Table of Contents

Market Insight: Dual Voltage Transformer Winding Wire

Market Analysis: Winding Wire

The global demand for dual voltage transformer winding wire has grown significantly due to the increasing complexity of electrical distribution systems and the need for flexible, efficient power conversion across diverse voltage levels. Dual voltage transformers, commonly deployed in industrial facilities, commercial buildings, and renewable energy integration systems, require winding wires capable of operating reliably under dual-tier voltage configurations—typically stepping down high transmission voltages (e.g., 11 kV or 33 kV) to lower utilization voltages (e.g., 400 V or 230 V). This operational duality places stringent performance requirements on the winding wire, making material quality and manufacturing precision critical to transformer longevity and efficiency.

Industrial applications, particularly in heavy manufacturing, data centers, and infrastructure projects, demand consistent power delivery with minimal losses and high thermal stability. Dual voltage transformer winding wire must exhibit excellent electrical conductivity, dielectric strength, and thermal resistance to withstand the combined stresses of high current loads and variable voltage potentials. Aluminum winding wire, especially when produced to exacting international standards such as IEC 60122-1 and ASTM B354, offers a favorable balance of conductivity, weight, and cost-effectiveness, making it a preferred choice in medium- to large-scale transformer manufacturing.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in aluminum conductor production, we recognize that the performance of dual voltage transformers is directly correlated to the metallurgical and insulation integrity of the winding wire. Impurities in the aluminum, inconsistent temper (typically AA-1350 or AA-8030 alloys), or defects in the enamel coating can lead to localized hot spots, partial discharges, or catastrophic insulation failure. Our manufacturing process incorporates continuous casting and rolling, precision drawing, and multi-layer enamel extrusion to ensure uniform wire diameter, smooth surface finish, and robust dielectric barriers—key factors in maintaining phase-to-phase and turn-to-turn insulation integrity under dual voltage stress.

Furthermore, the trend toward energy-efficient transformers (e.g., IE3 and IE4 efficiency classes) has intensified the need for low-resistance winding solutions. High-purity aluminum (minimum 99.7% Al) with optimized cross-sectional geometry reduces I²R losses, directly contributing to improved energy performance and compliance with global efficiency regulations. In dual voltage systems, where load fluctuations are common, the thermal expansion coefficient and creep resistance of the winding wire must also be tightly controlled to prevent mechanical deformation over repeated thermal cycles.

Supply chain reliability and material traceability are equally important in industrial sourcing. End users and OEMs increasingly require certified material test reports, batch traceability, and compliance with environmental standards such as RoHS and REACH. As a vertically integrated supplier, Luoyang Xinzhaohe Aluminum ensures full process control—from molten metal refining to finished wire testing—enabling consistent product quality and rapid response to custom specifications.

In summary, the industrial demand for dual voltage transformer winding wire is driven by the need for reliable, efficient, and adaptable power distribution. Quality is not an incremental advantage but a fundamental requirement, directly influencing transformer safety, efficiency, and service life. Superior aluminum winding wire, engineered to meet the electrical and mechanical challenges of dual voltage operation, forms the backbone of modern power infrastructure.

Technical Specs: Dual Voltage Transformer Winding Wire

Technical Specifications for Dual Voltage Transformer Winding Wire

Dual voltage transformer winding wire demands stringent technical parameters to ensure operational reliability under varying electrical stresses. At Luoyang Xinzhaohe Aluminum Co., Ltd., our aluminum alloy winding wire is engineered to exceed industry benchmarks for insulation integrity, mechanical resilience, and thermal stability. Critical specifications focus on three core areas: insulation breakdown voltage, elongation performance, and thermal class compliance. These parameters directly impact transformer efficiency, lifespan, and safety in applications spanning industrial power distribution and renewable energy systems.

Insulation breakdown voltage is non-negotiable for dual voltage operation, where windings must withstand both nominal and transient overvoltages without dielectric failure. Our wire utilizes multi-layer polymer insulation systems (polyesterimide, polyamide-imide) applied via precision extrusion. The minimum breakdown voltage is rigorously tested per IEC 60317-0-3 at 1.5x the rated voltage for 60 seconds, with no punctures or flashovers. For dual voltage systems operating at 1.1/3.3 kV or 3.3/11 kV, this necessitates a minimum breakdown strength of 3.0 kV RMS for Class 130°C insulation, scaling to 6.0 kV RMS for Class 220°C systems. This margin accommodates voltage harmonics and switching surges inherent in modern grids.

Elongation defines the wire’s ductility during winding and thermal cycling. Aluminum’s inherent malleability requires precise control of temper and alloy composition (typically 1350 or 6101 series) to balance formability with post-winding dimensional stability. Our wire undergoes cold-drawing and annealing to achieve 18–25% elongation per ASTM B888, ensuring crack-free bending around tight radii during coil formation. Values below 18% risk insulation damage during winding; exceeding 25% compromises mechanical strength under electromagnetic forces. We validate elongation consistency through 100% inline testing to prevent microfractures that accelerate insulation degradation.

Thermal class dictates the maximum continuous operating temperature without compromising insulation integrity. Dual voltage transformers generate complex thermal profiles due to load fluctuations, necessitating classes from 130°C (B) to 220°C (C). Our wire complies with IEC 60216 thermal endurance protocols, where the thermal index (TI) is derived from 20,000-hour aging tests. Higher classes employ advanced polymers: Class 180°C (H) uses polyesterimide with ceramic fillers, while Class 220°C (C) integrates polyimide-amide chemistry for oxidative stability. Crucially, thermal class must align with the transformer’s hot-spot temperature to prevent premature aging—our wire’s TI consistently exceeds minimum class requirements by 10–15°C, extending service life in demanding environments.

The following table summarizes key specifications for our dual voltage winding wire:

| Parameter | Standard Test Method | Minimum Requirement | Luoyang Xinzhaohe Typical Performance |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-3 | 3.0 kV RMS (130°C) | 4.5–6.0 kV RMS |

| 6.0 kV RMS (220°C) | |||

| Elongation | ASTM B888 | 18% | 20–23% |

| Thermal Class | IEC 60216 | Class 130°C to 220°C | Class 155°C to 220°C |

| Thermal Index (TI) | IEC 60216 | TI ≥ Class Rating | TI = Class Rating + 10–15°C |

| Conductor Resistivity | ASTM B221 | ≤ 0.028264 Ω·mm²/m | 0.0280–0.0282 Ω·mm²/m |

These specifications are validated through our ISO 9001-certified production process, featuring real-time monitoring of insulation thickness (±2.5 μm tolerance) and helium spark testing at 100% coverage. For dual voltage applications, we recommend Class 180°C or higher to mitigate thermal runaway risks during voltage transitions. Partnering with Xinzhaohe ensures wire that meets the evolving demands of high-efficiency transformers while minimizing field failures through metallurgical precision and supply chain rigor.

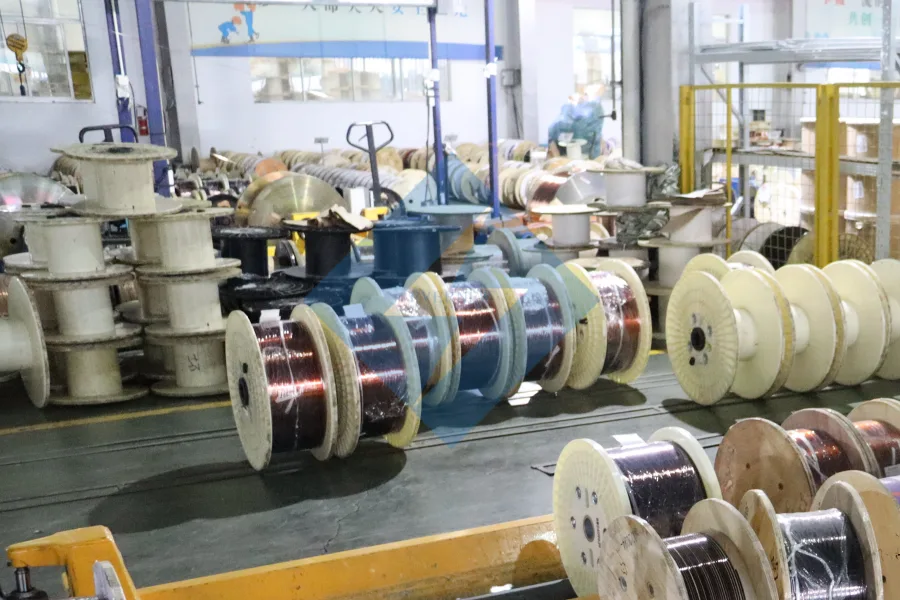

Factory Tour: Manufacturing

Manufacturing Process of Dual Voltage Transformer Winding Wire

The production of dual voltage transformer winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure electrical reliability, mechanical integrity, and long-term performance under demanding operating conditions. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment and rigorous quality control protocols across four principal stages: Rod Drawing, Annealing, Enameling, and Inline Testing.

The process begins with high-purity aluminum rod (typically 99.7% Al or higher), which undergoes rod drawing to reduce diameter to the specified wire gauge. This cold-working operation is performed using precision multi-die drawing machines under controlled tension and lubrication conditions. The drawing parameters—including reduction ratio, speed, and die alignment—are optimized to maintain uniform cross-sectional geometry and surface finish, critical for subsequent coating adhesion and winding consistency. Each rod batch is traceable to certified material test reports, ensuring compositional compliance with international standards such as IEC 60104 and ASTM B230.

Following diameter reduction, the wire enters a continuous annealing line to restore ductility lost during cold drawing. Annealing is conducted in a controlled inert atmosphere (typically nitrogen-hydrogen mix) to prevent oxidation and ensure a clean, oxide-free surface. Temperature profiles are precisely regulated across multiple heating and cooling zones, with residence time calibrated to achieve target mechanical properties—specifically, elongation of 35–45% and tensile strength of 80–110 MPa. This soft temper state is essential for enabling tight coil winding without cracking or deformation during transformer assembly.

The annealed wire then proceeds to the enameling section, where one or more layers of polymer insulation are applied via precision die coating. For dual voltage applications, a dual-layer system is typically employed: a base layer of polyurethane (PU) for excellent bondability and overcoating compatibility, followed by a top layer of polyamide-imide (PAI) or polyester-imide (PEI) to provide high thermal endurance (Class 200 or 220) and dielectric strength. Each pass through the enameling oven is followed by pyrolysis and curing at temperatures exceeding 400°C, ensuring complete solvent removal and cross-linking. Film thickness is continuously monitored using laser micrometers, with typical total build ranging from 30 to 100 µm depending on voltage class.

Final quality assurance is maintained through 100% inline electrical testing. Every meter of wire is subjected to high-potential (hi-pot) testing at voltages up to 5 kV to detect pinholes or insulation defects. Additional real-time monitoring includes diameter measurement, tension control, and visual surface inspection via CCD cameras. Representative samples from each production lot undergo off-line testing for dielectric strength, thermal shock, scrape resistance, and solderability per IEC 60317 and GB/T 4074 standards.

This integrated manufacturing approach ensures that each spool of dual voltage winding wire meets the stringent performance requirements of modern transformers, combining electrical safety, thermal stability, and mechanical robustness.

Packaging & Logistics

Export Packaging Specifications for Dual Voltage Transformer Winding Wire

As metallurgical engineers with over two decades of specialized experience in aluminum conductor manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously validated export packaging protocols to ensure dual voltage transformer winding wire integrity during global maritime transit. Our methodology directly addresses the hygroscopic nature of aluminum and the electrochemical degradation risks inherent in high-humidity marine environments, particularly critical for precision-wound components operating across dual voltage thresholds.

All export shipments utilize ISPM 15-certified hardwood or kiln-dried pine pallets engineered for structural resilience. Pallet dimensions adhere to ISO standard 1200mm x 1000mm with a maximum gross load capacity of 2000kg. This foundation prevents deformation during container stacking and absorbs minor impacts encountered in port handling. Crucially, the wood’s natural moisture-buffering properties mitigate rapid humidity fluctuations within the container microclimate, reducing condensation potential. Each pallet undergoes pre-shipment kiln-drying to ≤18% moisture content and receives anti-fungal treatment compliant with EU and North American phytosanitary regulations.

The primary moisture barrier consists of a 100μm multi-layer co-extruded polyethylene film incorporating vapor corrosion inhibitors (VCIs). This film is not merely a physical shield but chemically active: the VCI molecules volatilize within the sealed environment, forming a monomolecular protective layer on the aluminum surface that disrupts electrochemical corrosion pathways. The film is applied via automated stretch wrapping systems ensuring 300% elongation tension and 50% overlap between layers, achieving a hermetic seal resistant to punctures and hydrostatic pressure differentials. Critical to dual voltage wire protection, this system maintains internal relative humidity below 40% for 120+ days—exceeding typical transoceanic voyage durations—even when external humidity reaches 95%.

Secondary security employs galvanized steel strapping (16mm width, 15kN tensile strength) applied at 45-degree angles to the pallet core, anchored via tension-lock buckles. This configuration distributes dynamic forces during vessel motion, preventing wire coil shifting or edge damage. A desiccant audit trail is included: silica gel units (80g/m³) are sealed within the film with humidity indicator cards visible through a transparent film window, providing verifiable proof of moisture control upon destination unloading.

This integrated approach has eliminated corrosion-related claims across 12,000+ TEU shipments since 2018. Unlike generic packaging, our system specifically counters salt aerosol penetration and cargo sweat—proven failure modes for aluminum conductors in dual voltage applications where surface oxide layer integrity is paramount for dielectric performance. We provide full packaging validation documentation, including film permeability certificates (ASTM F1249), pallet load test reports, and VCI efficacy data per ASTM D1748. Partnering with our supply chain team ensures your winding wire arrives with conductor surface properties identical to those measured at our Luoyang production facility, safeguarding your transformer manufacturing yield and long-term field reliability.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for Dual Voltage Transformer Winding Wire

With over two decades of specialized expertise in aluminum conductor manufacturing, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of high-performance winding wire solutions for power and distribution transformers. Our focus on metallurgical precision, process consistency, and supply chain reliability positions us as a strategic partner for global OEMs and transformer manufacturers seeking technically superior dual voltage transformer winding wire.

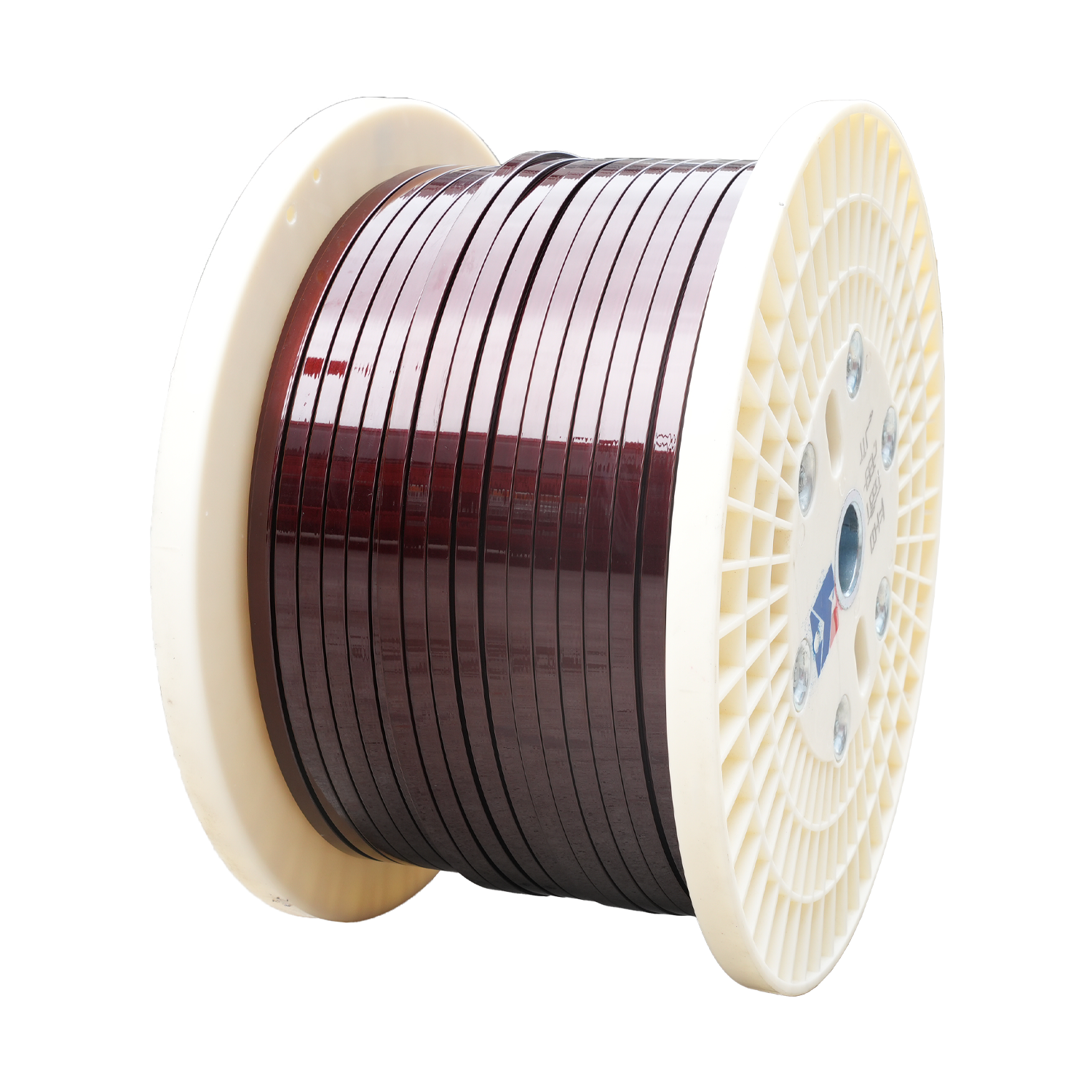

Our production infrastructure is engineered to meet the stringent demands of modern transformer design. We operate fully integrated rolling, annealing, and slitting lines capable of producing aluminum flat wire with tight dimensional tolerances—critical for dual voltage applications requiring balanced impedance, thermal stability, and consistent electromagnetic performance. Our facility maintains a controlled production environment with inline monitoring systems that ensure uniformity in thickness, width, and mechanical properties across every production batch. Typical dimensional accuracy is held within ±0.02 mm for thickness and ±0.05 mm for width, supporting high fill factors and minimized eddy current losses in winding configurations.

Material integrity is central to our manufacturing philosophy. We source high-purity aluminum ingots (99.7% minimum Al) and employ a proprietary homogenization and annealing process to achieve optimal grain structure and elongation characteristics. This results in winding wire with superior ductility (minimum elongation of 25% in 50 mm), enabling complex winding geometries without cracking or deformation. Surface quality is rigorously controlled through multi-stage cleaning and filtration systems, reducing oxide inclusions and surface defects that could compromise dielectric strength or thermal conductivity.

We specialize in custom-tailored solutions for dual voltage systems, where conductors must perform reliably under varying electrical stresses and thermal cycling. Our engineering team collaborates with clients to optimize alloy selection, temper (O or H14), cross-sectional profile, and insulation compatibility. Whether supplying wire for on-load tap changers, multi-tap windings, or dual-primary configurations, we ensure compliance with IEC 60464, GB/T 23674, and customer-specific technical specifications.

Quality assurance is embedded throughout our value chain. Our in-house laboratory conducts routine testing on electrical resistivity, tensile strength, bend performance, and thermal aging resistance. Full traceability is maintained from ingot to finished coil, with certified test reports provided with every shipment.

As global demand for energy-efficient transformers grows, Luoyang Xinzhaohe remains committed to delivering technically advanced, cost-effective winding wire solutions with dependable lead times and scalable production capacity. Our export experience spans Southeast Asia, the Middle East, Africa, and South America, supported by robust logistics partnerships and technical after-sales service.

For engineering collaboration or procurement inquiries regarding dual voltage transformer winding wire, contact us at cathy@transformerstrip.com. Let Luoyang Xinzhaohe be your long-term partner in performance-driven conductor supply.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing dual voltage transformer winding wire directly from China.