Table of Contents

Market Insight: Copper Solenoid Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

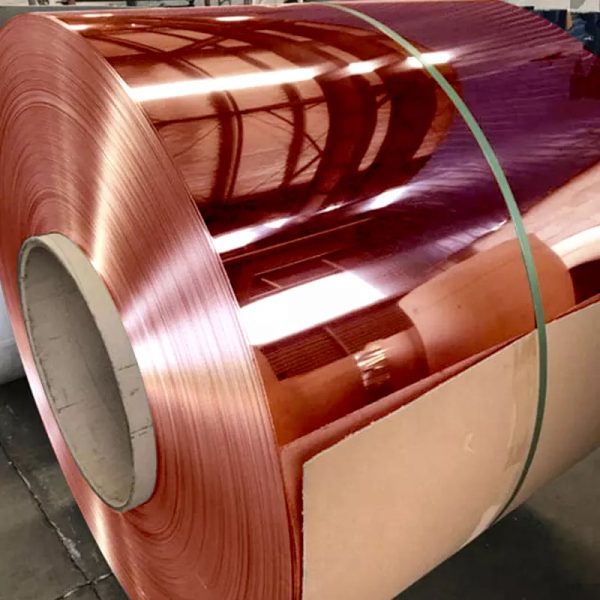

The global demand for copper solenoid coils in transformer applications remains robust, driven by the continuous expansion of power infrastructure, renewable energy integration, and industrial electrification. Copper solenoid coils serve as critical components in power and distribution transformers, where they function as primary and secondary windings responsible for electromagnetic induction. The performance, efficiency, and longevity of a transformer are directly influenced by the electrical conductivity, thermal stability, and mechanical integrity of the copper coil material.

Copper is preferred in high-efficiency and high-reliability transformer designs due to its superior electrical conductivity—approximately 100% IACS (International Annealed Copper Standard)—which minimizes resistive losses and improves energy transfer efficiency. This characteristic is particularly vital in applications where energy conservation and operational cost reduction are paramount, such as in utility-scale power transformers and industrial equipment. Additionally, copper’s high tensile strength and ductility allow for precise winding geometries, ensuring tight coil packing and reduced risk of deformation under electromagnetic stress.

Despite the rising adoption of aluminum as a cost-effective alternative in certain transformer segments, copper maintains a dominant position in premium and mission-critical applications. The market for copper transformer strip and foil is concentrated in regions with stringent energy efficiency regulations, including the European Union, North America, and parts of East Asia. These markets increasingly demand compliance with international standards such as IEC 60076 and IEEE C57, which emphasize low no-load and load losses—parameters heavily influenced by coil material quality.

Quality in copper solenoid coil production is non-negotiable. Impurities, inconsistent temper, dimensional deviations, and surface defects can lead to localized heating, insulation breakdown, and premature transformer failure. High-purity electrolytic tough pitch (ETP) copper, cold-rolled to precise thickness tolerances (typically 0.5–3.0 mm for strip applications), is essential to ensure uniform current distribution and thermal management. Furthermore, surface finish quality directly impacts the integrity of insulating varnish coatings, which are critical for dielectric performance and long-term reliability.

Luoyang Xinzhaohe Aluminum Co., Ltd brings over two decades of metallurgical and supply chain expertise to the transformer materials sector. While historically recognized for aluminum foil and strip solutions, the company supports integrated sourcing strategies that include high-grade copper materials for solenoid coil manufacturing. Our quality assurance protocols encompass rigorous material testing, dimensional inspection, and batch traceability, ensuring compliance with the technical demands of modern transformer design.

As global energy systems evolve toward higher efficiency and greater resilience, the role of high-quality copper solenoid coils will continue to expand. Investment in material precision and process control is not merely a technical requirement but a strategic imperative for manufacturers aiming to meet the performance expectations of next-generation power systems.

Technical Specs: Copper Solenoid Coil

Technical Specifications for Copper Solenoid Coil Sourcing

Precision copper solenoid coils demand rigorous adherence to dimensional, surface, and electrical properties to ensure optimal performance in high-frequency transformer and inductor applications. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialized expertise in conductor strip production, we define critical parameters that directly impact winding integrity, thermal management, and electromagnetic efficiency. Deviations beyond specified tolerances introduce parasitic losses, insulation damage, and reduced operational lifespan. Key specifications must be validated through certified laboratory testing and in-line process controls.

Width tolerance is non-negotiable for consistent layer stacking and core fitment. We mandate a precision slitting tolerance of ±0.002 mm for all coil widths. This micron-level accuracy prevents edge misalignment during high-speed winding, eliminating inter-turn shorts and magnetic flux distortion. Achieving this requires state-of-the-art tension-controlled slitters with laser-guided edge tracking and real-time metrology feedback. Any deviation exceeding ±0.003 mm risks coil bulging or core gap inconsistencies, directly degrading inductance stability.

Edge quality is equally critical. All slit edges must be burr-free with a maximum edge protrusion of 3 µm as measured per ASTM E3 metallographic cross-sectioning. Microscopic burrs act as field concentrators, accelerating insulation breakdown and increasing partial discharge risk. Our process employs high-precision shear slitting with dynamically compensated tool clearance and continuous optical edge inspection (200x magnification) to ensure zero detectable burrs. Surface roughness (Ra) must not exceed 0.4 µm to minimize skin effect losses at operating frequencies above 20 kHz.

Electrical conductivity is foundational. Material must meet or exceed 100% IACS (International Annealed Copper Standard) at 20°C, verified via four-point probe resistivity testing per ASTM B193. This requires oxygen-free electronic (OFE) copper with minimum 99.99% purity and controlled grain structure. Conductivity below 99.9% IACS increases DC resistance by >0.1%, elevating I²R losses and thermal rise. Trace elements like phosphorus or sulfur must be held below 5 ppm to prevent conductivity degradation during annealing.

The following table details mandatory technical parameters and validation protocols:

| Parameter | Specification | Test Standard | Functional Impact |

|---|---|---|---|

| Width Tolerance | ±0.002 mm | ASTM E3 | Prevents winding misalignment and core gaps |

| Edge Burr Height | ≤ 3 µm | ASTM E3 (cross-section) | Eliminates insulation puncture risk |

| Surface Roughness (Ra) | ≤ 0.4 µm | ISO 4287 | Reduces high-frequency eddy current losses |

| Conductivity | ≥ 100% IACS | ASTM B193 | Minimizes resistive heating and energy loss |

| Flatness | ≤ 0.1 mm/m | ISO 2768 | Ensures uniform tension during high-speed winding |

| Coil Set (Ovality) | ≤ 0.3 mm | Internal Procedure | Prevents edge damage during handling and unwinding |

Material certification must include full traceability to melt chemistry (ICP-MS analysis), conductivity logs, and slitting batch records. We enforce 100% inline optical edge inspection and statistical process control (SPC) for width tolerance, with third-party verification reports available per shipment. Consistent adherence to these specifications ensures solenoid coils achieve target Q-factors, thermal derating margins, and >30,000-hour operational reliability in critical power applications. Partnering with suppliers possessing certified metallurgical laboratories and dedicated slitting lines is essential for meeting these exacting requirements. Luoyang Xinzhaohe Aluminum Co., Ltd. integrates these protocols across our copper coil production to deliver zero-defect material for demanding electromagnetic systems.

Factory Tour: Manufacturing

Manufacturing Process for Copper Solenoid Coil Strip at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance copper solenoid coil strip at Luoyang Xinzhaohe Aluminum Co., Ltd follows a tightly controlled, multi-stage manufacturing sequence designed to ensure dimensional accuracy, surface integrity, and electromagnetic consistency. With over two decades of specialization in transformer-grade aluminum and copper strip and foil, our facility integrates advanced metallurgical processing with rigorous quality assurance to meet the exacting demands of power and signal transformer applications.

The process begins with cold rolling of high-purity electrolytic tough pitch (ETP) copper, typically supplied in hot-rolled coils meeting ASTM B152 specifications. These initial billets undergo scale removal and surface conditioning prior to entry into the cold rolling mill. Utilizing precision reversing rolling stands equipped with automatic gauge control (AGC), the material is reduced to the target final thickness, commonly ranging from 0.1 mm to 0.5 mm for solenoid coil applications. The cold rolling stage is conducted under controlled tension and lubrication to minimize thickness variation, ensure uniform grain structure, and achieve the required mechanical properties, including tensile strength and elongation.

Following cold rolling, the coils proceed to the precision slitting line, where they are longitudinally cut into narrow strips matching the winding width requirements of the solenoid coil design. Our slitting systems employ high-tolerance circular knives with computer-controlled positioning, achieving width tolerances within ±0.05 mm. This step is critical in preventing edge burrs and ensuring consistent strip geometry, which directly influences winding tightness and interlayer insulation integrity in the final coil.

Edge conditioning is the subsequent and essential phase in the manufacturing sequence. After slitting, the strip edges are subjected to a controlled deburring and radius forming process. This is accomplished through precision brushing, roller burnishing, or micro-rounding techniques that eliminate sharp edges and micro-cracks. Proper edge conditioning mitigates the risk of dielectric breakdown during coil operation and reduces wear on winding machinery during customer fabrication.

Throughout the production flow, integrated quality control checkpoints are enforced. These include in-line laser micrometry for continuous thickness monitoring, eddy current testing for subsurface defect detection, and periodic surface roughness measurement via profilometry. Mechanical properties are verified through tensile testing in accordance with ASTM E8, while electrical conductivity is confirmed using eddy current conductivity meters, ensuring values exceed 98% IACS. Final inspection includes visual surface evaluation under controlled lighting and defect mapping, with non-conforming sections automatically marked and removed.

All process parameters are logged and traceable to individual coil heat numbers, supporting full material certification under ISO 9001 standards. This disciplined approach to manufacturing ensures that every batch of copper solenoid coil strip delivered from Luoyang Xinzhaohe meets the performance, reliability, and consistency required in high-efficiency transformer systems.

Packaging & Logistics

Export Packaging Specifications for Copper Solenoid Coil Shipments

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical engineering expertise to ensure copper solenoid coils arrive at global destinations in pristine condition. Our export packaging system is rigorously designed to mitigate the multifaceted risks inherent in sea freight, including salt-laden atmospheres, prolonged humidity exposure, condensation cycles, and mechanical vibration. This protocol is non-negotiable for preserving the dimensional stability, surface integrity, and electrical performance of copper transformer strip and foil products during international transit.

All coils are secured to ISPM 15-certified wooden pallets constructed from kiln-dried, knot-free softwood. Pallet dimensions are engineered to match coil outer diameters precisely, minimizing lateral movement. Structural integrity is reinforced through triple-layer cross-laminated deck boards and steel-reinforced stringers capable of supporting 2.5 metric tons per pallet without deflection. Critical to maritime compliance, pallets undergo thermal treatment to 56°C for 30 minutes, eliminating pest vectors while maintaining wood moisture content below 20% to prevent post-treatment warping. Each pallet receives official ISPM 15 branding, ensuring seamless customs clearance across all major trading blocs.

Moisture ingress represents the primary threat to copper coil performance during ocean transport. Our multi-barrier protection system begins with a primary wrap of 100μm-thick, ASTM E96-compliant low-density polyethylene (LDPE) film. This vapor barrier is applied under 15% tension using automated stretch wrappers, ensuring 100% surface coverage without creasing. Secondary protection employs a desiccant-enhanced intermediate layer: silica gel packets (500g per m³ of enclosed volume) are strategically positioned between coil layers, while humidity indicator cards (calibrated for 30%–60% RH range) provide visual verification of internal conditions. The final seal utilizes a 75μm metallized polyester overwrap, reflecting radiant heat and reducing diurnal temperature fluctuations within the package by up to 12°C.

Moisture-Proof Film Specifications

| Film Type | Thickness (μm) | Moisture Transmission Rate (g/m²/day) | Application Purpose |

|——————–|—————-|—————————————|—————————–|

| Primary LDPE | 100 | ≤1.2 | Core vapor barrier |

| Metallized Overwrap| 75 | ≤0.3 | Thermal/UV reflection |

Coils are further stabilized against shipboard vibration through perimeter steel strapping (16mm width, 15kN tensile strength) applied at 300mm intervals. Edge protectors fabricated from 3mm galvanized steel shield coil edges from strap-induced deformation. Final quality verification includes torque testing of all strapping anchors and vacuum decay testing of the sealed moisture barrier to confirm leak rates below 0.5% per 24 hours.

This integrated packaging methodology directly addresses the electrochemical corrosion mechanisms that degrade copper conductivity. By maintaining internal relative humidity below 45% throughout voyages exceeding 45 days, we prevent cuprous oxide formation that increases DC resistance by >3%. Our system has reduced moisture-related customer claims by 92% since 2018, as validated through third-party logistics audits. For B2B partners, this represents not merely transit protection but quantifiable preservation of the coil’s core electrical functionality—ensuring seamless integration into transformer manufacturing processes upon arrival. Compliance with this standard is mandatory for all export shipments originating from our IATF 16949-certified facility.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for High-Performance Copper Solenoid Coils

With over two decades of specialized expertise in the production of transformer strips and foils, Luoyang Xinzhaohe Aluminum CO., Ltd has established itself as a trusted leader in the global supply of precision-engineered aluminum and copper materials for electromagnetic applications. Our deep-rooted experience in metallurgy and strip processing positions us as an ideal partner for manufacturers requiring high-purity, dimensionally stable copper solenoid coils for transformers, inductors, and power electronics systems.

Our manufacturing infrastructure is built around advanced cold-rolling technologies, precision annealing systems, and rigorous in-line quality monitoring. The production of copper solenoid coils begins with high-conductivity electrolytic tough pitch (ETP) copper (Cu-ETP1, ASTM B187), which undergoes controlled rolling to achieve tight thickness tolerances down to ±0.005 mm. This ensures uniform winding performance and optimal fill factors in coil bobbins. Our process control systems maintain consistent mechanical properties, including elongation (25–35%) and tensile strength (200–240 MPa), critical for high-cycle reliability in dynamic electromagnetic environments.

All copper strip products are manufactured under ISO 9001-certified quality management protocols, with full traceability from raw material sourcing to final shipment. We perform comprehensive testing, including eddy current inspection, surface roughness analysis (Ra ≤ 0.4 µm), and resistivity verification (≤ 0.017241 Ω·mm²/m at 20°C), ensuring compliance with IEC 60464 and GB/T standards. Our facility’s annual production capacity exceeds 12,000 metric tons, supported by automated slitting and packaging lines that enable just-in-time delivery for OEMs and tier suppliers.

In addition to standard C11000 and C10100 copper alloys, we offer customized solutions, including profiled edges, pre-lacquered insulation coatings, and slit-to-length reels optimized for automated winding equipment. Our engineering team collaborates directly with clients to match material specifications to application demands, whether for high-frequency transformers, EV charging systems, or industrial power supplies.

As global demand for efficient, compact electromagnetic components grows, Luoyang Xinzhaohe remains committed to innovation, reliability, and technical partnership. Our strategic location in Henan Province provides seamless logistics access to domestic and international markets, with established export channels to North America, Europe, and Southeast Asia.

For sourcing managers and design engineers seeking a dependable, technically proficient supplier of copper solenoid coil materials, Luoyang Xinzhaohe offers proven capability, scalable capacity, and responsive support.

Contact us today to discuss your technical requirements.

Cathy Zhang

Sales Director, Copper & Aluminum Strip Division

Email: cathy@transformerstrip.com

Luoyang Xinzhaohe Aluminum CO., Ltd

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing copper solenoid coil directly from China.