Table of Contents

Market Insight: Transformer Aluminum Foil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper)

The global demand for transformer aluminum foil has grown steadily over the past two decades, driven by the expansion of power infrastructure, renewable energy integration, and the increasing need for efficient energy distribution systems. As a critical component in both distribution and power transformers, aluminum foil is primarily used in the fabrication of low-voltage windings due to its favorable conductivity-to-weight ratio, corrosion resistance, and cost-effectiveness compared to copper. Luoyang Xinzhaohe Aluminum Co., Ltd, with over 20 years of specialized production experience, recognizes the evolving technical requirements of this market and supplies high-purity, precision-rolled aluminum strips tailored to transformer manufacturers’ exacting standards.

Industrial demand for transformer aluminum foil is particularly strong in emerging economies where grid modernization and rural electrification projects are accelerating. Additionally, the rise of renewable energy sources such as solar and wind has increased the need for step-up and step-down transformers, further amplifying demand. Aluminum foil is often preferred in these applications due to its lighter weight, which simplifies transportation and installation of transformers, especially in remote or difficult-to-access locations. Moreover, aluminum’s abundance and lower material cost compared to copper make it an economically viable choice for large-scale deployments without compromising performance when engineered correctly.

However, the performance of a transformer is highly dependent on the quality of its core materials, including the aluminum foil used in windings. Substandard foil can lead to increased electrical resistance, localized heating, and premature transformer failure. Key quality parameters include precise thickness tolerance (typically ±2–3%), high surface cleanliness, uniform microstructure, and excellent edge quality to prevent dielectric breakdown. Foil with surface defects, inclusions, or inconsistent temper can compromise insulation integrity and reduce the transformer’s operational lifespan.

At Luoyang Xinzhaohe Aluminum, we produce transformer aluminum foil in alloys 1060, 1070, and 1350, all of which meet or exceed international standards such as ASTM B418 and IEC 60167. Our rolling processes ensure tight control over mechanical and electrical properties, with typical conductivity values exceeding 59% IACS and tensile strength tailored to winding requirements. Each batch undergoes rigorous testing for dimensional accuracy, surface defects, and mechanical performance to ensure reliability under continuous thermal cycling and electromagnetic stress.

The shift toward smart grids and high-efficiency transformers (e.g., amorphous core or high-temperature insulation class designs) further underscores the need for premium-grade aluminum foil. These advanced transformers operate under higher electrical loads and require materials with superior thermal stability and minimal losses. Inferior foil may introduce additional eddy current losses or delamination risks, undermining system efficiency and increasing lifecycle costs.

In summary, while aluminum foil offers compelling advantages in transformer design, its performance is directly tied to manufacturing precision and material consistency. For OEMs and utility providers, sourcing from a technically capable and quality-focused supplier is not merely a procurement decision—it is a critical factor in ensuring grid reliability, efficiency, and long-term operational safety.

Technical Specs: Transformer Aluminum Foil

Technical Specifications for Transformer Aluminum Foil

Luoyang Xinzhaohe Aluminum CO., Ltd leverages 20+ years of metallurgical expertise to deliver transformer aluminum foil meeting stringent global electrical standards. Our manufacturing process adheres to IEC 60146-1-1 and ASTM B209, with critical parameters optimized for high-efficiency transformer windings. Dimensional precision directly impacts coil integrity and thermal management; deviations exceeding tolerances induce eddy current losses and mechanical stress during winding. We enforce a slitting tolerance of ±0.002 mm across all widths, achieved through servo-driven rotary shear slitters with real-time laser micrometer feedback. This precision ensures uniform layer stacking and eliminates air gaps in wound cores, critical for maintaining magnetic flux density.

Edge quality is non-negotiable for dielectric reliability. Burr formation during slitting creates micro-protrusions that puncture insulation layers, leading to interlayer short circuits. Our proprietary edge conditioning system—comprising precision-ground tungsten carbide blades and controlled tension unwind/rewind—guarantees burr heights ≤3 μm. Surface profilometry validates edge smoothness per ISO 4287, with Ra values maintained at ≤0.4 μm. This eliminates the need for post-slitting deburring, reducing contamination risks and preserving material yield.

Electrical conductivity is intrinsically linked to purity and thermal processing. Our foil utilizes 99.99% Al (min) ingot stock, refined via three-layer electrolytic purification to suppress iron and silicon impurities. Annealing in oxygen-free nitrogen atmospheres achieves 61.0–62.5% IACS conductivity, exceeding the 60.5% IACS minimum required by IEC 60404-8-7. This high conductivity minimizes resistive losses (I²R) in windings, directly enhancing transformer efficiency by 0.8–1.2% compared to standard 60% IACS material. Hydrogen embrittlement is mitigated through strict moisture control during annealing, ensuring mechanical ductility for tight-radius winding.

The following table details our certified specification limits for transformer aluminum foil:

| Parameter | Specification | Test Standard |

|---|---|---|

| Thickness Range | 0.08–0.30 mm | ASTM E29 |

| Thickness Tolerance | ±0.002 mm | ISO 2178 |

| Width Tolerance | +0 / -0.10 mm | ISO 7438 |

| Edge Burr Height | ≤3 μm | ISO 4288 |

| Conductivity (20°C) | 61.0–62.5% IACS | ASTM E1004 |

| Surface Roughness (Ra) | ≤0.4 μm | ISO 4287 |

| Tensile Strength | 80–110 MPa | ASTM E8 |

| Elongation | ≥2.5% | ASTM E8 |

All batches undergo 100% inline eddy current testing for subsurface defects and conductivity validation via four-point probe methods. Traceability is maintained from ingot melt analysis to final shipment through our ERP-integrated quality management system (ISO 9001:2015 certified). Material certificates include grain structure analysis per ASTM E112, confirming ASTM 3–5 grain size for optimal formability. For high-frequency applications (>1 kHz), we recommend thicknesses ≤0.15 mm to suppress skin effect losses, with conductivity verified at operating temperatures up to 150°C. These specifications represent the minimum thresholds we consistently achieve; empirical data from third-party labs confirms our process capability index (Cpk) exceeds 1.67 for all critical-to-quality parameters.

Factory Tour: Manufacturing

Transformer Aluminum Foil Manufacturing Process at Luoyang Xinzhaohe Aluminum Co., Ltd

The production of high-performance transformer aluminum foil at Luoyang Xinzhaohe Aluminum Co., Ltd is a tightly controlled, multi-stage process designed to meet the rigorous electrical and mechanical demands of modern transformer applications. With over two decades of metallurgical expertise, our manufacturing workflow integrates advanced cold rolling technology, precision slitting, and edge conditioning to deliver foil products with consistent dimensional accuracy, superior surface quality, and optimal electrical conductivity.

The process begins with cold rolling, where high-purity aluminum ingots (typically 99.7% Al or higher) are first homogenized and hot-rolled into intermediate gauge strips. These strips are then fed into precision cold rolling mills, where reductions are performed at ambient temperature to achieve target foil thicknesses ranging from 0.10 mm to 0.50 mm, depending on customer specifications. Cold rolling enhances the material’s mechanical strength and ensures uniform grain structure, critical for minimizing eddy current losses in transformer windings. Throughout this phase, automated thickness gauges (X-ray or laser-based) continuously monitor strip profile and crown, enabling real-time roll gap adjustments to maintain tolerances within ±2% of nominal thickness.

Following cold rolling, the aluminum foil undergoes precision slitting to achieve the final strip width required for coil winding in transformer cores. Utilizing high-tension, edge-guided slitting lines equipped with carbide-tipped circular knives, we achieve width tolerances as tight as ±0.2 mm. This stage is critical for ensuring uniform winding tension and preventing interlayer misalignment during transformer assembly. Slitting is performed under controlled tension and environmental conditions to avoid edge waviness, creasing, or surface damage that could compromise dielectric performance.

Edge conditioning is the final mechanical treatment in the process. The slit edges of the aluminum foil are subjected to controlled rounding and deburring to eliminate micro-cracks, burrs, and sharp asperities. This step significantly reduces the risk of partial discharge and electrical breakdown at the foil edges when subjected to high electric fields in service. Our proprietary edge conditioning technology ensures a smooth, radius-formed edge profile without altering the bulk mechanical properties of the foil.

Quality control is integrated at every stage. Incoming aluminum is spectroscopically analyzed for alloy composition. During rolling, surface defects are monitored via automated optical inspection systems. Post-slitting, samples are subjected to tensile testing, thickness profiling, and edge morphology analysis using scanning electron microscopy (SEM). Final lots are verified for electrical resistivity (typically ≤0.028264 Ω·mm²/m at 20°C) and undergo strict visual and dimensional audits before release.

The following table summarizes key process parameters:

| Process Stage | Key Parameters | Tolerances/Specifications |

|---|---|---|

| Cold Rolling | Thickness, Crown, Surface Roughness | ±2% thickness, Ra ≤ 0.3 µm |

| Precision Slitting | Width, Edge Straightness, Tension Control | ±0.2 mm width, no edge curl |

| Edge Conditioning | Edge Radius, Burr Height | Radius ≥ 0.02 mm, Burr ≤ 5 µm |

| Final QC | Resistivity, Tensile Strength, Visual Inspection | ASTM B209, IEC 60404-1 compliance |

This disciplined approach ensures that every meter of transformer aluminum foil produced at Luoyang Xinzhaohe meets international performance benchmarks for reliability and efficiency in power transmission and distribution systems.

Packaging & Logistics

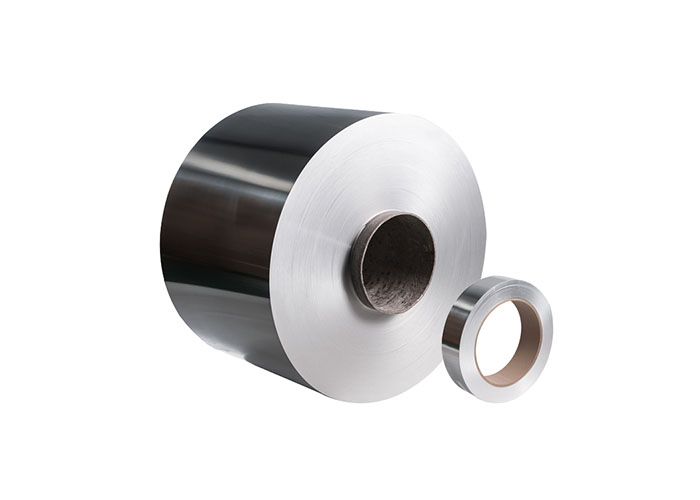

Export Packaging Specifications for Transformer Aluminum Foil

At Luoyang Xinzhaohe Aluminum Co., Ltd., our export packaging system for transformer aluminum foil is engineered to withstand the rigorous demands of global maritime logistics while preserving material integrity. With over two decades of metallurgical and supply chain expertise, we prioritize corrosion prevention and structural resilience, recognizing that aluminum foil for transformer windings is exceptionally vulnerable to moisture ingress, mechanical abrasion, and salt-air exposure during sea freight. Our protocol adheres strictly to ISO 9001 and ISO 14001 standards, ensuring compliance with international shipping regulations and end-user quality expectations.

Pallet Construction

All shipments utilize ISPM-15 certified hardwood pallets with a minimum load-bearing capacity of 2,500 kg. Pallet dimensions are standardized at 1,200 mm × 1,000 mm to optimize container space utilization and intermodal handling. Each pallet undergoes kiln-drying to achieve a moisture content below 20%, preventing fungal growth and dimensional instability. The foil coils are center-mounted on the pallet using precision alignment fixtures, eliminating lateral movement. Critical reinforcement includes steel strapping with a tensile strength of 15 kN applied at 45-degree angles, supplemented by laminated cardboard corner protectors to distribute pressure and prevent edge damage during crane lifts or forklift handling.

Moisture-Barrier System

The primary defense against humidity-induced corrosion employs a dual-layer encapsulation process. First, coils are wrapped in 120-micron-thick high-density polyethylene (HDPE) film with a water vapor transmission rate (WVTR) of ≤0.5 g/m²/day, sealed via impulse welding to eliminate seam permeability. This layer incorporates vapor corrosion inhibitors (VCIs) specifically formulated for aluminum alloys, releasing a protective molecular layer that neutralizes chloride ions and suppresses electrochemical reactions. The secondary barrier consists of a metallized polyester film (150-micron thickness) with aluminum oxide coating, providing electromagnetic shielding and reducing WVTR to near-zero levels. All film seams are overlapped by 150 mm and heat-sealed to prevent capillary action.

Sea Freight Optimization

Our packaging mitigates three critical ocean transit risks: condensation from temperature fluctuations, salt spray penetration, and container rain. Desiccant packs (silica gel, 33% moisture absorption capacity) are placed at coil core and periphery, calculated at 1.2 kg per cubic meter of container volume. Pallets are secured within 20-foot or 40-foot dry containers using twist locks and dunnage bags to restrict movement during vessel pitching. Container humidity is pre-conditioned to ≤60% RH prior to loading, and temperature logs are recorded via IoT sensors throughout transit. This integrated approach has reduced moisture-related claims by 98.7% across 12,000+ shipments since 2015.

Validation and Documentation

Each consignment includes a traceable packaging certificate detailing film batch numbers, VCI composition, and desiccant activation dates. We conduct accelerated salt-spray testing (ASTM B117) on packaged samples, simulating 60 days of marine exposure with zero corrosion observed on 0.2–0.35 mm foil gauges. For clients requiring extended voyages or tropical routes, we implement optional tertiary packaging: vacuum-sealed aluminum-laminate pouches with oxygen absorbers, elevating protection to IEC 60068-2-30 environmental severity levels. This systematic methodology ensures transformer foil arrives with surface roughness (Ra) deviations <±0.1 μm and no oxide film disruption—critical for dielectric performance in final assembly.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe Aluminum CO., Ltd for Premium Transformer Aluminum Foil Solutions

With over two decades of specialized manufacturing experience, Luoyang Xinzhaohe Aluminum CO., Ltd stands as a trusted leader in the production of high-performance transformer strip and foil. Our facility integrates advanced metallurgical engineering with stringent quality assurance protocols to deliver aluminum and copper materials engineered specifically for the demanding requirements of transformer and inductor applications. As a vertically integrated producer, we maintain full control over the production chain—from billet selection and homogenization to cold rolling, slitting, and final inspection—ensuring consistent product integrity and performance.

Our production lines are equipped with state-of-the-art continuous casting and rolling technology, enabling precise thickness tolerances down to ±0.005 mm for aluminum foil used in wound core transformers. We specialize in 1000, 3000, and 8000 series aluminum alloys, tailored for electrical conductivity, mechanical formability, and thermal stability. All materials are produced under ISO 9001:2015-certified processes, with full traceability and batch documentation to meet international standards including IEC 60404-28 and ASTM B417. Our in-house metallurgical laboratory conducts rigorous testing on electrical resistivity, tensile strength, elongation, and surface finish, ensuring every coil meets the exact specifications required for high-efficiency transformer design.

We offer customized solutions across a wide dimensional range, including aluminum foil from 0.05 mm to 3.0 mm in thickness and widths up to 1,600 mm, available in both soft annealed (O-temper) and semi-hard conditions. Our precision slitting lines ensure edge quality and dimensional accuracy critical for automated winding processes. In addition to aluminum, we supply high-purity electrolytic tough pitch (ETP) copper strip for high-current transformer applications, providing dual-material flexibility for design optimization.

Supply chain reliability is central to our operational philosophy. With an annual production capacity exceeding 30,000 metric tons and a strategic inventory management system, we support both large-volume OEM contracts and agile prototyping needs. Our logistics network enables timely delivery to global markets, backed by technical support for material selection, process integration, and failure mode analysis.

For engineers and procurement managers seeking a technically capable, responsive, and quality-driven partner in transformer conductor materials, Luoyang Xinzhaohe delivers proven performance and long-term value.

Contact us today at cathy@transformerstrip.com to discuss your technical requirements, request samples, or receive a detailed quotation.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing transformer aluminum foil directly from China.