Table of Contents

Market Insight: Copper Foil Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

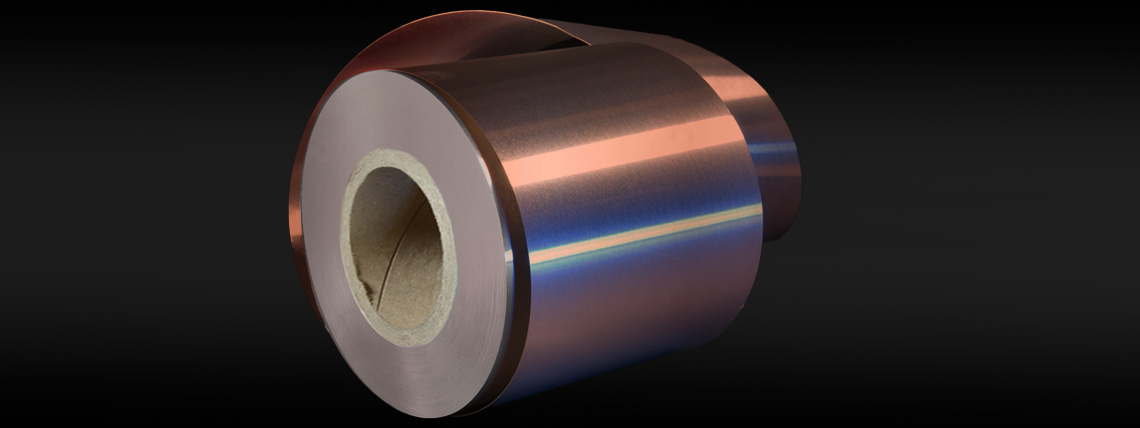

The global demand for copper foil strip in transformer manufacturing continues to grow, driven by the expansion of power infrastructure, renewable energy integration, and the increasing need for high-efficiency electrical distribution systems. Copper foil strip, characterized by its high electrical conductivity, thermal stability, and mechanical formability, remains a critical material in the construction of low-voltage and medium-voltage transformers, particularly in wound-core and shell-type designs. Its use is predominant in applications where minimal resistive losses and reliable long-term performance are paramount.

Copper’s intrinsic properties make it especially suitable for transformer windings, where energy efficiency directly correlates with material purity and dimensional consistency. A typical copper foil strip used in transformers ranges from 0.05 mm to 3.0 mm in thickness, with widths varying between 10 mm and 300 mm, depending on design specifications. The material must meet stringent international standards such as IEC 60137, ASTM B152, and GB/T 14594, ensuring uniform conductivity (minimum 98% IACS), tight thickness tolerances (±0.01 mm), and surface integrity free from scratches, oxidation, or edge defects.

Industrial demand for high-quality copper foil strip is further amplified by regulatory trends promoting energy-efficient transformers. Programs such as the DOE 2016 efficiency mandates in the U.S. and the European Ecodesign Directive have pushed manufacturers to adopt premium-grade conductive materials that minimize no-load and load losses. In this context, copper foil strip outperforms alternatives due to its superior current-carrying capacity and thermal dissipation characteristics. Additionally, its compatibility with vacuum pressure impregnation (VPI) processes and resin-based insulation systems enhances the reliability of dry-type transformers used in urban substations, data centers, and industrial facilities.

Quality control in copper foil strip production is non-negotiable. Variations in thickness, edge burrs, or surface contamination can lead to localized hotspots, insulation breakdown, or premature transformer failure. At Luoyang Xinzhaohe Aluminum Co., Ltd, we apply rigorous in-line monitoring, including laser micrometry, eddy current testing, and tensile strength validation, to ensure every coil meets the exacting demands of transformer OEMs. Our production process emphasizes oxygen-free copper (OFC) with grain structure optimization to enhance flexibility during winding and reduce micro-cracking under thermal cycling.

While aluminum foil strip is increasingly used as a cost-effective alternative in certain applications, copper remains the material of choice for high-performance and mission-critical transformer systems. The initial material cost is offset by reduced lifecycle losses, higher durability, and compliance with evolving energy standards. As global electrification accelerates, the demand for precision-engineered copper foil strip will remain robust, particularly in markets prioritizing grid resilience, sustainability, and operational efficiency.

| Parameter | Typical Specification for Copper Foil Strip |

|---|---|

| Material Purity | ≥ 99.95% Cu (OFC) |

| Conductivity | ≥ 98% IACS |

| Thickness Range | 0.05 – 3.0 mm |

| Thickness Tolerance | ±0.01 mm |

| Tensile Strength | 200 – 250 MPa |

| Elongation | ≥ 5% |

| Surface Finish | Clean, oxide-free, no edge burrs |

| Standards Compliance | IEC 60137, ASTM B152, GB/T 14594 |

In summary, copper foil strip is a foundational element in modern transformer design, where performance, safety, and efficiency are interdependent. Consistent material quality is not merely a production requirement—it is a determinant of system reliability and energy sustainability.

Technical Specs: Copper Foil Strip

Technical Specifications for Copper Foil Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd leverages its 20+ years of precision metal processing expertise to deliver copper foil strip meeting the stringent demands of modern transformer and inductor manufacturing. While aluminum strip remains our core heritage, our copper foil strip production adheres to equally rigorous metallurgical and dimensional control standards essential for high-efficiency electromagnetic components. Critical performance parameters are meticulously controlled to ensure optimal electrical performance, winding integrity, and long-term reliability in demanding power applications.

Precision slitting accuracy is paramount for consistent coil layering and minimizing air gaps within transformer windings. Our copper foil strip achieves a width tolerance of ±0.002 mm across the full production run. This exceptional dimensional fidelity is maintained through state-of-the-art tension control systems, high-precision German-engineered slitting lines equipped with laser micrometer feedback loops, and rigorous environmental controls within the slitting facility. Consistent width directly impacts magnetic flux distribution and core losses; deviations beyond this tolerance can induce localized eddy currents and thermal hotspots, compromising transformer efficiency and lifespan.

Edge quality is non-negotiable for dielectric integrity. All copper foil strip undergoes mandatory burr inspection and removal processes, guaranteeing burr-free edges with a maximum height of 5 micrometers (μm). This is verified using optical profilometry and high-magnification edge scanning. Microscopic burrs act as stress concentrators for insulation materials, significantly increasing the risk of partial discharge initiation and eventual insulation breakdown under operational voltage stress. Our proprietary edge conditioning techniques ensure smooth, clean edges that preserve the integrity of adjacent insulation layers during high-speed winding operations.

Electrical conductivity is fundamental to minimizing resistive losses. Our copper foil strip is manufactured from high-purity Electrolytic Tough Pitch (ETP) copper (C11000), achieving a minimum conductivity of 100.5% IACS at 20°C, consistently exceeding the ASTM B152 standard minimum of 100% IACS. This high conductivity is achieved through strict control of oxygen content (0.02-0.04%) and meticulous elimination of trace impurities during melting and casting. Superior conductivity directly translates to lower operating temperatures and higher energy efficiency in the final transformer assembly. Surface roughness (Ra) is maintained below 0.4 μm to ensure uniform contact pressure and minimize interfacial resistance in wound coils.

The following table details the comprehensive technical parameters guaranteed for our transformer-grade copper foil strip:

| Parameter | Specification | Test Standard | Measurement Method |

|---|---|---|---|

| Material | ETP Copper (C11000) | ASTM B152 | Spectrographic Analysis |

| Thickness Range | 0.05 mm – 0.50 mm | ASTM E29 | Micrometer (100% Inline) |

| Width Tolerance | ±0.002 mm | ASTM E29 | Laser Micrometer (100% Inline) |

| Edge Burr Height | ≤ 5 μm | IPC-TM-650 2.2.14 | Optical Profilometry |

| Conductivity (20°C) | ≥ 100.5% IACS | ASTM E1004 | Eddy Current Tester |

| Tensile Strength | 200 – 250 MPa | ASTM E8 | Universal Tester |

| Elongation | ≥ 5% | ASTM E8 | Universal Tester |

| Surface Roughness (Ra) | ≤ 0.4 μm | ISO 4287 | Stylus Profilometer |

| Flatness | ≤ 3 mm/m | Custom Gauge | Optical Flatness Measurement |

All parameters are subject to 100% inline dimensional verification during slitting and rigorous batch testing in our accredited in-house laboratory. This commitment to precision engineering ensures our copper foil strip provides the foundational quality required for high-performance, reliable transformer cores in critical power infrastructure.

Factory Tour: Manufacturing

Manufacturing Process of Copper Foil Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of copper foil strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, mechanical consistency, and surface integrity required for high-performance applications in transformers, inductors, and power electronics. With over two decades of expertise in non-ferrous strip processing, our facility integrates advanced cold rolling technology with precision slitting and edge conditioning to deliver copper foil strip products meeting international quality standards.

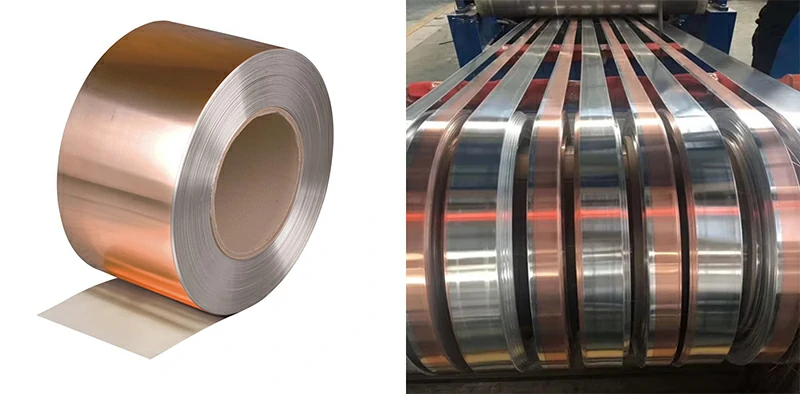

The process begins with high-conductivity electrolytic tough pitch (ETP) copper in the form of hot-rolled coils, typically starting at thicknesses between 6–10 mm. These coils undergo surface cleaning and inspection before being fed into our fully automated cold rolling mills. Cold rolling is performed under controlled temperature and tension conditions to progressively reduce the material thickness to the final specified gauge, which can range from 0.05 mm to 3.0 mm depending on customer requirements. This stage is critical for achieving the desired mechanical properties, including tensile strength and elongation, while maintaining uniform thickness tolerance within ±0.01 mm. The rolling mills are equipped with laser micrometers and automated feedback systems to continuously monitor strip thickness and adjust roll gap in real time.

Upon completion of cold rolling, the copper strip is rewound and transferred to our precision slitting lines. Here, the master coils are slit into narrower widths using high-precision circular knives with micron-level alignment control. Slit widths can be customized from 10 mm to 500 mm, with edge deviation maintained below ±0.1 mm. The slitting process is optimized to minimize burr formation and edge distortion, which is essential for downstream winding and insulation processes in transformer manufacturing.

Following slitting, all copper foil strips undergo edge conditioning. This step involves controlled edge rolling or brushing to remove micro-burrs and smooth the longitudinal edges. Smooth edges reduce the risk of dielectric breakdown in wound components and enhance handling safety. The conditioned strips are then tension-levelled to eliminate coil set and crossbow, ensuring flatness suitable for automated winding equipment.

Quality control is embedded throughout the production chain. In-process inspections include eddy current testing for subsurface defects, surface roughness measurement via profilometry, and periodic tensile and hardness testing. Final coils are subjected to 100% visual surface inspection under angled lighting to detect scratches, pits, or oxidation. Each batch is accompanied by a material test report (MTR) verifying chemical composition, mechanical properties, and dimensional conformance to ASTM B152 and IEC 60140 standards.

This integrated approach ensures that every copper foil strip produced at Luoyang Xinzhaohe meets the rigorous demands of modern electrical engineering applications.

Packaging & Logistics

Export Packaging Specifications for Copper Foil Strip: Ensuring Integrity in Global Logistics

At Luoyang Xinzhaohe Aluminum CO., Ltd., with over two decades of specialized production and export experience in high-precision transformer strip and foil, we recognize that packaging is not merely a container but a critical engineering component safeguarding product integrity throughout the complex sea freight cycle. Copper foil strip, due to its extreme thinness, high surface area-to-volume ratio, and susceptibility to oxidation and mechanical damage, demands packaging engineered specifically for the harsh realities of maritime transport. Our standardized export protocol is rigorously designed to mitigate the primary threats: moisture ingress, salt air exposure, physical impact, and vibration-induced coil deformation.

All copper foil strip shipments originate on robust, kiln-dried wooden pallets meeting ISPM-15 international phytosanitary standards. These pallets utilize hardwood components with a verified moisture content consistently below 12%, preventing internal condensation and microbial growth within the load. Pallet dimensions are precisely calculated to maximize container cubic utilization while ensuring structural stability under dynamic load conditions; standard configurations support coil weights up to 5,000 kg without deflection. Coils are securely strapped to the pallet base using high-tensile steel or polyester banding, with tension calibrated to prevent slippage during transit without inducing edge damage or core distortion. Critical edge protection is applied using custom-molded polyethylene corner guards, absorbing impact energy during handling and preventing the “telescoping” of coil layers.

The primary moisture barrier is a multi-layer, co-extruded polyethylene film system. This is not a simple plastic wrap but a sophisticated vapor barrier film with a certified water vapor transmission rate (WVTR) of ≤ 0.5 g/m²/24hr at 38°C and 90% RH, per ASTM E96. The film is applied under controlled tension using automated wrapping systems, ensuring complete, seamless coverage with a minimum of six overlapping layers across all coil surfaces and edges. A desiccant package, rated for the specific coil volume and anticipated voyage duration (typically 60-90 days), is hermetically sealed within the innermost film layer. This dual defense—high-performance film combined with targeted moisture absorption—creates a microclimate that actively combats “container rain” and prevents electrochemical degradation of the copper surface. All film seams are thermally sealed to eliminate potential ingress points.

Final external protection involves a heavy-duty, UV-stabilized polyethylene cover secured over the entire palletized load, providing an additional layer against weather exposure during port handling and storage. Pallets are clearly labeled with humidity indicator cards, handling instructions per ISO 780, and critical shipment data. This integrated packaging system, validated through accelerated salt spray and humidity chamber testing simulating 120-day voyages, ensures copper foil arrives at destination facilities with surface cleanliness and dimensional stability fully compliant with IEC 60140 specifications for transformer windings. We document all packaging parameters within the shipment’s quality dossier, providing traceability and assurance that the material’s critical electrical properties remain uncompromised from factory to fabrication line. Safe sea freight for copper foil is an engineering discipline; our packaging embodies this principle.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum Co., Ltd for Precision Copper Foil Strip Solutions

With over two decades of specialized expertise in the production of transformer-grade metal strips, Luoyang Xinzhaohe Aluminum Co., Ltd stands as a trusted manufacturer of high-performance copper foil strip and aluminum strip products for critical electrical applications. Our vertically integrated production facility in Luoyang, China, combines advanced metallurgical engineering with stringent quality control to deliver materials that meet the demanding requirements of power transformers, reactors, and high-efficiency electrical systems.

Our manufacturing infrastructure is built around precision rolling technology, enabling us to produce copper foil strip with tight dimensional tolerances, exceptional surface finish, and consistent mechanical properties. We offer copper foil strip in a full range of tempers (soft, 1/4 hard, 1/2 hard, full hard), thicknesses from 0.1 mm to 3.0 mm, and widths up to 300 mm, customizable to customer specifications. All material is produced under controlled atmospheric conditions to minimize oxidation and ensure high conductivity, with typical resistivity values conforming to GB/T 5584.1 and IEC 60464 standards.

Material traceability and process control are central to our production philosophy. Each batch of copper foil strip undergoes comprehensive testing, including tensile strength, elongation, bend testing, and surface defect inspection, performed in our on-site laboratory equipped with OES, universal testing machines, and profilometers. Our quality management system is certified to ISO 9001:2015, ensuring repeatability and compliance across all production runs.

In addition to copper foil strip, we maintain parallel production lines for aluminum transformer strip, allowing us to serve clients with dual-material requirements from a single source. Our annual production capacity exceeds 15,000 metric tons, supported by automated slitting, edging, and recoiling lines that ensure high throughput without compromising precision.

We specialize in direct collaboration with transformer OEMs, winding contractors, and electrical component suppliers across Asia, Europe, and the Americas. Our technical team provides material selection support, custom packaging solutions (including wooden reels and moisture-resistant wrapping), and logistics coordination to ensure on-time delivery under Incoterms 2020.

As the global demand for efficient, reliable power systems grows, the integrity of conductive materials becomes increasingly critical. At Luoyang Xinzhaohe, we are committed to delivering copper foil strip that meets the highest industrial standards, backed by technical expertise and responsive customer service.

For sourcing inquiries, technical data sheets, or sample requests, contact us at cathy@transformerstrip.com. Partner with a manufacturer that combines metallurgical precision with supply chain reliability.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper foil strip directly from China.