Table of Contents

Market Insight: Mirror Aluminum Plate Sheet

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Surface Quality Imperatives

The industrial demand for high-purity aluminum strip and foil within the transformer manufacturing sector is driven by stringent efficiency, reliability, and longevity requirements. While the term “mirror aluminum plate sheet” is frequently encountered in broader aluminum markets, its direct application in transformer windings is a significant misconception. Mirror-finish aluminum, characterized by its highly reflective, polished surface, is primarily utilized in decorative, architectural, or lighting applications where visual aesthetics are paramount. Transformer windings, whether aluminum or copper, demand fundamentally different surface characteristics focused on electrical performance and manufacturability, not reflectivity.

Transformer conductor strip and foil require an exceptionally clean, uniform, and defect-free surface. Microscopic surface imperfections – including scratches, pits, residual rolling oils, oxide inclusions, or edge burrs – act as initiation points for partial discharges under high electrical stress. These discharges progressively degrade the solid insulation (typically paper or polymer film) surrounding the conductor, ultimately leading to premature transformer failure. Surface cleanliness is equally critical; contaminants can impede the adhesion of insulating varnishes or create localized hot spots. The industry standard prioritizes a smooth, consistent matte or lightly etched surface optimized for insulation bonding and devoid of electrical weak points, not optical reflectivity.

Quality in transformer aluminum strip and foil is non-negotiable due to the catastrophic consequences of failure. Substandard material directly impacts core transformer performance metrics:

Electrical Conductivity: Must consistently meet or exceed 61.0% IACS (International Annealed Copper Standard) for high-purity grades. Even minor impurities (Fe, Si) or inconsistent annealing significantly reduce conductivity, increasing resistive losses (I²R losses) and operational temperature, thereby decreasing efficiency and lifespan.

Dimensional Precision: Tight tolerances on thickness (often ±0.005mm or better for foil) and width are essential for controlled winding tension, uniform magnetic flux distribution, and optimal core utilization. Variations cause winding instability, increased stray losses, and potential internal short circuits.

Mechanical Properties: Controlled tensile strength and elongation ensure the material can withstand the stresses of high-speed winding without breakage or excessive stretching, which compromises dimensional stability.

The table below illustrates the critical relationship between aluminum purity, conductivity, and suitability for transformer applications:

| Purity Level | Typical Conductivity (IACS %) | Key Impurities | Transformer Suitability |

|---|---|---|---|

| 99.99% (4N) | ≥ 63.0% | Minimal Fe, Si | Premium: Highest efficiency, longest life |

| 99.85% (3N85) | 61.0% – 61.5% | Controlled Fe, Si | Standard High-Grade: Meets IEC 60137 |

| < 99.80% | < 60.5% | Higher Fe, Si | Unsuitable: Excessive losses, reliability risk |

Luoyang Xinzhaohe Aluminum leverages over two decades of specialized production experience to deliver transformer strip and foil meeting the most exacting global standards (IEC 60137, ASTM B418). Our process rigor focuses on molten metal purification (de-gassing, filtration), precision cold rolling with controlled surface finish, and annealing in oxygen-free atmospheres to ensure optimal conductivity and a pristine, consistent surface. This unwavering commitment to metallurgical precision and surface integrity directly translates to transformers with lower no-load and load losses, enhanced thermal stability, and extended operational life – critical factors in today’s energy-conscious and reliability-driven power infrastructure markets. Sourcing decisions must prioritize demonstrable quality control data over superficial finish characteristics.

Technical Specs: Mirror Aluminum Plate Sheet

Technical Specifications for Mirror Aluminum Plate Sheet

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision mirror aluminum plate sheets designed for critical applications in transformer strips, electronic shielding, and high-reflection industrial systems. With over two decades of metallurgical expertise, our production processes ensure strict adherence to dimensional tolerances, surface integrity, and electrical performance. The following technical specifications define the core parameters of our mirror-finish aluminum plate sheets, optimized for reliability in demanding electrical and mechanical environments.

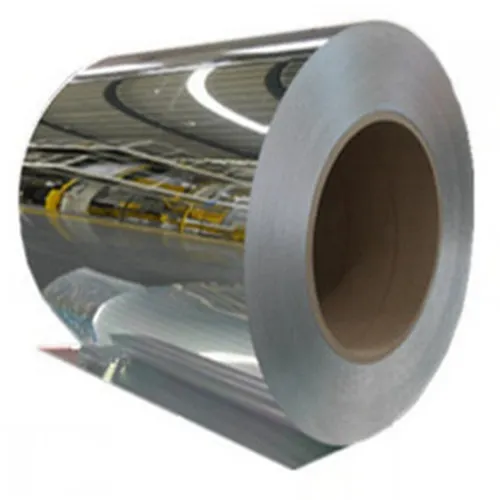

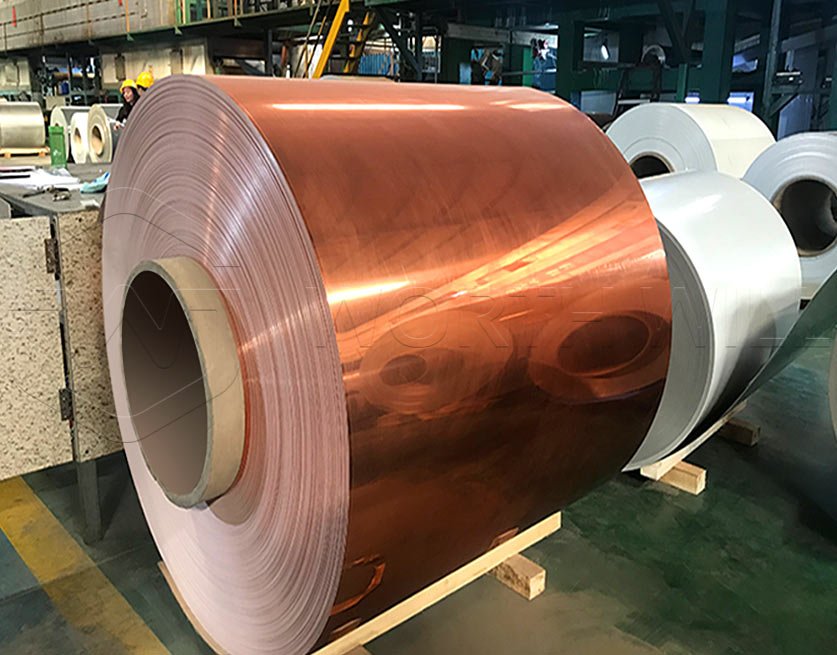

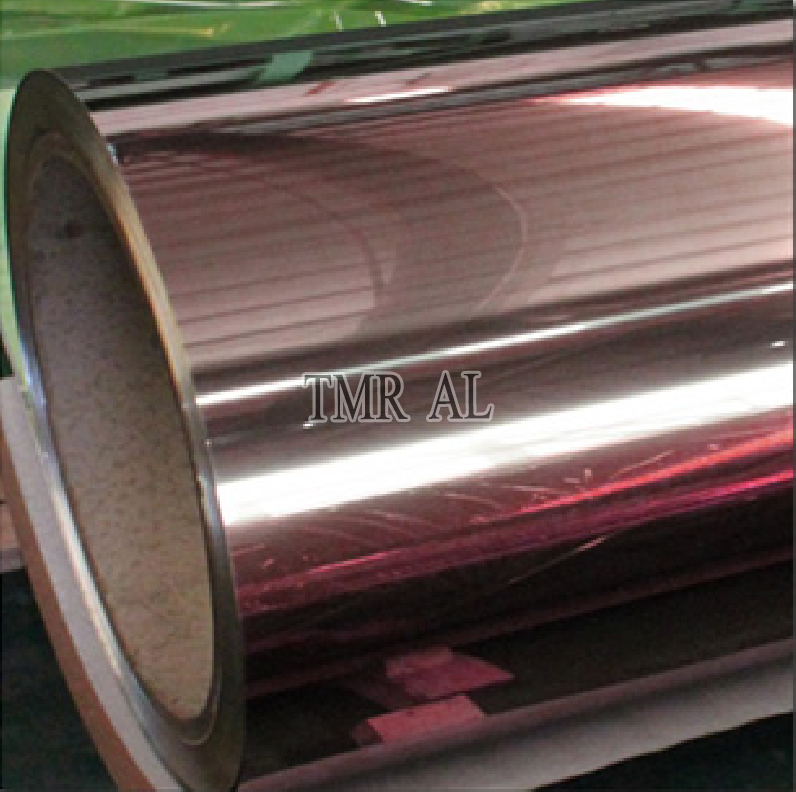

Our mirror aluminum plate sheets are produced from high-purity aluminum alloys, typically 1060, 1070, or 1100, selected for superior surface reflectivity and electrical conductivity. These alloys undergo a multi-stage rolling and polishing process to achieve a specular finish with a reflectivity exceeding 85%, making them ideal for optical and thermal management applications. The surface roughness (Ra) is maintained below 0.05 µm, ensuring minimal light scattering and consistent performance in reflective assemblies.

A defining feature of our product is precision slitting capability, with a tolerance of ±0.002 mm. This level of accuracy is achieved through computer-controlled rotary slitting lines equipped with high-speed servo feedback systems. Such precision ensures uniform strip widths, critical for automated winding processes in transformer and capacitor manufacturing. The slitting operation is integrated with real-time edge monitoring to eliminate dimensional drift and maintain consistency across production batches.

Edge quality is rigorously controlled to ensure burr-free finishes. Post-slitting, all edges undergo deburring and edge rounding processes using precision brushing and micro-grinding techniques. This eliminates sharp edges and micro-fractures that could compromise downstream handling or electrical insulation integrity. Burr height is consistently maintained below 1 µm, verified through profilometric inspection at multiple points per coil.

Electrical conductivity is a key performance metric, particularly for transformer and busbar applications. Our mirror aluminum sheets achieve a minimum conductivity of 59% IACS (International Annealed Copper Standard) in the annealed (O) temper condition. This ensures low resistive losses and efficient current transfer. Conductivity is validated using eddy current testing and four-point probe methods, with batch certification available upon request.

All products are subject to 100% inline surface inspection via high-resolution CCD systems to detect defects such as scratches, pits, or roll marks. Final quality verification includes dimensional checks, surface reflectivity measurement, and electrical testing.

| Parameter | Specification |

|---|---|

| Alloy Series | 1060, 1070, 1100 (O Temper) |

| Thickness Range | 0.1 mm – 3.0 mm |

| Width Tolerance (Slitting) | ±0.002 mm |

| Surface Roughness (Ra) | ≤ 0.05 µm |

| Reflectivity (60° gloss) | ≥ 85% |

| Edge Burr Height | < 1 µm |

| Electrical Conductivity | ≥ 59% IACS |

| Tensile Strength | 65 – 95 MPa |

| Elongation (min) | 35% |

| Coil ID | 200 mm, 300 mm, 505 mm |

| Max Coil OD | 1200 mm |

| Packaging | Anti-corrosion film, wooden pallet, sealed carton |

Factory Tour: Manufacturing

Manufacturing Process for Mirror Finish Aluminum Plate Sheet

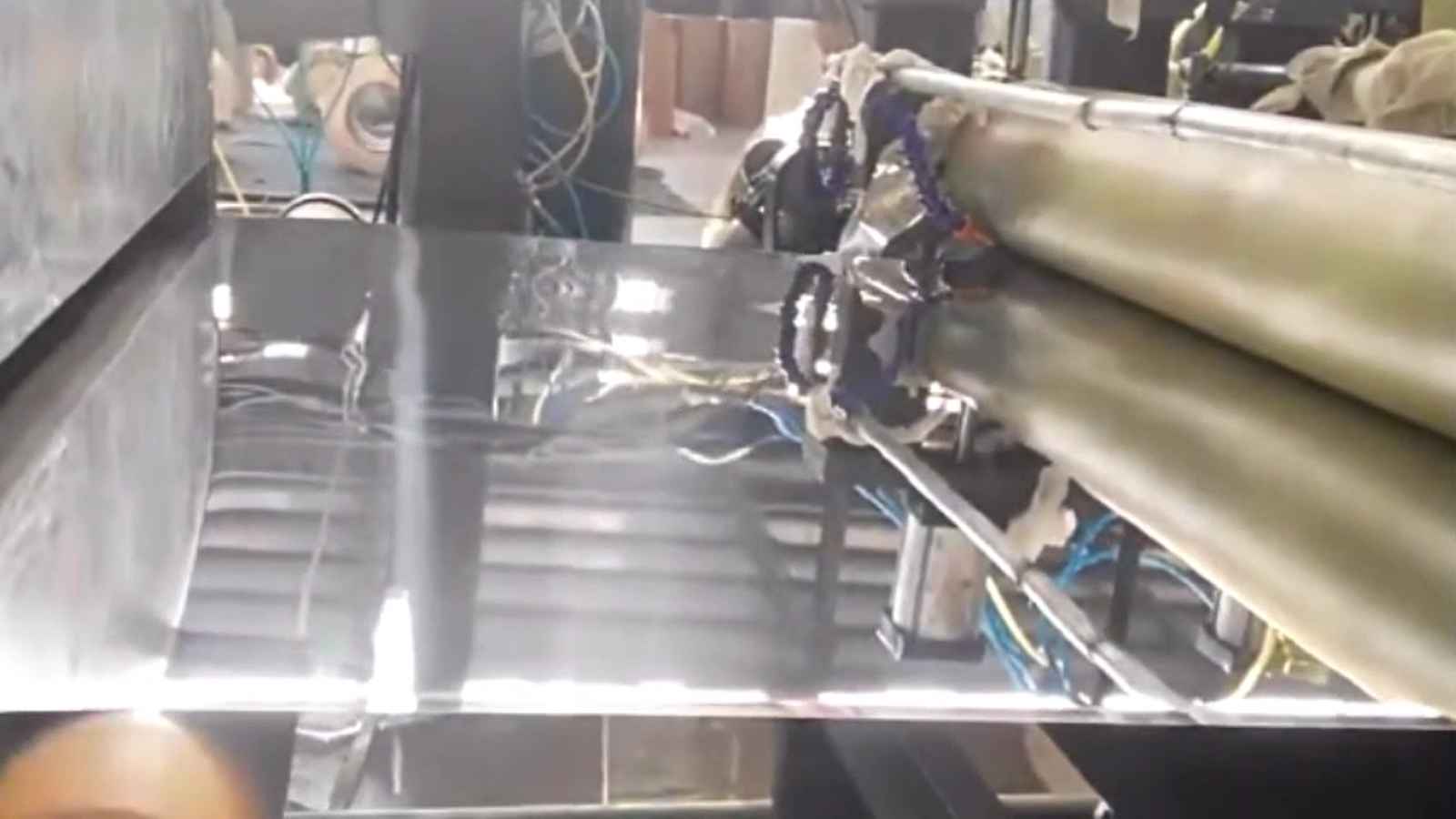

Luoyang Xinzhaohe Aluminum CO.,Ltd leverages two decades of specialized expertise in transformer-grade aluminum strip production to deliver mirror finish plate sheet meeting stringent electrical and surface integrity requirements. Our integrated manufacturing sequence begins with cold rolling, where high-purity aluminum ingots (typically 99.85%+ Al) undergo multi-stand reduction to achieve precise final thicknesses ranging from 0.1 mm to 0.5 mm. Critical parameters including roll gap tolerance (±2 µm), interstand tension control (±0.5%), and coolant purity (particle count <50/100ml) are continuously monitored via inline sensors to eliminate micro-roughness and ensure uniform grain structure. This stage establishes the foundational surface flatness (I-Units <0.5) and dimensional stability essential for subsequent mirror finishing.

Precision slitting follows cold rolling, utilizing computer-controlled rotary shear lines with tungsten carbide knives adjusted to 0.02 mm clearance tolerances. Coils are processed under constant tension (15-25 MPa) to prevent edge waviness or burr formation, with slit widths held to ±0.05 mm accuracy. Laser micrometers validate width consistency at 10-meter intervals, rejecting any deviation exceeding 0.1%. This phase is critical for transformer lamination stacks, where dimensional inaccuracies directly impact core loss and magnetic flux distribution.

Edge conditioning constitutes the final surface refinement step, employing a dual-stage process: First, mechanical brushing with non-woven abrasive belts (grit #400 to #800) removes residual rolling oils and micro-burrs. Second, electrochemical polishing in a phosphoric-sulfuric acid bath (45-60°C, 8-12 V DC) selectively dissolves surface peaks to achieve Ra values ≤0.05 µm. The process eliminates subsurface deformation from prior stages, yielding optical reflectivity >90% at 632.8 nm wavelength while maintaining edge squareness within 0.03 mm.

Quality Control Integration

QC protocols are embedded at all stages, not as end-point checks but as process-critical controls. Inline surface scanners detect defects >5 µm depth during rolling, while post-slitting edge profilometry verifies burr height <3 µm. Final mirror inspection employs spectral reflectometers and automated vision systems analyzing 100% of the surface per ASTM E430. Key acceptance criteria include:

| Parameter | Standard Requirement | Xinzhaohe Control Limit |

|---|---|---|

| Surface Roughness (Ra) | ≤0.08 µm | ≤0.05 µm |

| Reflectivity (632.8 nm) | ≥85% | ≥90% |

| Edge Burr Height | ≤5 µm | ≤3 µm |

| Thickness Variation | ±3% | ±1.5% |

All batches undergo cross-sectional SEM analysis to confirm absence of intermetallic clusters or subsurface cracks. Documentation includes full traceability from ingot melt chemistry to final coil, with test reports compliant with IEC 60404-8-7 for transformer core materials. This rigor ensures our mirror aluminum plate sheet achieves the surface perfection and electromagnetic performance demanded in high-efficiency transformer laminations.

Packaging & Logistics

Export Packaging for Mirror Aluminum Plate Sheet: Ensuring Integrity in International Shipments

At Luoyang Xinzhaohe Aluminum CO., Ltd, with over two decades of specialized experience in the production and global distribution of high-precision aluminum materials, we recognize that effective export packaging is as critical as the metallurgical quality of the product itself. For mirror aluminum plate sheet—characterized by its highly reflective, defect-sensitive surface—packaging is engineered not only to prevent mechanical damage but also to maintain surface integrity throughout extended sea freight logistics.

All mirror aluminum plate sheets destined for international markets are systematically secured on robust wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets are designed to meet the structural demands of multi-tier stacking and dynamic load conditions encountered during ocean transport. The dimensional stability and load-bearing capacity of the wooden base ensure that the aluminum sheets remain immobilized, minimizing the risk of edge deformation, scratching, or warping due to vibration and shifting during vessel transit.

Each stack of mirror aluminum plate sheet is wrapped in multiple layers of high-density, moisture-proof polyethylene film. This vapor barrier film is heat-sealed at all seams to form a hermetic enclosure that prevents the ingress of humidity, salt-laden air, and condensate—common hazards in marine environments. Given that aluminum is susceptible to surface oxidation and water spotting, particularly on optically finished grades, the moisture barrier is essential for preserving the material’s aesthetic and functional performance upon arrival.

Additional protective measures include the interposition of kraft paper or non-woven separator sheets between individual aluminum plates to prevent surface-to-surface contact and mitigate the risk of micro-scratching. Edge protectors made from corrugated plastic or reinforced cardboard are applied to all four sides of the stack to absorb impact and resist lateral abrasion during handling and container loading.

All packaged units are labeled with weather-resistant, multilingual marking tags indicating product specifications, batch numbers, handling instructions, and orientation indicators (e.g., “This Side Up”). These labels comply with international shipping standards and facilitate seamless customs clearance and warehouse processing at destination ports.

Our packaging protocol has been validated through years of successful delivery to markets across Southeast Asia, the Middle East, Europe, and the Americas. It reflects a comprehensive understanding of the interplay between material science, logistics engineering, and environmental exposure in global supply chains. By integrating mechanical protection, moisture resistance, and regulatory compliance, Luoyang Xinzhaohe ensures that every shipment of mirror aluminum plate sheet arrives in the same condition as it left our facility—ready for immediate processing and integration into high-value applications such as architectural cladding, lighting reflectors, and decorative paneling.

For technical inquiries regarding custom packaging configurations or compliance documentation, our supply chain engineering team is available to support project-specific requirements.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe: Precision Mirror Aluminum Plate Sheet Manufacturing

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of specialized metallurgical expertise to deliver mirror aluminum plate sheet meeting the most stringent industrial specifications. Our integrated production ecosystem, spanning direct-chill casting through precision cold rolling and surface finishing, ensures absolute control over material properties and dimensional accuracy. We operate eight high-precision cold rolling lines with tension-leveling capabilities, maintaining flatness deviation below 0.5mm/m and thickness tolerances of ±0.005mm for critical applications in transformer cores, electronic shielding, and high-reflectivity components. Annual production capacity exceeds 20,000 metric tons, supported by twelve continuous annealing furnaces calibrated for exact thermal profiles to achieve target temper states (H18, O, H24) without compromising surface integrity.

Surface quality is non-negotiable in mirror aluminum applications. Our proprietary polishing and etching protocols, combined with ISO Class 8 cleanroom finishing environments, consistently achieve Ra surface roughness ≤0.05μm and reflectivity >95% across 1060, 1070, and 1100 alloy grades. Rigorous inline monitoring via non-contact laser profilometry and spectrophotometric analysis validates every coil against ASTM B479 and IEC 60404-1 standards. This precision is underpinned by our certified metallurgical laboratory, equipped for full compositional verification (OES), microstructure analysis (SEM), and mechanical testing (tensile, bend, cupping). Our ISO 9001:2015 and IATF 16949 certified quality management system mandates 100% surface inspection via automated vision systems, eliminating defects as minute as 10μm.

Supply chain resilience is engineered into our operational model. Vertical integration from billet casting to slitting enables rapid response to complex B2B demands, including custom widths up to 1,650mm and thicknesses from 0.1mm to 3.0mm. We maintain strategic raw material buffers of 99.85%+ purity aluminum ingot, mitigating market volatility. Our logistics network guarantees 15–20 day lead times for 500kg+ orders, with DDP solutions to major industrial hubs in Asia, Europe, and North America. Dedicated supply chain engineers collaborate with clients to optimize inventory planning, reducing landed costs through container consolidation and JIT scheduling.

For transformer manufacturers requiring flawless magnetic shielding substrates or electronics producers demanding optical-grade reflectivity, Luoyang Xinzhaohe eliminates supply chain bottlenecks through technical partnership. We provide full material traceability via blockchain-enabled documentation and co-develop process-specific solutions for challenging applications. Initiate a technical consultation to receive alloy-specific mechanical property datasheets, surface finish validation reports, and capacity allocation details. Contact Cathy directly at cathy@transformerstrip.com to schedule a metallurgical review and secure production slots for your next mirror aluminum plate sheet requirement. Partner with proven engineering rigor where surface perfection defines performance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing mirror aluminum plate sheet directly from China.