Table of Contents

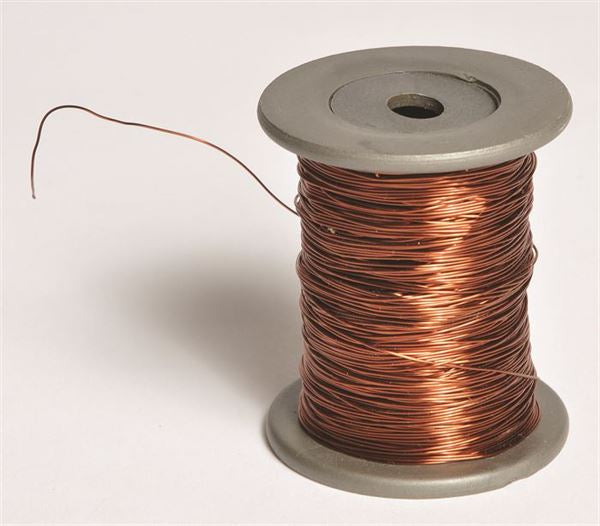

Market Insight: Copper Wire Without Enamel

Market Analysis: Winding Wire – Copper Wire Without Enamel in Transformer Applications

The industrial demand for copper wire without enamel, particularly in transformer manufacturing, remains a critical segment within the broader winding wire market. While enameled copper wire dominates applications requiring electrical insulation at the conductor level, bare copper wire—free of any insulating coating—plays a pivotal role in specific transformer subsystems and assembly processes. This includes use in grounding windings, tap changers, busbar connections, and internal structural components where external insulation systems are employed. The absence of enamel allows for direct metal-to-metal contact, essential for maintaining low-resistance electrical paths and efficient heat dissipation in high-current zones.

Transformers, especially power and distribution units operating at medium to high voltages, require materials that ensure long-term reliability under continuous thermal and electromagnetic stress. In such environments, the quality of bare copper wire directly influences performance, efficiency, and service life. High-purity electrolytic tough pitch (ETP) copper, with a minimum conductivity of 100% IACS (International Annealed Copper Standard), is the benchmark material. Impurities such as oxygen in excess, sulfur, or metallic residuals can lead to increased resistivity, reduced ductility, and susceptibility to thermal fatigue. Consistent mechanical properties, including tensile strength and elongation, are equally vital to ensure the wire withstands coiling, bending, and compression during transformer assembly without cracking or work hardening prematurely.

Moreover, surface integrity is paramount. A clean, oxide-free surface ensures optimal solderability and contact resistance, especially in joints and terminations where electrical continuity is non-negotiable. Surface defects such as scratches, pits, or residual drawing lubricants can initiate localized heating or galvanic corrosion, leading to premature failure. Therefore, precision in drawing, controlled annealing, and protective handling throughout production are essential quality control measures.

From a supply chain perspective, the demand for high-quality bare copper wire is closely tied to infrastructure development, renewable energy integration, and grid modernization. As global energy demands rise and transmission efficiency becomes a regulatory priority, transformer manufacturers increasingly source materials from suppliers with proven metallurgical expertise and consistent process control. Companies with vertical integration capabilities, traceable raw material sourcing, and adherence to international standards such as IEC 60317 and ASTM B3, are preferred partners in this technically stringent market.

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of metallurgical experience to deliver copper conductors that meet the rigorous demands of transformer engineering. While primarily recognized for aluminum solutions, our copper wire production follows the same principles of precision, purity, and process stability, ensuring reliability in mission-critical electrical infrastructure. In the context of winding wire systems, even non-insulated components must meet exacting standards—because in high-voltage applications, every conductor, coated or bare, contributes directly to system integrity.

Technical Specs: Copper Wire Without Enamel

Technical Specifications for Bare Copper Winding Wire (Non-Enamelled)

Luoyang Xinzhaohe Aluminum Co., Ltd. clarifies that while our core expertise spans aluminum alloys, we supply precision bare copper winding wire as a complementary product for specialized electromagnetic applications. This specification addresses uncoated copper conductor wire, where electrical insulation relies solely on the native copper oxide layer (Cu₂O), distinct from polymer-enamelled magnet wire. Critical performance parameters must be rigorously controlled to ensure reliability in high-stress winding environments such as transformers, reactors, and high-frequency inductors.

Insulation breakdown voltage is the paramount specification for bare copper wire, as it quantifies the dielectric strength of the naturally formed oxide film. This parameter directly correlates with surface cleanliness, oxygen content during drawing, and post-drawing annealing stability. Values below 150 V AC indicate inadequate oxide layer formation, risking inter-turn shorts under operational voltage transients. Our production process maintains breakdown voltages between 150–300 V AC (tested per IEC 60317-0-3 at 50 Hz, 1 min), achieved through oxygen-controlled annealing and precision surface passivation. Deviations outside this range signal inconsistent oxide growth or surface contamination, rendering the wire unsuitable for precision windings.

Elongation, measured per GB/T 4909.3, reflects the wire’s ductility and resistance to fracture during tight-radius winding. Bare copper wire for winding applications requires a minimum elongation of 2.0% to withstand mechanical stress without micro-cracking, which would compromise the oxide insulation layer. Our standard range is 2.0–8.0%, optimized via controlled cold-drawing reduction ratios and intermediate annealing. Values exceeding 8.0% indicate excessive softness, risking dimensional instability during high-speed winding, while sub-2.0% elongation increases breakage rates and reduces fatigue life under thermal cycling.

Thermal class defines the wire’s compatibility with insulation systems in end-use assemblies, not the bare wire’s standalone temperature limit. For bare copper, thermal classes 130 (B), 155 (F), 180 (H), and 220 (C) denote the maximum ambient temperature the integrated winding system can sustain without degrading the oxide layer’s dielectric properties. Class 130°C is the minimum viable threshold; operation above 130°C accelerates oxide layer crystallization, reducing breakdown voltage. Our wire is validated for continuous operation up to 220°C within properly designed Class 220 systems, contingent on controlled thermal aging during manufacturing to stabilize the oxide morphology.

Critical Parameter Summary Table

| Parameter | Standard Range | Test Method | Engineering Significance |

|---|---|---|---|

| Insulation Breakdown Voltage | 150–300 V AC | IEC 60317-0-3 | Minimum dielectric strength of native oxide layer; <150 V risks inter-turn failure |

| Elongation | 2.0–8.0% | GB/T 4909.3 | Ductility for winding integrity; <2.0% increases breakage risk |

| Thermal Class | 130°C to 220°C | IEC 60085 | Compatible system operating temperature; oxide stability degrades above class limit |

| Metallurgical Purity | ≥99.97% Cu | GB/T 5231 | Minimizes resistivity and ensures uniform oxide formation |

| Diameter Tolerance | ±0.003 mm (0.1–1.0 mm) | GB/T 5584.3 | Critical for fill factor and thermal management in windings |

Bare copper wire without enamel demands stricter process control than enameled alternatives due to the absence of a protective polymer barrier. Suppliers must demonstrate traceable oxygen control during annealing, surface roughness management (Ra ≤ 0.2 μm), and rigorous lot traceability. At Luoyang Xinzhaohe, we implement in-line eddy current testing for surface defects and automated breakdown voltage validation per lot, ensuring compliance with aerospace and industrial power electronics specifications. Procurement should prioritize suppliers with audited process stability in oxide layer engineering, as field failures typically originate from inconsistent native insulation rather than bulk conductivity. Supply chain resilience for this niche product requires strategic raw material buffering and dual-path annealing capabilities to mitigate copper purity volatility.

Factory Tour: Manufacturing

Manufacturing Process of Copper Wire Without Enamel

The production of copper wire without enamel, also referred to as bare copper winding wire, involves a tightly controlled sequence of metallurgical and mechanical processes designed to ensure optimal electrical conductivity, mechanical strength, and dimensional accuracy. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of experience in non-ferrous metal processing, this process is executed with precision across four principal stages: Rod Drawing, Annealing, Enameling (excluded in this product variant), and Inline Testing. Each phase is supported by rigorous quality control protocols to meet international standards such as IEC 60228, ASTM B3, and GB/T 3953.

The process begins with high-purity electrolytic copper rod, typically of Grade 1 (Cu ≥ 99.99%) sourced from certified suppliers. The rod, usually in 8 mm diameter, undergoes rod drawing—a cold working process where the rod is pulled through a series of tungsten carbide or diamond dies to reduce its diameter to the target size, which can range from 0.05 mm to 3.5 mm depending on application requirements. This reduction is performed under controlled tension and lubrication conditions to prevent surface defects and ensure uniform elongation. The drawing line is equipped with precision diameter monitoring systems that provide real-time feedback to maintain tight tolerances, typically within ±0.005 mm.

Following drawing, the wire enters the continuous annealing stage. Cold drawing increases the wire’s tensile strength but reduces ductility, necessitating thermal treatment to restore flexibility and conductivity. The wire is passed through an induction-heated annealing furnace under an inert nitrogen atmosphere to prevent oxidation. Temperature is maintained between 450°C and 600°C, depending on wire gauge and desired mechanical properties. Post-annealing, the wire is rapidly quenched using deionized water to stabilize the recrystallized microstructure. This step ensures the final product achieves soft temper (Type 1 or Type 2 per ASTM B3) with elongation exceeding 25% and conductivity of at least 100% IACS.

Although enameling is a standard step in magnet wire production, for bare copper wire applications—such as busbar fabrication, grounding systems, or tinned wire feedstock—the wire exits the annealing stage without any insulating coating. However, the line remains compatible with optional surface treatments such as tinning or silver plating, if specified.

Inline testing is integral to ensuring product consistency. The wire passes through automated inspection systems that monitor diameter via laser gauges, detect surface irregularities using high-resolution optical scanners, and verify electrical continuity. Tensile strength and elongation are sampled at regular intervals using certified mechanical testers. All data is logged for traceability, with non-conforming batches automatically rejected.

Final quality control includes visual inspection, packaging verification, and certification of material test reports (MTRs), ensuring compliance with customer specifications and industry standards. This disciplined manufacturing approach guarantees that Luoyang Xinzhaohe delivers bare copper wire with superior conductivity, mechanical reliability, and batch-to-batch consistency.

Packaging & Logistics

Export Packaging Standards for Bare Copper Winding Wire

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously validated export packaging protocols for bare copper winding wire, specifically engineered to mitigate corrosion and physical damage during extended sea freight transit. With over 20 years of metallurgical and supply chain expertise, our methodology addresses the hygroscopic nature of copper and the electrochemical corrosion risks inherent in marine environments. This ensures dimensional stability and electrical integrity upon delivery, critical for downstream winding applications.

All shipments utilize ISPM 15-certified wooden pallets constructed from kiln-dried, non-resinous softwood. These pallets feature a minimum load-bearing capacity of 2,500 kg and incorporate reinforced stringers to prevent torsional deformation under dynamic cargo stresses. Pallet dimensions strictly adhere to ISO standard container footprints (1,200 x 1,000 mm or 1,140 x 1,140 mm) to maximize container space utilization and minimize interstitial movement. Each pallet base is treated with a borate-based preservative to inhibit fungal growth without introducing chlorides that accelerate copper oxidation.

The primary moisture barrier consists of a triple-layer polyethylene film system incorporating volatile corrosion inhibitors (VCI). This film is heat-sealed under controlled tension to form a hermetic envelope around the wire coils, eliminating air pockets that could facilitate condensation. The VCI technology actively releases organic compounds that adsorb onto copper surfaces, forming a molecular layer that suppresses electrochemical corrosion at humidity levels up to 95% RH. Unlike standard polyethylene, our VCI film maintains efficacy throughout voyages exceeding 60 days. Critical film specifications are detailed below.

| Parameter | VCI-Enhanced Film | Standard PE Film |

|---|---|---|

| Water Vapor Transmission Rate | ≤ 0.5 g/m²/day | ≥ 5.0 g/m²/day |

| VCI Active Lifespan | 180 days | N/A |

| Oxygen Permeability | ≤ 10 cm³/m²/day | ≥ 150 cm³/m²/day |

| Seal Integrity Test | 90 kPa for 30 min | 30 kPa for 10 min |

Coils are secured to pallets using galvanized steel strapping with a minimum 15 kN tensile strength, applied at four vertical and two horizontal axes. Strapping tension is calibrated to 30% of breaking load to prevent coil distortion while ensuring resistance to 1.5G inertial forces during vessel motion. Edge protectors distribute pressure across coil flanges, eliminating localized deformation.

Final container loading employs dunnage mats between pallet tiers and anti-slip pads at container walls. Humidity indicator cards (calibrated to 40%, 60%, and 75% RH thresholds) are placed within each pallet envelope, providing visual verification of barrier integrity upon arrival. Container desiccant is deployed at 150g/m³ volume, targeting a maximum internal humidity of 65% during transit.

These protocols, refined through decades of global logistics experience, ensure copper wire arrives with surface oxidation levels consistently below 0.5 mg/cm² – meeting IEC 60122-1 standards for bare conductor materials. We validate all packaging configurations through accelerated salt-spray testing (ASTM B117) and real-world voyage monitoring, providing certified assurance for high-value industrial shipments. Partnering with Xinzhaohe guarantees not only material excellence but also demonstrable supply chain resilience for critical winding wire procurement.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Wire Without Enamel

Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted industrial partner in the production of high-purity copper wire without enamel, serving global clients in power transmission, transformer manufacturing, and heavy electrical equipment sectors. With over two decades of metallurgical expertise and process refinement, our facility integrates advanced drawing technology, stringent quality control, and scalable production capacity to deliver bare copper winding wire that meets international standards including IEC 60317, ASTM B3, and GB/T 3953.

Our manufacturing infrastructure is engineered for precision and consistency. We operate fully automated copper rod casting and continuous wire drawing lines capable of producing diameters ranging from 0.8 mm to 10.0 mm, with tight tolerances and superior surface finish. Raw materials are sourced from certified electrolytic tough pitch (ETP) copper (Cu ≥ 99.90%), ensuring optimal electrical conductivity (≥ 100% IACS) and mechanical performance. Each production batch undergoes rigorous testing for tensile strength, elongation, ovality, and resistivity, verified through in-house laboratories equipped with state-of-the-art spectrometers, tensile testers, and micro-resistance measurement systems.

As a vertically integrated supplier, Luoyang Xinzhaohe maintains control over every stage of production—from rod casting to final spooling. This integration enables us to guarantee material traceability, reduce lead times, and offer customized solutions tailored to client specifications. Whether supplying soft-drawn (annealed) or hard-drawn copper wire in axial reels, trunnion spools, or customer-defined packaging, we adhere to exact dimensional, mechanical, and electrical requirements.

Our facility is ISO 9001:2015 certified, with documented quality management systems that ensure repeatability and compliance across high-volume orders. We support bulk deliveries with consistent batch-to-batch uniformity, making us a preferred supplier for OEMs requiring reliable input materials for winding operations in transformers, reactors, and industrial motors.

Strategically located in Luoyang, China, our plant benefits from streamlined logistics access to major ports and rail networks, enabling efficient domestic and international distribution. We export to North America, Southeast Asia, the Middle East, and Europe, maintaining long-term partnerships through technical collaboration, responsive service, and competitive pricing.

For sourcing managers and procurement engineers seeking a dependable supplier of copper wire without enamel, Luoyang Xinzhaohe offers proven technical capability, production stability, and a commitment to on-time delivery. Our team provides full technical documentation, including mill test certificates (MTCs), process capability studies, and sample kits upon request.

Contact us today to discuss your specifications and volume requirements. Partner with a manufacturer built on metallurgical excellence and industrial reliability.

Cathy Zhang

International Sales Manager

Luoyang Xinzhaohe Aluminum CO., Ltd

Email: cathy@transformerstrip.com

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper wire without enamel directly from China.