Table of Contents

Market Insight: Three Phase Transformer Winding Material

Market Analysis: Winding Wire for Three-Phase Transformers

Global demand for three-phase transformer winding material is experiencing sustained growth, driven primarily by critical infrastructure investments. Key drivers include the modernization of aging electrical grids, particularly in North America and Europe, the rapid expansion of renewable energy integration requiring step-up transformers at solar and wind farms, and increasing industrial electrification in emerging economies. This demand manifests across voltage classes, from distribution transformers (up to 36 kV) to large power transformers (115 kV and above), each imposing distinct material performance requirements. While copper has historically dominated the market due to its superior conductivity, aluminum conductor material (ACM) has gained significant traction, especially in distribution and sub-transmission applications, driven by compelling economic and weight advantages. Aluminum offers approximately 60% of the electrical conductivity of copper by volume but only 30% of the weight and a significantly lower raw material cost, translating to substantial savings in material procurement and structural support requirements for the transformer core and tank. This cost-to-performance ratio makes high-purity aluminum an increasingly strategic choice for cost-sensitive projects without compromising essential reliability.

The criticality of winding material quality cannot be overstated, as it directly dictates transformer longevity, efficiency, and operational safety. Substandard conductors introduce multiple failure pathways. Impurities exceeding stringent limits (e.g., Fe, Si) significantly increase electrical resistivity, elevating I²R losses and causing excessive heat generation under load. Poor mechanical properties, such as insufficient tensile strength or elongation, compromise the wire’s ability to withstand the significant electromagnetic forces and thermal cycling inherent during fault conditions and normal operation, potentially leading to winding deformation or fracture. Inadequate surface quality promotes insulation damage during the winding process, creating weak points prone to partial discharge and eventual dielectric failure. Crucially, inconsistent dimensional tolerances disrupt the precise layering required for optimal magnetic coupling and cooling oil flow, exacerbating hot spots and accelerating thermal degradation cascades. These quality deviations collectively reduce transformer efficiency (impacting T&D losses), shorten operational lifespan, increase maintenance costs, and elevate the risk of catastrophic in-service failures with significant financial and safety repercussions.

Luoyang Xinzhaohe Aluminum leverages over two decades of specialized metallurgical expertise to address these exacting demands. We understand that sourcing winding wire is not merely a commodity transaction but a strategic risk management decision. Our production process, centered on high-purity (99.99% min) aluminum ingot smelting with rigorous vacuum degassing and continuous casting, ensures exceptional homogeneity and minimal impurity levels. Precision rolling and drawing under tightly controlled parameters guarantee consistent mechanical properties and dimensional accuracy essential for reliable high-speed winding. The table below outlines critical quality parameters where Xinzhaohe’s adherence to international standards (ASTM B418, IEC 60122) provides tangible operational security.

| Parameter | Critical Standard Range | Consequence of Deviation | Xinzhaohe Control Method |

|---|---|---|---|

| Electrical Resistivity | ≤ 0.02826 Ω·mm²/m (20°C) | Increased I²R losses, overheating | Vacuum degassing, purity control |

| Tensile Strength | 130-160 MPa | Winding deformation, fracture | Precision annealing control |

| Elongation | ≥ 4% | Brittleness, cracking during winding | Homogeneous microstructure |

| Dimensional Tolerance | ±0.01 mm (diameter) | Poor layering, hot spots | Laser micrometry, closed-loop control |

| Surface Roughness | Ra ≤ 1.0 µm | Insulation damage, PD inception | Precision drawing dies, cleaning |

Selecting a winding material supplier with demonstrable process control and metallurgical rigor is paramount. Xinzhaohe’s integrated quality management system, validated through decades of supplying major transformer OEMs globally, ensures the material integrity necessary for transformers to meet demanding efficiency standards (e.g., DOE 2016, IEC 60076-20) and deliver decades of trouble-free service in critical power infrastructure. Quality is the non-negotiable foundation of transformer reliability.

Technical Specs: Three Phase Transformer Winding Material

Technical Specifications for Three Phase Transformer Winding Material

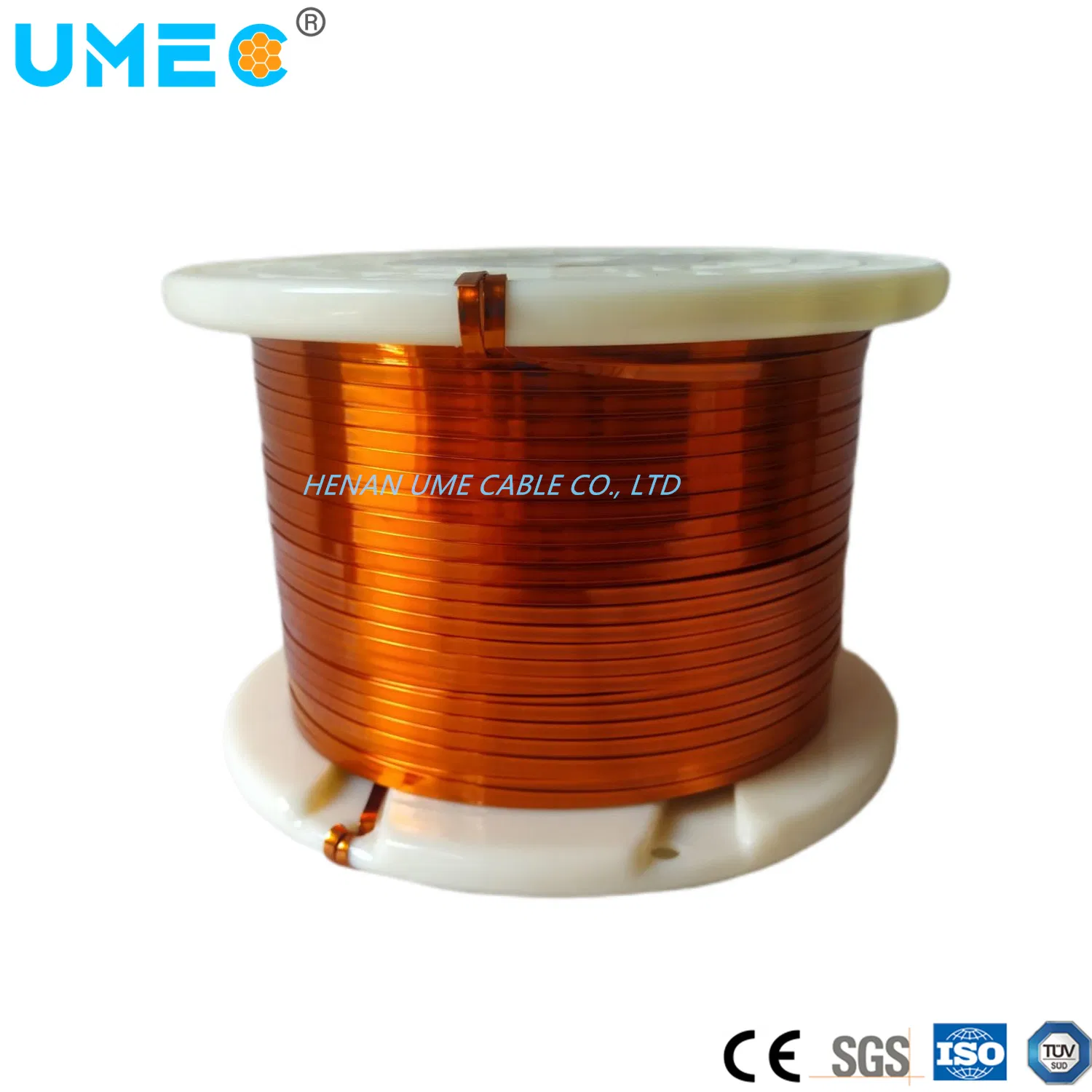

The selection of winding material for three-phase transformers is a critical determinant of performance, reliability, and operational lifespan. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of metallurgical and industrial manufacturing expertise, we emphasize precision in material properties to ensure compatibility with high-efficiency transformer designs. The primary parameters governing the performance of aluminum winding wire in three-phase transformers include insulation breakdown voltage, elongation, and thermal class rating. These characteristics directly influence dielectric integrity, mechanical resilience during winding processes, and thermal stability under continuous load conditions.

Insulation breakdown voltage is a fundamental measure of the dielectric strength of the enamel or polymer coating applied to the aluminum conductor. This parameter ensures that the winding material can withstand high electric field stresses without experiencing partial discharge or insulation failure. For medium and high-voltage three-phase transformers, a minimum breakdown voltage of 6 kV is recommended, with premium-grade materials achieving up to 12 kV under standardized test conditions (IEC 60317, ASTM D4355). Consistent insulation thickness and defect-free coating application are essential to maintain uniform dielectric performance across the entire coil assembly.

Elongation, measured as a percentage during tensile testing, reflects the ductility of the aluminum alloy core. High elongation values—typically ranging from 18% to 28%—enable the wire to endure the mechanical stresses of coil winding, especially in large power transformers where tight bending radii are unavoidable. Insufficient elongation may lead to micro-cracking of the conductor or insulation, compromising both electrical and mechanical integrity. Our aluminum winding wire is engineered using high-purity AA-1350 and AA-8030 alloys, processed through controlled drawing and annealing to achieve optimal balance between strength and flexibility.

Thermal class defines the maximum continuous operating temperature the insulation system can endure without significant degradation. For three-phase transformers, thermal classes ranging from 130°C to 220°C are commonly specified, depending on application severity. Materials rated at Class 130°C are suitable for general distribution transformers, while Class 180°C (H-class) and Class 220°C (C-class) insulation systems are deployed in high-load or industrial transformers requiring enhanced thermal endurance. Our winding wires utilize polyamide-imide, polyester-imide, and silicone-based coatings to meet these thermal demands, with thermal index values verified through thermal aging tests per IEC 60216.

The following table summarizes key technical parameters for aluminum winding wire used in three-phase transformer applications:

| Parameter | Standard Value Range | Test Standard | Notes |

|---|---|---|---|

| Insulation Breakdown Voltage | 6 kV – 12 kV | IEC 60317, ASTM D4355 | Measured at 1x coating thickness |

| Elongation (min) | 18% – 28% | ASTM B562 | Dependent on alloy and temper |

| Thermal Class | 130°C, 155°C, 180°C, 200°C, 220°C | IEC 60216, UL 1446 | Based on insulation system |

| Conductor Material | AA-1350, AA-8030 | ASTM B233 | High purity, low resistivity |

| Diameter Tolerance | ±0.01 mm – ±0.03 mm | IEC 60122 | Ensures winding precision |

These specifications are rigorously maintained through in-line quality control and third-party certification. Consistency in these parameters ensures reliable transformer operation under fluctuating load and environmental conditions.

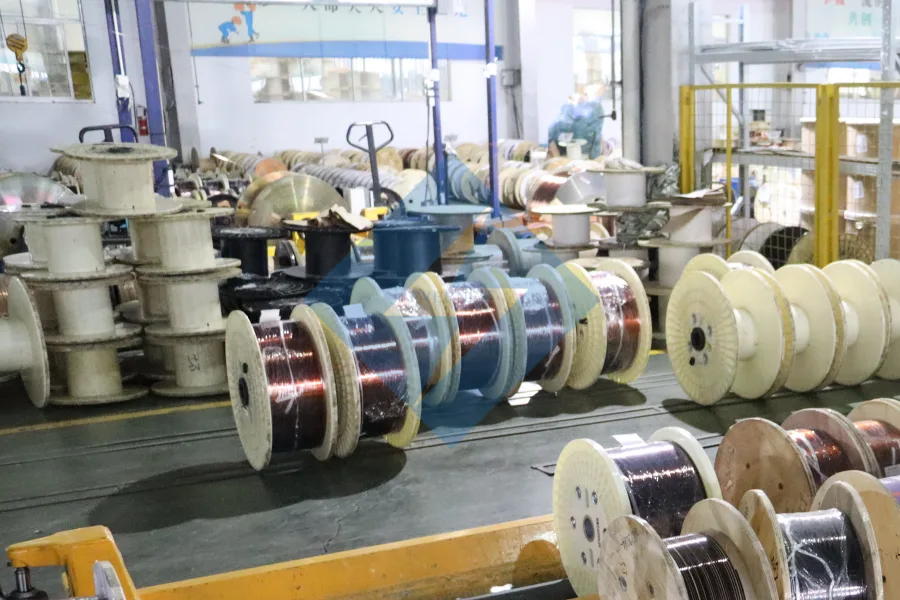

Factory Tour: Manufacturing

Manufacturing Process for Three-Phase Transformer Winding Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of specialized expertise in aluminum conductor production to deliver high-reliability winding material for three-phase power transformers. Our vertically integrated manufacturing process ensures stringent control over material properties critical for thermal stability, electrical efficiency, and mechanical integrity under continuous high-load operation. The sequence begins with high-purity aluminum rod (99.70% min. Al) sourced under certified supply chain protocols, directly impacting final conductivity and impurity levels.

Rod drawing forms the foundational step where rods undergo multi-pass cold drawing through precision tungsten carbide dies. This process reduces diameter to the specified wire gauge with micron-level dimensional accuracy (±0.005 mm tolerance). Critical parameters including reduction ratio, drawing speed, and lubricant viscosity are continuously monitored via PLC systems to prevent micro-cracking and ensure uniform surface finish essential for subsequent enameling adhesion. Real-time diameter measurement using laser micrometers triggers automatic die adjustments, maintaining consistency across production runs.

The drawn wire then enters a continuous inert-atmosphere annealing furnace. Precise thermal profiling (typically 300–400°C) eliminates work hardening from drawing, restoring optimal ductility (minimum 3% elongation) and achieving target electrical conductivity (61.0–61.8% IACS, copper-equivalent performance). Oxygen-free nitrogen purging prevents surface oxidation, while controlled cooling rates mitigate residual stresses. This step is vital for enabling tight coil winding without fracture and ensuring long-term creep resistance under electromagnetic forces.

Enameling applies the primary electrical insulation using a multi-layer solvent-based polyurethane-imide system. The wire passes through a series of coating dies and precision metering systems, followed by staged curing ovens with zone-specific temperature control (250–480°C). Each layer thickness is maintained within ±2 µm tolerance to guarantee dielectric strength (min. 3.5 kV for 0.07 mm build) while preserving thermal class 200 (F) performance. Film continuity and adhesion are validated via mandrel bend testing per IEC 60851 standards immediately post-cure.

Inline testing constitutes our non-negotiable quality gate. Every meter of wire undergoes 100% electrical testing: high-potential (hi-pot) verification at 5 kV AC for 5 seconds detects pinholes, while continuous resistance monitoring ensures conductivity compliance. Simultaneous optical surface inspection identifies defects like scratches or blisters. Final QC includes destructive sampling for thermal shock (200°C for 30 min), solderability, and elongation. All process data—including annealing profiles, coating thickness, and test results—is digitally logged for full traceability per ISO 9001 requirements.

This integrated approach, combining metallurgical precision with real-time quality verification, ensures our aluminum winding wire meets the rigorous demands of modern three-phase transformers, minimizing failure risks and supporting extended operational lifespans in critical grid infrastructure. Our commitment to process control directly translates to supply chain integrity for transformer manufacturers.

Packaging & Logistics

Export Packaging for Aluminum Winding Wire: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of specialization in high-purity aluminum conductor materials for electrical applications, we recognize that the performance of three-phase transformer winding wire begins not only with metallurgical precision but also with uncompromised material protection throughout the global supply chain. Our export packaging system is engineered to meet the rigorous demands of international sea freight, where prolonged exposure to humidity, temperature fluctuations, and mechanical stress can compromise wire integrity. To mitigate these risks, we implement a dual-layer protective packaging strategy centered on wooden pallets and industrial-grade moisture-proof film.

All aluminum winding wire coils are wound under controlled atmospheric conditions to minimize initial oxide formation and are immediately prepared for export using standardized wooden pallets that comply with ISPM-15 international phytosanitary regulations. These heat-treated wooden bases provide structural stability, enabling secure stacking and resistance to compression during containerized transport. Each coil is firmly affixed to the pallet using steel strapping, preventing lateral movement that could lead to deformation or edge damage during loading, transit, or port handling.

The primary defense against environmental degradation is our multi-layer moisture-proof wrapping system. Each palletized load is completely encased in high-density polyethylene laminate film with integrated aluminum foil barriers, offering a water vapor transmission rate (WVTR) of less than 0.5 g/m²·day. This vapor barrier effectively isolates the aluminum wire from ambient humidity, a critical factor in preventing surface oxidation and maintaining the clean, solderable finish required for high-voltage winding applications. The film is heat-sealed at all seams and extends fully to the base of the pallet to prevent capillary ingress from container floors, which are prone to condensation during transoceanic voyages.

In addition to material protection, our packaging design supports logistical efficiency. Pallet dimensions are optimized for 20-foot and 40-foot dry freight containers, maximizing cubic utilization while allowing for forklift access on all standard shipping vessels. Each package is labeled with UV-resistant, tamper-evident markings including batch number, alloy designation (e.g., EC Al 99.70+), temper (O or H14), net weight, and handling instructions compliant with IMDG Code recommendations for non-hazardous cargo.

This integrated packaging methodology has been validated across shipments to North America, Southeast Asia, the Middle East, and Europe, consistently delivering wire with retained mechanical ductility and electrical conductivity. For transformer manufacturers relying on precise winding tolerances and long-term reliability, our sea freight packaging is not merely a logistical step—it is an extension of our quality assurance framework.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Transformer Winding Material

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise to deliver high-performance aluminum winding materials engineered explicitly for three-phase transformer applications. Our vertically integrated manufacturing ecosystem ensures uncompromising control over critical material properties, directly impacting transformer efficiency, thermal management, and long-term reliability. As a strategic partner, we provide OEMs and tier-1 suppliers with scientifically validated solutions that meet stringent global standards while optimizing total cost of ownership.

Our core strength lies in precision metallurgical process control. We utilize ultra-high-purity primary aluminum (99.99% min) with proprietary trace element management to achieve consistent electrical conductivity exceeding 61.0% IACS. This is critical for minimizing resistive losses in high-current windings. Our cold-rolling lines operate under real-time laser gauging systems, maintaining thickness tolerances within ±0.005 mm for strip and ±0.003 mm for round wire—ensuring uniform current distribution and reducing eddy current losses. Advanced continuous annealing furnaces with oxygen-controlled atmospheres produce defect-free surfaces with Ra ≤ 0.4 μm, eliminating insulation damage during high-speed winding operations and preventing partial discharge initiation.

Quality assurance is embedded at every process stage through our ISO/IEC 17025-accredited laboratory. Every production batch undergoes rigorous validation including:

Electrical resistivity mapping via four-point probe testing

Tensile strength and elongation profiling per ASTM E8

Surface defect analysis using automated optical inspection

Chemical composition verification via OES spectroscopy

This data-driven approach guarantees compliance with IEC 60137, ASTM B354, and customer-specific technical dossiers. Our supply chain resilience is fortified by dedicated production cells for transformer materials, ensuring priority scheduling and lead times averaging 15–20 days for standard grades. Strategic raw material partnerships with certified smelters mitigate volatility risks, while our 12,000-ton monthly capacity accommodates both prototyping and volume demands without compromise.

Unlike commodity suppliers, we collaborate early in your design phase to optimize material specifications for your core geometry and cooling architecture. Our engineering team provides technical documentation including conductivity-temperature coefficients, creep resistance curves, and finite element analysis support—enabling accurate loss modeling and thermal simulation. This reduces time-to-market while ensuring performance predictability in demanding grid environments.

For three-phase transformers requiring 135 kV+ class insulation systems or high-efficiency amorphous core designs, our R&D division develops customized alloys with enhanced thermal conductivity and reduced thermal expansion coefficients. Recent innovations include surface-treated strips for vacuum pressure impregnation (VPI) compatibility and low-oxygen wire for hermetically sealed units.

Partner with Luoyang Xinzhaohe to transform material specifications into competitive advantage. We deliver not just aluminum, but validated performance data and supply chain certainty. Contact Cathy directly at cathy@transformerstrip.com to request our technical datasheets or schedule a metallurgical consultation. Specify your voltage class, kVA rating, and winding configuration for a tailored material solution proposal within 48 hours.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing three phase transformer winding material directly from China.