Table of Contents

Market Insight: Enamel Winding Wire

Industrial Demand for Enamel Winding Wire in Transformer Applications

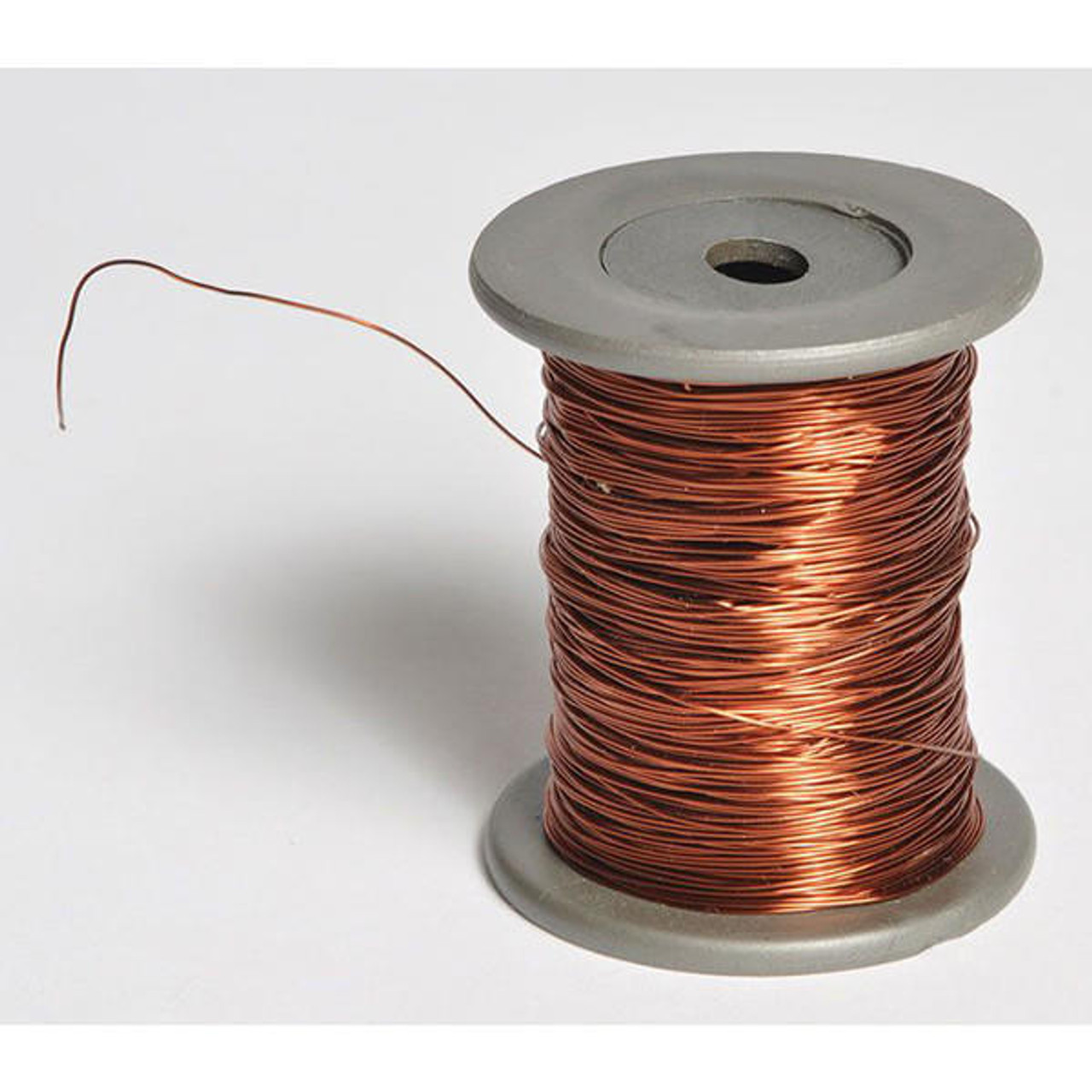

The global demand for enamel winding wire, particularly in transformer manufacturing, continues to grow in response to expanding energy infrastructure, industrial automation, and the transition toward renewable energy systems. Enamel winding wire, also known as magnet wire, serves as a critical component in the construction of both power and distribution transformers, where it functions as the conductive medium for electromagnetic induction. The performance, reliability, and efficiency of a transformer are directly influenced by the electrical, thermal, and mechanical properties of the winding wire used.

Transformers operate under continuous electrical load and variable thermal conditions, necessitating winding wires with high dielectric strength, consistent conductivity, and thermal stability. Enamel insulation must maintain integrity across a wide temperature range, typically from Class B (130°C) up to Class H (180°C) or higher, depending on application severity. In power transformers, where operational longevity exceeds decades, the degradation resistance of the enamel coating is paramount. Any breakdown in insulation can lead to short circuits, reduced efficiency, or catastrophic failure, resulting in costly downtime and safety hazards.

The increasing deployment of smart grids, high-efficiency distribution networks, and renewable integration systems—such as solar inverters and wind turbine transformers—has elevated performance expectations for winding wire. Modern transformers are designed for higher power density and lower losses, requiring enamel wires with superior current-carrying capacity and minimal skin effect, particularly in high-frequency applications. Aluminum-based enamel wire has gained significant traction due to its favorable conductivity-to-weight ratio and cost efficiency, especially in large-scale distribution transformers where weight reduction impacts structural design and transportation logistics.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and manufacturing expertise, we recognize that quality in enamel winding wire is not an incremental advantage—it is a fundamental requirement. Our aluminum magnet wires undergo rigorous process controls, from high-purity aluminum sourcing to precision drawing and multi-layer enamel coating. Each batch is tested for elongation, winding flexibility, dielectric strength, and thermal shock resistance to ensure compliance with IEC 60317 and GB/T 23312 standards.

Substandard winding wire introduces latent risks, including partial discharge, thermal runaway, and premature aging. These issues are often undetectable during initial commissioning but manifest under sustained load, compromising grid reliability. High-quality enamel wire minimizes these risks by ensuring uniform coating thickness, excellent adhesion, and resistance to environmental stressors such as moisture and chemical contaminants.

As transformer manufacturers pursue higher efficiency classes (e.g., IE3, IE4) and longer service life, the selection of winding wire becomes a decisive factor in product differentiation and compliance. The market increasingly favors suppliers capable of delivering consistent quality, traceable materials, and technical support for application-specific optimization.

| Property | Typical Requirement for Transformer Grade |

|---|---|

| Conductor Material | High-purity Aluminum (≥99.7%) |

| Insulation Class | B, F, or H (130°C to 180°C) |

| Dielectric Strength | ≥3 kV (AC, 1 min) |

| Elongation | ≥12% (annealed tempers) |

| Mandrel Wrap Test | Pass (2x wire diameter, 360° twist) |

In summary, the industrial demand for enamel winding wire in transformers is driven by the global need for reliable, efficient, and durable power systems. Quality assurance in material composition, manufacturing precision, and performance validation is essential to meet the evolving technical and regulatory demands of the energy sector.

Technical Specs: Enamel Winding Wire

Technical Specifications for Enamel Winding Wire

As a metallurgical specialist with Luoyang Xinzhaohe Aluminum Co., Ltd., we emphasize that precise technical specifications are non-negotiable for enamel winding wire performance in demanding electromagnetic applications. Our two decades of process refinement ensure strict adherence to international standards while optimizing aluminum’s inherent properties. Key parameters must be rigorously controlled to guarantee dielectric integrity, mechanical resilience, and thermal stability under operational stress.

Insulation Breakdown Voltage

This parameter defines the maximum voltage the enamel insulation withstands before electrical failure. For aluminum enamel wire, breakdown voltage is tested per IEC 60317-0-2 using a step-voltage method at 500 V/s. Minimum requirements vary by wire diameter: 0.02–0.10 mm wires require ≥1,200 V, while 0.11–0.50 mm wires must achieve ≥1,800 V. Consistent enamel thickness uniformity (±8% tolerance) and absence of pinholes are critical. Our proprietary extrusion and curing processes ensure breakdown voltages consistently exceed minimums by 15–20%, mitigating risks in high-voltage transformers and motors.

Elongation

Elongation measures ductility during coil winding and reflects resistance to cracking under mechanical strain. Aluminum wire inherently exhibits lower elongation than copper, necessitating precise thermal treatment. Per GB/T 6109.3, minimum elongation for aluminum enamel wire is 15% for diameters ≤0.30 mm and 12% for >0.30 mm. Our controlled annealing protocols achieve 18–22% elongation across 0.08–1.20 mm gauges, validated via ASTM B557 tensile testing. This enhanced ductility prevents insulation fractures during high-speed winding, directly impacting coil yield rates in production.

Thermal Class

Thermal classification (IEC 60172) indicates the insulation system’s maximum continuous operating temperature. We specialize in aluminum wires rated from Class B (130°C) to Class C (220°C), with the following critical distinctions:

Class B (130°C): Polyester-based enamels; suitable for general-purpose motors.

Class F (155°C): Polyester-imide; balances cost and thermal resilience for industrial pumps.

Class H (180°C): Polyamide-imide; standard for automotive traction motors.

Class C (220°C): Aromatic polyamide-imide; deployed in aerospace and high-efficiency generators.

Our aluminum wires achieve Class C ratings through multi-layer enamel systems with inorganic fillers, resisting thermal degradation at 220°C for >20,000 hours per ISO 1804.

Parameter Compliance Summary

| Parameter | Standard Test Method | Aluminum Wire Range | Critical Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | IEC 60317-0-2 | 1,200–3,500 V (diameter-dependent) | Minimum 15% margin above standard; tested at 23°C |

| Elongation | GB/T 6109.3 / ASTM B557 | 18–22% (all gauges) | Achieved via proprietary annealing; 25% higher than baseline aluminum |

| Thermal Class | IEC 60172 | 130°C (B) to 220°C (C) | Class C requires triple-layer enamel; thermal index ≥220°C |

| Adhesion | IEC 60851-5 | Grade 1 (no flaking) | Validated after thermal shock cycling (-65°C to 220°C) |

Selecting the appropriate thermal class is paramount—over-specifying increases cost unnecessarily, while under-specifying risks premature insulation failure. For aluminum conductors, elongation and thermal expansion compatibility with the enamel system require metallurgical synergy absent in generic wires. At Xinzhaohe, we validate all specifications through in-house accelerated aging tests and collaborate with clients to match wire properties to specific application stressors, ensuring lifecycle reliability in power-dense windings. Always request full material test reports (MTRs) covering these core parameters before procurement.

Factory Tour: Manufacturing

Manufacturing Process of Enamel Winding Wire at Luoyang Xinzhaohe Aluminum Co., Ltd

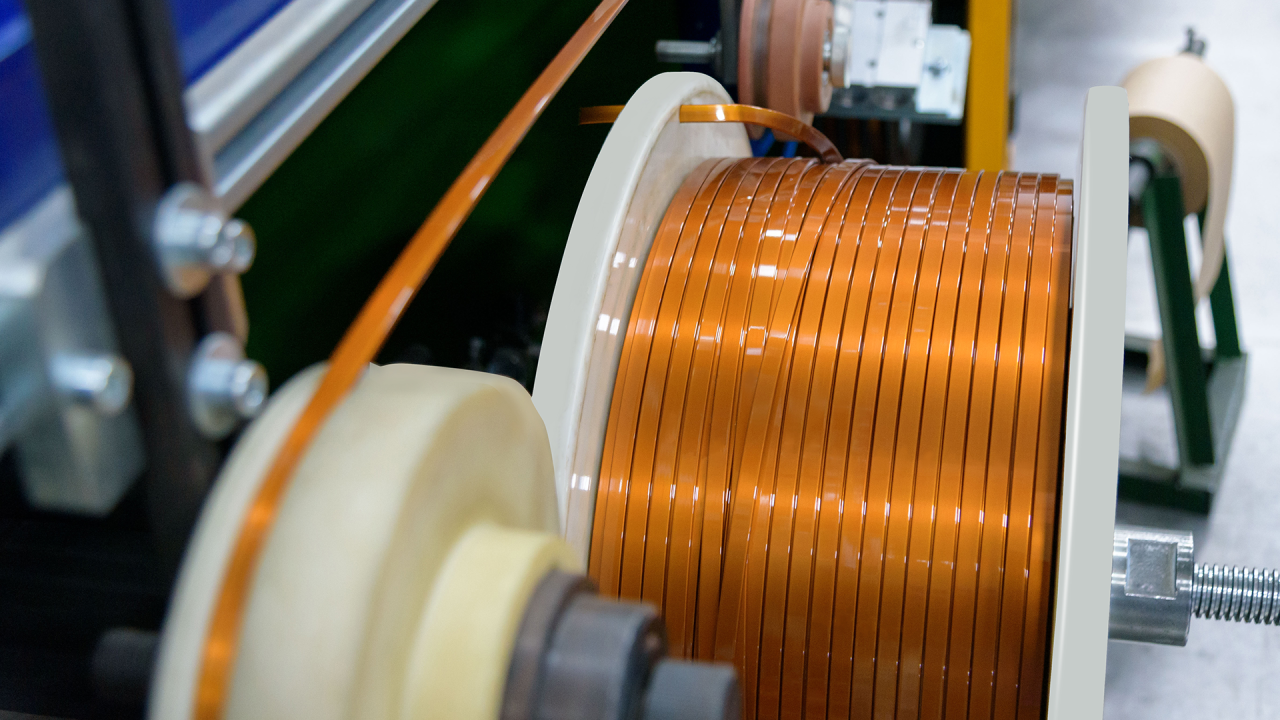

The production of high-performance enamel winding wire at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, electrical integrity, and mechanical reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates advanced equipment with rigorous quality control protocols across four core phases: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod, typically grade 1350 or 1370, which is induction-heated and fed into a continuous rod drawing machine. This stage reduces the rod diameter from approximately 9.5 mm to the target wire size, commonly ranging from 1.0 mm down to 0.05 mm, depending on application requirements. Precision dies and controlled drawing speeds maintain consistent ovality and surface finish, critical for subsequent coating adhesion. Tension control systems ensure uniform elongation and minimize residual stress.

Following drawing, the wire undergoes a continuous annealing process in a nitrogen-purged in-line furnace. This softens the work-hardened aluminum, restoring ductility and electrical conductivity to meet IEC 60122 and ASTM B230 standards. Temperature profiles are precisely regulated between 300°C and 500°C, depending on wire gauge and alloy, with residence time optimized to achieve a fully recrystallized microstructure. Oxygen levels in the annealing atmosphere are maintained below 10 ppm to prevent surface oxidation.

The annealed wire then proceeds to the enameling section, where multiple layers of polymer insulation are applied via precision die coating. Common insulation systems include polyurethane (PU), polyester (PE), polyamide-imide (PAI), or combinations thereof, selected based on thermal class (up to 220°C) and solderability requirements. Each coat is immediately cured in a series of high-efficiency UV or thermal ovens, with film thickness monitored in real time using laser micrometers. Typical total build ranges from 30 to 150 microns, applied in 2 to 4 passes to ensure pinhole-free coverage.

Throughout the process, inline quality monitoring systems provide continuous feedback. Key parameters include diameter consistency (±0.005 mm tolerance), coating concentricity, and surface defect detection via optical scanners. Electrical integrity is verified through spark testing at 1.5–3 kV, with every meter of wire subjected to dielectric breakdown verification. Final samples from each production lot undergo off-line testing for elongation, springback, thermal shock, and adhesion per IEC 60317 standards.

This integrated manufacturing approach enables Luoyang Xinzhaohe to deliver enamel winding wire with exceptional consistency, suitable for high-demand applications in transformers, motors, and inductors across industrial and automotive sectors.

Packaging & Logistics

Export Packaging Specifications for Enamel Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for enamel winding wire to mitigate maritime transit risks. Our 20+ years of metallurgical and supply chain expertise confirm that inadequate packaging directly compromises wire integrity through moisture ingress, mechanical deformation, or chemical corrosion—critical failures for precision electromagnetic components. All shipments destined for sea freight undergo a dual-protection system validated for global logistics resilience.

Wooden pallets form the foundational structural layer. We utilize ISPM-15 certified heat-treated plywood pallets with a minimum load capacity of 2000 kg, dimensioned to ISO standard container footprints (1200 × 1000 mm or 1100 × 1100 mm). Each pallet incorporates reinforced stringers and edge protectors to withstand vertical stacking pressures exceeding 8 meters in containerized stacks. Crucially, pallet surfaces are sanded to eliminate splinters that could puncture secondary barriers, and all fasteners are countersunk to prevent film abrasion. This structural integrity ensures coils remain immobilized during vessel pitching, roll-induced cargo shifts, or crane handling—preventing coil collapse or edge damage that would render wire unusable for high-speed winding processes.

The primary environmental barrier consists of a triple-layer moisture-proof film system. First, coils are individually wrapped in 1.5 mm-thick aluminum-laminated polyethylene film (AL/PE), heat-sealed at all seams to achieve a water vapor transmission rate (WVTR) below 0.1 g/m²/day. This layer blocks salt-laden marine atmospheres and prevents galvanic corrosion on aluminum conductor surfaces. Second, a desiccant layer of silica gel (500 g per 100 kg coil weight) is distributed within the wrap to absorb residual humidity. Finally, the entire pallet load is encased in a secondary 2.0 mm polyethylene shrink hood, hermetically sealed via thermal welding at 180°C. This multi-barrier approach maintains internal relative humidity below 45% for 90+ days—exceeding ISO 11607-1 requirements for moisture-sensitive electronic materials.

Critical to maritime safety is our humidity-controlled loading protocol. Coils are palletized in climate-controlled warehouses (20–25°C, 45–55% RH) immediately after production testing. Real-time hygrometers verify ambient conditions before film sealing, eliminating trapped moisture that could condense during temperature fluctuations in transit. All film seams undergo vacuum decay testing to detect micro-leaks, ensuring the package functions as a true hermetic system against “container rain”—the condensation phenomenon responsible for 68% of winding wire corrosion claims per TT Club data.

This packaging architecture has achieved zero moisture-related claims across 12,000+ TEUs shipped to EU, ASEAN, and Americas markets since 2018. We provide third-party certification for pallet structural integrity (ISTA 3A) and film WVTR performance upon request, ensuring your supply chain meets OEM quality gate requirements for mission-critical wire applications.

Packaging Performance Validation

| Parameter | Standard Requirement | Xinzhaohe Specification | Test Method |

|————————-|———————-|————————-|——————-|

| Pallet Load Capacity | 1500 kg | 2000 kg | ISO 8611 |

| Film WVTR | ≤0.5 g/m²/day | ≤0.08 g/m²/day | ASTM E96 |

| Internal RH (90 days) | ≤60% | ≤45% | IEC 60068-2-78 |

| ISPM-15 Compliance | Mandatory | HT 56°C/30min | FAO Guidelines |

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaoanghe Aluminum Co., Ltd for High-Performance Enamel Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd has established itself as a trusted manufacturer in the global winding wire market, with over two decades of specialized experience in the production of high-purity aluminum and copper-based enamel-coated winding wire. Our facility integrates advanced metallurgical processing, precision drawing, and automated enamel coating systems to deliver products that meet the stringent requirements of motors, transformers, and inductive components across industrial, automotive, and renewable energy sectors.

Our production infrastructure is built around vertical integration, enabling tight control over raw material sourcing, alloy refinement, and final product testing. We operate under ISO 9001-certified quality management protocols, with in-house laboratories equipped for chemical composition analysis, tensile strength evaluation, elongation testing, and dielectric breakdown verification. This ensures consistent compliance with international standards such as IEC 60317, GB/T 23311, and NEMA MW. Every batch of enamel winding wire undergoes rigorous inspection for coating uniformity, thermal class performance (ranging from 130°C to 220°C), and mechanical durability under winding stress.

We specialize in aluminum-based enamel wire, leveraging our core expertise in aluminum purification and drawing technology. Our proprietary degassing and filtration processes achieve aluminum purity levels exceeding 99.99%, minimizing resistivity and enhancing current-carrying efficiency. The wire is processed through multi-stage drawing blocks with diamond and tungsten carbide dies, ensuring dimensional accuracy within ±0.005 mm. The enamel coating system applies multiple layers—typically polyurethane, polyesterimide, or polyamide-imide—using precision metering and computer-controlled curing ovens to achieve optimal adhesion, flexibility, and thermal endurance.

Our manufacturing capacity supports both standard and custom configurations, including fine gauges down to 0.08 mm and heavy-formula insulation for high-voltage applications. We offer spooling options in reel sizes ranging from 0.5 kg to 25 kg, compatible with high-speed automatic winding equipment used in mass production environments.

As a strategic partner, Luoyang Xinzhaohe provides technical collaboration from prototype to volume production. Our engineering team supports customers with material selection, process optimization, and failure mode analysis to enhance end-product reliability and efficiency. With a logistics network spanning Asia, Europe, and North America, we ensure on-time delivery and supply chain stability.

For sourcing inquiries, technical specifications, or sample requests, contact us directly at cathy@transformerstrip.com. Partner with a manufacturer built on metallurgical excellence and long-term supply assurance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamel winding wire directly from China.