Table of Contents

Market Insight: Copper Coil Radiator

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

Global demand for copper coil radiators in power and distribution transformers continues robust growth, driven by expanding electrical infrastructure, renewable energy integration, and grid modernization initiatives. The International Energy Agency (IEA) projects a 4.5 annual increase in global transformer capacity through 2030, directly elevating requirements for high-performance thermal management components. Copper coil radiators remain the dominant solution for critical cooling applications due to copper’s superior thermal conductivity (398 W/m·K versus aluminum’s 237 W/m·K), essential for dissipating heat generated during transformer operation. This thermal efficiency directly impacts transformer lifespan and reliability, particularly under sustained overload conditions common in industrial and utility settings.

The preference for copper in radiator coils stems from its material properties. High-purity electrolytic tough pitch (ETP) copper or oxygen-free electronic (OFE) copper ensures minimal electrical resistance and optimal heat transfer. Even minor deviations in purity—such as oxygen content exceeding 0.04% in OFE grades or trace iron impurities—can create localized hotspots through galvanic corrosion or reduced thermal diffusivity. Dimensional precision is equally critical; coil wall thickness tolerances must adhere to ±0.02 mm per IEC 60137 standards to maintain consistent coolant flow dynamics and structural integrity under thermal cycling. Inadequate tolerances risk turbulent flow, reduced heat exchange efficiency, and accelerated fatigue failure at bend points.

Quality deviations incur severe operational consequences. Substandard copper with inconsistent grain structure exhibits lower creep resistance, leading to coil deformation after repeated thermal expansion cycles. Surface imperfections from improper annealing or handling act as nucleation sites for corrosion when exposed to insulating oils, potentially causing leaks and catastrophic transformer failure. Field data from major utilities indicate that 32% of premature radiator failures correlate directly to material non-conformities in conductivity or mechanical properties. Compliance with ASTM B187 (electrical conductivity ≥100% IACS) and ISO 6892-1 tensile strength specifications (200–240 MPa) is non-negotiable for critical infrastructure applications.

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to address these stringent requirements. While specializing in aluminum transformer strip and foil, our deep understanding of copper’s role in thermal systems informs rigorous quality control protocols applicable across both material streams. We emphasize traceable material certifications, in-process eddy current testing for conductivity verification, and precision coiling techniques to ensure dimensional stability. For copper radiator supply chains, this technical rigor mitigates risks of thermal runaway and extends transformer service life beyond 30 years—proving that material quality is not a cost factor but a fundamental reliability imperative.

| Key Quality Parameter | Critical Threshold | Failure Risk if Non-Compliant |

|---|---|---|

| Electrical Conductivity | ≥100% IACS (ASTM B187) | Hotspot formation, reduced cooling efficiency |

| Wall Thickness Tolerance | ±0.02 mm | Turbulent flow, structural fatigue |

| Oxygen Content (OFE) | ≤0.003% | Hydrogen embrittlement, porosity |

| Tensile Strength | 200–240 MPa (ISO 6892-1) | Deformation under thermal cycling |

Investing in certified copper coil radiators with verifiable material properties directly correlates with reduced lifecycle costs and grid resilience. As transformer loading demands intensify, metallurgical precision becomes the cornerstone of sustainable energy infrastructure.

Technical Specs: Copper Coil Radiator

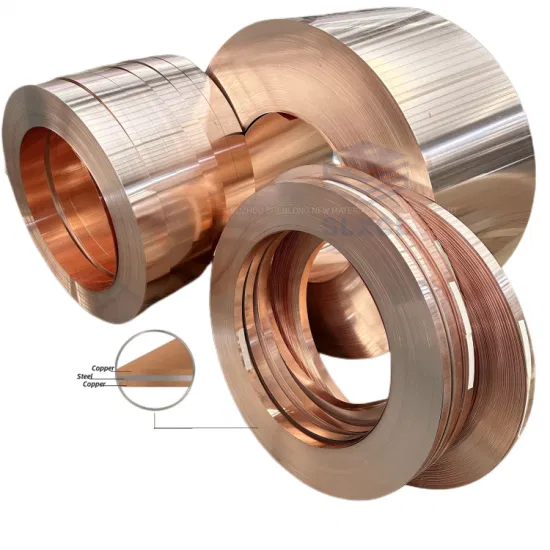

Technical Specifications for Copper Coil Radiator – Precision Performance for High-Efficiency Thermal Systems

Luoyang Xinzhaohe Aluminum Co., Ltd. leverages over two decades of metallurgical and precision processing expertise to deliver high-performance copper coil radiators tailored for advanced thermal management applications, particularly within power transformers and high-current electrical systems. Our copper coil radiators are engineered to meet stringent industrial standards, ensuring optimal heat dissipation, structural integrity, and long-term reliability under continuous operational loads. The technical parameters detailed below reflect our commitment to dimensional accuracy, material purity, and edge quality—critical factors influencing both performance and system safety.

Precision slitting is a core manufacturing process in the production of copper coil radiators, directly impacting fit, thermal contact efficiency, and electromagnetic compatibility. Our advanced slitting lines maintain a tolerance of ±0.002 mm across coil widths, ensuring uniformity and repeatability in high-volume production runs. This level of dimensional control is essential for maintaining consistent coil spacing and minimizing hot spots in transformer cooling assemblies. The slit edges are subjected to a proprietary deburring process, resulting in burr-free surfaces with edge roughness values consistently below 1.6 µm Ra. This eliminates the risk of localized arcing, insulation damage, or mechanical interference during coil winding and core assembly.

Material conductivity is a defining characteristic of copper used in radiator applications. Our electrolytic tough pitch (ETP) copper (Cu-ETP, C11000) achieves a minimum conductivity of 100% IACS (International Annealed Copper Standard) at 20°C, ensuring minimal resistive losses and efficient heat transfer. The copper is sourced from certified refineries and undergoes rigorous in-house testing via eddy current and four-point probe methods to validate conductivity and detect inhomogeneities. All coils are supplied in a fully annealed (soft) temper condition to enhance formability and thermal cycling resilience.

Surface quality is maintained through controlled atmosphere annealing and precision cleaning, resulting in oxide-minimized, contaminant-free surfaces suitable for direct integration into transformer windings. Coils are available in standard widths ranging from 10 mm to 150 mm, with thicknesses from 0.1 mm to 3.0 mm, and delivered in continuous lengths up to 500 meters per spool. Each batch is traceable via mill test certificates (MTCs) compliant with ASTM B152 and IEC 60137 standards.

| Parameter | Specification |

|---|---|

| Material | Cu-ETP (C11000) |

| Conductivity | ≥100% IACS at 20°C |

| Thickness Tolerance | ±0.002 mm |

| Width Tolerance | ±0.002 mm |

| Edge Quality | Burr-free, Ra ≤1.6 µm |

| Temper | O5 (Fully Annealed) |

| Surface Condition | Clean, oxide-controlled, no laminations |

| Standard Compliance | ASTM B152, IEC 60137 |

| Coil Length Range | 350–500 meters (customizable) |

| Packaging | Vacuum-sealed with desiccant, wooden spool |

All copper coil radiators are subject to 100% inline eddy current inspection and batch-based mechanical and electrical testing. Luoyang Xinzhaohe Aluminum Co., Ltd. ensures that every product meets the precision and reliability demands of modern power infrastructure.

Factory Tour: Manufacturing

Manufacturing Process for Copper Coil Radiator Stock

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages 20+ years of metallurgical expertise to produce precision copper coil radiator stock, adhering to stringent thermal and electrical performance requirements. Our integrated production sequence ensures dimensional stability, surface integrity, and metallurgical consistency critical for high-efficiency heat exchangers. The process commences with Cold Rolling, where electrolytic tough pitch (ETP) copper ingots undergo multi-stand rolling at controlled temperatures below recrystallization thresholds. This stage eliminates residual stresses from casting while optimizing grain structure for enhanced thermal conductivity and formability. Critical parameters—including roll gap tolerances (±0.005 mm), interstand tension control, and lubricant viscosity—are monitored via inline laser profilometers to achieve target thicknesses (0.1–3.0 mm) with flatness deviations < 5 I-Units. Surface roughness is maintained at Ra 0.2–0.8 μm to ensure uniform brazing adhesion in subsequent radiator assembly.

Following cold rolling, coils enter Precision Slitting for width conversion. Utilizing servo-driven rotary shear lines with tungsten carbide blades, we achieve slit widths from 10 mm to 1,200 mm at tolerances of ±0.05 mm. Blade clearance is dynamically adjusted based on material hardness (typically 60–90 HV for ETP copper) to prevent edge burrs exceeding 0.02 mm—critical for preventing fin punctures during radiator core stacking. Real-time vision systems inspect edge squareness (±0.1°) and detect micro-tears, triggering automatic blade recalibration to sustain edge quality.

The final stage, Edge Conditioning, addresses micro-defects introduced during slitting. Coils pass through abrasive brushing and precision deburring units where controlled contact pressure removes residual burrs while preserving edge radius consistency (0.05–0.15 mm). This step is vital for eliminating stress concentration points that could initiate fatigue cracks under thermal cycling. Edge profiles are validated via optical metrology, ensuring radii fall within customer-specified ranges to facilitate smooth coil handling in automated radiator production lines.

Quality Control Integration

QC protocols are embedded at each phase to guarantee compliance with ASTM B152 and EN 13601 standards. Key verification steps include:

| Process Stage | Inspection Parameter | Method | Acceptance Criterion |

|---|---|---|---|

| Cold Rolling | Thickness Profile | Laser micrometer array | ±0.01 mm over 1,000 mm width |

| Precision Slitting | Edge Burr Height | Optical comparator | ≤ 0.02 mm |

| Edge Conditioning | Edge Radius | 3D profilometry | 0.05–0.15 mm (as specified) |

| Final Coil | Electrical Conductivity | Eddy current testing | ≥ 100% IACS |

Full-coil eddy current testing screens for subsurface inclusions, while tensile samples from tail ends verify mechanical properties (yield strength 60–120 MPa, elongation > 40%). All data is logged in our ERP system for traceability, supporting ISO 9001-certified documentation. This end-to-end control ensures copper coil radiator stock meets the thermal cycling durability and brazing reliability demanded by automotive and industrial HVAC applications, minimizing field failures and optimizing supply chain continuity for global OEMs.

Packaging & Logistics

Export Packaging for Copper Coil Radiator Components

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized experience in the production and export of transformer strip and foil—both aluminum and copper—we adhere to stringent international packaging standards to ensure product integrity during global logistics. The export packaging of copper coil radiators and related components is a critical phase in the supply chain, designed to withstand the rigors of sea freight, which remains the primary mode of transportation for bulk industrial shipments.

All copper coil radiators and associated strip/foil products are prepared for export using a robust, multi-layer packaging system centered on wooden pallets and high-grade moisture-proof film. The wooden pallets utilized meet ISPM 15 (International Standards for Phytosanitary Measures No. 15) requirements, ensuring compliance with global customs and biosecurity regulations. These pallets are constructed from kiln-dried, heat-treated hardwood, providing structural stability and resistance to mechanical stress during loading, unloading, and long-distance transit. The dimensions and load-bearing capacity of the pallets are engineered to match the weight and geometry of the copper coils, minimizing movement and preventing deformation.

Each copper coil is individually wrapped with industrial-grade moisture-proof film, typically composed of multi-layer co-extruded polyethylene with an embedded aluminum barrier. This film provides a hermetic seal against humidity, salt air, and condensation—common challenges in maritime transport, especially across tropical and coastal routes. The wrapping process is performed in a controlled environment to prevent surface oxidation and contamination, preserving the metallurgical surface quality essential for downstream applications in transformer and radiator manufacturing.

Following encapsulation, the coils are secured to the pallet using galvanized steel strapping and corner protectors to distribute tension and prevent edge damage. Additional protection is achieved through the use of edge boards and top covers made from corrugated fiberboard or plywood, depending on coil size and shipment configuration. For high-value or long-haul shipments, desiccant packs are placed within the sealed film layer to actively absorb residual moisture and maintain a stable internal microclimate.

Our packaging protocol is validated through internal drop, tilt, and vibration testing, simulating real-world sea freight conditions. This ensures that the packaged copper coils can endure stacking pressures in container holds, transshipment handling, and extended voyages without compromise. Furthermore, all export packages are clearly labeled with product specifications, handling instructions, batch numbers, and barcodes to facilitate traceability and customs clearance.

By integrating engineering precision with logistics expertise, Luoyang Xinzhaohe Aluminum Co., Ltd. guarantees that every copper coil radiator component arrives at its destination in optimal condition, ready for immediate integration into high-performance electrical systems.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Copper and Aluminum Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver critical aluminum and copper strip and foil solutions for demanding electrical applications, including copper coil radiators. Our deep understanding of the interplay between material properties, manufacturing processes, and end-use performance in thermal management systems positions us as a strategic partner for B2B sourcing. We focus exclusively on producing high-purity, dimensionally stable strip and foil meeting stringent transformer and radiator specifications, ensuring optimal thermal conductivity, formability, and long-term reliability under operational stress.

Our integrated production facility combines advanced melting and casting with precision cold rolling, heat treatment, and slitting capabilities under rigorous process control. This vertical integration, managed by experienced metallurgical engineers, guarantees consistent microstructure and mechanical properties essential for radiator coil integrity. We utilize high-conductivity electrolytic tough pitch (ETP) copper (C11000) and select aluminum alloys, processed to achieve the exact grain structure, surface finish, and edge quality required for seamless coil winding and brazing. Critical parameters such as thickness tolerance, flatness, and residual stress are meticulously controlled to prevent deformation during radiator assembly and operation, directly impacting thermal efficiency and lifespan.

Production Capability Overview

| Parameter | Copper Strip/Foil Range | Aluminum Strip/Foil Range | Key Standard Compliance |

|——————–|————————-|—————————|————————-|

| Annual Capacity | 8,000 MT | 12,000 MT | IEC 60138, ASTM B1, GB/T 5584 |

| Thickness Range | 0.10 mm – 3.00 mm | 0.10 mm – 6.00 mm | Tight tolerances ±0.005 mm achievable |

| Width Range | 50 mm – 1,250 mm | 50 mm – 1,650 mm | Custom slit widths per drawing |

| Core ID | 508 mm, 610 mm | 508 mm, 610 mm | Standard and custom options |

| Key Attributes | High conductivity >98% IACS, Low oxygen content, Excellent edge condition | High purity, Controlled temper, Superior surface cleanliness | ISO 9001:2015 certified processes |

Quality assurance is embedded at every stage, from raw material verification through in-process testing to final inspection. Our laboratory employs spectrographic analysis, tensile testing, conductivity measurement, surface profilometry, and eddy current testing to validate conformance to customer specifications and international standards. This systematic approach minimizes defects such as surface scratches, edge burrs, or thickness variations that could compromise radiator coil performance or cause leaks. Our supply chain infrastructure is optimized for just-in-time delivery of engineered materials, featuring robust inventory management, dedicated logistics coordination, and proactive risk mitigation strategies to ensure supply continuity for your production schedules.

Partnering with Luoyang Xinzhaohe provides access to a reliable source of technically superior strip and foil, backed by metallurgical insight and responsive engineering support. We collaborate closely with radiator manufacturers to understand specific application challenges and tailor material solutions. Initiate a technical consultation to optimize your copper coil radiator material sourcing. Contact Cathy Zhang, International Sales Manager, directly at cathy@transformerstrip.com to discuss your specifications and secure a competitive quotation based on proven manufacturing excellence.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper coil radiator directly from China.