Table of Contents

Market Insight: Copper Sheet Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for copper sheet coil within the transformer sector remains robust, driven by sustained infrastructure investment, renewable energy integration, and electrification trends. Electrical grid modernization programs worldwide, particularly in emerging economies, necessitate large quantities of distribution and power transformers. Concurrently, the rapid expansion of solar and wind generation requires specialized step-up transformers, while electric vehicle charging infrastructure deployment further amplifies demand for compact, high-efficiency units. Copper sheet coil, primarily utilized in high-voltage windings and critical busbar applications due to its superior electrical conductivity (approximately 100% IACS minimum for ETP copper), is essential for minimizing resistive losses and ensuring thermal stability under continuous load. This inherent material property translates directly to higher transformer efficiency ratings, a critical factor under increasingly stringent global energy efficiency regulations like DOE 2016 (USA) and MEPS standards (EU, Asia). Despite aluminum’s cost and weight advantages in lower-voltage applications, copper maintains dominance in performance-critical transformer segments where space constraints, maximum efficiency, and long-term reliability are paramount.

The uncompromising quality of copper sheet coil is non-negotiable for transformer integrity and operational lifespan. Impurities, even at trace levels, significantly degrade electrical and mechanical properties. Oxygen content must be tightly controlled (typically 200-400 ppm for ETP) to ensure optimal ductility during winding and prevent hydrogen embrittlement. Excessive oxygen leads to porosity and reduced conductivity, while sulfur contamination causes hot shortness. Dimensional precision is equally critical; thickness tolerances often specified within ±0.02 mm for foil and ±0.05 mm for strip directly impact winding tightness, magnetic flux distribution, and ultimately, no-load and load losses. Surface quality is paramount to prevent dielectric breakdown; scratches, pits, or residual rolling oils create weak points prone to partial discharge initiation under high electrical stress. Consistent mechanical properties, including tensile strength and elongation, are vital for withstanding the significant mechanical forces during winding and transformer operation without deformation or fracture. Substandard coil introduces field failure risks, including premature insulation degradation, localized overheating, and catastrophic winding faults, leading to costly outages and reputational damage.

Procurement decisions must prioritize suppliers with rigorous metallurgical process control and comprehensive testing protocols. Essential quality verification includes certified chemical analysis (ASTM B115), precise dimensional metrology, surface profilometry, electrical resistivity testing (ASTM B9), and mechanical property validation (ASTM E8). Traceability from cathode to finished coil is mandatory for root cause analysis in case of anomalies. While Luoyang Xinzhaohe Aluminum specializes in high-purity aluminum transformer materials, our two decades of metallurgical expertise underscore that copper’s performance advantages in critical applications are irreplaceable only when matched by stringent quality assurance. Sourcing copper sheet coil demands a partnership with manufacturers possessing deep process understanding and unwavering commitment to the exacting standards defined in IEC 60137 and IEEE C57.12.00. Compromising on coil quality inevitably compromises transformer performance, efficiency, and long-term operational reliability, representing a significant strategic risk for OEMs and utilities.

Technical Specs: Copper Sheet Coil

Technical Specifications for Copper Sheet Coil

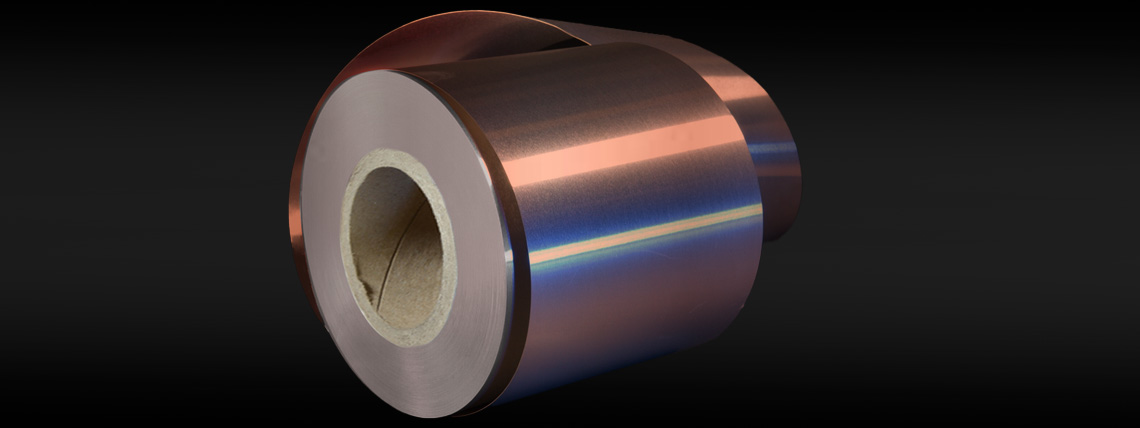

Luoyang Xinzhaoang Aluminum Co., Ltd. has over two decades of specialized expertise in the production and supply of high-precision transformer strip and foil, including both aluminum and copper variants. Our copper sheet coil products are engineered to meet the stringent demands of power transmission, electronics, and high-efficiency transformer applications. Each coil undergoes a rigorous manufacturing process that ensures dimensional accuracy, superior electrical performance, and edge integrity essential for downstream processing and final product reliability.

The core technical parameters of our copper sheet coil are defined by three critical performance indicators: dimensional precision, edge quality, and electrical conductivity. Dimensional control begins with precision slitting, where coil widths are maintained within a tolerance of ±0.002 mm. This level of accuracy is achieved through servo-controlled slitting lines equipped with laser-guided monitoring systems, ensuring consistent width across the entire coil length. Such tight tolerances are essential for automated winding operations in transformer manufacturing, where even minor deviations can lead to core misalignment, increased eddy current losses, or mechanical stress.

Edge quality is equally critical. All copper sheet coils are processed to deliver burr-free edges, with a maximum burr height of ≤0.005 mm. Burr formation is mitigated through optimized tooling geometry, controlled shear clearance, and real-time edge inspection using optical profilometry. Smooth, deburred edges reduce the risk of dielectric breakdown in transformer windings and prevent damage to insulation layers during coiling. Additionally, burr-free edges enhance operator safety and improve handling efficiency in automated production environments.

Electrical conductivity is measured in terms of International Annealed Copper Standard (IACS) percentage. Our copper sheet coils are manufactured from high-purity, oxygen-free copper (OF-Cu, >99.99% Cu), delivering a minimum conductivity of 100% IACS. This ensures optimal current-carrying capacity and minimizes resistive losses in high-frequency and high-current applications. Conductivity is verified through four-point probe resistivity testing at multiple points along the coil to ensure uniformity.

All coils are supplied in annealed (soft) temper unless otherwise specified, providing excellent formability for tight-radius bending and complex shaping operations. Surface finish is maintained to a Ra ≤0.4 µm, free from scratches, pits, or oxidation, ensuring compatibility with varnish impregnation and insulation coating processes.

| Parameter | Specification |

|---|---|

| Material | Oxygen-Free Copper (OF-Cu, >99.99% Cu) |

| Thickness Range | 0.10 mm – 3.00 mm |

| Width Tolerance | ±0.002 mm |

| Burr Height | ≤0.005 mm |

| Electrical Conductivity | ≥100% IACS |

| Temper | Annealed (Soft) or As-Required |

| Surface Roughness (Ra) | ≤0.4 µm |

| Coil Inner Diameter (ID) | 200 mm, 300 mm, 508 mm (customizable) |

| Coil Outer Diameter (OD) | Up to 1200 mm |

| Packaging | Waterproof wrapping, wooden core, steel banding |

These specifications are validated through in-house quality control protocols compliant with ISO 9001 standards, including tensile testing, eddy current inspection, and dimensional metrology. Luoyang Xinzhaohe Aluminum Co., Ltd. supports customization for specialized applications, ensuring technical alignment with client design and performance requirements.

Factory Tour: Manufacturing

Manufacturing Process for High-Precision Copper Sheet Coil

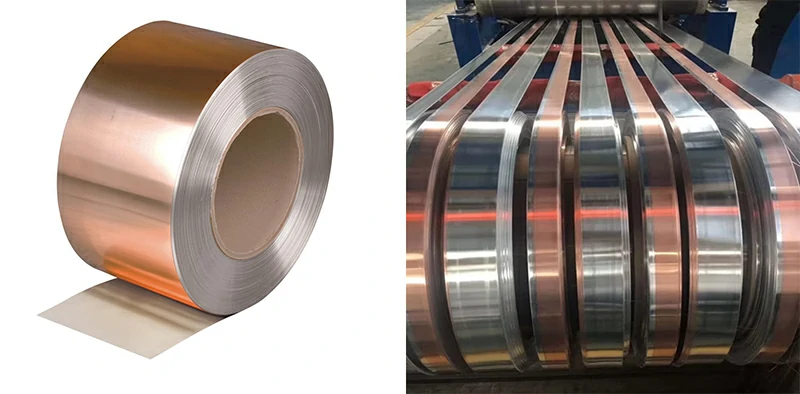

Luoyang Xinzhaohe Aluminum CO.,LTD leverages two decades of metallurgical expertise to produce transformer-grade copper sheet coil through a rigorously controlled sequence. The process begins with cold rolling of electrolytic tough pitch (ETP) copper ingots, typically conforming to ASTM B152 standards. Initial hot-rolled strips undergo multi-stand reversing cold rolling mills, achieving reductions of 85–92% to final thicknesses ranging from 0.10 mm to 0.50 mm. Critical parameters include precise roll gap calibration (±2 µm), interstand tension control (±0.5 MPa), and emulsion-based cooling to maintain surface roughness (Ra) below 0.4 µm. In-process quality control employs real-time X-ray gauges for thickness deviation monitoring and automated optical inspection systems to detect surface defects exceeding 10 µm depth.

Precision slitting follows cold rolling to achieve specified coil widths, typically 50–600 mm for transformer applications. This stage utilizes high-tolerance rotary shear slitters with tungsten carbide knives, maintained at 0.005 mm runout accuracy. Tension is dynamically adjusted via dancer rolls to prevent edge waviness during high-speed operation (up to 800 m/min). Width tolerance is held to ±0.10 mm for widths ≤300 mm and ±0.15 mm for wider formats. Quality verification includes laser micrometer scans across the slit edge every 2 meters and edge profile analysis to ensure straightness deviations remain under 0.5 mm per meter.

Edge conditioning is critical for transformer foil performance, as burrs or microcracks induce electrical arcing. We implement dual-stage mechanical deburring: first with abrasive brushes (grit size 120–180) to remove macroscopic burrs, followed by precision edge rolling to achieve a controlled radius of 20–50 µm. This process eliminates edge defects exceeding 5 µm in height, verified via optical profilometry and particle contamination testing (per ASTM F313). All coils undergo final edge inspection under 50x magnification to confirm absence of micro-tearing.

Integrated quality control spans every phase, with traceability maintained through laser-etched batch codes linking to raw material certificates (including oxygen content ≤0.0005%) and process logs. Final certification includes tensile testing (yield strength 60–110 MPa), electrical conductivity verification (≥100% IACS), and dimensional rechecks per customer specifications. Our facility’s ISO 9001-certified protocols ensure <0.15% defect incidence in shipped material, with statistical process control data provided in material test reports. This end-to-end precision guarantees copper sheet coil meets the stringent demands of transformer winding efficiency and thermal stability.

Packaging & Logistics

Export Packaging Standards for Copper Sheet Coil at Luoyang Xinzhaohe Aluminum Co., Ltd

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer-grade aluminum and copper strip and foil, we maintain rigorous standards in export packaging to ensure product integrity during international transit. Our copper sheet coil packaging system is engineered to withstand the dynamic conditions of sea freight, which remains the primary mode of transport for bulk industrial shipments. The design prioritizes mechanical protection, environmental resistance, and compliance with international logistics protocols.

Each copper sheet coil is mounted on a high-strength wooden pallet constructed from kiln-dried, pest-free hardwood. These pallets are fabricated to support the coil’s full weight—accounting for densities typical of copper alloys—while maintaining dimensional stability under stacking loads in containerized shipping environments. The wooden base is treated in accordance with ISPM 15 regulations to prevent the spread of wood-borne pathogens, ensuring customs clearance across global markets without delays related to phytosanitary non-compliance.

Immediately following coil placement, the entire unit undergoes multi-layer moisture protection. A primary wrap of high-density polyethylene (HDPE) film, minimum 125 microns thick, is applied to form a sealed vapor barrier. This layer prevents ingress of ambient humidity, salt air, and condensation—common risks during prolonged ocean voyages, especially in tropical and coastal regions. Over this, an additional layer of aluminum-laminated moisture-proof film is applied, offering enhanced resistance to water vapor transmission and mechanical abrasion. The film is heat-sealed at all seams to eliminate potential entry points for moisture.

To further secure the load, the wrapped coil is strapped laterally and diagonally using galvanized steel or heavy-duty polyester straps, tensioned to industry-standard specifications. These straps anchor the coil firmly to the pallet, minimizing movement during vessel motion, crane handling, and truck transfers. Edge protectors are installed at critical contact points to prevent deformation of coil edges under strap pressure.

All packaged units are labeled with durable, weather-resistant identification tags containing essential shipment data: coil ID, alloy type, temper, dimensions, net and gross weight, batch number, and handling instructions. These labels are affixed to multiple locations on the pallet to ensure visibility post-transport, even if partial wrapping is compromised.

Our packaging methodology is validated through internal quality audits and real-world performance tracking across key export routes, including Asia-Europe, Trans-Pacific, and Middle East corridors. This systematic approach ensures that copper sheet coils arrive at destination facilities in optimal condition, ready for immediate processing in transformer and electrical component manufacturing lines.

Luoyang Xinzhaohe Aluminum Co., Ltd treats export packaging not as a logistical afterthought, but as an integral component of product quality assurance in the global supply chain.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper Sheet Coil Sourcing

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and supply chain expertise to deliver mission-critical copper sheet coil for transformer and electrical applications. While our corporate name reflects historical focus, our core competency extends definitively to high-purity copper processing, operating as a trusted supplier for demanding global transformer manufacturers requiring stringent material performance. We understand that copper sheet coil for transformer strip and foil represents a foundational element where material consistency directly impacts core efficiency, thermal management, and long-term reliability. Partnering with us mitigates supply risk through vertically integrated process control and deep technical collaboration.

Metallurgical Precision for Transformer Performance

Our copper sheet coil production begins with certified high-conductivity cathode copper, typically exceeding 99.99% Cu+Ag purity. Advanced melting and continuous casting ensure homogeneous chemical composition, critical for minimizing stray losses. We employ proprietary hot and cold rolling sequences with precise temperature and reduction profiling to achieve target mechanical properties and optimal grain structure. This granular control delivers consistent tensile strength, elongation, and crucially, electrical conductivity values meeting or exceeding ASTM B301 and IEC 60138 standards. Surface integrity is paramount; our in-line cleaning, tension leveling, and eddy current testing systems eliminate defects that could initiate partial discharges in transformer windings.

Integrated Production and Quality Assurance

Operating our own dedicated rolling facility provides unparalleled control over the entire value stream. We manage coil processing from slab to final annealed temper with state-of-the-art equipment, including precision thickness gauges and automated width control systems. Every coil undergoes rigorous final inspection per customer specifications, with comprehensive mill test reports documenting chemical analysis, mechanical properties, conductivity, dimensions, and surface quality. Our ISO 9001 certified quality management system integrates statistical process control throughout production, ensuring batch-to-batch repeatability essential for transformer core lamination stacking factors and magnetic performance.

Supply Chain Resilience and Technical Partnership

Beyond manufacturing, we function as a strategic supply chain partner. Our established relationships with primary copper producers secure stable raw material access, while optimized logistics planning minimizes lead time volatility. We maintain strategic inventory buffers for key tempers and gauges to support just-in-time delivery requirements without compromising quality. Crucially, our engineering team collaborates directly with your design and procurement staff to resolve material challenges, provide metallurgical data for qualification, and tailor processing parameters to your specific transformer performance targets. This proactive technical engagement reduces time-to-market and ensures seamless integration of our copper sheet coil into your production flow.

Choosing Luoyang Xinzhaohe means selecting a supplier whose technical depth matches the exacting demands of transformer-grade copper. We deliver not just material, but verified performance, supply assurance, and collaborative engineering support. Contact our technical sales team to discuss your specific copper sheet coil requirements and receive a detailed capability profile.

Initiate your sourcing discussion today. Reach Cathy Zhang, Technical Sales Manager, at cathy@transformerstrip.com for a precise quotation and metallurgical data package.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper sheet coil directly from China.