Table of Contents

Market Insight: Enamel Wire Gauge Chart

Industrial Demand Drivers for Enamel Wire Gauge Charts

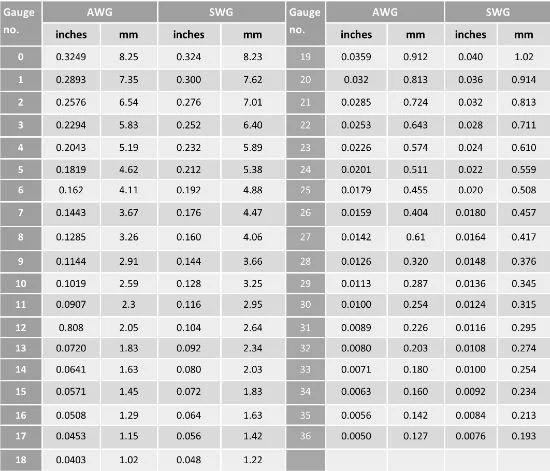

Transformer manufacturers globally rely on precise enamel wire gauge charts as foundational engineering tools during the electromagnetic design phase. These charts, correlating American Wire Gauge (AWG) or metric diameters to critical electrical and physical properties, directly dictate core parameters including current density, fill factor, and thermal management within the winding assembly. The relentless industry push for higher efficiency standards (e.g., DOE 2016, IEC 60076-20) and compact designs intensifies the need for exact gauge selection. An incorrect wire diameter choice, even within nominal tolerance bands, propagates errors through the entire design, potentially leading to excessive copper losses, inadequate heat dissipation, or core saturation. Consequently, procurement teams prioritize suppliers who provide not only the physical wire but also rigorously validated, application-specific gauge data sheets traceable to international standards like IEC 60317 or ASTM B267. This demand is amplified in high-frequency and high-voltage transformer segments, where skin effect and dielectric stress necessitate micron-level precision in conductor sizing.

Quality Implications in Transformer Applications

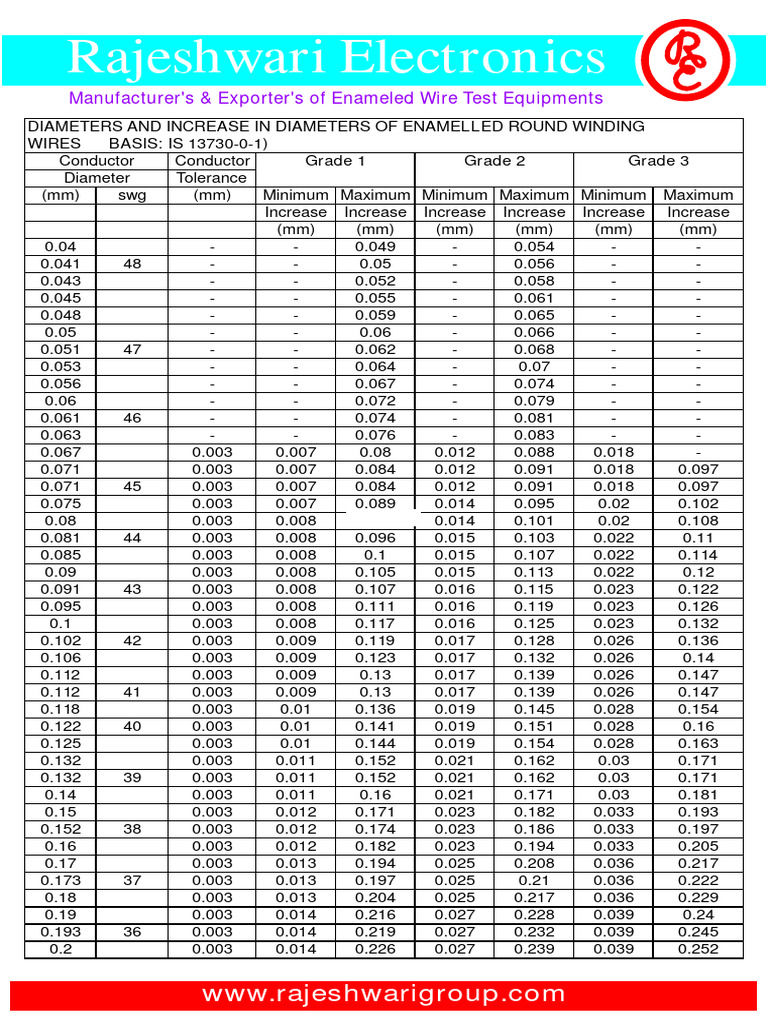

The integrity of the enamel insulation system, intrinsically linked to the underlying conductor gauge consistency, is non-negotiable for transformer reliability and longevity. Substandard wire exhibiting diameter variations beyond ±0.005 mm or insulation defects (pinholes, thin spots, poor adhesion) creates critical failure vectors. During operation, localized hotspots develop at points of reduced cross-section or compromised insulation, accelerating thermal aging and potentially initiating partial discharges. In oil-immersed transformers, even minor enamel imperfections can permit oil penetration, degrading dielectric strength and increasing the risk of catastrophic ground faults. Dry-type transformers face equally severe consequences; inconsistent wire gauge disrupts thermal conduction pathways within the winding, while poor enamel adhesion leads to inter-turn shorts under thermal cycling stress. Luoyang Xinzhaohe Aluminum’s two decades of metallurgical process control focus on minimizing ovality and ensuring uniform enamel build-up directly mitigates these risks. Our quality protocols verify tensile strength, elongation, and thermal shock resistance per IEC 60851, ensuring the wire performs as predicted by the gauge chart under real-world operational stresses.

Supply Chain Considerations for Quality Assurance

Sourcing enamel wire based solely on nominal gauge without stringent quality validation introduces significant latent supply chain risk. Counterfeit or non-compliant wire often meets basic dimensional checks but fails under operational thermal or electrical stress, leading to field failures with costs far exceeding initial material savings. Procurement specialists must therefore mandate supplier documentation proving conformance across the full spectrum of properties referenced in the gauge chart: conductor resistivity, insulation thickness tolerance, thermal class rating (e.g., 180°C, 200°C), and solderability. Luoyang Xinzhaohe Aluminum implements full lot traceability from aluminum rod casting through enameling, with independent third-party certification for critical parameters. This integrated metallurgical and process control approach ensures the gauge chart data provided is not theoretical but empirically verified for every production batch. For transformer OEMs, partnering with suppliers possessing this depth of technical oversight transforms the enamel wire gauge chart from a simple reference tool into a reliable predictor of end-product performance and durability, safeguarding brand reputation and minimizing total cost of ownership.

Technical Specs: Enamel Wire Gauge Chart

Technical Specifications for Enamel Wire Gauge Chart

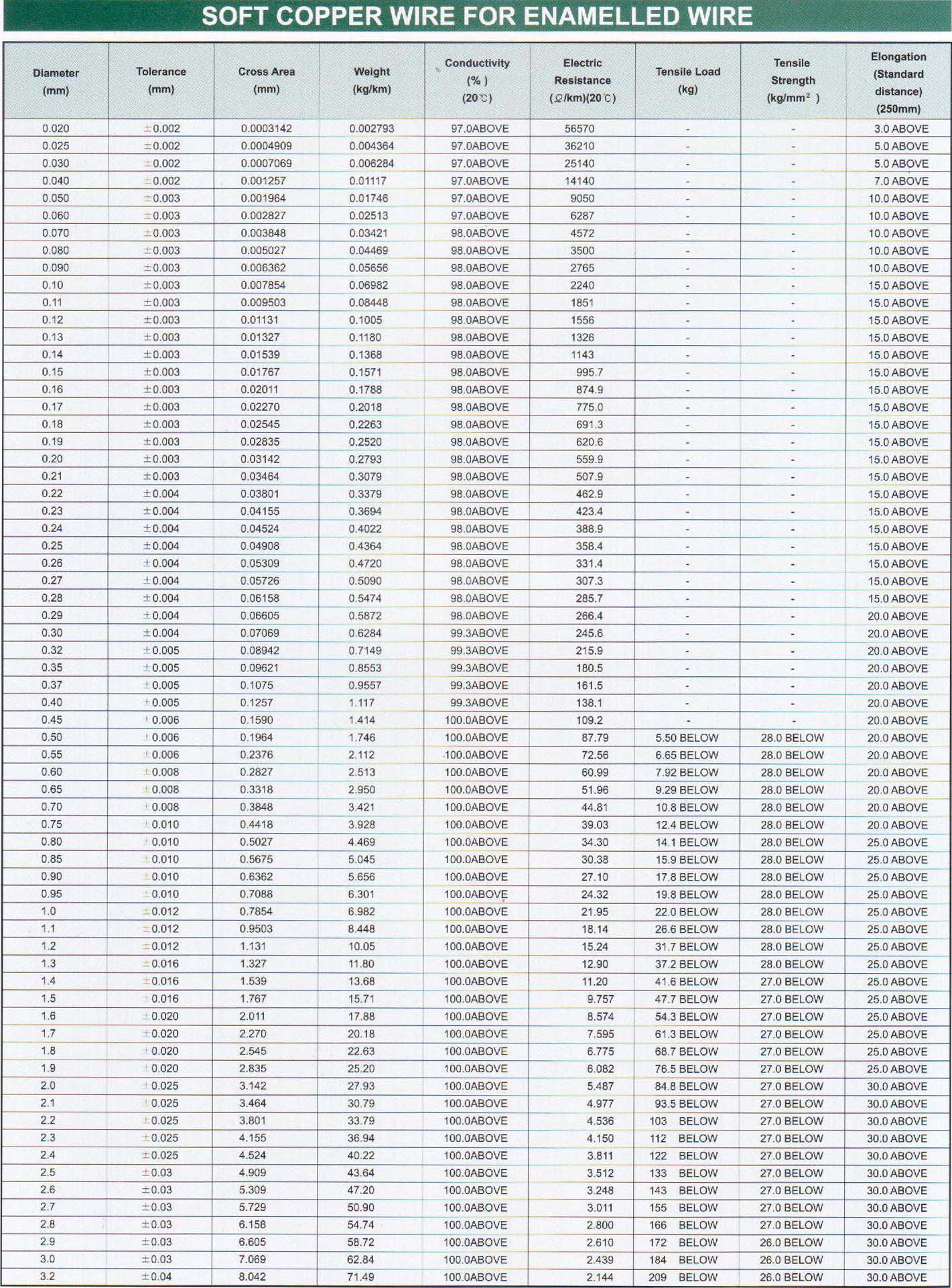

Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and supply of high-performance winding wires, provides this technical reference for enamel-coated aluminum and copper winding wires. This guide focuses on critical parameters essential for industrial and commercial sourcing decisions, particularly insulation breakdown voltage, elongation characteristics, and thermal class ratings ranging from 130°C to 220°C. These specifications are standardized in accordance with IEC 60317, GB/T 6109, and equivalent international norms, ensuring compatibility across global manufacturing platforms.

Insulation breakdown voltage is a primary indicator of dielectric strength and determines the wire’s ability to withstand electrical stress without failure. The measured breakdown voltage varies with wire diameter and insulation thickness, typically increasing proportionally with conductor size. For standard single-build enamel coatings, breakdown voltages range from 1,200 V to over 6,000 V AC, depending on gauge and insulation system. Double and triple-build variants offer enhanced dielectric performance, critical for high-voltage motor windings and transformer applications. Testing is conducted under controlled humidity and temperature conditions, with voltage applied at a steady rate until insulation failure occurs.

Elongation, expressed as a percentage, reflects the ductility of the conductor and its ability to withstand mechanical deformation during winding operations. For aluminum-based enamel wires, typical elongation values range between 18% and 30%, depending on temper and alloy composition. Copper variants generally exhibit higher elongation, between 30% and 45%, due to the inherent malleability of the base metal. Adequate elongation ensures crack resistance in the enamel layer during coiling, reducing the risk of short circuits and premature failure in end-use applications.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. Our product line supports thermal classes from 130°C (Class B) up to 220°C (Class C), utilizing advanced polymer coatings such as polyesterimide, polyamide-imide, and silicone-based formulations. Higher thermal classes offer extended service life in demanding environments, including automotive traction motors, industrial compressors, and aerospace actuators. Thermal endurance is validated through accelerated aging tests, with life expectancy extrapolated using the Arrhenius model.

The following table summarizes key technical parameters across standard enamel wire gauges:

| Gauge (AWG) | Conductor Diameter (mm) | Insulation Thickness (mm) | Min. Breakdown Voltage (V AC) | Elongation (%) | Thermal Class (°C) |

|---|---|---|---|---|---|

| 18 | 1.024 | 0.050 | 2,800 | 20–30 | 130–180 |

| 22 | 0.644 | 0.040 | 2,200 | 22–32 | 155–200 |

| 26 | 0.405 | 0.030 | 1,800 | 25–35 | 180–220 |

| 30 | 0.255 | 0.025 | 1,500 | 28–40 | 200–220 |

| 34 | 0.160 | 0.020 | 1,200 | 30–45 | 220 |

These values are representative for standard production batches and may vary slightly based on custom formulations and customer-specific requirements. Luoyang Xinzhaohe Aluminum Co., Ltd. maintains rigorous in-process quality control and third-party certification to ensure compliance with global performance standards.

Factory Tour: Manufacturing

Manufacturing Process for Precision Enamel Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to execute a rigorously controlled production sequence for enamel aluminum winding wire. Our process begins with high-purity aluminum rod drawing, where 99.7% min. conductivity feedstock undergoes multi-stage reduction through precision tungsten carbide dies. This cold-working phase employs computerized tension control and aqueous polymer lubricants to achieve target gauges per IEC 60317 standards, with continuous laser micrometry ensuring dimensional tolerance within ±0.001 mm. Critical QC checkpoints include real-time diameter validation and surface defect scanning via high-resolution optical sensors, rejecting deviations exceeding 0.5% ovality.

Annealing follows immediately after drawing to restore ductility and electrical properties compromised by work hardening. Wires pass through a continuous inert atmosphere furnace (N₂/H₂ mix, oxygen <10 ppm) at precisely controlled 550±5°C for 30–120 seconds, depending on gauge. This recrystallization step eliminates dislocations in the aluminum lattice while preventing surface oxidation—a critical differentiator for aluminum versus copper systems. Pyrometric monitoring and exit-coil conductivity tests (verifying ≥58% IACS) validate thermal profile consistency, with automatic line stoppage triggered by ±2°C excursions.

The enameling stage applies thermosetting polymer insulation via multi-zone coating dies. Single or dual-layer systems (e.g., polyester-imide over polyamide-imide) are metered at 0.02–0.05 mm wet film thickness, with viscosity maintained at 25±0.5 seconds (DIN 4mm cup). Convection ovens then polymerize the enamel through staged curing: pre-bake (150–250°C), main cure (350–420°C), and cooling under tension. In-process QC includes spark testing at 2.5× operating voltage (per gauge-specific tables), adhesion peel tests (max 0.5 N/mm force), and thermal shock validation at -65°C/155°C cycles.

Final inline testing integrates automated spark testers (100% coverage at 3–15 kV depending on gauge), precision diameter gauges (±0.003 mm), and elongation verification (min 1.5% for 0.1–1.0 mm gauges). All parameters feed into our SPC database, with real-time SPC charts tracking Cpk >1.67 for critical dimensions. Every production lot undergoes destructive validation: cross-section microscopy for enamel uniformity, salt-water dielectric tests (1000 hrs, 85°C), and thermal class endurance per NEMA MW 1000. This closed-loop system ensures compliance with global standards while minimizing scrap rates to <0.3%.

The result is enamel wire with exceptional thermal stability (Class 180–220), consistent bendability, and dielectric integrity—enabling reliable performance in EV traction motors, transformers, and industrial coils where aluminum’s weight-to-conductivity ratio delivers system-level advantages. Our process control documentation, including gauge-specific annealing time-temperature matrices and enamel viscosity logs, is available for technical audit upon sourcing engagement.

Packaging & Logistics

Export Packaging for Enamel Wire: Ensuring Integrity in Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global distribution of high-performance winding wire, we recognize that packaging is not merely a logistical necessity but a critical component in preserving product integrity throughout the export supply chain. For enamel wire—a precision product sensitive to mechanical stress, moisture, and contamination—robust export packaging is essential to maintain electrical performance, surface finish, and dimensional consistency upon delivery.

Our standard export packaging system is engineered specifically for the rigors of international sea freight, the dominant mode of transport for bulk wire shipments. Each consignment is secured on high-strength wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to withstand stacking loads in containerized shipping environments while providing a stable base that prevents coil deformation during loading, transit, and unloading. The use of nailed hardwood frames ensures structural rigidity, minimizing lateral movement and vibration-induced damage over long maritime journeys.

Prior to palletization, each wire coil—whether aluminum or copper-based—is individually wrapped in multi-layer moisture-proof composite film. This laminated barrier film incorporates aluminum foil and polyethylene layers to achieve a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24hr at 38°C and 90% relative humidity, effectively isolating the coil from ambient moisture. Given that moisture absorption can compromise the dielectric strength of the enamel insulation and promote oxidation of the conductor surface, this vapor barrier is a non-negotiable element of our packaging protocol.

Once sealed, the coils are arranged on the pallet in a tiered, interlocking configuration to optimize space utilization and center-of-gravity stability. The entire load is then unitized using high-tensile strapping—typically polyester or steel—anchored to the pallet frame at multiple points. Additional edge protectors are applied to safeguard coil edges from strap indentation. The completed unit is overwrapped with UV-resistant stretch film to provide an extra layer of dust and weather protection, particularly during open-deck storage or transshipment.

All packaging materials are verified for salt-spray resistance and compliance with international phytosanitary regulations, ensuring seamless customs clearance across key markets including Southeast Asia, Europe, and North America. Our packaging design has been validated through accelerated aging tests and real-world shipment monitoring, demonstrating consistent performance under 40-day ocean transits with humidity levels exceeding 85%.

By integrating material science, logistics engineering, and decades of field feedback, Luoyang Xinzhaohe’s export packaging system delivers a proven defense against the environmental and mechanical hazards inherent in global freight. This approach not only safeguards product quality but also reinforces our commitment to on-time, damage-free delivery—cornerstones of reliable B2B partnerships in the winding wire industry.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Enamel Aluminum Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and manufacturing expertise to deliver industry-leading aluminum enamel winding wire solutions. Our vertically integrated production facility in Luoyang, China, is engineered specifically for the stringent demands of magnet wire applications, ensuring dimensional accuracy, coating integrity, and consistent electrical performance critical for transformer, motor, and inductor manufacturers globally. We understand that precise adherence to gauge specifications within enamel wire charts is non-negotiable for end-product efficiency and reliability; our processes are designed to exceed these requirements consistently.

Advanced Manufacturing Infrastructure

Our production lines incorporate state-of-the-art continuous annealing furnaces and precision drawing blocks calibrated to sub-micron tolerances, directly supporting accurate gauge replication across the full spectrum defined in standard enamel wire charts (AWG, SWG, IEC). Dedicated enamel application systems utilize multi-zone curing ovens with tightly controlled thermal profiles, guaranteeing uniform coating thickness and adhesion at every gauge size. This infrastructure minimizes dimensional variance, ensuring wire conforms precisely to specified diameters and build classes, eliminating fitment or performance issues during automated winding operations. Real-time diameter monitoring via laser micrometers provides immediate feedback, maintaining tight process control.

Metallurgical & Quality Assurance Excellence

As metallurgical specialists, we control the entire aluminum rod production process, starting from high-purity primary aluminum (99.85% min) through optimized homogenization and continuous casting. This foundational control ensures consistent electrical conductivity (61.0% IACS min) and mechanical properties essential for drawing fine gauges without breakage. Our enamel wire undergoes rigorous in-process and final testing per IEC 60317 and ASTM B354 standards. Key parameters verified include conductor diameter tolerance (±0.003mm for fine gauges), elongation (15-30% depending on temper), dielectric strength (minimum 3000V), thermal class validation (up to 220°C), and solderability. Every production batch receives full traceability documentation, providing complete confidence in material pedigree and performance.

Reliable Supply Chain Integration

With 20+ years serving global Tier-1 electrical component manufacturers, we have developed a resilient supply chain model. Strategic raw material stockpiling of aluminum ingot and enamel resins mitigates market volatility risks. Our ERP system enables seamless order tracking from melt shop to dispatch, with standard lead times of 15-25 days for containerized shipments. We maintain significant finished goods inventory across common gauge ranges to support urgent requirements, reducing customer downtime. This operational discipline, combined with ISO 9001 and IATF 16949 certified quality management, ensures on-time delivery of defect-free material meeting exact gauge chart specifications.

Partnering with Luoyang Xinzhaohe provides direct access to metallurgical expertise and manufacturing precision that translates enamel wire gauge chart specifications into reliable, high-performance components. We eliminate the risk of dimensional inconsistency or coating defects that compromise winding efficiency and end-product lifespan. For technical consultation on selecting the optimal aluminum alloy temper, gauge, and enamel system for your specific application, or to request certified test reports against your required standards, contact our Technical Sales Manager Cathy directly.

Initiate your precision supply chain solution: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamel wire gauge chart directly from China.