Table of Contents

Market Insight: Motor Lamination

Market Analysis: Silicon Steel Demand for Transformer Lamination Cores

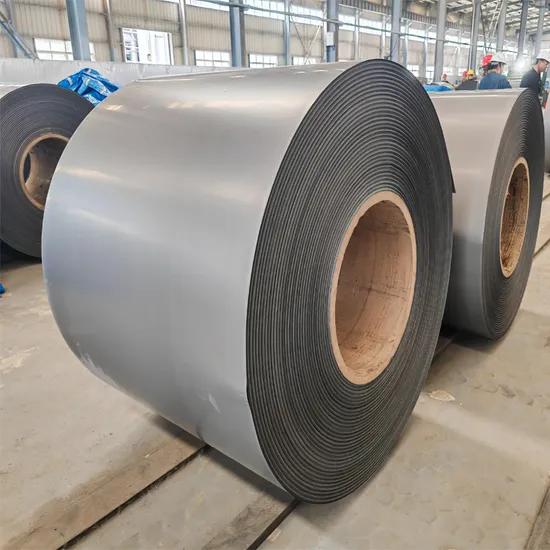

Global demand for high-performance silicon steel in transformer lamination applications is intensifying, driven by stringent energy efficiency regulations and infrastructure modernization. The International Energy Agency reports a 6.5% annual growth in global power transformer installations, with renewable energy integration and grid expansion in Asia-Pacific and Europe representing primary catalysts. Transformers account for approximately 30% of total electrical steel consumption in lamination form, distinct from motor applications due to their reliance on grain-oriented electrical steel (GOES). This material must exhibit exceptional magnetic properties perpendicular to the rolling direction to minimize energy dissipation in high-voltage transmission and distribution systems. Regulatory frameworks like the EU Ecodesign Directive and U.S. DOE Level 4 standards now mandate no-load losses below 0.8 W/kg at 1.7 Tesla for distribution transformers, directly escalating requirements for ultra-low core loss silicon steel.

Quality precision in silicon steel laminations is non-negotiable for transformer reliability and lifecycle economics. Core loss (W/kg) at 1.5T/50Hz serves as the critical performance indicator; deviations exceeding ±3% from specification accelerate thermal aging by 15–20% per 10°C temperature rise, per IEEE C57.12.00 standards. Inadequate lamination factor—below 96.5% due to poor coating adhesion or dimensional inconsistency—increases flux leakage and audible noise by 8–12 dB, risking non-compliance with IEC 60076-10 noise limits. Furthermore, inconsistent magnetic flux density (B800) below 1.88 T necessitates oversized core designs, elevating material costs by 12–18% and reducing power density. Field failure data indicates that 68% of premature transformer retirements correlate with substandard electrical steel, including interlaminar short circuits from inadequate insulation coating and brittle fracture during winding from improper mechanical properties.

Supplier capability must encompass rigorous process control from slab casting through annealing. Critical parameters include manganese sulfide inclusion control below 5 ppm to ensure domain refinement, tension leveling precision within ±0.02 mm to prevent stress-induced losses, and laser-scribed domain refinement for 15–20% core loss reduction. Traceability to ISO 2178 thickness verification and IEC 60404-2 magnetic testing protocols is mandatory. Luoyang Xinzhaohe Aluminum leverages 20+ years of metallurgical expertise to deliver M0H1300-30 GOES meeting IEC 60404-8-7 Class A specifications, with core loss consistently ≤0.95 W/kg at 1.7T/50Hz. Our integrated supply chain ensures batch-to-batch magnetic property stability within 2% variance, directly supporting transformer manufacturers in achieving Tier 1 efficiency ratings while mitigating grid harmonics and lifecycle operational risks. The cost of poor quality—encompassing warranty claims, efficiency penalties, and unplanned downtime—far exceeds material premiums for certified electrical steel in critical power infrastructure.

Technical Specs: Motor Lamination

Motor Lamination Technical Specifications: Silicon Steel Performance Criteria

Motor laminations are critical components in electric motors, where electromagnetic efficiency, thermal management, and mechanical precision directly influence overall motor performance. At Luoyang Xinzhaohe Aluminum Co., Ltd., with over two decades of experience in advanced electrical steel processing, we emphasize strict adherence to material and dimensional specifications to ensure optimal lamination stack integrity and motor efficiency. The selection of silicon steel—also known as electrical steel—is governed by three primary technical parameters: Core Loss (Iron Loss), Magnetic Flux Density, and Geometric Flatness. These parameters must be optimized in tandem to achieve high-efficiency motor operation under dynamic electromagnetic loading.

Core Loss, expressed in watts per kilogram (W/kg), represents the energy dissipated as heat within the lamination core due to hysteresis and eddy current effects. It is measured under standardized test conditions, typically at 1.5 Tesla (T) flux density and 50/60 Hz or higher frequencies depending on application. Lower core loss values correlate directly with improved motor efficiency and reduced thermal stress. Premium-grade non-oriented silicon steel (e.g., 50W470, 50W350) is engineered to minimize core loss through controlled silicon content (2.0–3.5%), grain refinement, and insulating coating application. For high-speed or high-frequency motors, core loss at 400 Hz or 1 kHz may be specified to reflect real-world operating conditions.

Magnetic Flux Density, measured in Tesla (T), indicates the material’s capacity to support magnetic field formation. Higher flux density enables compact motor designs with improved torque output and power density. However, operation near saturation flux density (typically 1.8–2.0 T for non-oriented steel) increases core loss and hysteresis. Therefore, a balanced selection is essential—common grades operate effectively at 1.5–1.7 T under sinusoidal excitation. The magnetic performance is validated through Epstein frame or Single Sheet Tester (SST) measurements per IEC 60404-3 and ASTM A343 standards.

Flatness is a critical geometric specification, particularly for high-precision stacking in servo and traction motors. Deviations from planarity lead to air gaps, localized flux crowding, and increased vibration and noise. Laminations must maintain flatness within ±0.05 mm over 100 mm for stacks exceeding 50 mm in height. This is achieved through precision stamping, stress-relief annealing, and controlled blanking processes. Surface roughness and coating uniformity further influence interlaminar insulation and stack factor, which should exceed 96% for high-performance applications.

The following table outlines key technical parameters for motor lamination silicon steel:

| Parameter | Standard Unit | Typical Range (Non-Oriented Si-Steel) | Test Standard | Importance |

|---|---|---|---|---|

| Core Loss (P1.5/50) | W/kg | 2.0 – 6.0 | IEC 60404-2, ASTM A343 | Efficiency, thermal control |

| Magnetic Flux Density (B50) | Tesla (T) | 1.50 – 1.75 | IEC 60404-3 | Power density, torque |

| Thickness Tolerance | mm | ±0.01 to ±0.03 (0.2–0.5 mm typical) | ISO 2174 | Stacking accuracy, air gap control |

| Flatness | mm | ≤ 0.05 / 100 mm | Internal QC, customer spec | Vibration, noise, flux uniformity |

| Insulation Coating Weight | mg/m² | 1.5 – 3.0 | ASTM A976 | Interlaminar resistance, eddy current suppression |

| Stack Factor | % | 96 – 98 | Calculated from density | Effective core utilization |

These specifications form the foundation of high-performance motor lamination design. Luoyang Xinzhaohe Aluminum Co., Ltd. ensures full traceability, batch consistency, and compliance with international quality systems to support OEMs in achieving superior motor efficiency and reliability.

Factory Tour: Manufacturing

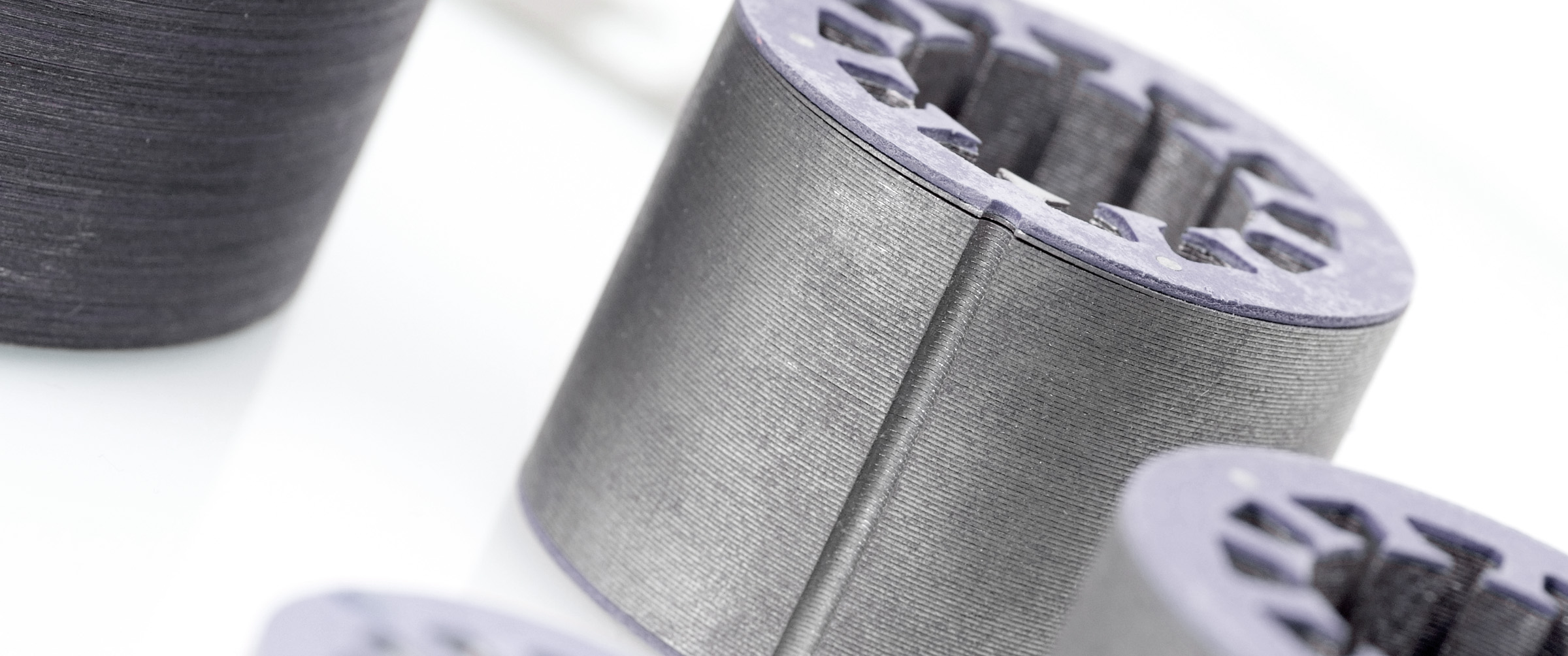

Motor Lamination Production Process: Silicon Steel Critical Path

Luoyang Xinzhaohe Aluminum CO., Ltd leverages two decades of specialized expertise in non-oriented electrical steel processing to deliver motor laminations meeting stringent global performance standards. Our integrated manufacturing sequence ensures optimal magnetic properties, dimensional fidelity, and interlaminar insulation integrity essential for high-efficiency electric motors. The core process flow comprises four critical, interdependent stages with embedded quality control checkpoints.

Slitting initiates the process, converting master coils of specified grade electrical steel (e.g., 50JN350, 35JN230) into precise strip widths matching lamination stack requirements. Utilizing precision-guided, servo-controlled slitting lines, we maintain strict width tolerances of ±0.05 mm. Critical process parameters include controlled line tension to prevent edge wave or center buckle and optimized blade geometry to achieve burr-free edges below 0.01 mm. In-process verification includes 100% width measurement via laser micrometers and edge quality inspection under magnification to eliminate micro-cracks that could propagate during subsequent stamping.

Annealing follows slitting, a thermomechanical treatment vital for restoring magnetic properties degraded during cold rolling and slitting. Strips pass through continuous furnaces under precisely controlled protective atmospheres (typically endothermic gas with strict dew point <-40°C) at temperatures ranging 750-850°C, depending on steel grade and final application requirements. This stage relieves residual stresses, promotes grain growth, and optimizes domain structure to minimize core loss (W10/400). Rigorous QC involves periodic core loss and permeability testing per IEC 60404-2 on witness samples, alongside continuous furnace atmosphere monitoring to prevent surface oxidation.

Insulation Coating application occurs post-annealing. We apply thin, uniform layers of either inorganic (e.g., phosphate-based) or organic (e.g., epoxy-silicate hybrid) insulation coatings via roll-coating or spray systems. Coating weight is meticulously controlled between 0.8-1.5 g/m² per side, directly impacting interlaminar resistance (>50 Ω·cm² typical target) and punchability. Adhesion is critical; coatings must withstand lamination stamping without flaking. QC includes gravimetric coating weight checks, dielectric strength testing, and accelerated adhesion tests per customer specifications.

Precision Cutting forms the final lamination geometry using high-speed progressive or compound dies within stamping presses. Tooling design and maintenance are paramount, ensuring dimensional accuracy within ±0.02 mm and minimizing burr height to ≤0.03 mm. Stacking factors exceeding 97% are consistently achieved through precise blanking and careful handling to prevent lamination distortion. Final QC involves 100% automated optical inspection for critical dimensions, burr measurement via profilometry, and periodic stack factor verification.

Integrated Quality Control Parameters

| Process Stage | Key Parameter | Target Tolerance | Verification Method |

|---|---|---|---|

| Slitting | Strip Width | ±0.05 mm | Laser Micrometer |

| Edge Burr | ≤0.01 mm | Optical Microscope | |

| Annealing | Core Loss (W10/400) | Per Grade Spec | Epstein Frame Tester |

| Atmosphere Dew Point | < -40°C | Chilled Mirror Hygrometer | |

| Coating | Coating Weight | 0.8-1.5 g/m²/side | Gravimetric Analysis |

| Interlaminar Resistance | >50 Ω·cm² | Four-Point Probe | |

| Precision Cutting | Dimensional Accuracy | ±0.02 mm | CMM / Optical Comparator |

| Burr Height | ≤0.03 mm | Surface Profilometer |

This disciplined, data-driven manufacturing sequence, underpinned by Xinzhaohe’s deep metallurgical understanding of electrical steel behavior, guarantees laminations that maximize motor efficiency, minimize noise, and ensure long-term operational reliability in demanding applications.

Packaging & Logistics

Export Packaging Standards for Silicon Steel Motor Laminations

At Luoyang Xinzhaohe Aluminum Co., Ltd, we adhere to stringent export packaging protocols designed to ensure the integrity and performance of silicon steel motor laminations during international transit, particularly via sea freight. With over two decades of experience in the electrical steel supply chain, we recognize that proper packaging is not merely a logistical consideration but a critical component in preserving material quality and dimensional stability.

All motor lamination shipments are secured on high-grade wooden pallets constructed from durable, kiln-dried hardwood. These pallets are engineered to meet international phytosanitary standards (ISPM 15), ensuring compliance with global import regulations. The structural design of the pallet provides uniform load distribution, minimizing the risk of warping, edge damage, or deformation during handling and long-haul transport. Each lamination stack is firmly fastened to the pallet using steel strapping and reinforced corner protectors, preventing lateral movement and mechanical impact throughout the shipping cycle.

To address the inherent vulnerability of silicon steel to moisture-induced oxidation, we employ a multi-layer moisture-proof packaging system. The laminations are first wrapped in oil-coated, vapor-corrosion inhibiting (VCI) paper, which provides an electrochemical barrier against rust formation. This layer is then sealed within a high-density polyethylene (HDPE) shrink film, creating an impermeable enclosure that resists humidity, salt spray, and condensation—common challenges in maritime environments. The sealed unit is further enclosed in a heat-shrunk polyolefin outer sleeve, enhancing puncture resistance and providing additional protection against external contaminants.

This comprehensive packaging system is validated under simulated sea freight conditions, including temperature cycling and high-humidity exposure, to ensure long-term material integrity over voyages exceeding 30 days. Our methodology aligns with ISO 9001 quality management standards and is routinely audited to maintain consistency across production batches.

For containerized shipping, we optimize pallet configuration to maximize space utilization while maintaining adequate airflow and load stability within the container. Each shipment is labeled with durable, weather-resistant markings indicating handling instructions, batch traceability codes, and destination details to facilitate efficient logistics management.

Luoyang Xinzhaohe Aluminum Co., Ltd treats export packaging as an extension of our metallurgical commitment—ensuring that the silicon steel delivered to our clients arrives in the same condition as it leaves our facility. This precision in packaging supports downstream manufacturing reliability, reduces material waste, and reinforces trust in our global supply chain performance.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision Motor Lamination Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical expertise and vertically integrated manufacturing to deliver high-performance non-oriented electrical steel (NOES) specifically engineered for demanding motor lamination applications. Our core strength lies in the precise control of material properties critical to motor efficiency, thermal management, and manufacturability, directly impacting your end-product performance and total cost of ownership. We operate a dedicated production ecosystem encompassing advanced cold rolling, continuous annealing, and specialized coating lines, ensuring consistent material characteristics from coil to lamination.

Production Capabilities and Material Performance

Our facility produces a comprehensive range of silicon steel grades optimized for motor stator and rotor cores, spanning M4 to M19 classifications. Rigorous process control during steelmaking, hot rolling, cold rolling, and final annealing guarantees tight tolerances on magnetic induction (B50), core loss (W10/400, W15/50), and mechanical properties. This precision minimizes energy losses within the motor core and ensures dimensional stability during high-speed progressive die stamping. Key electrical steel specifications are summarized below.

| Grade Designation | Typical Thickness Range (mm) | Max Core Loss W15/50 (W/kg) | Min Magnetic Induction B50 (T) | Common Coating Types |

|---|---|---|---|---|

| M15 | 0.35 – 0.65 | 3.20 | 1.50 | C3, C5 |

| M12 | 0.35 – 0.50 | 2.50 | 1.55 | C3, C5 |

| M10 | 0.27 – 0.35 | 2.00 | 1.60 | C3, C5 |

| M8 | 0.20 – 0.30 | 1.70 | 1.65 | C3, C5 |

Integrated Quality Assurance and Supply Chain Resilience

Quality is embedded at every process stage through our ISO 9001 and IATF 16949 certified management system. We employ in-line magnetic property measurement systems (SMPMS) and rigorous offline testing per ASTM A343/A343M and IEC 60404-2 standards for every production batch, providing full traceability from melt to finished coil. Our dedicated slitting lines ensure precise edge quality and dimensional accuracy essential for high-yield lamination stamping. Crucially, our vertically integrated model—from raw material sourcing oversight to final coating application—eliminates third-party variability, guaranteeing batch-to-batch consistency and reducing supply chain disruption risks. We maintain strategic inventory buffers of key grades to support Just-in-Time delivery requirements without compromising lead times.

Optimizing Your Motor Production Economics

Partnering with Xinzhaohe translates to reduced total procurement costs through minimized scrap rates during stamping, lower motor core losses improving end-product efficiency ratings, and reliable on-time delivery underpinned by robust production planning. Our engineering team collaborates directly with customers to select the optimal grade and coating for specific motor designs, balancing performance targets with cost efficiency. We understand that material consistency is non-negotiable for high-volume motor manufacturing.

Request detailed technical datasheets, coating specifications, or a customized production capability assessment. Contact our Technical Sales Manager Cathy directly at cathy@transformerstrip.com to initiate a precision supply solution for your motor lamination requirements. Let Xinzhaohe’s metallurgical expertise become your competitive advantage.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing motor lamination directly from China.