fracture during winding, especially in large-scale transformer coils with small bend radii. Consistent elongation across spool lengths ensures uniform processing and minimizes in-line breakage during automated winding operations.

Thermal classification defines the maximum continuous operating temperature at which the insulation system retains its dielectric and mechanical properties. Our product portfolio spans thermal classes from 130°C to 220°C, enabling selection based on transformer design and cooling methodology. Class 130 (B) and Class 155 (F) wires are commonly used in dry-type transformers with natural or forced air cooling, while Class 180 (H) and Class 220 wires are employed in high-efficiency or compact designs requiring superior thermal endurance. The thermal index is validated through thermal aging tests per IEC 60216, with insulation life extrapolated to 20,000 hours at rated temperature.

The following table summarizes the core technical parameters of our transformer winding wire offerings:

| Parameter | Test Standard | Class 130 (B) | Class 155 (F) | Class 180 (H) | Class 220 |

|---|---|---|---|---|---|

| Insulation Breakdown Voltage (min) | IEC 60172 | 3,000 V AC | 4,000 V AC | 5,000 V AC | 6,000 V AC |

| Elongation (min) | ASTM E8 | 25% | 25% | 25% | 25% |

| Thermal Class | IEC 60216 / GB 11021 | 130°C | 155°C | 180°C | 220°C |

| Conductor Material | ASTM B233 | Aluminum 1350-O | Aluminum 1350-O | Aluminum 1350-O | Aluminum 1350-O |

| Typical Applications | — | Distribution Transformers | Power Transformers | High-Temperature Dry-Type | Specialty Transformers |

These specifications reflect our commitment to delivering winding wire solutions that balance electrical safety, mechanical processability, and thermal resilience. All products undergo 100%在线 testing for insulation continuity and diameter consistency, ensuring batch-to-batch reliability for global transformer manufacturers.

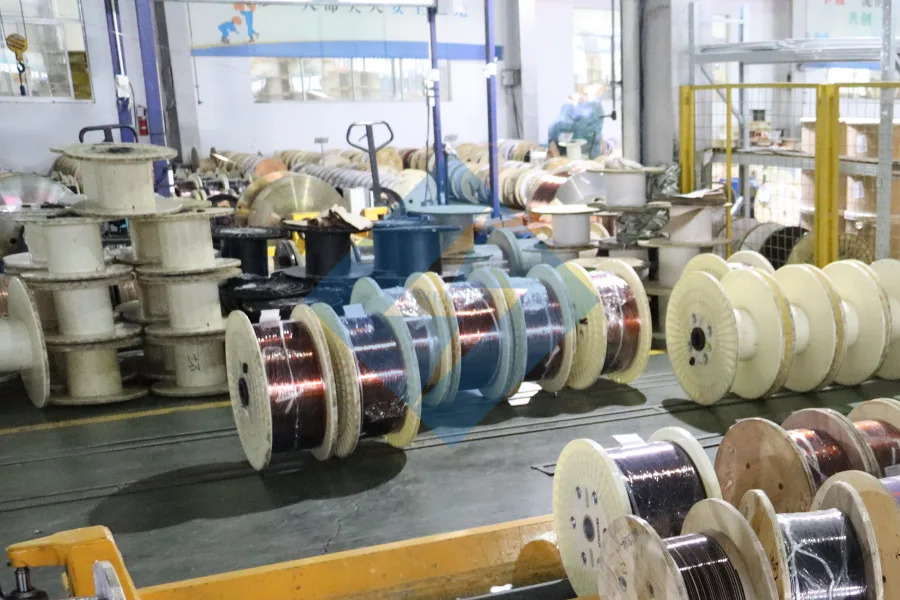

Factory Tour: Manufacturing

Transformer Winding Wire Manufacturing Process at Luoyang Xinzhaohe Aluminum

The production of high-reliability aluminum transformer winding wire at Luoyang Xinzhaohe Aluminum CO., Ltd. follows a rigorously controlled sequence designed to meet stringent electrical and mechanical specifications demanded by modern power and distribution transformers. Our 20+ years of metallurgical expertise ensures each stage adheres to international standards while optimizing for end-use performance.

Rod Drawing Process

The foundation begins with high-purity aluminum rod (typically 99.70% min Al, alloy 1350), subjected to precision cold drawing through a series of tungsten carbide or diamond dies. This process reduces the rod diameter to the precise wire gauge required, ranging from coarse sizes for large power transformers down to fine gauges for distribution units. Critical parameters such as reduction ratio per pass, drawing speed, and lubricant viscosity are meticulously monitored and controlled. Excessive speed or improper lubrication induces residual stresses and surface defects, directly impacting subsequent annealing homogeneity and ultimate wire ductility. In-process diameter verification using laser micrometers occurs continuously, with deviations triggering immediate process adjustment to maintain tolerances within ±0.005 mm.

Annealing Stage

Following drawing, the work-hardened wire undergoes continuous annealing in a controlled atmosphere furnace. Xinzhaohe employs nitrogen-purged or inert gas environments to prevent oxidation and ensure a clean, oxide-free surface essential for optimal enamel adhesion. Temperature profiles are precisely calibrated based on wire size and target temper (typically O-soft or H14 semi-hard). Under-annealing leaves excessive hardness, increasing breakage risk during winding; over-annealing compromises tensile strength. Our systems dynamically adjust line speed and furnace temperature to achieve uniform recrystallization, verified through real-time tensile and elongation testing on automated sample cutters. Surface resistivity is concurrently measured to confirm absence of conductive oxides.

Enameling Application

The cleaned, annealed wire enters the enameling line where multiple layers of thermosetting polymer resin (typically polyurethane, polyester-imide, or polyamide-imide based) are applied via precision die coating. Each layer is immediately cured through high-temperature ovens under controlled oxygen levels to prevent discoloration and ensure complete cross-linking. Layer thickness uniformity is paramount for dielectric strength and thermal conductivity; Xinzhaohe utilizes closed-loop optical sensors to maintain enamel build within ±2% of target. Critical enamel properties—adhesion, flexibility, thermal class (180°C, 200°C, 220°C), and dielectric breakdown voltage—are validated against IEC 60851 standards at multiple points along the line.

Integrated Quality Control and Inline Testing

Quality assurance is embedded throughout the process, not isolated to final inspection. Key parameters are continuously monitored and recorded:

| Measurement Point | Critical Parameter | Tolerance/Requirement | Verification Method |

|—————————-|—————————–|—————————–|———————————–|

| Post-Drawing | Diameter | ±0.005 mm | Laser Micrometer (100% inline) |

| Post-Annealing | Tensile Strength / Elongation | Per ASTM B230 | Automated Tensile Tester (Sample) |

| Post-Enameling | Enamel Thickness Uniformity | ±2% of nominal | Optical Sensor (100% inline) |

| Final Winding | Pinhole Density | ≤ 0.5 pinholes/meter @ 2x kV | High-Voltage Spark Tester (100%) |

Final validation includes 100% high-potential (Hi-Pot) testing at voltages exceeding operational requirements to detect microscopic defects, alongside batch sampling for thermal aging, solderability, and thermal shock resistance per IEC 60216 and IEC 60851. This integrated approach, combining decades of metallurgical process control with advanced inline metrology, ensures Xinzhaohe delivers aluminum winding wire with exceptional consistency for demanding transformer applications.

Packaging & Logistics

Export Packaging for Transformer Winding Wire – Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we recognize that the integrity of transformer winding wire extends beyond production—it is equally defined by the reliability of packaging during export logistics. Our export packaging system is engineered to preserve product quality, maintain dimensional stability, and ensure safe transit across global supply chains, particularly under the demanding conditions of sea freight.

All transformer winding wire shipments are secured on robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets are designed to ISO 15552 standards for load-bearing capacity and dimensional compatibility with international handling equipment. Each pallet is treated to ISPM 15 regulations, ensuring compliance with global phytosanitary requirements for wood packaging material. This certification guarantees that the wood has undergone thermal treatment to eliminate biological contaminants, a critical requirement for customs clearance in North America, Europe, and Asia-Pacific markets.

The winding reels, fabricated from reinforced plywood or steel-reinforced composite materials, are firmly affixed to the pallet base using high-tensile steel strapping. This configuration prevents axial and radial displacement during vessel loading, unloading, and long-haul container transport. To mitigate the risk of mechanical damage, edge protectors are installed at critical stress points, and reel flanges are shielded with polyethylene corner guards.

A multi-layer moisture barrier system is applied to protect against humidity, salt spray, and condensation—common hazards in maritime environments. The primary layer consists of high-density polyethylene (HDPE) film, 125 microns thick, wrapped circumferentially around the entire reel and pallet assembly. This is followed by a secondary enclosure in aluminum-laminated moisture-proof film, which provides a vapor transmission rate of less than 0.5 g/m²/24hr at 38°C and 90% RH. Seams are heat-sealed to ensure continuity, and the package is further secured with weather-resistant adhesive tapes.

Desiccant packs, rated at 1000 g per cubic meter of enclosed volume, are placed within the reel core and beneath the top flange to absorb residual moisture and buffer against internal condensation during temperature fluctuations. The packaged unit is then labeled with orientation arrows, “This Side Up” indicators, and humidity indicator cards for visible monitoring of internal conditions.

This integrated packaging methodology has been validated through accelerated climatic testing and real-world shipping cycles across Southeast Asia, the Middle East, and South America. It ensures that aluminum winding wire arrives at destination facilities with maintained electrical conductivity, surface finish, and mechanical properties—critical for downstream processing in transformer coil winding operations.

For procurement teams and OEM partners, our packaging protocol represents a quantifiable reduction in transit-related claims and rework. It reflects Luoyang Xinzhaohe’s commitment to technical rigor and supply chain resilience in the global energy infrastructure sector.

Sourcing from Luoyang Xinzhaohe

Strategic Partnership with Luoyang Xinzhaohe Aluminum Co., Ltd

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial manufacturing expertise to deliver transformer winding wire solutions meeting the most stringent global power transmission and distribution requirements. Our factory represents a vertically integrated production ecosystem engineered for reliability, precision, and technical excellence in aluminum conductor manufacturing. Partnering with us provides direct access to deep process knowledge and controlled supply chain execution critical for transformer performance and longevity.

Our core strength resides in advanced aluminum metallurgy and wire drawing science. We operate proprietary melting and purification systems achieving aluminum purity levels exceeding 99.85% Al, essential for optimal electrical conductivity and thermal stability in high-voltage applications. Precise grain structure control through optimized homogenization and annealing protocols ensures consistent mechanical properties—tensile strength, elongation, and bending fatigue resistance—across every production batch. This metallurgical foundation directly translates to reduced transformer losses, enhanced thermal management, and extended operational life under demanding load cycles. We strictly adhere to international standards including IEC 60137, ASTM B354, and GB/T 3954, with full traceability from raw material ingot to finished coil.

Advanced Production Capabilities underpin our ability to meet complex specifications. Our facility integrates state-of-the-art continuous casting and rolling lines with precision multi-die drawing machines capable of producing aluminum strip and round wire from 0.80mm to 6.00mm cross-sections. Tight dimensional tolerances (±0.01mm on thickness/width, ±0.005mm on diameter) are maintained through real-time laser micrometry and automated tension control systems. Dedicated annealing furnaces with precise atmosphere management guarantee uniform temper (O-temper standard, custom tempers available) and surface integrity, minimizing oxide formation and ensuring optimal solderability for winding processes. Annual production capacity exceeds 30,000 metric tons, supporting large-scale project demands without compromise.

Rigorous Quality Assurance is non-negotiable. Every meter of wire undergoes comprehensive inline and offline testing. Our accredited laboratory validates electrical resistivity (max 0.028264 Ω·mm²/m at 20°C), mechanical properties per ASTM E8, surface roughness (Ra ≤ 0.8µm), and dimensional accuracy using calibrated equipment. Statistical Process Control (SPC) methodology monitors critical parameters, enabling immediate corrective action. Full material certification packages, including chemical composition analysis and mechanical test reports, are provided with every shipment, ensuring compliance and simplifying your quality documentation.

Supply Chain Resilience is engineered into our operations. Strategic partnerships with primary aluminum suppliers secure consistent raw material quality. Our optimized logistics network, featuring dedicated container loading facilities and experienced freight management, ensures on-time delivery to global ports. We maintain flexible production scheduling to accommodate urgent requirements while minimizing lead times through efficient inventory management of key alloy grades.

For transformer manufacturers demanding unwavering quality, technical partnership, and supply security in aluminum winding conductors, Luoyang Xinzhaohe Aluminum Co., Ltd is the engineered solution. Contact our Technical Sales Team to discuss your specific project requirements and receive a detailed capability statement. Initiate your sourcing evaluation by emailing Cathy directly at cathy@transformerstrip.com. We will provide comprehensive technical data, sample coordination, and a tailored production plan to support your next-generation transformer development.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer winding wire directly from China.