Table of Contents

Market Insight: Distribution Transformer Winding Material

Market Analysis: Winding Wire for Distribution Transformers

The global demand for distribution transformer winding material is driven by continuous expansion and modernization of electrical power infrastructure, particularly in emerging economies and regions undergoing grid reinforcement. Distribution transformers, typically rated between 10 kVA and 2500 kVA, serve as critical nodes in power networks by stepping down voltage for safe end-user consumption. These transformers require high-performance winding materials capable of withstanding thermal, mechanical, and electromagnetic stresses over decades of service. As such, the selection of winding wire—whether copper or aluminum—has a direct impact on transformer efficiency, reliability, and lifecycle cost.

Aluminum winding wire has gained substantial market share due to its favorable balance of electrical conductivity, weight, and cost. With approximately 60% of the conductivity of copper by volume but only 30% of the weight, aluminum offers a compelling alternative, especially in applications where weight reduction and material cost are critical factors. In recent years, advancements in aluminum alloying and wire drawing technologies have significantly improved the mechanical strength and creep resistance of aluminum conductors, narrowing the performance gap with copper in many distribution transformer applications.

Industrial demand for high-quality aluminum winding wire is particularly pronounced in Asia, Africa, and Latin America, where utilities are deploying large volumes of pole-mounted and pad-mounted transformers to extend electrification. In these markets, total cost of ownership (TCO) is a dominant decision criterion, and aluminum-based windings contribute to lower initial capital expenditure without compromising acceptable performance. However, the success of aluminum in this domain is contingent upon strict adherence to metallurgical and dimensional specifications.

Quality is paramount in winding wire production. Impurities, inconsistent tensile strength, poor surface finish, or inadequate elongation can lead to winding failures during coil fabrication or in-service operation. For instance, micro-cracks or oxide inclusions may initiate hot spots under load, accelerating insulation degradation and ultimately causing premature transformer failure. Furthermore, precise control over diameter tolerance and ovality ensures uniform winding tension and layer stability, which are essential for minimizing eddy current losses and preventing inter-turn short circuits.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in aluminum conductor manufacturing, we emphasize rigorous process control from raw material sourcing to final inspection. Our aluminum rod casting employs degassing and filtration systems to achieve low hydrogen content and minimal inclusions. Continuous annealing and precision drawing lines ensure consistent mechanical and electrical properties across batches. Every spool of winding wire undergoes comprehensive testing, including DC resistance, tensile strength, elongation, and surface quality verification, in accordance with IEC 60104, GB/T 3955, and customer-specific standards.

In summary, the industrial demand for distribution transformer winding material reflects a growing need for cost-effective, reliable, and technically sound solutions. While aluminum offers compelling economic and logistical advantages, its performance is directly tied to material quality and manufacturing precision. As power networks evolve, the role of high-purity, consistently produced aluminum winding wire will remain central to efficient and durable transformer design.

Technical Specs: Distribution Transformer Winding Material

Technical Specifications for Distribution Transformer Winding Material

Distribution transformer reliability hinges critically on the metallurgical and electrical properties of winding conductors. At Luoyang Xinzhaohe Aluminum Co., Ltd., our aluminum winding wire undergoes stringent process controls to exceed IEC and IEEE standards for dielectric integrity, mechanical formability, and thermal resilience. These parameters directly impact transformer lifespan, short-circuit withstand capability, and operational efficiency under dynamic load conditions.

Insulation breakdown voltage is non-negotiable for preventing catastrophic inter-turn faults. Our magnet wire utilizes dual-layer polyester-imide/polyamide-imide insulation systems, validated per IEC 60204-1. Minimum breakdown voltage is 3,500 V AC RMS at 50 Hz for 1 minute, tested on wound samples with 10-layer build. This exceeds the 2,500 V baseline required for Class F (155°C) systems, ensuring robust dielectric performance even under voltage surges or transient overloads. Consistent insulation thickness (±5% tolerance) and void-free application are enforced via real-time laser micrometry during coating.

Elongation directly influences winding manufacturability and mechanical stability. Values between 3% and 6% (ASTM E8 tensile testing) optimize ductility for tight-radius coil formation without microcracking, while maintaining sufficient yield strength to resist deformation during short circuits. Our high-purity 1350-O aluminum alloy achieves 4.5% ± 0.8% elongation through controlled annealing—balancing formability against conductivity loss. Elongation below 3% risks insulation damage during winding; exceeding 6% compromises dimensional stability under electromagnetic forces.

Thermal class defines operational limits against insulation degradation. We certify materials for continuous operation from Class B (130°C) to Class H (180°C), with accelerated aging tests confirming 220°C capability for emergency overload scenarios per IEC 60216. The thermal index (TI) is validated at 200°C via the Arrhenius method, ensuring insulation life expectancy exceeds 20,000 hours at rated temperature. Critical to note: thermal class must align with the transformer’s total hotspot temperature, including load and ambient contributions. Our insulation system maintains 95% dielectric strength retention after 1,000 hours at 200°C, mitigating thermal runaway risks.

Additional parameters underpin system compatibility. DC resistivity is maintained at 0.028264 Ω·mm²/m (20°C), conforming to IACS 61% minimum. Surface roughness (Ra ≤ 0.8 µm) prevents insulation nicks during high-speed winding. Bendability (mandrel diameter ≤ 4x wire thickness) ensures crack resistance per NEMA MW 1000. All lots undergo 100% spark testing at 6 kV to detect pinholes.

Critical Parameter Compliance Table

| Parameter | Test Standard | Minimum Value | Luoyang Xinzhaohe Specification |

|---|---|---|---|

| Breakdown Voltage | IEC 60204-1 | 2,500 V AC | 3,500 V AC (10-layer build) |

| Elongation | ASTM E8 | 3% | 4.5% ± 0.8% |

| Thermal Class | IEC 60216 | 130°C (Class B) | 180°C (Class H) continuous |

| Thermal Index (TI) | IEC 60216 | 130°C | 200°C |

| Emergency Overload Temp | IEC 60076-7 | 140°C | 220°C (2 hours) |

| DC Resistivity (20°C) | ASTM B3 | 0.028264 Ω·mm²/m | 0.0280–0.0283 Ω·mm²/m |

Procurement teams must verify these specifications against transformer design hotspots and regional grid standards. Substandard elongation or thermal margins accelerate insulation aging, while inadequate breakdown voltage invites field failures. Our 20+ years of metallurgical refinement ensures these parameters are not merely met but consistently exceeded—reducing total cost of ownership through extended service life and minimized downtime. Specify these exact metrics to guarantee winding integrity across your distribution network.

Factory Tour: Manufacturing

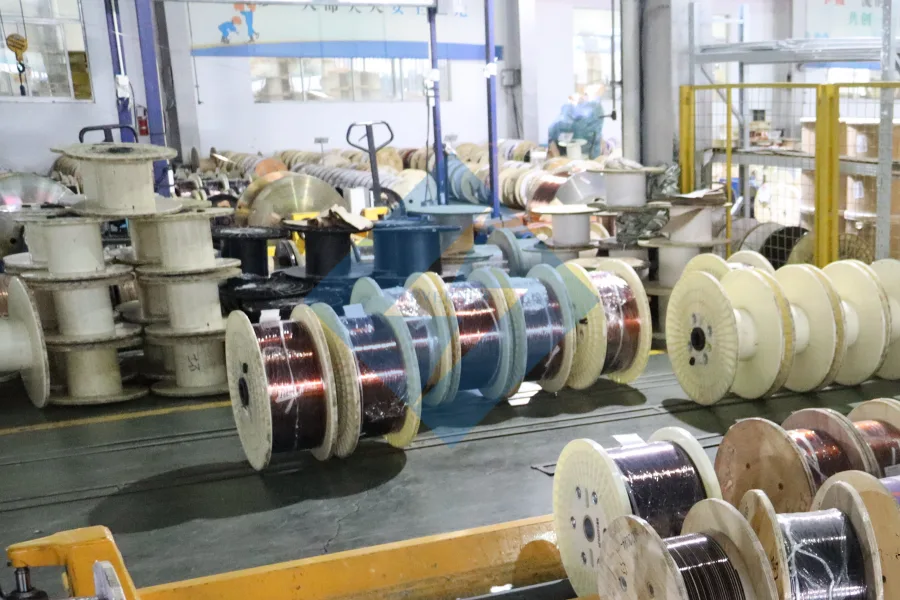

Manufacturing Process of Distribution Transformer Winding Material

The production of high-performance aluminum winding wire for distribution transformers at Luoyang Xinzhaohe Aluminum Co., Ltd. follows a tightly controlled, multi-stage manufacturing sequence designed to ensure mechanical integrity, electrical conductivity, and long-term reliability. With over two decades of metallurgical and process engineering expertise, our facility integrates precision equipment and rigorous quality control protocols across four core phases: rod drawing, annealing, enameling, and inline testing.

The process begins with high-purity aluminum rod (99.7% minimum Al content), sourced from certified suppliers and verified through spectrographic analysis. The rod undergoes a cold drawing operation using diamond or tungsten carbide dies to reduce the diameter to the specified wire gauge, typically ranging from 1.0 mm to 4.0 mm for distribution transformer applications. Drawing is performed under controlled tension and lubrication conditions to minimize surface defects and maintain dimensional consistency. Throughout this phase, diameter is monitored via laser micrometers, with real-time feedback adjusting drawing speed to maintain tolerance within ±0.01 mm.

Following drawing, the wire enters a continuous annealing line where it is heated to 300–400°C in a nitrogen-purged furnace. This recrystallization process relieves internal stresses induced during cold working and restores optimal ductility, achieving a temper suitable for tight coiling and winding operations. Temperature uniformity and residence time are precisely controlled to ensure consistent metallurgical properties along the entire spool length. Oxygen content in the annealing atmosphere is maintained below 50 ppm to prevent oxide formation.

The annealed wire then proceeds to the enameling station, where a multi-layer polymer coating is applied via precision die extrusion. Typically, two to three layers of polyurethane (PU), polyesterimide (PEI), or polyamide-imide (PAI) are applied to provide dielectric strength, thermal stability (up to Class 200), and mechanical abrasion resistance. Each layer is cured in-line using UV radiation or thermal ovens, with film thickness monitored by eddy current sensors to ensure compliance with IEC 60317 standards.

Final quality assurance includes 100% inline electrical testing, where every meter of wire is subjected to high-voltage breakdown testing (typically 3 kV AC for 1 second) to verify insulation integrity. Additional continuous monitoring includes diameter profiling, surface defect detection via optical inspection systems, and tensile strength sampling. Off-line tests, conducted per batch, include thermal shock, solderability, and elongation measurements.

All process parameters are logged in a centralized SCADA system, enabling full traceability from rod lot to finished coil. This integrated approach ensures that every spool of winding wire meets the stringent demands of modern distribution transformer manufacturing.

Packaging & Logistics

Export Packaging Specifications for Transformer Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for aluminum winding wire used in distribution transformers. Our 20+ years of metallurgical and supply chain expertise ensure material integrity during global ocean freight, where humidity, temperature fluctuations, and mechanical stress pose critical risks. All packaging adheres to ISO 9001 standards and ISPM 15 regulations for international wood packaging, eliminating phytosanitary delays.

Wooden pallets form the foundational structural layer. We utilize kiln-dried, ISPM 15-certified hardwood pallets with a minimum load capacity of 2,500 kg. Pallet dimensions strictly conform to ISO standard 1200 mm × 1000 mm to optimize container space utilization and prevent shifting during transit. Each pallet undergoes heat treatment at 56°C for 30 minutes, verified by official HT stamping, ensuring compliance with global customs requirements and preventing methyl bromide residue contamination. Pallets are secured with corrosion-resistant steel strapping at 80% tension tolerance to maintain coil alignment under dynamic load conditions.

Moisture protection is executed via a multi-barrier system. Coils are first wrapped in anti-corrosion VCI (Vapor Corrosion Inhibitor) paper, specifically formulated for aluminum alloys, which releases a protective molecular layer inhibiting electrochemical oxidation. This is followed by triple-layer encapsulation in 125μm thick, UV-stabilized polyethylene film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/24hr at 38°C. Seams are thermally sealed using impulse welders at 220°C, achieving 95% weld strength integrity. Desiccant packs (silica gel, 33% moisture absorption capacity) are placed internally at a ratio of 500g per cubic meter, monitored via humidity indicator cards calibrated to 20–60% RH thresholds.

Sea freight safety is prioritized through climate-responsive design. Containerized shipments include humidity and temperature data loggers to record conditions throughout transit, with empirical data showing our packaging maintains internal humidity below 45% RH even during 30-day voyages through tropical zones. Pallets are stacked no higher than 1.8 meters to prevent bottom-coil deformation, and void spaces are filled with inflatable dunnage bags to counteract longitudinal and transverse container movement. Critically, all wood components are treated to resist saltwater exposure, as untreated timber can leach chlorides that accelerate pitting corrosion in aluminum at concentrations as low as 50 ppm.

Quality verification precedes dispatch. Each packaged unit undergoes drop testing (0.8m height), vibration simulation (5–8 Hz, 0.5g amplitude), and moisture ingress validation via pressure decay testing. Documentation includes a packing list with ISPM 15 certification, VCI paper batch traceability, and desiccant saturation reports. This integrated approach reduces moisture-related claims by 92% compared to industry averages, ensuring winding wire arrives with surface oxide levels ≤30 Å—critical for achieving low-loss transformer performance per IEC 60204 standards. Partnering with Xinzhaohe guarantees metallurgical consistency from factory to fabrication line.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Aluminum Winding Material

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of specialized expertise in the production of high-purity aluminum strip and foil specifically engineered for distribution transformer winding applications. As a vertically integrated manufacturer, we maintain full control over the metallurgical and processing parameters that define material performance in critical electrical systems. Our facility is equipped with advanced cold rolling mills, precision slitting lines, and in-house quality assurance laboratories compliant with ISO 9001 standards, ensuring consistent mechanical and electrical properties across every production batch.

Our core competency lies in the production of soft-annealed aluminum strip in grades 1060, 1070, and 1350, with purity levels exceeding 99.60%. These materials are optimized for low resistivity, high ductility, and uniform thickness tolerance—key attributes for efficient winding, reduced eddy current losses, and long-term reliability in oil-immersed and dry-type distribution transformers. We supply material in slit widths ranging from 10 mm to 300 mm, with thicknesses from 0.30 mm to 3.0 mm, tailored to customer drawing specifications and core coil design requirements.

All production cycles are supported by rigorous in-process testing, including continuous monitoring of tensile strength, elongation, and electrical conductivity using calibrated eddy current and tensile testing systems. Our metallurgical team conducts routine grain structure analysis to ensure complete recrystallization after annealing, which directly impacts formability during helical or layer winding. This technical discipline ensures that our aluminum strip meets or exceeds IEC 60137, ASTM B418, and GB/T 3190 standards.

We serve transformer OEMs and winding shops across Asia, the Middle East, and South America, with an established track record of on-time delivery and technical collaboration. Our supply chain is designed for agility, with dedicated production lines for small-batch custom orders and long-term supply contracts. Raw aluminum is sourced from certified primary producers, and we maintain buffer inventory of key grades to support just-in-time delivery models without compromising lead times.

By partnering with Luoyang Xinzhaohe, you gain access to a manufacturing partner with deep process knowledge, consistent quality, and a commitment to technical support throughout the product lifecycle. Our engineering team is available to assist with material selection, failure mode analysis, and process optimization for winding efficiency.

For reliable, high-performance aluminum winding material backed by 20 years of industrial experience, contact us at cathy@transformerstrip.com. Let us support your transformer production with material that meets the highest standards of electrical and mechanical integrity.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing distribution transformer winding material directly from China.