Table of Contents

Market Insight: Copper Strip For Transformer

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

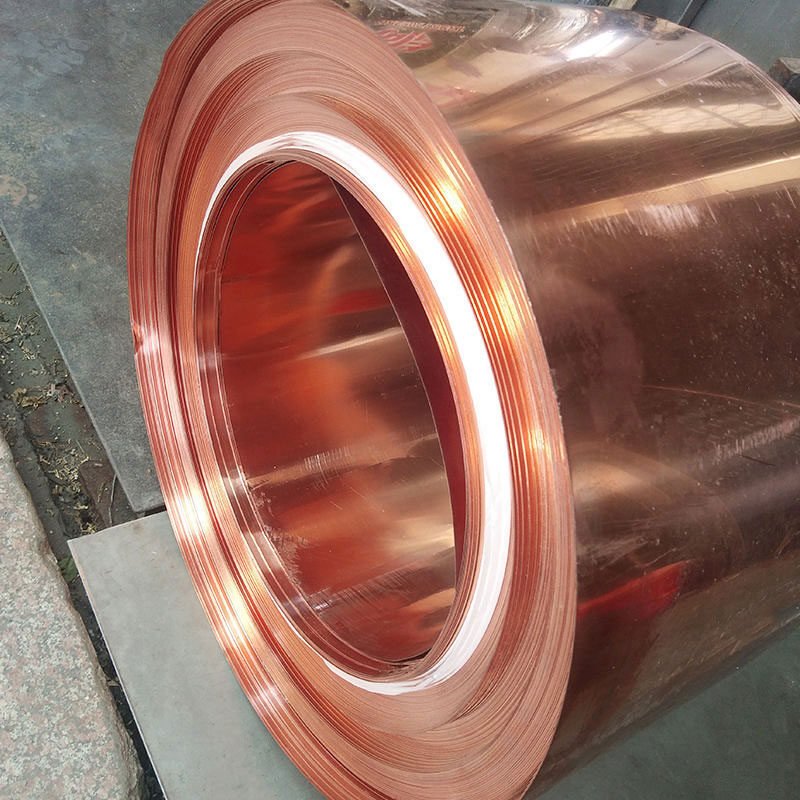

Global demand for copper strip in transformer manufacturing remains robust, driven by critical infrastructure modernization, renewable energy integration, and stringent energy efficiency regulations. Copper strip—distinct from foil due to its greater thickness (typically 0.1–3.0 mm)—serves as the primary conductor material for high-voltage windings in distribution and power transformers. Its dominance persists despite aluminum alternatives, owing to copper’s superior electrical conductivity (101% IACS minimum per ASTM B187), thermal stability, and mechanical resilience under cyclic loading. Current market expansion is fueled by grid upgrades in emerging economies and the proliferation of solar/wind substations requiring compact, high-efficiency transformers. However, supply chain volatility, including copper price fluctuations and geopolitical constraints on refined metal, necessitates strategic sourcing partnerships with vertically integrated suppliers capable of ensuring material continuity.

Quality precision in copper strip is non-negotiable for transformer reliability and lifecycle performance. Substandard material directly compromises core operational parameters. Impurities exceeding 50 ppm (e.g., oxygen, sulfur) or inconsistent annealing homogeneity induce localized hotspots, accelerating insulation degradation and risking catastrophic failure under load. Dimensional tolerances must adhere to tight specifications: thickness deviation ≤±0.02 mm and flatness ≤0.5 mm/m are essential to prevent winding misalignment, which increases eddy current losses and reduces thermal management efficiency. Surface defects—such as scratches, pits, or residual oxides—create nucleation points for corona discharge, particularly in high-voltage applications (>36 kV). These flaws violate IEC 60138 and IEEE C57.12.00 standards, leading to premature field failures and costly warranty claims.

The consequences of inadequate quality control extend beyond immediate technical failures. Transformers using non-compliant copper strip exhibit 15–20% higher no-load losses over their operational lifespan, directly contravening DOE Tier 4 and EU Ecodesign efficiency mandates. This results in significant financial penalties for utilities and OEMs through energy waste and regulatory non-compliance. Furthermore, inconsistent strip properties necessitate production line slowdowns for manual adjustments, increasing manufacturing costs by 8–12%. For end-users, the lifecycle cost impact is severe: a single transformer failure due to conductor defects can incur downtime losses exceeding $500,000 in critical infrastructure settings.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical expertise to mitigate these risks. Our copper strip undergoes triple-stage purification, precision cold rolling with laser-guided thickness control, and in-line eddy current testing to ensure defect-free surfaces. Each batch is certified to 99.99% Cu minimum purity with traceable mill test reports, guaranteeing compliance with global standards. In transformer manufacturing, where material integrity dictates asset longevity, partnering with a supplier possessing rigorous process discipline is not merely advantageous—it is fundamental to operational and economic success. Specifying copper strip to exacting technical parameters is an investment in grid resilience, regulatory adherence, and total cost of ownership reduction.

Technical Specs: Copper Strip For Transformer

Technical Specifications for Copper Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum Co., Ltd. provides high-precision copper strip materials engineered specifically for transformer manufacturing. Our copper strips are produced under stringent quality controls to meet the electrical, mechanical, and dimensional demands of modern power and distribution transformers. The performance of a transformer is significantly influenced by the quality of conductive materials used, particularly in terms of electrical conductivity, edge integrity, and dimensional consistency. Our copper strips are cold-rolled, annealed, and precision slit to ensure optimal performance in winding and stacking operations.

Dimensional accuracy is critical in transformer design to ensure uniform winding tension and minimize interlayer stresses. Our copper strips are precision slit with a thickness tolerance of ±0.002 mm, ensuring consistency across production batches. This tight tolerance supports high fill factors in windings and reduces the risk of localized hotspots due to uneven current distribution. Width tolerances are maintained within ±0.05 mm, achieved through advanced slitting lines equipped with laser-guided edge monitoring systems.

Edge quality is paramount in preventing insulation damage during coil winding. All copper strips supplied by Luoyang Xinzhaohe are processed to deliver burr-free edges, with a maximum burr height of 2% of material thickness. This is achieved through optimized slitting knife geometry, controlled roll alignment, and in-line deburring systems. Smooth, clean edges reduce the risk of dielectric breakdown and enhance the long-term reliability of transformer insulation systems.

Electrical conductivity is a defining characteristic of copper used in transformer windings. Our copper strips are manufactured from high-purity electrolytic tough pitch (ETP) copper (Cu-ETP1, C11000), with a minimum conductivity of 98% IACS at 20°C. This ensures low resistive losses and high energy efficiency in transformer operation. Conductivity is verified batch-wise using eddy current testing and four-point probe methods in accordance with ASTM B3 and IEC 60317 standards.

Mechanical properties are tailored to support formability during winding. Typical tensile strength ranges from 200–240 MPa with an elongation of ≥40%, providing a balanced combination of strength and ductility. The material is supplied in a soft-annealed (O-temper) condition unless otherwise specified.

All strips are cleaned post-annealing to remove residual oils and oxides, ensuring excellent adhesion in subsequent insulation coating or varnishing processes. Surface roughness is maintained below 0.5 µm Ra to minimize friction during winding.

The following table summarizes key technical parameters for our copper strip products used in transformer applications:

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | Cu-ETP1 (C11000) | ASTM B187 |

| Thickness Range | 0.10 – 3.00 mm | ±0.002 mm tolerance |

| Width Range | 10 – 300 mm | ±0.05 mm tolerance |

| Edge Burr | ≤ 2% of thickness, burr-free | Optical microscopy |

| Electrical Conductivity | ≥ 98% IACS | ASTM B3, IEC 60462 |

| Tensile Strength | 200 – 240 MPa | ASTM E8 |

| Elongation (min) | ≥ 40% | ASTM E8 |

| Temper | O (Annealed) | ASTM B976 |

| Surface Roughness (Ra) | ≤ 0.5 µm | ISO 4287 |

| Packaging | Waterproof wrapping, wooden core, palletized | Customizable per order |

Each shipment is accompanied by a material test certificate (MTC) in compliance with ISO 9001:2015 and customer-specific quality requirements. Luoyang Xinzhaohe’s two decades of experience in non-ferrous strip production ensure consistent delivery of copper strips that meet the highest technical standards for transformer manufacturing.

Factory Tour: Manufacturing

Manufacturing Process for High-Purity Copper Strip in Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical and precision strip production expertise to deliver copper strip meeting the stringent demands of transformer manufacturing. While our primary heritage is in aluminum, our dedicated copper processing lines apply identical process rigor and quality control to ensure optimal electromagnetic performance and winding integrity. The production sequence for transformer-grade copper strip is a tightly controlled sequence of cold rolling, precision slitting, and critical edge conditioning, each stage integral to final product reliability.

Cold rolling forms the foundational step, transforming high-conductivity electrolytic tough pitch (ETP) copper cast ingots into precise strip dimensions. We utilize multi-stand reversing mills with advanced tension control and computerized roll gap adjustment. This process achieves the exact thickness tolerances required, typically ranging from 0.10mm to 3.00mm, while simultaneously optimizing the material’s mechanical properties through controlled work hardening. Critical parameters monitored include thickness deviation (held to ±0.005mm for critical grades), surface roughness (Ra < 0.4µm), and flatness (I-Units < 10). Precise temperature management during rolling prevents overheating, which could lead to surface oxidation or inconsistent grain structure detrimental to conductivity and formability. Intermediate annealing steps may be employed to restore ductility for subsequent rolling passes, ensuring the final temper (e.g., H01, H02) meets customer specifications for winding behavior.

Precision slitting follows cold rolling, where wide master coils are longitudinally cut into the exact widths demanded by transformer coil designs. Our state-of-the-art slitting lines feature high-precision circular knives with micron-level alignment control and active tension management systems. This minimizes edge defects such as camber, edge wave, or width variation (controlled to ±0.10mm). Crucially, the slitting process must be optimized to prevent work hardening or micro-cracking at the newly formed edges, which could propagate during winding or operation. Real-time laser width monitoring provides continuous feedback to the slitting mechanism.

Edge conditioning is a non-negotiable step for transformer copper strip. Raw slit edges often contain micro-burrs or sharp protrusions that can puncture interlayer insulation during coil winding, causing catastrophic short circuits. We employ proprietary mechanical brushing and/or precision grinding techniques to achieve a consistent, smooth edge radius. This process meticulously removes burrs while controlling the edge profile to a defined radius, typically between 0.05mm and 0.15mm, significantly reducing the risk of insulation damage. The conditioned edge must maintain metallurgical integrity without introducing surface defects or excessive work hardening.

Rigorous quality control permeates every stage. Inline systems continuously monitor thickness, width, surface defects (via high-resolution cameras), and flatness. Final inspection involves comprehensive testing per ASTM B152 and customer specifications. Key parameters include:

| Parameter | Typical Requirement | Test Method |

|——————–|————————–|——————-|

| Thickness Tolerance| ±0.005mm (critical grades)| Micrometer/EDX |

| Edge Burr Height | < 0.01mm | Optical Profilometer |

| Conductivity | ≥ 100% IACS | Eddy Current |

| Tensile Strength | 220-250 MPa (H02) | ASTM E8 |

| Elongation | ≥ 5% | ASTM E8 |

This integrated manufacturing and QC approach ensures the copper strip delivered possesses the dimensional accuracy, surface perfection, and edge quality essential for high-yield transformer winding and long-term operational reliability.

Packaging & Logistics

Export Packaging for Copper Strip in Transformer Applications

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized manufacturing experience in conductive strip materials for power transmission systems, we recognize that packaging is not merely a logistical necessity but a critical component in preserving material integrity during international transit. For copper strip used in transformer windings, maintaining dimensional stability, surface cleanliness, and oxidation resistance is paramount. Our export packaging system is engineered to meet these requirements under the variable and often harsh conditions encountered during sea freight.

All copper strip shipments are secured on high-load-bearing wooden pallets constructed from kiln-dried, ISPM-15 certified hardwood. This certification ensures compliance with international phytosanitary standards for wood packaging material, preventing the spread of pests and enabling seamless customs clearance across global markets. The structural design of the pallets supports uniform weight distribution and facilitates safe handling via forklift or crane, both in warehouse environments and at port terminals. Each coil is precisely centered and affixed to the pallet using galvanized steel strapping anchored to load-bearing blocks, minimizing lateral movement and vibration-induced deformation during ocean transport.

Immediately following coil winding and inspection, the copper strip is wrapped in multiple layers of industrial-grade moisture-proof composite film. This multilayer film incorporates a metallized polyethylene barrier that provides a vapor transmission rate of less than 0.5 g/m²·24h at 38°C and 90% relative humidity, effectively isolating the strip from ambient moisture. Given that copper is susceptible to surface oxidation and tarnishing—particularly in saline maritime environments—this barrier is essential to prevent the formation of cupric oxide (CuO) and other deleterious surface compounds that could compromise electrical conductivity and winding performance.

An additional layer of black-out UV-resistant polyethylene outer wrap is applied to protect against solar radiation during open-deck storage, a common occurrence in container yards and during transshipment. Desiccant packs are strategically placed within the sealed envelope to absorb residual moisture, and humidity indicator cards are included for post-arrival verification of internal conditions.

All packaged units are labeled with durable, weather-resistant tags indicating product specifications, batch number, net weight, handling instructions, and orientation arrows. This labeling system supports full traceability and ensures proper handling throughout the supply chain.

Our packaging methodology has been validated through accelerated aging tests and real-world shipping data across major trade lanes, including trans-Pacific and Europe-Asia routes. By integrating robust mechanical support with advanced moisture control, Luoyang Xinzhaohe ensures that copper strip arrives at its destination in the same condition as it left our facility—ready for precision processing in high-efficiency transformer manufacturing.

Sourcing from Luoyang Xinzhaohe

Strategic Partnership Advantages with Luoyang Xinzhaohe Aluminum Co., Ltd

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver mission-critical copper strip solutions for transformer manufacturing. Our vertically integrated facility in Luoyang, China, operates under stringent ISO 9001 and IATF 16949 certified quality management systems, ensuring every coil meets the exacting electrical and mechanical demands of modern power infrastructure. With an annual production capacity exceeding 15,000 metric tons of precision copper strip, we provide scalable supply chain resilience for global OEMs and tier-1 suppliers facing volatile market conditions.

Our technical excellence originates in advanced process control capabilities. We specialize in oxygen-free electronic copper (C10100/C10200) and phosphorus-deoxidized alloys (C12200), processed to tight tolerances of ±0.005 mm in thickness (0.10–3.00 mm range) and ±0.10 mm in width (20–500 mm). All material undergoes rigorous in-line monitoring via laser micrometry and eddy current testing, guaranteeing surface defect levels below 5 µm Ra and conductivity values ≥100% IACS per IEC 60468 standards. Critical mechanical properties are consistently maintained within narrow bands: tensile strength 200–240 MPa and elongation ≥40% for O6 temper, validated through ASTM E8 tensile testing on every production batch.

Quality assurance extends beyond compliance through our integrated metallurgical laboratory. We conduct full-spectrum analysis including grain size evaluation per ASTM E112, hydrogen embrittlement testing to ASTM B577, and chemical composition verification via OES spectrometry against EN 13601 specifications. Complete material traceability is enforced through blockchain-enabled lot tracking from cathode sourcing to final shipment, providing auditable documentation for regulatory compliance in all major markets. This systematic approach has driven our defect rate below 50 PPM over the past five years, significantly below industry benchmarks.

Supply chain robustness is engineered into our operational model. Strategic partnerships with primary copper refiners secure priority access to LME Grade A cathodes, while our dual-mode production lines (tandem cold rolling and precision slitting) enable rapid reconfiguration for urgent orders. We maintain dedicated inventory buffers for high-volume transformer programs, ensuring 99.2% on-time delivery performance even during peak demand cycles. Our logistics network integrates with major global ports via bonded warehousing, providing flexible Incoterms 2020 execution including DDP solutions for EU and North American clients.

Partnering with Luoyang Xinzhaohe eliminates technical and supply chain vulnerabilities in your transformer production. Our engineering team collaborates directly with client R&D departments to optimize strip specifications for lamination efficiency, core loss reduction, and winding integrity. Request a technical dossier or schedule a metallurgical consultation to validate our capability for your next-generation transformer program. Contact Cathy Zhang, Global Sourcing Manager, at cathy@transformerstrip.com to initiate a capacity review and receive sample coils for qualification testing within 72 hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper strip for transformer directly from China.