Table of Contents

Market Insight: 6Mm Copper Coil

Market Analysis: Transformer Strip/Foil (Aluminum/Copper) – Focus on 6mm Copper Coil Demand

The 6mm copper coil dimension represents a critical standard within the global transformer manufacturing sector, particularly for medium and large power and distribution transformers. This specific width is engineered to optimize winding efficiency, thermal management, and structural integrity in core-coil assemblies. Industrial demand for 6mm copper coil remains robust and strategically significant, driven by continuous global power grid modernization, the rapid expansion of renewable energy integration requiring robust step-up/step-down transformers, and escalating industrial electrification demands. Utilities and Original Equipment Manufacturers (OEMs) consistently specify this dimension for high-voltage windings due to its proven balance between current-carrying capacity, manufacturability, and minimized eddy current losses within the constrained geometry of transformer tanks. The transition towards higher-efficiency transformer classes (e.g., DOE 2016, EU Lot 20) further intensifies reliance on precisely dimensioned conductors like 6mm coil to meet stringent no-load and load loss requirements.

Quality assurance for 6mm copper coil is non-negotiable in transformer applications, directly impacting product reliability, lifespan, and safety. Copper purity must consistently achieve minimum 100% IACS (International Annealed Copper Standard) conductivity, typically requiring oxygen-free electronic (OFE) or electrolytic-tough-pitch (ETP) grades with impurity levels strictly controlled below 50 ppm total. Deviations induce excessive resistive heating, accelerating insulation degradation and potentially leading to catastrophic failure. Surface integrity is equally critical; microscopic scratches, pits, or excessive roughness (Ra > 0.8 μm) act as stress concentrators and nucleation points for partial discharges within the oil-paper insulation system. Dimensional precision, especially consistent width tolerance (±0.05mm) and edge straightness, is paramount for automated winding processes. Variations cause uneven tension, misalignment, and compromised interlayer insulation, significantly increasing the risk of turn-to-turn faults under operational electromagnetic forces.

The consequences of substandard 6mm copper coil manifest in tangible operational and financial losses. Poor conductivity elevates operating temperatures, reducing transformer efficiency by 0.5-1.5% and shortening insulation life exponentially per the Arrhenius equation. Surface defects initiate partial discharges, a primary precursor to insulation breakdown, leading to unplanned outages with costs often exceeding $100,000 per incident for large units. Dimensional inconsistencies disrupt high-speed winding lines, increasing scrap rates by 3-8% and causing production bottlenecks. Transformer failures stemming from conductor defects carry severe safety implications and reputational damage for OEMs. Luoyang Xinzhaohe Aluminum Co., Ltd leverages its two-decade metallurgical expertise in conductor processing to emphasize that rigorous quality control—spanning raw material traceability, continuous casting homogeneity, precision rolling, and final surface inspection—is fundamental, not optional, for mission-critical power infrastructure.

Key quality parameters and their failure risks are summarized below:

| Quality Parameter | Critical Threshold | Primary Failure Risk Consequence |

|---|---|---|

| Electrical Conductivity | < 100% IACS (58 MS/m) | Elevated operating temperature, reduced efficiency, accelerated insulation aging |

| Surface Roughness (Ra) | > 0.8 μm | Partial discharge initiation, insulation degradation, potential short circuits |

| Width Tolerance | > ±0.05 mm | Winding misalignment, uneven tension, increased turn-to-turn fault risk |

| Edge Quality | Burrs, micro-cracks | Piercing of interlayer insulation during winding, immediate or latent faults |

Technical Specs: 6Mm Copper Coil

Technical Specifications for 6mm Copper Coil – Precision Transformer Strip

Luoyang Xinzhaohe Aluminum Co., Ltd. manufactures high-precision 6mm copper coils engineered specifically for advanced electrical applications, including transformers, inductors, and high-efficiency windings. With over two decades of metallurgical and slitting expertise, our production process ensures strict adherence to dimensional tolerances, edge quality, and electrical performance. Each coil is produced under ISO 9001-certified quality management systems, guaranteeing consistency and reliability in high-volume industrial applications.

The 6mm copper coil is precision slit from high-purity electrolytic tough pitch (ETP) copper (Cu-101 or C11000) to meet the demanding requirements of modern transformer design. Critical to performance is the dimensional accuracy achieved through our advanced tension leveling and servo-controlled slitting lines, which maintain a width tolerance of ±0.002 mm. This level of precision ensures uniform layer winding, minimizes interlayer stress, and prevents insulation damage during coil winding operations. The slit edges are processed using hardened rotary shear blades with controlled clearance and in-line edge monitoring to eliminate burrs, micro-tears, and edge翘曲 (edge翘曲 refers to edge distortion; use “edge distortion” in English context). All coils undergo 100% edge inspection via optical profilometry to verify burr-free surfaces, critical for preventing dielectric breakdown in transformer insulation systems.

Electrical conductivity is maintained at a minimum of 100% IACS (International Annealed Copper Standard) at 20°C, measured in accordance with ASTM B3 and IEC 60317. This ensures optimal current-carrying capacity and minimizes resistive losses in operation. The copper substrate is fully annealed to achieve a soft temper (C11000-O), providing excellent formability and low mechanical stress during winding. Surface finish is controlled to a roughness average (Ra) of ≤0.4 µm, reducing friction during high-speed winding and enhancing adhesion for insulation coatings.

Mechanical properties are equally critical. The material exhibits a tensile strength range of 200–240 MPa and an elongation of ≥40% (ASTM E8), balancing ductility with structural integrity. Coils are supplied on robust polymer-reinforced spools with anti-corrosion wrapping, preventing oxidation and mechanical damage during transit. Standard inner diameters are 300 mm or 508 mm, with customizable outer diameters up to 1200 mm depending on customer requirements.

All 6mm copper coils undergo full batch traceability, with certified test reports (COA) provided for chemical composition, dimensions, conductivity, and mechanical properties. Our production line integrates real-time monitoring and statistical process control (SPC) to ensure lot-to-lot consistency.

| Parameter | Specification | Test Standard |

|---|---|---|

| Material | ETP Copper (Cu-101 / C11000) | ASTM B187 |

| Temper | Soft (O) | ASTM B976 |

| Width | 6.000 ± 0.002 mm | ASTM B919 |

| Thickness | 0.10–0.50 mm (customizable) | ASTM E3 |

| Edge Quality | Burr-free, no micro-tears, Ra ≤ 0.4 µm | Optical Profilometry |

| Conductivity | ≥100% IACS | ASTM B3 |

| Tensile Strength | 200–240 MPa | ASTM E8 |

| Elongation | ≥40% | ASTM E8 |

| Surface Finish (Ra) | ≤0.4 µm | ISO 4287 |

| Spool ID | 300 mm or 508 mm | Customizable |

| Packaging | Anti-oxidation film, sealed carton, wooden pallet | — |

Luoyang Xinzhaohe Aluminum Co., Ltd. applies stringent quality control throughout the production cycle, ensuring that every 6mm copper coil meets the highest standards for performance, safety, and reliability in transformer and electrical winding applications.

Factory Tour: Manufacturing

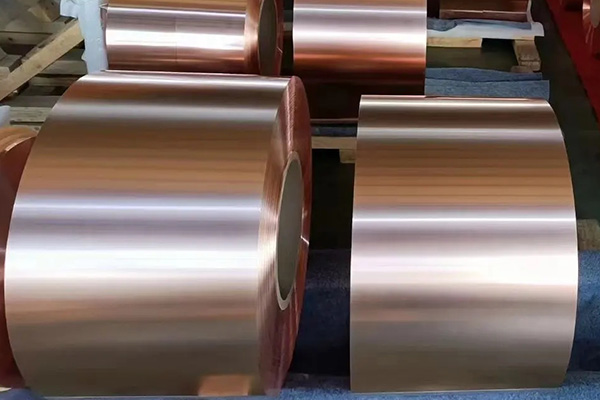

Manufacturing Process for 6mm Copper Coil: Precision Engineering for Transformer Applications

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of specialized expertise in non-ferrous strip production, including high-purity copper essential for transformer windings. Despite our corporate name emphasizing aluminum, our metallurgical capabilities extend rigorously to copper processing, adhering to stringent electrical and mechanical specifications demanded by the power transmission sector. The production of 6mm copper coil for transformer strip/foil applications follows a meticulously controlled sequence: Cold Rolling, Precision Slitting, and Edge Conditioning, each stage incorporating critical quality verification.

Cold rolling forms the foundational process, transforming cast and homogenized copper ingots into precise strip dimensions. Initial hot rolling produces a rough gauge, which then undergoes multiple passes through high-precision cold rolling mills under controlled tension. This stage achieves the target 6mm thickness with exceptional dimensional uniformity, typically maintaining thickness tolerances within ±0.05mm across the coil width. Critical process parameters include precise roll gap adjustment, controlled reduction per pass (typically 15-25% to prevent work hardening defects), and integrated interstand tension management. Intermediate annealing in continuous hydrogen-nitrogen atmosphere furnaces is strategically applied to restore ductility and achieve the required temper (e.g., H01, H02) while ensuring a clean, oxide-free surface crucial for subsequent insulation adhesion. Final skin-pass rolling imparts the necessary surface finish and flatness, verified through continuous laser profilometry measuring I-unit values below 15.

Precision slitting follows cold rolling to achieve the exact strip width required for transformer coil winding. Utilizing high-accuracy rotary shear slitters with hardened tool steel knives, the master coil is longitudinally cut into multiple narrower strips. Knife geometry, clearance settings, and precise alignment are paramount to prevent edge defects. Width tolerance is maintained within ±0.10mm, continuously monitored by laser micrometers. Real-time eddy current testing during slitting detects subsurface inclusions or conductivity variations exceeding 100.5% IACS minimum, ensuring only electrically homogeneous material progresses. Tension leveling integrated within the slitting line corrects any residual coil set or cross-bow, guaranteeing strip flatness essential for high-speed winding without edge buckling.

Edge conditioning represents the critical final stage, directly impacting transformer reliability. The slit edges undergo controlled mechanical brushing or precision grinding to eliminate micro-burrs and achieve a consistent edge radius. Unconditioned burrs can pierce interlayer insulation during winding, causing catastrophic short circuits. Our process targets a burr height of less than 2µm and a controlled edge radius of 0.05-0.15mm, validated through automated optical edge inspection systems scanning 100% of the strip length. This step also removes surface contaminants introduced during slitting. Final quality confirmation includes destructive sampling for microstructural analysis, tensile testing (yield strength ±15MPa, elongation >5%), and rigorous surface cleanliness verification per ASTM B577.

Throughout this integrated process, Luoyang Xinzhaohe implements a multi-stage QC protocol. In-process checks occur at each transition point, supported by our ISO 9001-certified laboratory conducting chemical composition verification (Cu ≥99.95%, controlled O₂ <200ppm), grain size analysis, and surface roughness measurements (Ra typically 0.4-0.8µm). This systematic approach ensures the 6mm copper coil consistently meets the demanding performance criteria for efficient, reliable transformer operation.

Packaging & Logistics

Export Packaging for 6mm Copper Coil: Ensuring Integrity During Sea Freight

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in the production and global supply of transformer strip and foil—both aluminum and copper—we maintain rigorous standards in export packaging to ensure product integrity during international transit. For 6mm copper coil shipments, our packaging protocol is engineered to withstand the demanding conditions of sea freight, particularly prolonged exposure to humidity, temperature fluctuations, and mechanical stress.

All 6mm copper coils are wound with precision and inspected prior to packaging to confirm dimensional accuracy and surface quality. The primary protective layer consists of high-density, moisture-proof plastic film, which is hermetically sealed around the coil. This film acts as a vapor barrier, preventing ingress of ambient moisture that could lead to surface oxidation or corrosion during extended maritime transport. The film is UV-stabilized and puncture-resistant, ensuring durability throughout handling and stacking operations.

The sealed coil is then mounted onto a robust wooden pallet, constructed from kiln-dried hardwood that complies with ISPM 15 international phytosanitary standards for wood packaging material. This certification ensures the wooden components have undergone thermal treatment to eliminate biological contaminants, meeting customs requirements across major export markets including the EU, North America, and Southeast Asia. The pallet is designed with structural reinforcement to support the coil’s weight—typically ranging from 1,500 to 3,000 kg—without deformation during lifting or transit.

Further mechanical protection is achieved through the use of edge protectors and corner bracing, fabricated from laminated plywood or steel-reinforced wood. These components minimize the risk of impact damage during loading, unloading, and container handling. The entire assembly is secured using high-tensile steel strapping, tensioned to industry specifications to prevent coil movement while allowing for safe release upon arrival.

For additional environmental protection, especially in tropical or high-humidity shipping routes, desiccant packs are placed within the sealed film envelope to absorb residual moisture. In certain cases, nitrogen flushing may be applied prior to sealing for customers requiring ultra-low oxidation tolerance, particularly for high-purity electrolytic copper coils used in precision transformer windings.

Each packaged unit is labeled with durable, weather-resistant tags indicating product specifications, batch number, net and gross weight, handling instructions, and orientation markers. This ensures traceability and proper handling throughout the logistics chain.

Our packaging methodology has been validated through years of successful deliveries to markets across Europe, the Middle East, and Asia. By integrating material science, structural engineering, and compliance expertise, Luoyang Xinzhaohe Aluminum Co., Ltd ensures that every 6mm copper coil arrives at its destination in optimal condition, ready for immediate processing.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision 6mm Copper Coil Supply

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of specialized metallurgical expertise to deliver mission-critical copper coil solutions for transformer manufacturing. Our vertically integrated facility in Luoyang, China, is engineered for uncompromising precision in producing 6mm width copper strip, adhering strictly to global standards including ASTM B152 and GB/T 5231. We address the core challenges of transformer core production: dimensional stability, electrical conductivity consistency, and supply chain resilience.

Our technical differentiation begins with proprietary melt-casting processes ensuring 99.99% Cu purity and homogeneous grain structure. Advanced tandem cold rolling mills achieve ±0.01mm thickness tolerance on 6mm coil, critical for minimizing eddy current losses in high-efficiency transformers. In-process eddy current testing and laser micrometry validate surface integrity and dimensional accuracy at 100% production speed, eliminating micro-cracks or thickness deviations that compromise lamination stacking factors. All coils undergo rigorous tensile testing (yield strength 60-85 MPa) and conductivity verification (100% IACS minimum) per batch certification.

Supply chain velocity is engineered into our operations. Dedicated annealing lines with controlled hydrogen atmospheres prevent oxide inclusions, while automated slitting and tension-leveling ensure flatness tolerance ≤0.5mm/m. This integrated approach reduces lead times by 30% versus fragmented supplier models. Our ISO 9001 and IATF 16949 certified systems guarantee traceability from cathode to coil, with digital batch records accessible via customer portal.

Key Production Capabilities for 6mm Copper Coil

| Parameter | Specification | Verification Method |

|---|---|---|

| Width Tolerance | 6.00 ± 0.05 mm | Laser micrometer (100% inline) |

| Thickness Range | 0.10–0.50 mm | Ultrasonic gauge (SPC controlled) |

| Conductivity | ≥100% IACS (20°C) | Four-point probe testing |

| Surface Roughness | Ra ≤ 0.4 μm | Profilometry (per ASTM E3) |

| Monthly Capacity | 8,000 metric tons | ERP-tracked production data |

We mitigate raw material volatility through strategic cathode partnerships with COMIBOL and JX Nippon, maintaining 45-day secured inventory buffers. Our logistics network features bonded warehouse options in Shanghai and Rotterdam, enabling DDP delivery within 25 days globally. For transformer OEMs, this translates to reduced scrap rates, consistent core loss performance, and elimination of secondary processing costs.

Initiate technical consultation to optimize your 6mm copper coil sourcing strategy. Our metallurgical team will conduct a free material suitability assessment against your transformer design parameters, including core loss modeling and cost-in-use analysis. Contact Cathy Zhang, International Sales Director, at cathy@transformerstrip.com to schedule a factory audit or request sample coils with full material test reports. Luoyang Xinzhaohe ensures your supply chain operates with the precision your transformer efficiency demands.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 6mm copper coil directly from China.