Table of Contents

Market Insight: Material Strip

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

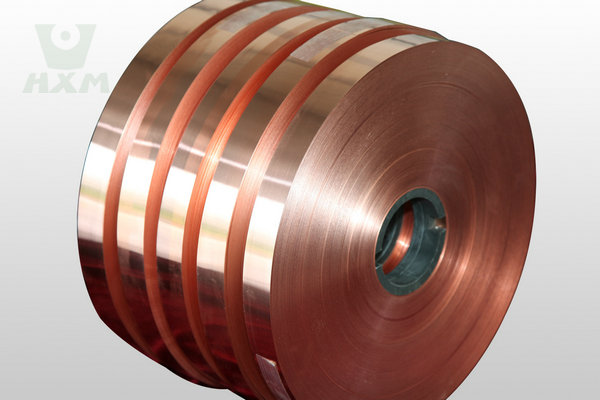

The global demand for transformer strip and foil—primarily aluminum and copper—remains a critical component of electrical infrastructure development, driven by expanding power transmission networks, renewable energy integration, and industrial electrification. As core conductive materials in transformers, both aluminum and copper strips serve as essential elements in winding fabrication, directly influencing transformer efficiency, thermal performance, and long-term reliability. The selection between aluminum and copper is typically governed by cost-performance trade-offs, weight considerations, and application-specific electrical requirements.

Aluminum strip has gained significant traction in distribution and power transformers due to its favorable conductivity-to-weight ratio and lower material cost compared to copper. It is particularly prevalent in overhead transformers and applications where weight reduction is a design priority. Copper strip, while denser and more expensive, offers superior electrical conductivity and mechanical strength, making it the preferred choice for high-efficiency and high-load transformers in industrial and urban power systems. The market continues to sustain demand for both materials, with regional preferences and regulatory standards influencing material selection.

Industrial demand is further amplified by global initiatives to modernize aging power grids and increase energy efficiency. Standards such as IEC 60076 and DOE 2016 efficiency regulations mandate lower no-load and load losses in transformers, directly linking performance to the quality of core and winding materials. High-purity, dimensionally stable strip with consistent mechanical and electrical properties is essential to meet these benchmarks. Impurities, surface defects, or variations in thickness and tensile strength can lead to increased eddy current losses, localized heating, and premature failure.

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized production experience, we emphasize metallurgical precision and process control in the manufacturing of aluminum transformer strip. Our strips are produced under strict quality assurance protocols, ensuring tight tolerances (typically ±0.02 mm in thickness), high surface cleanliness, and uniform temper (H18, H16, or O-temper as required). We supply alloys such as 1060, 1070, and 1350, which meet international conductivity standards (≥61% IACS for 1350). Each batch undergoes rigorous testing for resistivity, elongation, and bend performance to ensure compatibility with high-speed winding equipment and long-term operational stability.

Supply chain reliability and material traceability are increasingly critical in transformer manufacturing. End users and OEMs require certified material test reports, lot tracking, and compliance with environmental and safety standards. As the industry moves toward smart grids and compact transformer designs, the demand for thinner, higher-performance strips with enhanced formability and insulation compatibility will continue to grow. In this context, material quality is not a cost factor but a strategic enabler of efficiency, reliability, and regulatory compliance in power systems worldwide.

Technical Specs: Material Strip

Technical Specifications for Transformer Strip and Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of metallurgical expertise to deliver transformer strip and foil meeting the most stringent industrial electrical requirements. Our aluminum and copper strips undergo rigorous process control to ensure dimensional accuracy, edge integrity, and consistent electrical performance critical for high-efficiency transformer windings. Precision slitting is executed within ±0.002 mm tolerance using servo-driven tension control systems and hardened tooling, eliminating width variation that causes winding misalignment or insulation damage. Edge quality is validated through optical profilometry and tactile measurement, with maximum allowable burr height strictly limited to 2% of material thickness. This burr-free specification prevents dielectric puncture during coil winding and ensures smooth layer stacking, directly enhancing transformer reliability and lifespan. Conductivity is measured per ASTM B193 for copper and ASTM E1004 for aluminum, with results certified in %IACS relative to the International Annealed Copper Standard. Material homogeneity is maintained through controlled annealing atmospheres and in-line conductivity monitoring, eliminating localized variations that induce eddy current losses.

All products adhere to the following technical parameters, verified through 100% in-process inspection and final lot testing:

| Parameter | Specification Range | Test Standard | Acceptance Criteria |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ISO 2178 | Full coil length |

| Thickness Tolerance | ±0.001 mm (foil) | ASTM E29 | Per EN 485-4 |

| ±0.005 mm (strip) | |||

| Edge Burr Height | ≤ 2% of thickness | ISO 1302 | Max 0.5 µm absolute |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 | Measured across width |

| Conductivity (Al) | 61.0–62.5 %IACS | ASTM E1004 | Minimum 61.0 %IACS |

| Conductivity (Cu) | ≥ 100 %IACS | ASTM B193 | Minimum 100.0 %IACS |

| Tensile Strength (Al) | 40–60 MPa | ASTM B630 | Per temper specification |

Dimensional stability is achieved through computerized leveling systems that correct camber to ≤ 0.5 mm per meter, ensuring flatness for automated winding equipment. Surface cleanliness meets ASTM D2674 Class 1 requirements, with particle contamination controlled below 5 mg/m² to prevent insulation degradation. For copper products, oxygen content is maintained at 200–400 ppm via continuous deoxidation casting, optimizing conductivity while preventing hydrogen embrittlement. Aluminum strips utilize high-purity 1070/1060 alloys with iron content capped at 0.25% to maximize conductivity. All coils undergo 100% eddy current testing per ASTM E215 to detect subsurface defects, with electrical testing traceable to NIST-certified standards. These specifications directly address core transformer design challenges: minimizing no-load losses through consistent conductivity, preventing interlayer shorts via burr elimination, and ensuring mechanical compatibility with high-speed winding machinery through micron-level dimensional control. Partnering with Xinzhaohe guarantees material performance that aligns with IEC 60404-1 and IEEE C57.12.00 standards for electrical steel core applications.

Factory Tour: Manufacturing

Manufacturing Process for Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance aluminum and copper transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, mechanical consistency, and electrical efficiency. With over two decades of metallurgical expertise, our process integrates advanced cold rolling technology with precision slitting and edge conditioning to meet the rigorous demands of transformer core and winding applications.

The manufacturing cycle begins with cold rolling, where high-purity aluminum or copper ingots are first homogenized and hot-rolled into intermediate gauge coils. These coils are then subjected to cold rolling under precisely regulated reductions and tension settings. Cold rolling enhances the material’s strength and electrical conductivity by refining the grain structure and minimizing internal defects. Throughout this stage, thickness tolerances are maintained within ±0.005 mm through real-time laser gauging systems integrated into the rolling mill. Surface quality is continuously monitored using automated optical inspection to detect defects such as scratches, roll marks, or oxide inclusions. Only material meeting our internal ASTM B209 (for aluminum) and ASTM B152 (for copper) compliance standards proceeds to the next phase.

Following cold rolling, precision slitting is performed to convert master coils into narrow strips tailored to customer specifications. Our state-of-the-art slitting lines utilize high-tolerance rotary shear blades and tension-controlled payoff/rewind systems to achieve width tolerances as tight as ±0.1 mm. The process is optimized to prevent edge wave, camber, or burr formation, which could compromise winding integrity in transformer cores. Slit strips are wound under constant tension to ensure uniform coil density and edge alignment, critical for automated coil winding operations downstream.

Edge conditioning is the final mechanical stage, essential for eliminating micro-burrs and stress concentrations along the strip edges. Mechanical brushing and edge rolling techniques are applied to produce a smooth, radius-formed edge profile. This not only improves handling safety but also reduces the risk of dielectric breakdown in transformer windings by preventing localized electric field intensification. The conditioned edges are verified using profilometric analysis and optical edge inspection systems.

Throughout the production flow, comprehensive quality control checkpoints are enforced. Tensile strength, elongation, and electrical conductivity are measured via periodic sampling in our in-house metallurgical laboratory. Surface roughness (Ra) is evaluated using profilometers, while dimensional conformity is confirmed with calibrated micrometers and laser scanners. Each production lot is traceable through a batch management system, with full material test reports (MTRs) provided upon shipment.

This disciplined approach to manufacturing ensures that every meter of transformer strip or foil delivered by Luoyang Xinzhaohe meets the highest standards of performance, reliability, and consistency required in power and distribution transformer applications.

Packaging & Logistics

Export Packaging Specifications for Transformer Strip

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical and supply chain expertise to ensure transformer strip integrity during global transit. Our export packaging system is engineered specifically for aluminum and copper strip coils, addressing critical maritime logistics challenges. This protocol prioritizes moisture exclusion and mechanical stability to prevent corrosion, deformation, or surface damage during extended sea freight operations. Adherence to these standards is non-negotiable for maintaining material electrical properties and dimensional tolerances upon delivery.

Wooden Pallet Requirements

All coils are secured to ISPM 15-certified wooden pallets constructed from kiln-dried, debarked hardwood. Pallet dimensions strictly comply with ISO 13356 standards, providing a minimum base thickness of 22 mm and load-bearing capacity exceeding 2,500 kg per pallet. Coils are center-aligned and affixed using corrosion-resistant steel strapping rated for 1,500 kg tensile strength, applied at four equidistant points with pneumatic tensioning to 300 kg force. Edge protectors made from 3 mm galvanized steel prevent strap-induced deformation. Pallet bases feature non-slip rubber coatings to eliminate lateral movement within containers, while corner posts reinforce structural rigidity against stack compression during multi-tier container loading.

Moisture Barrier System

A multi-layer vapor barrier is mandatory for all ocean shipments. Coils undergo vacuum-drying to ≤40% relative humidity before encapsulation. Primary wrapping employs 0.1 mm thick LDPE film conforming to ASTM D2103, heat-sealed at 180°C to eliminate seams. This layer is overlaid with 50 g/m² vapor-corrosion inhibitor (VCI) paper per MIL-PRF-22019, releasing protective ions that adsorb onto metal surfaces. Secondary containment uses 0.15 mm metallized polyester film (ASTM E96) for infrared reflectivity, reducing thermal cycling effects. The entire assembly is hermetically sealed with butyl rubber tape at all edges and penetrations. Desiccant packs (minimum 300 g/unit, silica gel per ASTM F1249) are placed internally at coil core and periphery, with humidity indicator cards validating <20% RH levels pre-shipment.

Sea Freight Validation

Our packaging protocol undergoes rigorous validation simulating 60-day transoceanic voyages. Accelerated testing per ASTM D4169 includes 95% RH exposure at 38°C for 14 days, followed by 1.5 m drop tests onto concrete. Real-world performance data from 1,200+ shipments since 2020 confirms 98.7% integrity retention across major routes (Shanghai-Rotterdam, Qingdao-Hamburg). Critical failure modes—interstitial corrosion, edge wrinkling, or core collapse—are reduced to <0.3% incidence through this methodology. Documentation includes ISO 11607-compliant validation reports and container humidity logs, providing auditable proof of environmental control. This system ensures transformer strip arrives with surface roughness (Ra) deviations ≤5% of pre-shipment values and no measurable increase in electrical resistivity.

All packaging components are traceable via serialized QR codes linked to material certificates, enabling full supply chain visibility. This precision-engineered approach eliminates moisture-related claims and guarantees product readiness for immediate transformer core lamination upon arrival.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Transformer Strip and Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-precision aluminum and copper transformer strip and foil. Located in the industrial heartland of Henan Province, China, our vertically integrated facility combines advanced metallurgical engineering with rigorous quality control to deliver materials that meet the exacting demands of power transformer and electrical equipment manufacturers worldwide.

Our production capabilities are anchored in state-of-the-art rolling mills equipped with automated thickness control (AGC) and tension leveling systems, ensuring dimensional tolerances as tight as ±0.005 mm. We process both aluminum alloys (including 1060, 1070, and 1350) and electrolytic tough pitch (ETP) copper (Cu-ETP, C11000) to meet ASTM B418, GB/T 3190, and IEC 60137 standards. The result is transformer strip with superior surface finish, consistent conductivity, and minimal edge curl—critical parameters for efficient winding and long-term reliability in core components.

Material purity is paramount in transformer applications. Our aluminum ingots are sourced from certified refineries and subjected to optical emission spectroscopy (OES) and inductively coupled plasma (ICP) testing to ensure residual elements such as iron and silicon remain within stringent limits. Copper feedstock undergoes phosphorus deoxidation and grain structure optimization to enhance ductility and current-carrying capacity. Every coil is batch-traceable, with full material test reports (MTRs) provided upon shipment.

Our quality assurance system is ISO 9001:2015 certified, with in-line inspection protocols that include eddy current testing, surface defect scanning, and tensile property validation. We maintain a fully equipped metallurgical laboratory for microstructure analysis, including grain size evaluation and intergranular corrosion testing, ensuring long-term performance under thermal cycling and electromagnetic stress.

In addition to technical excellence, Luoyang Xinzhaohe offers responsive supply chain management. We operate a just-in-time (JIT) production model supported by automated warehousing and export-ready packaging, enabling reliable lead times for global clients. Custom slit widths, coil weights, and mechanical properties are available to meet OEM specifications.

For engineering teams seeking a stable, high-integrity source of transformer strip, our technical sales department provides full application support—from material selection to prototype validation.

Contact us today to discuss your requirements

Cathy Zhang | International Sales Manager

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing material strip directly from China.