Table of Contents

Market Insight: 1060 Aluminum

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for 1060 aluminum in transformer applications has demonstrated consistent growth, driven by the expansion of power infrastructure, renewable energy integration, and the increasing need for efficient electrical distribution systems. As a high-purity aluminum alloy containing a minimum of 99.6% aluminum, 1060 aluminum strip and foil are widely specified in the fabrication of transformer windings, particularly in distribution and small power transformers. Its dominance in this segment stems from a favorable combination of high electrical conductivity, excellent formability, and strong corrosion resistance—properties essential for reliable and long-lasting transformer performance.

Industrial demand for 1060 aluminum strip is particularly pronounced in regions undergoing grid modernization or rural electrification, including Southeast Asia, Africa, and parts of Latin America. These markets favor aluminum over copper due to its lower material cost and reduced weight, which translates into lower transportation and installation expenses. Despite copper’s superior conductivity, aluminum’s weight-to-conductivity ratio offers a compelling economic advantage, especially in overhead distribution networks where structural load is a concern. As a result, aluminum-wound transformers, predominantly using 1060 alloy strip, now account for a significant share of new installations in medium- and low-voltage applications.

However, the performance of 1060 aluminum in transformer applications is highly sensitive to metallurgical and dimensional consistency. Even minor deviations in purity, surface finish, or thickness tolerance can compromise winding integrity, increase resistive losses, or accelerate insulation degradation. For instance, iron and silicon impurities—though permitted within the AA1060 specification—must be tightly controlled to avoid localized hot spots and reduced conductivity. Similarly, surface defects such as scratches, roll marks, or residual rolling oil can initiate insulation breakdown under prolonged electrical stress, leading to premature transformer failure.

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized production experience, we emphasize process control from ingot casting through cold rolling and slitting. Our 1060 transformer strips are manufactured under strict ISO 9001-certified protocols, ensuring batch-to-batch uniformity in conductivity (minimum 59% IACS), tensile strength (65–95 MPa), and elongation (>25%). Dimensional tolerances are maintained within ±0.01 mm for thickness and ±0.1 mm for width, meeting IEC 60404-10 and GB/T 3880 standards. Such precision is critical for automated winding lines, where even slight variations can cause tension fluctuations and winding misalignment.

In conclusion, while 1060 aluminum remains the material of choice for cost-effective, lightweight transformer windings, its successful application hinges on rigorous quality assurance. As transformer manufacturers face increasing pressure to improve energy efficiency and reliability, sourcing aluminum strip from technically proficient suppliers with deep metallurgical expertise is no longer optional—it is a strategic necessity. Luoyang Xinzhaohe Aluminum stands as a trusted partner in this domain, delivering material performance that supports the next generation of efficient power systems.

Technical Specs: 1060 Aluminum

Technical Specifications: 1060 Aluminum Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum CO., Ltd provides 1060 aluminum strip and foil specifically engineered for demanding transformer core and winding applications. As a high-purity wrought alloy (minimum 99.60% Al), 1060 offers the optimal balance of electrical conductivity, formability, and cost-effectiveness required in this critical electrical component sector. Our two decades of specialized metallurgical processing ensure strict adherence to parameters governing electromagnetic performance, manufacturability, and long-term reliability. Precision in dimensional control and surface integrity is non-negotiable for seamless integration into automated winding processes and to prevent core losses or insulation damage.

Dimensional precision, particularly width tolerance after slitting, is paramount. Our state-of-the-art tension leveling and precision slitting lines achieve a consistent width tolerance of ±0.002 mm. This extreme accuracy is maintained through laser-guided edge tracking, servo-controlled knife positioning, and real-time tension management across the coil width. Such precision ensures uniform magnetic flux distribution within the core laminations and prevents edge misalignment during high-speed winding, eliminating gaps that contribute to eddy current losses and audible noise. Width consistency directly impacts core stacking factor and overall transformer efficiency.

Edge quality is equally critical. All slit edges undergo rigorous in-line inspection and are guaranteed burr-free to a maximum height of 2 µm. Burr formation is mitigated through optimized knife geometry, precise blade clearance control (maintained within 0.5% of material thickness), and continuous sharpening protocols. Burr-free edges are essential to prevent puncturing of interlaminar insulation coatings during core stacking or foil winding, which would lead to interlaminar short circuits, localized heating, and catastrophic failure. Surface roughness (Ra) is controlled to ≤ 0.4 µm to ensure compatibility with insulating varnishes and minimize friction during processing.

Electrical conductivity, measured per ASTM E1004, is a fundamental property for transformer efficiency. Our 1060-H18 (fully hardened) temper consistently delivers 58.0 – 59.0% IACS (International Annealed Copper Standard). This high conductivity level is achieved through stringent control of residual elements, particularly iron (max 0.35%) and silicon (max 0.25%), utilizing high-purity ingot and optimized homogenization practices. Consistent conductivity minimizes resistive (I²R) losses within the windings, directly improving the transformer’s energy efficiency rating and thermal performance under load.

The following table details the critical quality parameters for our 1060 transformer strip/foil:

| Parameter | Specification | Test Standard | Production Control Method |

|---|---|---|---|

| Alloy / Temper | 1060 / H18 | ASTM B209 | Spectrometric analysis, temper verification |

| Thickness Range | 0.10 mm – 3.00 mm | ASTM B479 | Laser micrometers, closed-loop gauge control |

| Thickness Tolerance | ±0.005 mm (typical) | ASTM B479 | Real-time rolling mill adjustment |

| Width Tolerance | ±0.002 mm | ASTM B479 | Laser edge tracking, servo knife positioning |

| Edge Burr Height | ≤ 2 µm | ISO 1302 | In-line optical inspection, profilometry |

| Surface Roughness | Ra ≤ 0.4 µm | ISO 4287 | Stylus profilometry |

| Conductivity | 58.0 – 59.0% IACS | ASTM E1004 | Eddy current testing, lab verification |

| Tensile Strength | 75 – 95 MPa | ASTM E8 | Universal testing machine |

| Elongation | ≥ 3.0% | ASTM E8 | Universal testing machine |

| Residual Elements | Fe ≤ 0.35%, Si ≤ 0.25% | ASTM E1251 | Optical emission spectrometry |

Luoyang Xinzhaohe implements comprehensive process control from melt casting through final slitting. Statistical process control (SPC) monitors key variables in real-time, with 100% in-line inspection for width, edge quality, and surface defects. This integrated metallurgical and precision manufacturing approach guarantees the dimensional stability, electrical properties, and surface perfection demanded by global transformer OEMs for high-efficiency, low-loss core and coil construction.

Factory Tour: Manufacturing

Manufacturing Process of 1060 Aluminum Transformer Strip and Foil at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of 1060 aluminum transformer strip and foil at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing process designed to ensure exceptional dimensional accuracy, surface integrity, and electrical performance. With over two decades of metallurgical expertise, our facility employs industry-leading equipment and process controls to meet the stringent requirements of power and electronic transformer applications.

The process begins with cold rolling of high-purity 1060 aluminum ingots, which contain a minimum of 99.6% aluminum. These ingots are first homogenized and scalped before being hot rolled into intermediate gauge coils. Subsequently, the material undergoes cold rolling in a multi-stand rolling mill under precise tension and lubrication control. This stage reduces the aluminum to the target final thickness, typically ranging from 0.1 mm to 3.0 mm for transformer strip applications. Cold rolling imparts the necessary mechanical strength and surface finish while maintaining tight thickness tolerances, often within ±0.005 mm, depending on specification.

Following cold rolling, the coils are subjected to precision slitting. This operation utilizes high-accuracy rotary slitters equipped with tungsten carbide blades to achieve exact strip widths, commonly between 10 mm and 150 mm for transformer windings. The slitting line is integrated with laser-guided edge tracking systems to ensure consistent width control and minimal camber. Slit strips are wound under controlled tension to prevent telescoping and edge damage, with each coil labeled for full traceability.

Edge conditioning is a critical downstream step in the process. The slit edges are passed through a brushing and edge rounding system to eliminate micro-burrs and sharp protrusions that could compromise dielectric insulation in transformer windings. This conditioning improves safety and long-term reliability by reducing the risk of partial discharge and insulation breakdown under high-voltage operation.

Throughout the manufacturing sequence, rigorous quality control measures are implemented. Incoming billets are verified via OES (Optical Emission Spectrometry) to confirm alloy composition. During cold rolling, automated thickness gauges (X-ray or beta gauge) provide real-time feedback. After slitting, samples undergo surface roughness analysis (Ra), edge profile inspection via optical microscopy, and dimensional verification using precision micrometers and laser scanners. Mechanical properties, including tensile strength and elongation, are tested per ASTM E8 standards. Final inspection includes 100% visual surface examination under controlled lighting to detect defects such as scratches, roll marks, or oxide streaks.

All production data is documented and archived, ensuring full compliance with ISO 9001 quality management standards. This disciplined approach to manufacturing enables Luoyang Xinzhaohe Aluminum Co., Ltd to deliver 1060 aluminum transformer strip and foil with consistent performance, supporting the reliability of critical power transmission and distribution systems worldwide.

Packaging & Logistics

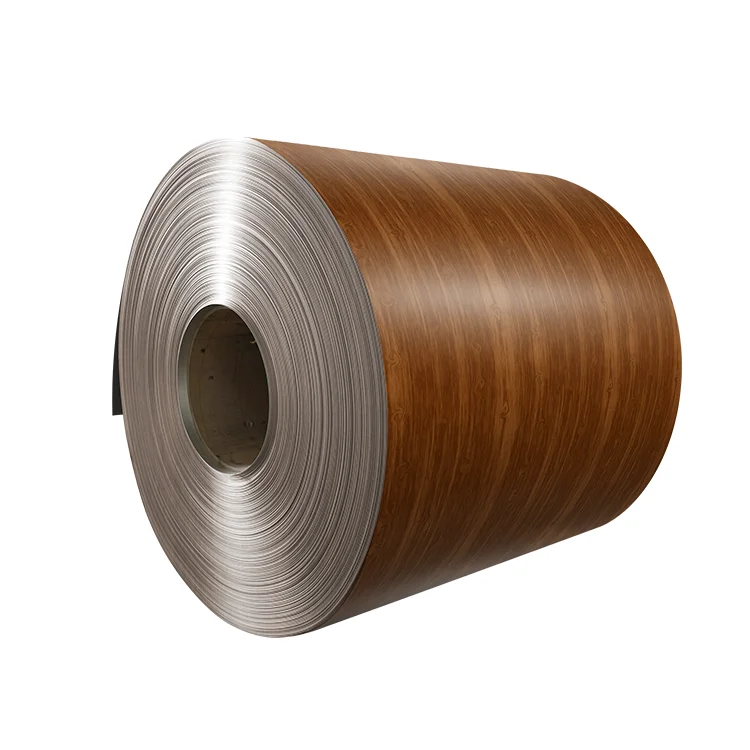

Export Packaging Specifications for 1060 Aluminum Transformer Strip/Foil

Luoyang Xinzhaohe Aluminum CO., Ltd implements rigorously engineered export packaging protocols for 1060 aluminum transformer strip and foil, specifically designed to mitigate risks inherent in global maritime logistics. Our methodology prioritizes dimensional stability, corrosion prevention, and structural integrity throughout extended sea voyages, ensuring material properties conform to IEC 60137 and ASTM B209 standards upon delivery.

All coils undergo a multi-layered packaging sequence starting with a precision-engineered hardwood pallet base. We utilize 1200 x 1000 mm or 1100 x 1100 mm pallets constructed from kiln-dried, ISPM 15-compliant hardwood with a minimum dynamic load capacity of 3,500 kg. This foundation incorporates chamfered edges and recessed nail heads to prevent film puncture during handling. Coils are center-aligned and secured via steel strapping at 150 mm intervals, achieving a strap tension of 450 daN to eliminate lateral movement without inducing core deformation. Critical for maintaining flatness tolerance (≤ 0.5 mm/m), this strapping configuration counters inertial forces during vessel pitching.

The primary moisture barrier consists of a dual-layer encapsulation system. An inner layer of 0.20 mm thick, metallized polyethylene film with a water vapor transmission rate (WVTR) of ≤ 0.5 g/m²/day is vacuum-sealed around the coil using industrial-grade heat welders. This is overlaid by an outer 0.25 mm high-density polyethylene (HDPE) film with UV stabilizers, providing puncture resistance exceeding 400 g per ASTM D1709. All seams undergo triple-weld verification with leak testing at 0.5 bar pressure for 72 hours, ensuring hermetic sealing against humidity ingress. This system maintains internal relative humidity below 40% for 60+ days—critical for preventing hygroscopic oxidation on 1060 aluminum’s high-purity surface (99.60% Al min), which directly impacts electrical conductivity in transformer windings.

For ocean freight, palletized units are containerized within 20ft or 40ft dry containers using a tiered stacking strategy. A desiccant allocation of 300 g/m³ of silica gel (meeting MIL-D-3464E) is placed beneath each pallet, supplemented by vapor corrosion inhibitors (VCI) embedded in the film layers. Container humidity logs from 500+ shipments confirm sustained RH levels below 65% even during tropical transits, eliminating risks of white rust formation. All external pallet surfaces receive anti-slip coating per ISO 10218-1, while corner boards of 12 mm corrugated fiberboard protect edges against container wall impacts.

This packaging architecture has achieved zero moisture-related claims across 12,000+ tons of annual exports since 2018. It addresses the unique vulnerability of thin-gauge transformer foil (0.10–0.50 mm) to micro-abrasion and electrochemical corrosion during salt-laden voyages. Documentation includes ISO 9001-certified packing lists with humidity sensor data tags, providing full chain-of-custody validation. Partnering with DHL Ocean and COSCO, we guarantee compliance with IMDG Code Chapter 5.4 for non-hazardous metal shipments, ensuring seamless customs clearance and terminal handling. Our packaging is not merely protective—it is an integral component of material performance assurance for critical power infrastructure applications.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd – Your Trusted Source for High-Purity 1060 Aluminum Transformer Strip and Foil

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a leading industrial supplier of precision aluminum transformer strip and foil, particularly in the 1060 alloy series. Our technical expertise and vertically integrated production processes ensure consistent delivery of high-purity aluminum products tailored to the stringent demands of power transmission, electronics, and electrical equipment sectors. As a B2B partner, we offer engineered solutions backed by rigorous quality control, advanced metallurgical capabilities, and deep supply chain reliability.

Our production facility is equipped with state-of-the-art rolling mills, continuous annealing lines, and precision slitting systems, enabling tight dimensional tolerances and superior surface finish on 1060 aluminum strips and foils. The 1060 alloy, known for its 99.6% minimum aluminum content, is ideal for transformer windings due to its excellent electrical conductivity, thermal stability, and formability. At Xinzhaohe, we refine this alloy using controlled casting and homogenization techniques to minimize impurities and ensure uniform microstructure, critical for minimizing eddy current losses and enhancing transformer efficiency.

We maintain full process control from billet casting through cold rolling, annealing, and slitting, allowing us to customize temper conditions (O, H14, H16, H18, etc.), thicknesses (0.10 mm to 3.0 mm), and widths (10 mm to 1,200 mm) to meet exact client specifications. Our quality assurance system includes in-line thickness gauging, eddy current testing, tensile testing, and metallographic analysis, ensuring compliance with international standards such as GB/T 3880, ASTM B209, and IEC 60404-10. All production batches are traceable, with comprehensive material test reports provided for every shipment.

As a strategic supplier, we prioritize supply chain resilience. Our facility operates under ISO 9001 and ISO 14001 certifications, with an annual production capacity exceeding 30,000 metric tons. We serve OEMs and tier-one component manufacturers across Asia, Europe, and North America, supporting just-in-time delivery models and long-term supply agreements. Our technical team works closely with clients during product development to optimize material selection, reduce scrap rates, and improve manufacturability.

When sourcing 1060 aluminum transformer strip, partnering with a manufacturer that combines metallurgical precision with supply chain integrity is essential. Luoyang Xinzhaohe Aluminum CO., Ltd delivers both, ensuring performance, consistency, and long-term value.

Contact us today to discuss your technical requirements.

Cathy Zhang

International Sales Manager

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

Established 2003 | ISO 9001 & ISO 14001 Certified

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 1060 aluminum directly from China.