Table of Contents

Market Insight: 42 Awg Enameled Copper Wire

Market Analysis: Industrial Demand for 42 AWG Enameled Copper Wire in Transformers

Luoyang Xinzhaohe Aluminum CO., Ltd leverages over two decades of metallurgical and supply chain expertise to address critical demands in the enameled wire sector. The 42 AWG (0.063 mm bare conductor diameter) enameled copper wire represents a high-precision segment driven by relentless miniaturization and efficiency mandates across transformer manufacturing. Industrial demand stems primarily from compact power electronics, including switch-mode power supplies (SMPS), high-frequency transformers for telecommunications infrastructure, medical imaging equipment, and aerospace avionics. These applications require extreme conductor density to achieve target power densities while adhering to strict thermal and spatial constraints. The global shift toward energy-efficient systems compliant with IE4/IE5 motor standards and DOE Level VI efficiency regulations further intensifies demand for ultra-fine wires capable of minimizing copper losses at elevated operating frequencies.

Quality in 42 AWG enameled copper wire is non-negotiable due to the amplified impact of microscopic defects at this scale. Thermal performance is paramount; insulation must maintain integrity at continuous operating temperatures of 180°C (Class H) or higher, as stipulated by IEC 60317 standards. Substandard thermal class ratings induce premature insulation degradation, leading to inter-turn shorts and catastrophic transformer failure under thermal cycling. Electrical properties are equally critical: the enamel coating must provide uniform dielectric strength exceeding 3 kV (per ASTM D2307) to prevent voltage breakdown between tightly wound layers. Even minor inconsistencies in coating thickness—measurable in microns—create weak points vulnerable to partial discharge in high-frequency operation. Mechanically, the wire must exhibit precise elongation (typically 8–12%) and mandrel bend test compliance to withstand automated winding stresses without cracking. Poor ductility or adhesion causes insulation fractures during high-speed coil winding, directly increasing scrap rates and production downtime.

Process reliability hinges on consistent solderability and thermal shock resistance. Inconsistent enamel composition impedes solder wetting during lead attachment, causing cold joints that compromise circuit integrity. Furthermore, inadequate thermal shock resistance (tested per IEC 60851-5) results in micro-cracks during reflow soldering, introducing latent failure modes. Field failure data indicates that transformers using non-conforming 42 AWG wire exhibit 3–5× higher failure rates in high-reliability applications, with root causes traced to insulation pinholes, thermal runaway, or mechanical fatigue. The cost of failure extends beyond component replacement to include warranty liabilities, production line stoppages, and reputational damage—particularly severe in medical or aerospace sectors where regulatory non-compliance carries severe penalties.

Luoyang Xinzhaohe Aluminum CO., Ltd mitigates these risks through rigorous in-house metallurgical controls. Our copper rod refining achieves oxygen content <10 ppm and grain structure optimization to ensure uniform drawability down to 42 AWG. Advanced polymer coating systems undergo real-time thickness monitoring via laser micrometry, with batch traceability to ISO 9001-certified process parameters. This precision engineering, coupled with supply chain resilience built over 20 years, guarantees that every reel meets the uncompromising quality thresholds demanded by next-generation transformer design. For B2B partners, sourcing 42 AWG wire from a vertically integrated specialist is not a cost decision—it is a strategic safeguard against systemic operational and reputational exposure.

Technical Specs: 42 Awg Enameled Copper Wire

Technical Specifications for 42 AWG Enameled Copper Wire

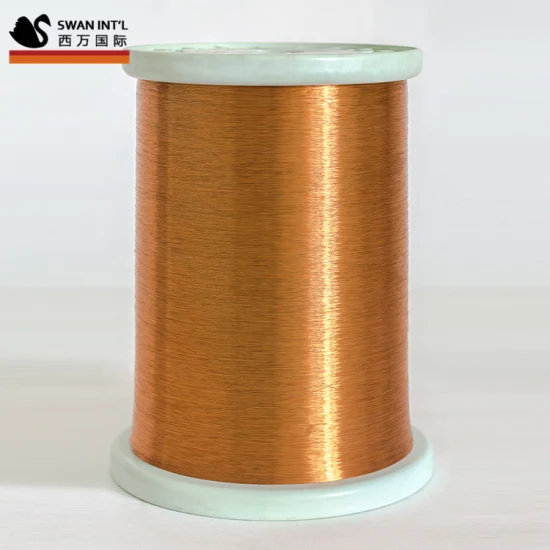

The 42 AWG enameled copper wire is a precision-grade magnet wire engineered for applications requiring fine conductors with high electrical efficiency and thermal stability. At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of expertise in winding wire manufacturing, we produce 42 AWG enameled copper wire to meet stringent international standards, ensuring reliability in demanding environments such as micro-motors, sensors, transformers, and high-frequency inductors.

A critical performance parameter for enameled wire is the insulation breakdown voltage, which determines the dielectric strength of the enamel coating. For 42 AWG wire, the insulation must withstand high electric stress due to the extremely small conductor diameter (approximately 0.0635 mm). Our standard single-build polyurethane or polyesterimide insulation provides a minimum breakdown voltage of 3,000 V RMS, tested under controlled conditions using a step-voltage method per IEC 60317 and ASTM D4683. This ensures robust electrical isolation even in compact coil windings where turn-to-turn voltage gradients are significant.

Elongation is another essential mechanical property, particularly during high-speed winding operations. The 42 AWG wire is drawn from high-purity electrolytic tough pitch (ETP) copper (Cu ≥ 99.97%), which undergoes precise annealing to achieve optimal ductility. Our product exhibits a minimum elongation of 12% over a 25 mm gauge length, as measured per ASTM B3. This level of ductility prevents wire breakage during fine winding and contributes to consistent processability across automated coil winding equipment.

Thermal performance is defined by the thermal class rating, which indicates the maximum continuous operating temperature the insulation can endure without significant degradation. Our 42 AWG enameled copper wire is available in multiple thermal classes, ranging from 130°C (Class B) to 220°C (Class H and higher), depending on the insulation system. Standard offerings include:

| Parameter | Value | Test Standard |

|---|---|---|

| Conductor Diameter | 0.0635 ± 0.003 mm | ASTM B2.6 |

| Insulation Breakdown Voltage (Min) | 3,000 V RMS | IEC 60317-0 |

| Elongation (Min) | 12% | ASTM B3 |

| Thermal Class Options | 130°C, 155°C, 180°C, 200°C, 220°C | NEMA MW 1000 |

| Resistance at 20°C | ~417 Ω/km | ASTM B193 |

| Adhesion (Pin Hole Test) | Pass (No cracking) | IEC 60851-5 |

| Thermal Shock (220°C, 2 hrs) | No cracking | IEC 60851-6 |

Thermal classes above 180°C typically utilize advanced insulation systems such as polyamide-imide (PAI) or dual-layer coatings (e.g., polyesterimide overcoated with polyamide-imide), providing superior thermal endurance and chemical resistance. Each batch undergoes rigorous quality control, including thermal endurance testing via the modified rigid loop method to validate long-term reliability.

All specifications are subject to customer requirements and application-specific adjustments. Luoyang Xinzhaohe Aluminum Co., Ltd adheres to ISO 9001 quality management systems, ensuring consistent product performance across large-volume production runs.

Factory Tour: Manufacturing

Manufacturing Process for 42 AWG Enameled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages 20+ years of specialized expertise in magnet wire production to ensure the stringent requirements of 42 AWG enameled copper wire are met. This ultra-fine gauge (0.063 mm nominal diameter) demands exceptional process control to achieve the required electrical performance, mechanical integrity, and winding reliability demanded by precision applications such as micro-motors, sensors, and medical devices. The production sequence is rigorously structured into four critical phases with integrated quality checkpoints.

The process initiates with high-conductivity electrolytic tough pitch (ETP) copper rod drawing. Rods undergo multi-pass reduction through precision tungsten carbide or diamond dies within a continuous drawing block machine. For 42 AWG, this requires extreme dimensional stability; intermediate annealing stages are integrated to prevent work hardening and maintain ductility. Final diameter tolerance is held to ±0.002 mm, verified via laser micrometry after the last drawing pass. Surface cleanliness is paramount, with continuous deionized water rinsing and ultrasonic cleaning to eliminate drawing lubricant residues that could compromise enamel adhesion.

Subsequent continuous annealing occurs in a controlled oxygen-free nitrogen atmosphere furnace. Precise temperature profiling (typically 450–550°C) and residence time optimization ensure complete recrystallization without grain growth, restoring maximum elongation (>15%) while eliminating residual stresses. Oxygen content is maintained below 10 ppm to prevent surface oxidation, which would lead to enamel defects. Real-time conductivity monitoring via eddy current testing confirms annealing efficacy, with deviations triggering automatic process adjustments.

Enameling applies multiple ultra-thin polymer layers via precision capillary coating dies. For 42 AWG, a triple-coat system is standard: a base layer of polyurethane (solvent-based) for solderability, a mid-layer of polyesterimide for thermal class 180°C performance, and a topcoat of polyamide-imide for mechanical and chemical resistance. Each pass undergoes immediate UV or infrared curing under inert atmosphere to prevent bubbling. Coating thickness is controlled to 0.008–0.012 mm per layer using closed-loop viscosity and tension monitoring, with total build tolerance ±0.003 mm.

Inline testing is continuous and non-destructive. Every meter undergoes high-voltage spark testing at 1,200–1,500 V DC to detect pinholes. Break detection systems halt the line instantly upon wire fracture, minimizing waste. Final verification includes mandrel wrap testing per IEC 60851-5 for flexibility, thermal shock testing at 200°C, and adhesion assessment via tape peel tests. Statistical process control (SPC) data from all stages is logged, with batch certificates documenting diameter, resistance, coating thickness, and HV test results. This integrated approach ensures 42 AWG wire meets the highest industry standards for performance-critical applications.

Packaging & Logistics

Export Packaging for 42 AWG Enameled Copper Wire – Industrial-Grade Protection for Global Shipments

At Luoyang Xinzhaohe Aluminum Co., Ltd, with over two decades of specialized experience in winding wire manufacturing, we recognize that export packaging is not merely a logistical necessity but a critical component of product integrity. For precision products such as 42 AWG enameled copper wire, where dimensional consistency and dielectric performance are paramount, robust and intelligent packaging ensures the material arrives at its destination in optimal condition, especially under the demanding conditions of sea freight.

Our standard export packaging system is engineered specifically to mitigate the risks associated with prolonged maritime transport, including high humidity, temperature fluctuations, mechanical shock, and salt-air exposure. Each shipment begins with the use of high-strength wooden pallets constructed from kiln-dried, ISPM 15-compliant hardwood. These pallets provide structural stability during stacking and handling, supporting reel weights typical of industrial wire spools without deformation or collapse. The ISPM 15 certification ensures compliance with international phytosanitary regulations, preventing delays at customs and facilitating smooth cross-border clearance.

Each reel of 42 AWG enameled copper wire is individually sealed using multi-layer moisture-proof composite film. This film consists of an aluminum-polyethylene laminate barrier with a low water vapor transmission rate (WVTR), effectively isolating the wire from ambient humidity. Given the ultra-fine gauge of 42 AWG wire—approximately 0.064 mm in diameter—exposure to moisture can lead to oxidation, insulation degradation, and compromised winding performance. The sealing process is performed in a climate-controlled environment to ensure no residual moisture is trapped prior to enclosure.

The sealed reels are then secured to the wooden pallet using steel strapping and corner protectors to prevent lateral movement during transit. A secondary overwrap of industrial-grade stretch film reinforces the load, while an additional layer of waterproof kraft paper or polyethylene hooding is applied to shield against condensation and splashing water, particularly in containerized shipping environments where “container rain” is a known risk.

Each packaged pallet is labeled with durable, weather-resistant identification tags indicating product specifications, batch number, net weight, handling instructions, and orientation markers. These labels are affixed to remain legible throughout extended voyages.

This integrated packaging approach has been validated across thousands of export shipments to North America, Europe, and Southeast Asia. It reflects our commitment to technical reliability and supply chain resilience. For OEMs and contract manufacturers dependent on uninterrupted production, our packaging standards ensure that every spool of 42 AWG enameled copper wire maintains its electrical and mechanical properties from factory to final assembly.

Sourcing from Luoyang Xinzhaohe

Partner with Luoyang Xinzhaohe for Precision 42 AWG Enameled Copper Wire

Luoyang Xinzhaohe Aluminum Co., Ltd leverages over two decades of specialized metallurgical engineering and industrial supply chain expertise to deliver mission-critical 42 AWG enameled copper winding wire. As a vertically integrated manufacturer, we control the entire production continuum—from high-purity electrolytic tough pitch (ETP) copper rod sourcing through precision drawing, annealing, and enamel coating—ensuring uncompromised consistency for the most demanding micro-electromechanical applications. Our facility is engineered specifically for ultra-fine gauge production, where the 0.063mm conductor diameter of 42 AWG wire demands exceptional process stability to prevent breakage and maintain dimensional tolerances within ±0.002mm. This precision is non-negotiable for high-frequency transformers, miniature sensors, and medical device coils where winding integrity directly impacts device performance and longevity.

Our manufacturing strength lies in proprietary annealing protocols and tension-controlled drawing systems calibrated for sub-0.1mm conductors. Standard production lines cannot reliably achieve the required elongation (10-15%) and tensile strength (250-350 MPa) for 42 AWG without micro-fractures. Xinzhaohe’s dedicated fine-wire division utilizes inert atmosphere annealing furnaces and laser micrometry feedback loops to maintain conductor metallurgical properties within strict IEC 60317 and NEMA MW specifications. Each production batch undergoes rigorous in-process testing, including continuous diameter monitoring, high-potential (hi-pot) voltage testing at 1500V AC, and thermal shock validation per UL 1446 requirements. Our enamel systems—polyurethane, polyester-imide, and self-bonding variants—are applied via precision capillary dies with real-time viscosity control, ensuring uniform insulation build (typically 0.015-0.020mm) and adhesion critical for automated high-speed winding operations.

Supply chain resilience is engineered into our operational DNA. We maintain strategic partnerships with Tier-1 copper suppliers for guaranteed OFHC copper purity (99.99% min), coupled with on-site rod testing via spark-OES spectroscopy. Our 15,000m² production complex includes dedicated climate-controlled warehousing for raw materials and finished goods, mitigating humidity-induced enamel defects. For global clients, we implement JIT logistics with regional distribution hubs in Shanghai and Rotterdam, reducing lead times by 30% compared to industry averages while maintaining full lot traceability via blockchain-enabled batch records. This integration of metallurgical science and supply chain orchestration minimizes production stoppages for your operations.

When sourcing 42 AWG enameled copper wire, component failure is not an option. Luoyang Xinzhaohe provides the process rigor, material science foundation, and logistical certainty required for next-generation micro-winding applications. Partner with an engineer-led manufacturer whose output meets the exacting standards of automotive EV components, aerospace instrumentation, and premium audio transducers. Contact Cathy directly at cathy@transformerstrip.com to discuss your technical specifications and receive a production capacity assessment within 24 hours. Specify your required enamel class, tensile properties, and volume to initiate a qualification sample run backed by our 100% on-time delivery commitment.

📉 Factory Direct Savings Calculator

Calculate your potential savings by importing 42 awg enameled copper wire directly from China.