Table of Contents

Market Insight: Self Bonding Enamelled Copper Wire

Market Analysis: Industrial Demand for Self-Bonding Enamelled Copper Wire in Transformers

The global market for self-bonding enamelled copper wire (SBECW) within power and distribution transformers exhibits sustained growth, driven by escalating energy demands, grid modernization initiatives, and the proliferation of renewable energy integration requiring robust power conversion infrastructure. Transformer manufacturers increasingly prioritize SBECW due to its critical role in enabling automated winding processes and enhancing coil mechanical stability. Unlike standard magnet wire, the integrated thermoplastic or thermoset bonding layer eliminates the need for external adhesives or mechanical bracing post-winding. This directly translates to reduced production cycle times, lower labor costs, and improved dimensional consistency of wound coils – factors paramount in high-volume transformer manufacturing where throughput and precision are non-negotiable.

Demand is particularly pronounced for medium and high-voltage distribution transformers (typically 10 kV to 36 kV class) and specialty power transformers used in industrial drives, traction, and renewable inverters. These applications impose severe operational stresses, including high electrical fields, significant thermal cycling, and intense mechanical vibrations during fault conditions. The self-bonding characteristic is not merely a production convenience; it is a fundamental reliability requirement. A uniformly bonded coil structure effectively suppresses inter-turn movement under electromagnetic forces, preventing insulation abrasion, partial discharge inception, and eventual catastrophic inter-turn short circuits. The integrity of the bond directly correlates with the transformer’s ability to withstand through-fault currents without mechanical degradation.

Quality parameters for SBECW in transformer applications are exceptionally stringent and non-negotiable. The enamel insulation must consistently meet or exceed thermal class requirements, typically Class 155 (F) or Class 180 (H), ensuring long-term dielectric integrity at elevated operating temperatures. Crucially, the bonding layer must exhibit precise thermal activation characteristics – bonding reliably at the specified oven temperature during curing without premature tackiness during winding, and maintaining bond strength stability throughout the transformer’s operational life under continuous thermal stress. Variability in bond strength, inadequate thermal endurance of the bond, or inconsistencies in enamel thickness directly compromise coil integrity. Substandard wire introduces microscopic defects or weak bonds that act as initiation points for electrical treeing or mechanical fatigue, accelerating insulation failure. The consequences manifest as premature transformer failures in the field, leading to costly unplanned outages, warranty claims, and severe reputational damage for the manufacturer.

The table below summarizes key quality attributes and their functional impact in transformer applications:

| Quality Attribute | Functional Impact in Transformers | Failure Consequence of Deficiency |

|---|---|---|

| Bond Strength Consistency | Ensures uniform coil rigidity, preventing inter-turn movement under electromagnetic forces | Insulation abrasion, partial discharge, inter-turn shorts |

| Thermal Endurance (Bond) | Maintains mechanical stability of bonded structure during thermal cycling and overload conditions | Coil deformation, loss of dimensional stability |

| Enamel Thickness Uniformity | Guarantees dielectric strength and minimizes partial discharge risk at high voltages | Electrical treeing, insulation breakdown |

| Thermal Class Compliance | Supports required operational temperature rise without accelerated aging | Premature insulation degradation, reduced lifespan |

For transformer manufacturers, sourcing SBECW is a high-stakes decision where initial cost differentials are insignificant compared to the lifecycle costs of failure. Luoyang Xinzhaohe Aluminum Co., Ltd leverages two decades of metallurgical and process expertise to deliver SBECW meeting the most rigorous IEC 60317 and NEMA MW specifications, ensuring the dimensional precision, thermal stability, and bond reliability essential for transformer performance and longevity in critical power infrastructure. Quality is not an option; it is the foundation of grid reliability.

Technical Specs: Self Bonding Enamelled Copper Wire

Technical Specifications for Self Bonding Enamelled Copper Wire

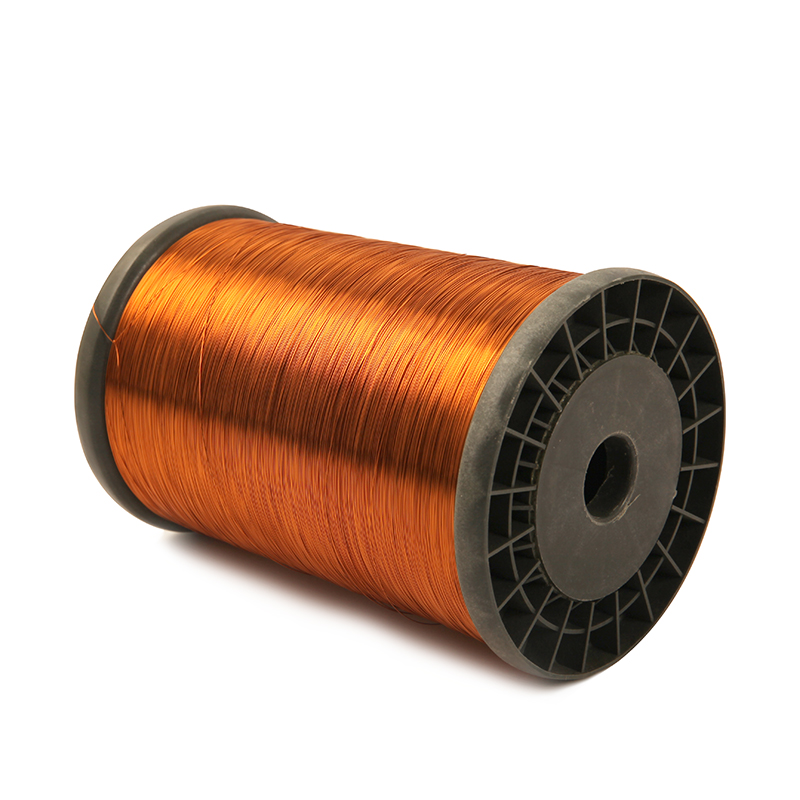

Self bonding enamelled copper wire is a specialized winding wire designed for applications requiring mechanical stability, electrical insulation integrity, and thermal endurance. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of metallurgical and materials engineering expertise, we manufacture self bonding wires to meet stringent industrial standards for performance in motors, transformers, solenoids, and precision electromagnetic devices. The bonding layer enables coil integrity without additional adhesives or varnishing, reducing production steps and enhancing long-term reliability.

Key technical parameters for self bonding enamelled copper wire are defined by international standards such as IEC 60317 and GB/T 23312. These include insulation breakdown voltage, elongation, and thermal class—each critical to the wire’s performance under operational stress. Breakdown voltage measures the dielectric strength of the enamel insulation, indicating the maximum electric field the insulation can withstand before failure. For self bonding wires, this value must be sufficient to prevent arcing between turns under rated voltage conditions, particularly in high-density windings. Our standard breakdown voltage is tested at 1 kV AC (rms), with values typically exceeding 1.5 kV depending on wire gauge and insulation build.

Elongation is a mechanical property reflecting the ductility of the copper conductor and the flexibility of the enamel coating. It is expressed as the percentage increase in length before fracture under tensile load. High elongation ensures the wire can endure winding stresses without cracking the insulation or breaking the conductor. We guarantee a minimum elongation of 15% for all diameters, ensuring compatibility with high-speed automatic winding equipment and complex coil geometries.

Thermal class defines the maximum continuous operating temperature the insulation system can endure while maintaining electrical and mechanical performance. Our self bonding enamelled copper wires are available in thermal classes ranging from 130°C to 220°C, utilizing advanced polymer systems such as polyamide-imide (PAI) with bonding resins. Higher thermal classes provide enhanced resistance to thermal aging, making them suitable for high-efficiency motors and demanding industrial environments.

The following table summarizes the core technical specifications for our self bonding enamelled copper wire product line:

| Parameter | Test Standard | Typical Value / Range | Notes |

|---|---|---|---|

| Conductor Material | GB/T 5584.1 | Electrolytic Tough Pitch Copper (ETP), Cu ≥ 99.95% | High conductivity, low oxygen |

| Insulation Material | IEC 60317-45 | Polyamide-imide with thermoplastic bonding layer | Solvent-resistant, thermal bondable |

| Thermal Class | IEC 60085 | 130, 155, 180, 200, 220 °C | Based on thermal endurance tests |

| Nominal Conductor Diameter | IEC 60122 | 0.10 mm – 2.50 mm | Tolerance per IEC 60122 |

| Breakdown Voltage (AC, 1 min) | IEC 60172 | ≥ 1.5 kV (at 0.1 mm insulation) | Increases with wire diameter |

| Elongation | GB/T 4909.3 | ≥ 15% | Measured on 250 mm gauge length |

| Bonding Strength | Internal Method | ≥ 1.0 N/mm² | After thermal activation at 150–180°C |

| Resistance to Soldering Heat | IEC 60122 | No cracking or delamination | 300°C for 3 seconds, 6 mm immersion |

These specifications ensure compatibility with automated manufacturing processes and long-term operational reliability in harsh thermal and electrical environments. Luoyang Xinzhaohe Aluminum Co., Ltd maintains strict process control from rod casting to final winding, ensuring consistency and traceability across all production batches.

Factory Tour: Manufacturing

Manufacturing Process for Self-Bonding Enamelled Copper Wire

The production of high-reliability self-bonding enamelled copper wire at Luoyang Xinzhaohe Aluminum CO., Ltd follows a rigorously controlled sequence, integrating metallurgical precision with advanced polymer application. This process ensures the wire meets stringent electrical, mechanical, and bonding performance requirements essential for demanding motor and transformer applications. The core stages commence with rod drawing, where high-conductivity electrolytic tough pitch (ETP) copper rod undergoes multi-die reduction to the precise final diameter. Critical parameters include controlled reduction ratios per pass and meticulous surface cleaning to eliminate contaminants that could compromise subsequent coating adhesion or electrical properties. Lubricant selection and removal are optimized to prevent carbon ingress.

Following drawing, the wire enters a continuous annealing furnace under a precisely managed inert or reducing atmosphere. This step is vital for restoring optimal ductility and electrical conductivity after cold working. Temperature profiles and residence time are tightly regulated to achieve the target tensile strength (typically 60-100 MPa) and elongation (8-25%) while preventing oxygen pickup or grain coarsening that could lead to brittleness. The metallurgical integrity established here directly impacts winding performance and final component reliability.

The annealed wire then proceeds to the enameling line, the defining stage for self-bonding functionality. Multiple layers are applied: typically a base insulating layer of polyurethane, polyesterimide, or polyamide-imide for dielectric strength and thermal class (e.g., 180°C), followed by the critical thermoset bonding resin layer. Application utilizes precision die or wheel systems ensuring uniform thickness. Curing occurs in multi-zone ovens with exact temperature and dwell time control to achieve complete cross-linking of the bonding resin without degrading the base insulation. The chemistry and application consistency of this bonding layer dictate the wire’s ability to form secure, insulated joints upon thermal activation during coil processing.

Integrated inline quality control is non-negotiable throughout the process. Key verification points include:

| Process Stage | Critical QC Parameter | Test Method | Acceptance Criteria |

|---|---|---|---|

| Post-Drawing | Diameter, Ovality | Laser Micrometer | Per IEC 60317 Tolerance Class A |

| Post-Annealing | Tensile Strength, Elongation | Universal Tester | Specified Range ±5% |

| Post-Enameling | Build-Up, Voltage Breakdown | Optical Comparator, HV Tester | Min 1.5kV @ 1.0mm, Spec Build-Up |

| Final Product | Bonding Strength, Thermal Shock | Custom Jig, Thermal Cycling | Min Force Spec, No Delamination |

Final inspection encompasses comprehensive electrical testing (conductor resistance, dielectric strength), mechanical evaluation (abrasion resistance, thermal shock), and specific bonding performance validation under simulated end-use curing conditions. All process parameters and QC results are digitally logged, enabling full traceability from rod batch to finished spool, a cornerstone of Luoyang Xinzhaohe’s 20+ years of supply chain excellence in winding wire solutions. This systematic approach guarantees the dimensional stability, insulation integrity, and reliable self-bonding action demanded by advanced electromechanical component manufacturers.

Packaging & Logistics

Export Packaging for Self-Bonding Enamelled Copper Wire

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in winding wire manufacturing, we ensure that every stage of production and logistics meets the highest industrial standards. Our export packaging system for self-bonding enamelled copper wire is engineered to maintain product integrity during international sea freight, where environmental and mechanical challenges are most pronounced. The packaging design prioritizes moisture resistance, structural stability, and load security to guarantee that wire spools reach global customers in optimal condition.

All export shipments are built upon robust wooden pallets constructed from high-density, kiln-dried hardwood. These pallets comply with ISPM 15 regulations, ensuring phytosanitary safety and global customs acceptance. The wood is treated to prevent warping, cracking, and fungal growth, maintaining dimensional stability throughout extended maritime transit. Each pallet is designed to support the full weight of densely wound copper wire coils, typically ranging from 200 kg to 1,000 kg per unit load, without deformation or structural compromise.

Upon palletization, wire spools are wrapped in multiple layers of industrial-grade moisture-proof film. This multi-layer encapsulation forms a hermetic barrier against humidity, salt air, and condensation—common hazards during ocean transport, especially in tropical and coastal regions. The film is heat-shrunk to ensure complete adhesion and eliminate gaps or crevices where moisture could ingress. Additionally, desiccant packs are strategically placed within the wrapping to absorb any residual atmospheric moisture, further enhancing protection.

To prevent mechanical damage during handling and stacking, edge protectors are affixed to the vertical corners of the pallet, and the entire assembly is secured using high-tensile steel or PET strapping. This ensures that the load remains immobile during crane lifts, container transfers, and rough port operations. The strapping pattern is cross-validated for load distribution, minimizing the risk of coil deformation or flange damage.

Each packaged unit is labeled with durable, weather-resistant tags containing critical shipment data, including batch number, wire specification, net weight, and handling instructions. Barcodes and QR codes are included for seamless integration into customer inventory systems. Pallets are also marked with internationally recognized hazard and orientation symbols to guide proper stowage in shipping containers.

Our packaging protocol has been validated across thousands of sea freight shipments to North America, Europe, Southeast Asia, and the Middle East. By combining engineered materials with rigorous quality control, Luoyang Xinzhaohe ensures that self-bonding enamelled copper wire arrives with undamaged insulation, consistent electrical performance, and ready for immediate processing in customer production lines. This reliability is a cornerstone of our commitment to global supply chain excellence.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Self-Bonding Enamelled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical and winding wire manufacturing expertise to deliver self-bonding enamelled copper wire meeting the most stringent global industrial demands. Our integrated production facility in Luoyang, Henan Province, represents a vertically controlled process chain from high-conductivity electrolytic tough pitch (ETP) copper rod sourcing through precision drawing, enamel application, and final bonding characterization. This deep process ownership ensures unparalleled consistency in critical parameters defining self-bonding wire performance.

Metallurgical refinement begins with rigorous copper purity validation (minimum 99.95% Cu) and controlled drawing sequences achieving precise conductor diameters with exceptional surface smoothness. Dimensional repeatability is maintained within ±0.002 mm tolerance, a prerequisite for reliable automatic winding in high-speed stator and rotor manufacturing. Our proprietary enamel formulation and application technology utilize advanced thermoplastic or thermosetting polymer systems engineered for specific thermal classes (155°C to 220°C). Precise control over polymerization kinetics during curing establishes the critical balance between initial bond strength for coil integrity and subsequent thermal stability during motor operation. Bond strength metrics consistently achieve 1.5 N/mm² minimum at activation temperatures calibrated to customer process requirements, verified through ASTM D3044 and IEC 60851-5 compliant testing protocols.

Quality assurance is embedded at every stage through automated inline monitoring and destructive testing. Key performance indicators tracked include elongation (min 10%), springback, dielectric strength (min 3000 Vrms), and thermal shock resistance. Our ISO 9001 and IATF 16949 certified systems mandate 100% spark testing on all production reels and statistical process control for enamel build uniformity. This disciplined approach minimizes field failures attributable to insulation defects or inconsistent bonding behavior. Supply chain resilience is fortified by strategic raw material partnerships and a dedicated logistics hub within China’s central industrial corridor, enabling reliable just-in-time delivery to global manufacturing centers with lead times optimized for production continuity.

Partnering with Luoyang Xinzhaohe mitigates technical and operational risk in your electromagnetic component supply chain. We provide comprehensive technical collaboration from material specification through process validation, supported by metallurgical analysis and application engineering resources. Our commitment to precision manufacturing and metallurgical integrity ensures your windings achieve maximum fill factor, thermal efficiency, and long-term reliability. For detailed technical specifications, sample requests, or to discuss custom formulation requirements, contact our Winding Wire Division directly. Cathy Zhang leads global sourcing engagement and will coordinate a technical consultation to address your specific self-bonding wire application challenges. Initiate the qualification process by emailing cathy@transformerstrip.com to receive our full product portfolio documentation and scheduling guidance.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing self bonding enamelled copper wire directly from China.