Table of Contents

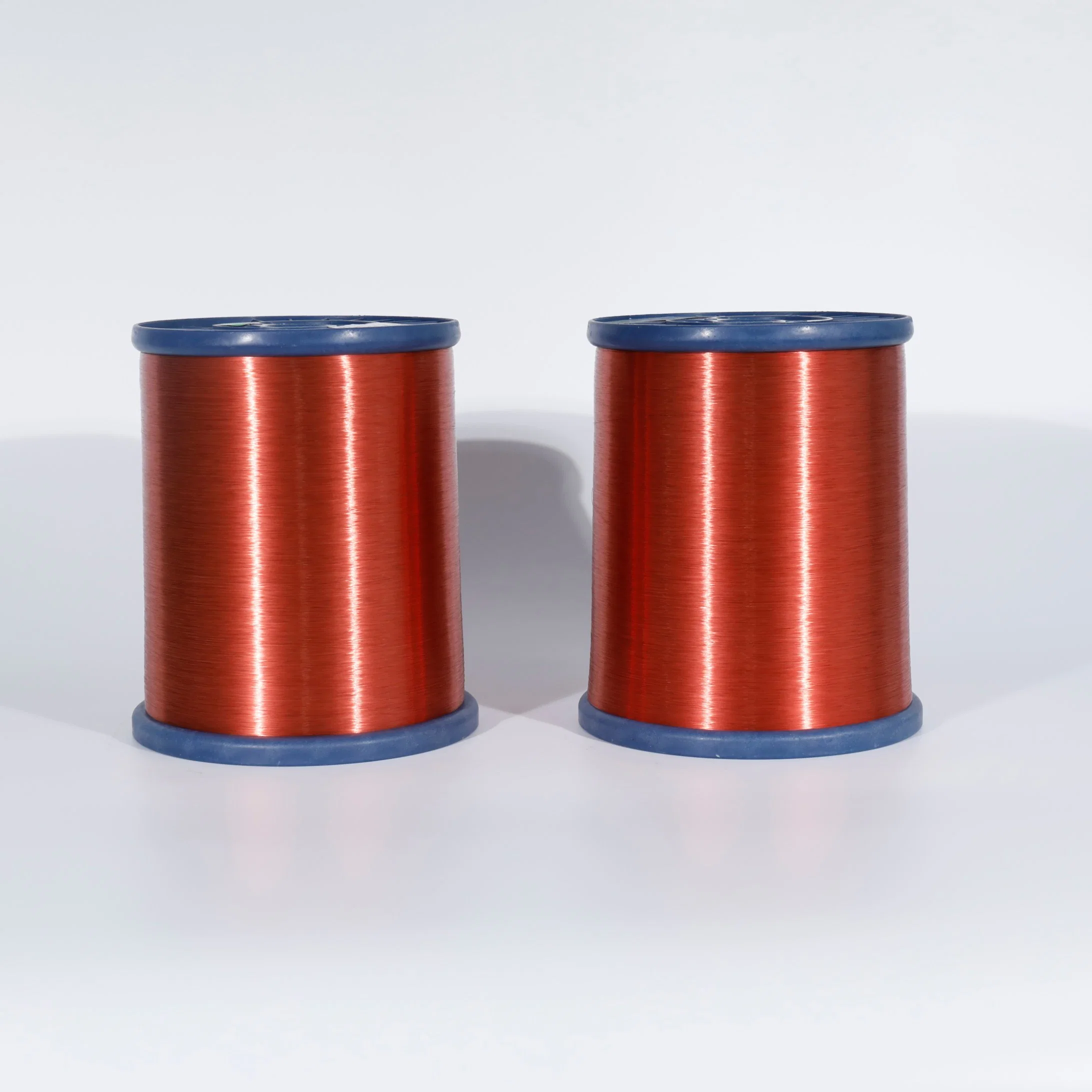

Market Insight: Enamelled Round Copper Wire

Market Demand Drivers for Enamelled Round Copper Wire in Transformers

Global demand for high-performance enamelled round copper wire in power and distribution transformers continues to expand, driven by critical infrastructure modernization, renewable energy integration, and stringent energy efficiency regulations. The transition toward ultra-low-loss transformers under standards like IEC 60076-30-1 and DOE Tier 4 mandates necessitates conductors with exceptional thermal stability and electrical conductivity. Copper remains the dominant material due to its superior conductivity (100% IACS minimum) and ductility compared to aluminum alternatives, directly impacting transformer efficiency, compactness, and lifecycle costs. Annual growth in the global transformer market, projected at 5.2% CAGR through 2028, correlates strongly with rising demand for Class 180 (H) and Class 200 (R) thermal index wires capable of sustaining 155°C–180°C continuous operation in high-load scenarios. Grid resilience initiatives in Asia-Pacific and Europe further amplify requirements for wires with robust partial discharge resistance and thermal shock endurance.

Criticality of Material and Process Quality

Quality deviations in enamelled copper wire directly compromise transformer reliability and operational economics. Substandard wire with inconsistent enamel thickness or curing defects initiates partial discharge at voltages below 1.5 kV/mm, accelerating insulation degradation and leading to premature failure. Metallurgical flaws—such as inadequate annealing homogeneity or residual stresses—manifest during high-tension winding as micro-cracks in the enamel layer, increasing scrap rates by 12–18% in automated coil production lines. Thermal endurance is equally pivotal; wires failing to meet IEC 60851-5 thermal aging tests exhibit 40% faster dielectric strength decay at 200°C, shortening transformer lifespan by 7–10 years. Furthermore, impurities exceeding 8 ppm oxygen content in the copper substrate elevate DC resistance, directly violating DOE efficiency tier requirements and incurring non-compliance penalties.

Consequences of Inferior Supply Chain Execution

Supply chain vulnerabilities in wire sourcing propagate systemic risks. Inconsistent batch-to-batch performance in elongation (>30% minimum) or mandrel bend test results disrupt high-speed winding operations, causing line stoppages costing $1,200–$1,800 per hour in large-scale manufacturing. Non-uniform thermal class compliance forces derating of transformer designs, sacrificing 3–5% efficiency gains and increasing total cost of ownership. Field failures linked to enamel delamination or thermal runaway incur recall costs exceeding $250,000 per unit in industrial applications. Luoyang Xinzhaohe Aluminum’s two decades of metallurgical process control ensure wire meets EN 135990 tolerances (±0.003 mm diameter) and IEC 60317 thermal indices through rigorous in-line monitoring of curing kinetics and copper purity.

Supplier Selection Imperatives

Procurement decisions must prioritize suppliers with demonstrable control over copper electrolysis purity, enamel polymerization, and thermal aging validation. Traceability to ISO 17025-certified testing of key parameters—thermal shock resistance, solderability, and dielectric breakdown—is non-negotiable for mitigating grid-scale failure risks. Partnering with vertically integrated manufacturers minimizes contamination risks during drawing and enameling, ensuring compliance with the evolving efficiency mandates defining the transformer industry’s future. Quality is not a cost factor but a capital preservation imperative.

Technical Specs: Enamelled Round Copper Wire

Technical Specifications for Enamelled Round Copper Wire

Enamelled round copper wire is a critical component in the production of electromagnetic coils used across motors, transformers, generators, and various electrical equipment. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in metallurgical engineering and precision wire manufacturing, we adhere to stringent technical standards to ensure reliability, durability, and performance under demanding thermal and electrical conditions. Key technical parameters such as insulation breakdown voltage, elongation, and thermal class are rigorously controlled during production to meet international quality benchmarks including IEC 60317 and GB/T 6109.

Insulation breakdown voltage is a fundamental measure of the dielectric strength of the enamel coating. It determines the wire’s ability to withstand high voltage stress without electrical failure. Our enamelled copper wires are engineered to deliver consistent breakdown performance, tested at both room temperature and elevated conditions. The breakdown voltage is evaluated using standardized step-voltage methods, with minimum thresholds established based on wire diameter. Superior insulation integrity ensures long-term operational safety, especially in high-voltage winding applications where partial discharge and insulation degradation must be minimized.

Elongation, expressed as a percentage, reflects the ductility of the copper conductor and its ability to endure mechanical deformation during winding processes without fracturing. High elongation values are essential for tight coiling, automated winding, and applications involving complex geometries. Our manufacturing process employs controlled annealing and drawing techniques to optimize the balance between tensile strength and ductility, ensuring that each batch maintains uniform elongation characteristics. This mechanical resilience directly impacts yield rates in coil production and reduces the risk of wire breakage during high-speed manufacturing.

Thermal class defines the maximum continuous operating temperature that the enamel insulation can withstand while preserving its electrical and mechanical properties. Our product range covers thermal classes from 130°C to 220°C, utilizing advanced polymer coatings such as polyurethane, polyester, polyamide-imide, and silicone-modified formulations. Higher thermal classes enable operation in demanding environments, such as in automotive traction motors, industrial compressors, and aerospace systems, where thermal cycling and prolonged heat exposure are common. Each thermal class is validated through thermal endurance testing, including resistance to thermal shock, thermal aging, and cold winding tests.

The following table outlines the core technical parameters for our standard enamelled round copper wire offerings:

| Parameter | Test Method | Value Range / Requirement | Notes |

|---|---|---|---|

| Conductor Material | GB/T 5584.1 | Oxygen-free copper, ≥99.97% purity | High conductivity, low impurity |

| Wire Diameter Range | GB/T 4074.2 | 0.05 mm – 2.50 mm | Tolerance per IEC 60317 |

| Insulation Breakdown Voltage (min) | IEC 60317-0-3 | 3 kV – 8 kV (depending on diameter) | Tested at 90°C, step voltage method |

| Elongation (min) | GB/T 4074.4 | ≥10% – 25% (varies with diameter and temper) | Measured on 25 mm gauge length |

| Thermal Class | IEC 60317, GB/T 6109 | 130°C, 155°C, 180°C, 200°C, 220°C | Based on 20,000-hour life expectancy |

| Thermal Shock Resistance | IEC 60317-0-7 | No cracking at specified mandrel diameter | Mandrel size per wire gauge |

| Resistance to Refrigerants | IEC 60317-12 | Pass (for specific grades) | Required for hermetic motor use |

These specifications reflect our commitment to delivering high-performance enamelled copper wire suitable for advanced industrial applications. Custom formulations and tighter tolerances are available upon request to meet specific OEM requirements.

Factory Tour: Manufacturing

Manufacturing Process for Enamelled Round Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of metallurgical and winding wire expertise to deliver high-reliability enamelled round copper wire. Our production rigorously adheres to IEC 60317 standards, ensuring optimal electrical, thermal, and mechanical performance for demanding applications like motors, transformers, and inductors. The integrated process begins with high-conductivity electrolytic tough pitch (ETP) copper rod (99.95% Cu min), sourced from certified suppliers meeting ISO 5754 specifications.

Rod Drawing

The copper rod undergoes precision cold drawing through diamond or tungsten carbide dies in a multi-stage continuous process. Reduction ratios are meticulously controlled to achieve target wire diameters (0.02–5.0 mm) while maintaining roundness tolerance within ±0.001 mm. Surface cleanliness is critical; rods pass through alkaline cleaning baths and deionized water rinses pre-drawing to eliminate oxides and contaminants. In-line laser micrometers continuously monitor diameter, triggering automatic die adjustments to sustain ±0.5% dimensional accuracy. Final drawing employs high-purity lubricants to prevent surface scoring, with residual lubricant removed via ultrasonic cleaning.

Annealing

Post-drawing, the wire enters a controlled atmosphere annealing furnace. Nitrogen-hydrogen gas mixtures (dew point ≤ -40°C) prevent oxidation while enabling precise recrystallization. Temperature gradients are maintained at 450–550°C with ±5°C uniformity across the wire cross-section. This restores ductility (min 10% elongation) and achieves 100% IACS conductivity while eliminating residual stresses. Tension control during annealing ensures straightness (max 2 mm/m camber) and consistent tensile strength (150–250 MPa).

Enameling

The annealed wire proceeds to multi-layer polymer application via precision die coating. For standard grades, a base layer of polyurethane (PU) or polyesterimide (PEI) is applied, followed by topcoats of polyamide-imide (PAI) or polytetrafluoroethylene (PTFE) for thermal class 180–240. Viscosity, solids content, and application speed are dynamically adjusted to achieve uniform film build (±5% thickness tolerance). Curing occurs in vertical ovens with zoned temperature profiles (250–450°C), ensuring complete polymer cross-linking without thermal degradation. Film adhesion is validated via mandrel wrap tests per IEC 60851-5.

Inline Testing and Quality Control

Every production meter undergoes 100% automated electrical and mechanical validation. Key inline tests include: breakdown voltage verification (min 3x rated voltage per IEC 60851-3), continuity monitoring, and elongation checks. Statistical process control (SPC) tracks critical parameters like film thickness, diameter, and resistance. Final QC includes salt-water dielectric testing, thermal shock resistance (200°C for 30 min), and solvent resistance per ASTM D471. All batches receive traceable certification with test reports documenting compliance to customer specifications.

This end-to-end process, governed by ISO 9001 and IATF 16949 systems, guarantees wire integrity from raw material to shipment. Our vertical integration and real-time QC protocols minimize process variation, delivering consistent performance for high-efficiency electromagnetic components.

| Key Process Parameter | Control Tolerance | Test Standard |

|---|---|---|

| Wire Diameter | ±0.5% | IEC 60173 |

| Film Thickness | ±5% | IEC 60851-2 |

| Breakdown Voltage | ≥ 3x Rated | IEC 60851-3 |

| Elongation | Min 10% | IEC 60851-4 |

| Thermal Shock | Pass 200°C/30min | IEC 60851-6 |

Packaging & Logistics

Export Packaging Standards for Enamelled Round Copper Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized manufacturing experience in winding wires, we maintain rigorous export packaging protocols to ensure product integrity during international transit. Enamelled round copper wire, due to its high electrical sensitivity and susceptibility to mechanical and environmental degradation, demands a packaging system engineered for long-distance sea freight, where exposure to humidity, vibration, and temperature fluctuations is inevitable. Our export packaging solution is designed to mitigate these risks through a dual-layer protection strategy: structural stability via wooden pallets and environmental shielding using moisture-proof film.

All export shipments of enamelled round copper wire are secured on custom-engineered wooden pallets constructed from kiln-dried, ISPM-15 compliant hardwood. These pallets are designed to ISO standard dimensions for containerized shipping, ensuring compatibility with global logistics infrastructure. Each pallet is load-rated to support coil weights up to 1,500 kg, maintaining structural rigidity under stacking pressure during container loading. The wooden base is treated against fungal and insect infestation, critical for extended maritime exposure, and includes corner bracing to prevent torsional deformation. Wire coils are centered and affixed using steel strapping anchored directly to the pallet frame, minimizing lateral movement and reducing the risk of coil deformation or flange damage during handling.

The primary environmental safeguard is a multi-layer moisture-proof wrapping system. Each palletized load is fully enveloped in a heat-sealed, laminated moisture barrier film composed of aluminum foil, polyethylene, and polyester layers. This composite film provides a water vapor transmission rate (WVTR) of less than 0.5 g/m²·24h, effectively isolating the wire from ambient humidity. The sealed film also acts as a barrier against salt-laden air, a critical factor in ocean transport through tropical and coastal regions. Desiccant packs are strategically placed within the sealed enclosure to absorb any residual moisture and maintain an internal relative humidity below 40% throughout the shipment duration.

All packaged units are labeled with international handling indicators, including “Fragile,” “This Way Up,” and “Do Not Stack,” printed in durable, weather-resistant ink. Batch traceability is ensured through serialized QR codes linked to production records, including wire specifications, test reports, and packaging date. Our packaging process adheres to IEC 60172 and GB/T 23311 standards for insulated winding wire handling and storage.

This integrated packaging system has been validated through accelerated climate testing and real-world shipment monitoring across major trade routes, including trans-Pacific and trans-Indian Ocean voyages. By combining robust mechanical support with advanced moisture protection, Luoyang Xinzhaohe ensures that every coil of enamelled round copper wire arrives at its destination in optimal condition, ready for immediate processing in motor, transformer, and inductor manufacturing applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Enamelled Round Copper Wire

Despite our corporate name referencing aluminum heritage, Luoyang Xinzhaohe Aluminum CO., Ltd has dedicated over 20 years to mastering the production of high-performance enamelled round copper wire for global winding applications. Our specialization in copper conductor technology stems from rigorous metallurgical expertise and vertically integrated manufacturing, ensuring uncompromised quality from raw material to finished coil. We resolve industry pain points through scientific process control, not incremental improvements.

Metallurgical Excellence in Core Material

We source only high-conductivity electrolytic tough pitch (ETP) copper rod meeting ASTM B3/B3A or IEC 60086-2 standards, with oxygen content strictly controlled below 10 ppm. Each batch undergoes OES spectrographic analysis to guarantee 99.99% minimum copper purity, eliminating impurities that cause hot shortness during drawing. Our proprietary annealing protocols maintain precise tensile strength between 150–250 MPa and elongation of 8–40%, tailored to customer winding speed and thermal class requirements. This foundational control prevents micro-cracking in the enamel layer during high-speed processing.

Precision Enamel Application and Process Validation

Our automated enamelling lines utilize multi-zone curing ovens with ±2°C thermal uniformity, applying polyesterimide (PEI), polyamide-imide (PAI), or silicone-based coatings to IEC 60317 tolerances. Critical parameters—build-up ratio, dielectric strength, and thermal shock resistance—are monitored in real time via inline capacitance and spark testing. Every production lot undergoes third-party validation per IEC 60851 standards, with traceable certificates documenting:

| Parameter | Standard Range | Our Control Limit |

|---|---|---|

| Diameter Tolerance | ±0.003 mm to ±0.015 mm | ±0.002 mm to ±0.012 mm |

| Dielectric Strength | ≥3000 Vrms | ≥3500 Vrms |

| Thermal Class | 180°C to 240°C | Certified to 220°C |

Supply Chain Resilience and Technical Collaboration

We mitigate raw material volatility through strategic partnerships with Tier-1 copper suppliers and in-house drawing capability down to 0.05 mm diameter. Our ISO 9001 and IATF 16949 certified facility maintains 99.2% on-time delivery via dynamic inventory buffers for key alloys. Unlike commodity suppliers, we embed metallurgical engineers within your NPI phase to co-develop wire specifications—optimizing enamel adhesion for high-frequency motor windings or thermal cycling stability in traction transformers. This reduces qualification cycles by 30% and eliminates field failures from interfacial stress.

Commit to Performance-Driven Sourcing

Global leaders in EV traction motors, industrial transformers, and aerospace actuators rely on our wire for zero-defect performance under extreme thermal and mechanical loads. We do not compete on price alone; we engineer out failure modes. Contact Cathy directly to initiate a technical dialogue on your specific application demands. Provide your target thermal index, winding tension profile, and expected service life—we will deliver a validated wire solution with full material traceability and accelerated life testing data.

Initiate your sourcing validation today. Email Cathy at cathy@transformerstrip.com with your project specifications to receive a metallurgical compliance dossier and sample reel within 72 hours. Partner with proven science, not procurement risk.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing enamelled round copper wire directly from China.